- 1Department of Anthropology, University of Toronto Mississauga, Mississauga, ON, Canada

- 2Zhejiang Provincial Institute of Cultural Relics and Archaeology, Hangzhou, China

In the past two decades, archaeological studies of knowledge and skill transmission for pottery and lithic production in preindustrial societies have significantly improved our understanding of how technological traditions were transmitted and how the transmission processes influenced technological persistence and changes. However, case studies of craft transmission for osseous technology are rare despite their equal importance to pottery and lithic industries in preindustrial societies. Our research fills the gap by examining early Hemudu Culture’s (7000–6000 BP) scapular implements in the southern Yangzi Delta to understand the linkage between learning and maintaining the scapular shovel tradition in Hemudu’s socio-economic context. We first traced the history of scapular tools to the precedent Kuahuqiao Culture (8200–7000 BP), then used published experimental results to identify the product traits pertinent to craft learning and infer Hemudu scapular shovel blades’ learning and production patterns. Hemudu scapular shovels had a unique, complicated hafting style and an evidential raw material preference for old water buffalo scapulae. However, the blades’ morphological details and technical solutions varied significantly. In addition, most finished products display manufacturing mistakes resulting from crafters’ lacking skills, experience, and intervention. Practice pieces are rare compared to finished and used products. Although additional evidence implies that practice might have been more common than the studied sample suggested, it was carried out with less-than-ideal bones and insufficient for developing technical competency. We argue that the Hemudu societal norms for a scapular shovel applied only to the highly visible aspects of the implement. The shaft and ligatures could reduce the visibility of many manufacturing flaws on the shovel blade to reach the desired visual effect of the shovel. The shovel blades were made by household crafters emulating from an artifact or a memorized template but had insufficient training and practice in manufacturing. Communities of practice were minimal to nonexistent among the shovel makers; alternative mechanisms to maintain the technical norms or hold a high product standard were also lacking. Therefore, we concluded that the scapular shovels were less important as a technical implementation than a visual communicator of social identity. The binary system of conformist style and material preference mixed with loose quality control in the shovel blade production reveals that social conformity and the associated learning pattern are circumstantial and fluid even for a community’s iconic implement. Further research with other artifact types in Yangzi Delta would help shed light on whether similar learning patterns were applied besides the creation of scapular shovels.

Introduction

In the past two decades, archaeological studies of technology have gone beyond the inquiries of manufacturing techniques and objects’ functions to explore technological practices’ social and cultural dimensions. Experts of osseous technology, for example, have begun to address how object production, variation, and adoption related to raw material availability, choices, production patterns, manufacturing tradition, and group identities in the past (Choyke, Vretemark, and Sten 2004). This paper focuses on identifying the learning patterns of the bone shovel tradition in Hemudu Culture in eastern China to understand the linkage between learning and maintaining a technological tradition and its particular socio-economic context.

Theoretical approaches to cultural transmission range from the more positivist biological and evolutionary angle (e.g., Boyd and Richerson 1985; Richerson, Boyd, and Henrich 2010; Laland and Brown 2011; Mesoudi 2013; Reyes-García, Gallois, and Demps 2016) to social interactions (e.g., Keith 2005; Bowser and Patton 2008; Wallaert 2008; Schniter et al., 2015), and those that lie between (e.g., Laland 2008; Gintis 2011; Chudek et al., 2013). Results from ethnoarchaeological and experimental studies of craft transmission highlight how biological relatedness, social relations, identities, and economic structures shape craft learning patterns and how craft learning process feedbacks to technological tradition and its broader social, cultural, and economic situations (e.g., Greenfield 1999; Gosselain 2008; Herbich and Dietler 2008; Wallaert 2008; Derex, Godelle, and Raymond 2013; Ellen and Fischer 2013; Puri 2013; Schniter et al., 2015).

Craft learning occurs typically in the context of doing in a wide range of settings. The persistent material patterns in the archaeological record must have resulted from uninterrupted intergenerational learning (Crown 2014). To maintain a technological style, some form of teaching must be in place to sustain stability, consistency, and persistency through time (Tehrani and Riede 2008). Craft transmission can occur between parents and children, between experienced and inexperienced community members, and among peers. Parent-child transmission generally results in the most conservative and retentive family traditions but increases variance across families within a society (Ellen and Fischer 2013); the other two transmission pathways generate higher uniformity within a social group (Cavalli-Sforza and Feldman 1981). Craft traditions can also be conserved through communities of practice, where members are encultured into the social meaning embedded within decorations and techniques, recognizing their importance in maintaining group identity (Lave 1991; Wenger 1998; Dorland 2018). Communities may inadvertently or intentionally limit acceptable innovations and changes (Wendrich 2012); the pressure to conform results in technical, stylistic, and raw material consistency (Gosselain 2008; Herbich and Dietler 2008; Roux 2015). Crafts tied to community identity set cultural boundaries between groups. This sense of group identity can grow to the point where using out-group markers may evoke negative attitudes and discrimination (Nettle and Dunbar 1997).

Craft learning takes diverse forms, ranging from the least formal, such as self-teaching (by trial and error) and playing (Keith 2005; Bowser and Patton 2008; Gosselain 2008; Lancy 2012), to the more structured that integrates verbal instruction and hands-on demonstration, and to the most formal such as a contractual apprenticeship. Unskilled crafters with minimal training generally create products that are irregular in form (Crown 2001; Bamforth and Finlay 2008; Ferguson 2008), exhibit inconsistencies in production (Bamforth and Finlay 2008) and deviation from expected chaîne opératoire, or present predictable errors (Ahler 1989; Shelley 1990; Bamforth and Finlay 2008), and, in the case of stone tools, mis-hits and hammer marks (Pigeot 1990; Shelley 1990; Bamforth and Finlay 2008). Therefore, long-lasting craft traditions that exhibit high fidelity and/or standardization usually have an extended and intensive period of training (Gosselain 2008; Tehrani and Riede 2008; Wallaert 2008). However, training alone does not guarantee material culture consistency. How trainers respond to learner errors also significantly influences the persistence and variation of the end products (Greenfield 1999; Crown 2001; Wallaert-Pêtre 2001; Hasaki 2012). Constant error correction suppresses innovation and creativity and significantly increases product consistency. In contrast, a looser learning structure encourages innovation and product variation. Once learned, the production process that involves motor habits, particularly manufacturing techniques, tends to run deeper into the unconscious, thus is much more resistant to change than decorative styles (Gosselain 2000, 2008; Wallaert 2008; Thulman 2014; Roux 2015).

Identifying the pathways and forms of craft learning that contributed to the consistency and variations in the archaeological assemblage requires attention to the minuscule traits pertinent within the products’ visual cues and manufacturing techniques. Most studies have been conducted on pottery making and, to a lesser extent, lithic production. Attempts to identify craft learning patterns for osseous technology from the archaeological record are sporadic (except Zidarov and Averbouh 2014). However, as commonly used as pottery and lithic in pre-industrial societies, osseous tools were in the object repertoire that served technical needs and signified social identity. In an ongoing effort to understand craft learning and material patterns, we applied a cultural transmission framework to analyze the scapular shovel tradition in Hemudu Culture.

Scapular Implements in the Southern Yangzi Delta

Most scapular implements in China have been unearthed from the southern Yangzi Delta. The oldest unearthed scapular implements are from Kuahuqiao Culture (8200–7000 BP) with a small number in the subsequent Majiabang culture (7000–5800 BP) and the more elaborated ones in a much larger quantity from early Hemudu Culture (7000–6000 BP). This section synthesizes Kuahuqiao and Hemudu Cultures with information from the Kuahuqiao, Hemudu, and Tianluoshan sites—where most scapular implements have been discovered—to situate the Hemuduc scapular shovel tradition in the region’s long-term and broader economic context.

Kuahuqiao, Hemudu, and Tianluoshan Sites

The Kuahuqiao site is the Kuahuqiao Culture type site situated on a hillside. The initial habitation surface is less than 1 m above the present sea level (W. Shi et al., 2008) and comprises Xiashu loess. Adjacent to the eastern rim of the habitation zone was an ancient lake at elevations of 1–2 m below the habitation surface (J. Shi 2009:14; ZPICHA and XM 2004:40-42); the lacustrine deposit in this area is waterlogged with excellent organic preservation. The site was occupied between 8200 BP and 7000 BP, a period between a freshwater inundation before occupation and a severe marine transgression that ended the occupation (Pan, Zheng, and Chen 2017). The site is estimated at 30,000 m2; 1,080 m2 have been excavated, with 2/3 of the excavated area covering the lacustrine deposit (ZPICHA and XM 2004:7-11). Most of the site has been destroyed by modern human activities, particularly large-scale clay exploitation for brick production. However, archaeological excavations in 1990 and 1999–2002 have salvaged remains of three small house structures, an earthen platform, a trench, and 25 pits (most for acorn storage). Pottery, some painted, includes mainly cooking and serving vessels, spindle whorls, animal remains, polished stone tools, bone tools, and artifacts of wood, bamboo, and antler were richly found. During the occupation, Kuahuqiao people relied principally on hunting (mainly deer and less frequently boar, water buffalo, and fowl), fishing, and gathering, complemented with rice cultivation and management of additional wetland and woodland plants, and domesticated pigs and dogs (ZPICHA and XM 2004; Fuller and Qin 2008; Yang and Jiang 2010; Zheng, Sun, and Chen 2012; Pan, Zheng, and Chen 2017).

The Hemudu and Tianluoshan sites are the only two Hemudu cultural sites that have been systematically excavated. Both sites are waterlogged with excellent preservation conditions. These two sites are 7 km apart, located in what is now the Yaojiang Basin. They were occupied soon after lands were exposed after the marine transgression that inundated the Kuahuqiao site, evidenced by the coastal sediments on top of which the initial occupation surfaces formed. These sites’ ecological and geological settings were similar to those of the Kuahuqiao site, situated between lowlands and hills, adjacent to freshwater bodies but also near the ocean, and with immediate access to diverse natural resources present at different elevations (Pan 2011, 144). Like the Kuahuqiao people, the Hemudu communities consumed a broad-spectrum diet from hunting, fishing, and gathering consistent with low-level food production that included domestication of rice, pigs, and dogs and effective management of the ecosystems. Terrestrial prey were mainly deer, less frequently boar, water buffalo and fowl (Zheng, Sun, and Chen 2012; ZPICHA 2003). Osseous tools predominated the early Hemudu tool kit, and they were in more diverse forms and greater quantity than stone and wooden tools (Mou 1980; ZPICHA 2003, Table 7). The osseous tools mainly consist of hunting, fishing, and weaving implements. Scapular implements were not as abundant in number as bone arrowheads. Still, they have received much research attention due to their hypothesized relation to si agriculture, an advanced Neolithic farming technique involving tillage. However, the most recent functional analysis revealed that these scapular implements were used on an irregular basis to modify the margins of wetlands for cultivation and occupation (Xie et al., 2017).

Appearance and Adoption of Scapular Implements in the Southern Yangzi Delta

Kuahuqiao Culture (8200–7000 BP) has the oldest scapular tools in the region. Scapulae of appropriate animals (i.e. deer and water buffalo) were available throughout occupation(s) at Kuahuqiao; however, scapular tools did not develop until the latest stage of occupation during 7200 to 7000 BP (Xie 2014).

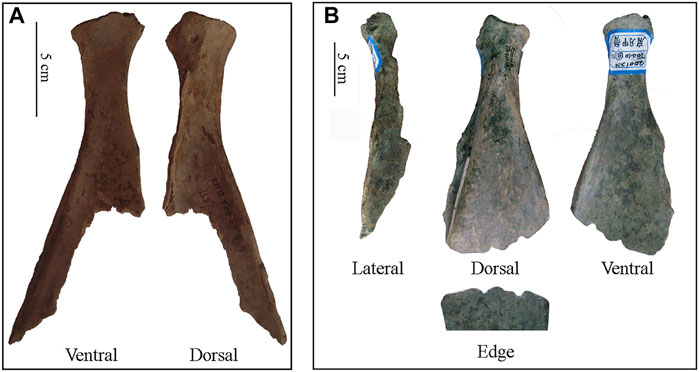

Excavations at Kuahuqiao led by the third author between 1999–2002 unearthed 24 scapular tools and 90 unmodified scapulae. Of the 24 tools, five have missed the diagnostic portions. Among the remaining 19 tools, 16 were crafted from deer scapulae, and most were expedient use of unintentionally broken scapulae as scrapers (Figure 1A). Only six deer scapular implements show evidence of intentional removal of unwanted portions, with the spine partially removed and a single edge created at the proximal end of the bone, diagonal to its long axis (Figure 1B). Two scapular implements were crafted from water buffalo: one is intact (Figure 2A), and the other is a dorsal portion of the bone’s distal end (Figure 2B). Both specimens display thorough removal of the acromion spine and a vertical shaft hole from the top at the center of the glenoid. The intact specimen also has an opening in the medial side and a sharpened edge at the proximal end of the bone. An additional specimen was crafted from a carnivore scapula without evidence of utilization (details in section The Kuahuqiao and Hemudu Manufacturing Techniques).

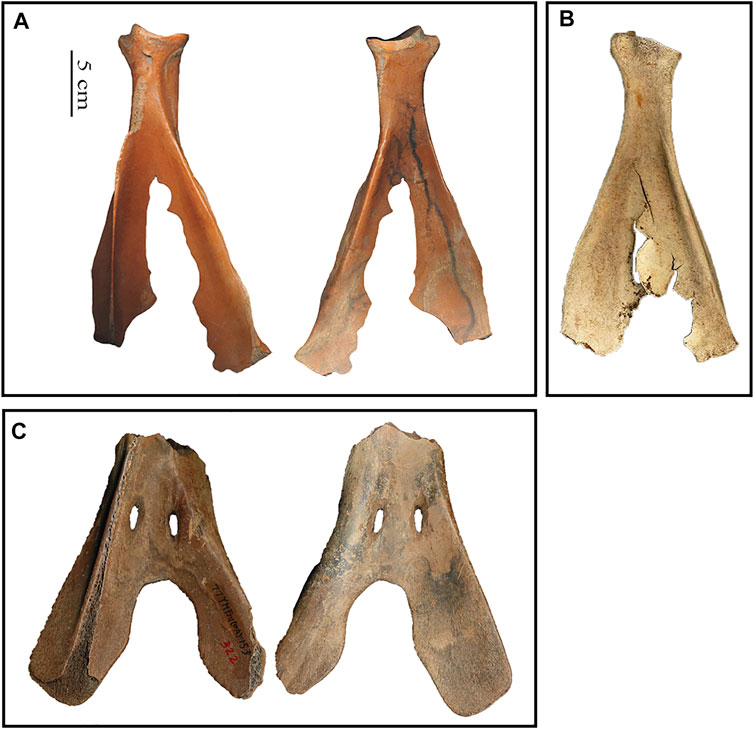

FIGURE 1. Deer scapular implements from Kuahuqiao. (A) Sample expedient scapular scraper T0409 (4). (B) Sample scapular implement that is more carefully shaped, T0410 (6); function(s) not identified. Note that the dorsal and ventral faces in all figures of this article refer to the surfaces of the bone, which may not correspond with the dorsal and ventral surfaces of the tool. For example, the dorsal surface of a scapula refers to the posterior or back portion of the bone in animal anatomy, but it could have been used as a shovel’s ventral surface facing toward the tool user (Xie 2018: Figure 1.1 for an anatomical scapula and an anatomical bone shovel).

FIGURE 2. Kuahuqiao water buffalo scapular implements. (A) 2001XKT0410 (5) A: 6, 13 cm long, 8 cm wide, with a 2.8 cm wide, 8.8 cm deep shaft hole in the center of the glenoid fossa of the scapula. (B) 2001XKT0410 (5) A: 7.

Microwear analysis revealed that some of the scapular tools crafted from deer bone processed animal tissue while the water buffalo scapular implement was for earth working (Xie et al., 2017). Thus, related to warm-keeping and construction activities, these scapular tools were likely invented to cope with needs arising from settling in the open-air site of Kuahuqiao either seasonally or year-round.

Scapular implements continued into the subsequent period, 7000–6000 BP. A few scapular earth-working implements of the Kuahuqiao hafting style have been unearthed in early Majiabang Culture in the Lake Taihu area (Xie 2014). In contrast, the Hemudu populations on the Ningshao Plain used scapular implements crafted from water buffalo and deer bones to a greater extent for over a millennium (Xie et al., 2017). The scapular implements crafted from deer bone reflect minimal modifications and a broader range of uses than those fabricated from water buffalo bones. Most deer scapular implements of Hemudu Culture show partial removal of acromion spines, slight modifications on the sides of the necks, and a two-pronged edge. Most two-pronged edges were formed from fractures likely resulting from hunting (compare Figure 3A with Figure 3B). Only a couple of such edges show a regulated contour that might have been intentionally shaped (e.g., Figure 3C).

FIGURE 3. Humudu culture deer scapular implements. (A) HMD 332 (dorsal and ventral views), with partial removal of the acromion spine, minimal modification on the sides of the neck, and a two-pronged edge likely resulted from hunting; (B) Unmodified caribou scapula from Palangana, Alaska (ventral view); housed in the Zooarchaeology Lab at the University of Arizona in Tucson; (C) HMD 322 (dorsal and ventral views), with a two-pronged edge likely shaped intentionally.

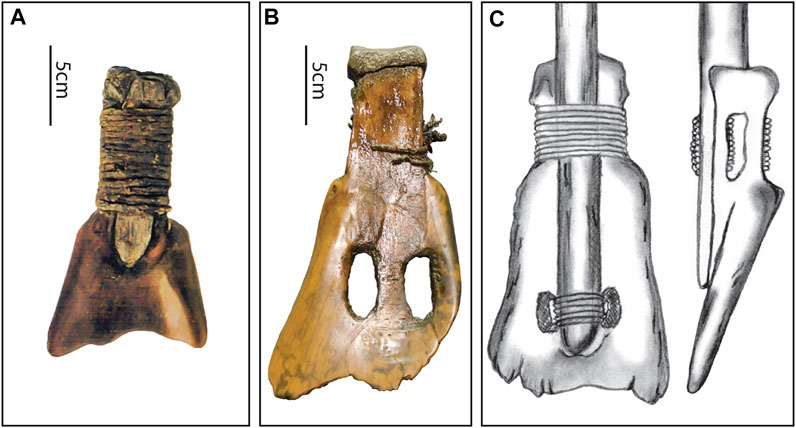

The implements crafted from deer scapulae were mainly used for processing hide and bark and occasionally for light earth-working tasks such as relocating soil (Xie et al., 2017). On the other hand, the Hemudu scapular implements crafted from water buffalo bones were primarily used for earth working in agricultural and construction contexts (Xie et al., 2017). The water buffalo scapular implements show complete or near-complete removal of the acromion spine and part of the posterior border that runs alongside the acromion spine. Most noticeably, these implements display sophisticated modifications for hafting, including 1) a groove on the ventral face with two perforations, 2) deep notches on the lateral sides of the scapular neck, which are usually transversely scored through, and 3) flattened projecting portions around the glenoid to ensure effective lashing (Xie 2018). These water buffalo scapular implements were hafted as shovels with the ligatures lashed across the sockets and entirely around the necks to fasten the shafts tightly (Figure 4).

FIGURE 4. Hemudu hafting styles for scapular shovels. (A) HMDT224 (4) B:175 with a small portion of the shaft and ligatures lashed across the socket and entirely around the neck (after ZPICHA 2003: plate 26–1). (B) TLST302 (8): 3 with partial ligatures across the socket. (C) Reconstructed hafting method followed Mou 1980:Figure 2 and Xie et al., 2017:Figure 4.

The Hemudu style of groove-perforation-scored notch design for earth-working implements is more elaborate than alternative hafting designs observed in other cultures across the globe. For example, in Kuahuqiao and Majiabang Cultures in Yangzi Delta and pre-industrial societies in Europe and America, the modifications include only removing the acromion spine, the posterior border of the bone and very light modification on the sides of the necks, occasionally with a socket created at the center of the glenoid or an opening created on the ventral surface of the bone (Xie et al., 2017). Compared to the simpler designs, the Hemudu hafting design fastened the blades to the handles much more securely, likely as a reaction to hafting failure in the increasingly arduous earth-working tasks in the Hemudu site due to the sticky soil condition (Xie et al., 2017; Xie 2018). However, the Hemudu crafters overdesigned the tight fastening elements. The excessive removal of a large quantity of the strongest (cortical) material required more effort and time to manufacture while significantly weakening the implements, causing consistent breakage along the weakened points of the tools during the implements’ use life (Xie et al., 2017). Xie has previously proposed two technical factors to explain the emergence of these overly sophisticated scapular tools: 1) the need for a tight joint and 2) the presence of advanced ground stone adzes, axes, and chisels that made the modifications relatively easy to accomplish (Xie 2014; Xie 2018: Fig 10 for sample stone tools unearthed from Tianluoshan suitable for fabricating scapular shovels).

Statistical analysis of the width and rugosity level of the scapulae neck show that scapulae from old adult wild buffalo was strongly preferred for crafting the Hemudu scapular earth-working implements and that Hemudu people likely took these heavy bones from kill sites but rarely transported scapulae from younger buffalo (Xie and Stiner 2018). The larger dimensions and greater robustness of old buffalo bones than those of deer and younger buffalo grant them the ability to withstand the abrasion and battering in the local soil conditions.

However, as discussed below, our research reveals that both the unique hafting style and the raw material preference served purposes beyond techno functional considerations: they visually communicated the Hemudu people’s social identity.

The Kuahuqiao and Hemudu Manufacturing Techniques

As aforementioned, most Kuahuqiao specimens were expedient use of unintentionally broken deer scapulae. The manufacture of the six lightly modified deer scapulae involved a hammerstone smashing part of the acromion spine and a grinding media shaping the functional edge at the proximal end of the bone. The production of water buffalo scapular implements is unclear due to the absence of diagnostic traces blurred from hafting friction. However, based on the techniques available at the time, our educated guess is that the production most likely involved a ground stone chisel or adze in creating the hole and the opening and a grinding media to sharpen the functional edge.

A sample of an intentionally modified non-tool at this site reveals additional information of an intended trial during the process of technological innovation. This implement, 2001XKT0411 (5)A:43, has a shaft hole 1.5–2 cm in diameter and 1.4 cm deep at the center of the glenoid (Figure 5). Unlike a functional tool, this artifact lacks other modifications and traces from hafting and use (compared Figures 2, 5). The shaft hole was crafted with the assistance of burning, leaving evident traces and resultant cracks around the hole’s entrance. Of all specimens unearthed from the Kuahuqiao, Hemudu, and Tianluoshan sites, 2001XKT0411 (5) A:43 is the only example manufactured by burning. As the technique turned out to cause cracks, the sample was not further modified or used. It is also the only example fashioned from a carnivore scapula, and it is much smaller (15.5 long, weight 70 g) and thinner than the scapula of a water buffalo or a large deer. Together these led to the conclusion that this implement represents an unsuccessful trial in manufacturing technique, tested with similar but less-than-ideal raw material. Alternatively, this implement could have been a child’s toy.

FIGURE 5. An unsuccessful trial with burning to create a shaft hole: T0411 (5) A:43 from Kuahuqiao (top and dorsal views).

Hemudu scapular implements’ sophisticated hafting modifications required a much more complicated reduction procedure. Results from replication experiments identified the optimum reduction sequence and the most practical technologies in each reduction step to eliminate accidental breakage during scapular shovel production (Xie 2018). The optimum reduction sequence with the ideal technologies is the following. First, remove the spine and proximal end with a hammerstone. Second, use a hafted groundstone axe to cut away unwanted mass from the scapular neck to fashion the notches. Third, flatten the interior side of the distal end with a coarse-grained abrader. Fourth, use a groundstone chisel with a hammerstone to create the grooves before perforations. Fifth, score through the notches with an awl. And finally, sharpen the edge with a coarse-grain abrader.

The manufacturing traces observed on the archaeological samples suggest that these techniques were among the diverse technical solutions the Hemudu craftspeople employed in scapular implement production. See Xie (2018): Supplementary Table 1 for inferred manufacturing techniques of the scapular earth-working implements from the Hemudu and Tianluoshan sites and further discussion below in the Results section concerning Hemudu people’s craft learning and production pattern for scapular shovel production.

Materials and Methods

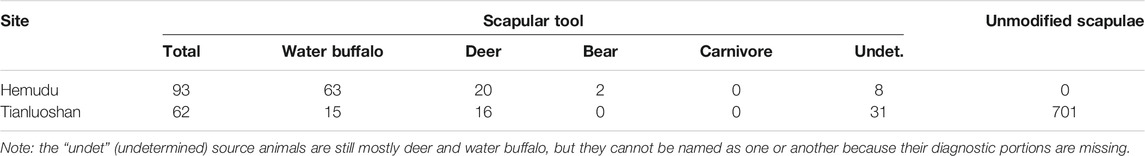

We examined all worked scapulae and discarded fragments from the sites of Hemudu and Tianluoshan, including 1) 93 specimens housed at the Hemudu Museum, representing about half of all scapular implements unearthed from the Hemudu site in the 1970s; 2) 62 scapular tools housed at the Tianluoshan Archaeological Station, representing 95% of scapular implements excavated from the Tianluoshan site between 2004 and 2011; and 3) a comparative sample including all 701 unmodified scapulae and all faunal fragments larger than 2 cm unearthed from the Tianluoshan site (Table 1). The Hemudu Museum collection mainly has relatively intact and visually appealing specimens selected from the 1970s’ excavations, whereas the Tianluoshan assemblage includes everything systematically collected from recent excavations. Therefore, we relied on the Tianluoshan collection for complementary clues for reconstructing the broader picture. All examined specimens are typically uncovered together with objects for daily use or from refuse in the habitation areas. There are no recognized differences between the distributions of worked scapulae and unmodified ones.

Cervidae (deer) and Bovidae (bovids) were the principal sources for the scapulae; occasionally, scapulae sourced from members of the Ursidae were also used (Table 1). Based on the bone’s dimension and concerning the archaeological fauna (Wei et al., 1990; Zhang et al., 2011), cervids Elaphurus davidianus (Père David’s Deer), Cervus unicolor (Sambar Deer), and Bubalus sp., probably B. Mephistopheles were the deer and bovid whose scapulae were crafted into tools at Hemudu and Tianluoshan. We use the common names of the animals in the discussion for simplicity’s sake.

Our research employed results from the replication experiments reported in Xie 2018 to identify the product traits pertinent to crafting learning and use these indicators to analyze crafting competency displayed in the archaeological sample. In addition, we calculated the Coefficient of Variation (CV) to measure the levels of morphological variation of hafting modifications in the archaeological assemblage. CV expresses the variation as a percentage of the sample standard deviation to the sample mean and has been proven to be the most robust, suitable statistical means for assessing product variation (Longacre 1999; Eerkens 2000; Eerkens and Bettinger 2001) and inferring specialized/non-specialized craft production (e.g., Longacre 1999; Roux 2003). Furthermore, we examined the practice pieces in the archaeological sample to further understand craft learning in the Hemudu society.

Results

Xie 2018 reconstructed the technical details of bone shovels and their manufacturing methods in Hemudu Culture using replication experiments. The following three paragraphs briefly reiterate the experimental observations regarding crafter’s technical competency to set the stage for further discussions on the archaeological observations concerning Hemudu’s cultural transmission system for bone shovel production. Most archaeological observations presented in this section have not been published elsewhere, with a few exceptions indicated with citations.

Xie and three adept crafters started to replicate the bone shovel after Xie had carefully gone over the archaeological collections once. The experimental results indicate that the adequate level of know-how for producing a product similar to a typical Hemudu bone shovel without breaking it is low because the quality of bone is stable and predictable. With a bit of formal or informal training and less than five trials, an adept person familiar with the mechanical properties of bone could craft a typical Hemudu-style scapular shovel of a workable quality from a large cattle scapula. The finished products’ quality varies depending on the person’s innate dexterity and bone-working experience; however, the quality is generally at the lower end of the spectrum.

Common errors in the early stage of the experiments included using less-than-ideal raw materials (i.e., scapulae from young cattle instead of old individuals), improper anvil arrangement, mislocation or disproportionate dimension of modifications, inappropriate reduction sequences, and failure in force control. Using a hard anvil, reversing specific steps of the optimum reduction sequence, and applying a force of improper amount or from the wrong angle often caused accidental breakages or, at best, produced flawed products. For example, one failure in force control in the experiment created a partially missing straight side of a hafting notch displayed in Xie 2018:Figure 7.1. Using scapulae of young buffalo and mislocating or disproporting the dimensions of modifications usually produced products that either did not look right or performed awkwardly.

Producing high-quality products free of manufacturing flaws would have taken much more experience. In particular, the accurate locations and proper proportions of modifications are not readily transferrable between young animals’ scapulae and the larger and more robust scapulae from old adults. Even with the right scapulae, Xie’s memorized template after examining the archaeological specimens was inaccurate for object reproduction. Thus she had to keep either a scanned photo or an actual model object in view to determine the accurate location and dimension for each modification. Even so, it took Xie a dozen more trials to develop the ability to accurately adjust the locations and dimensions of the hafting modifications according to a scapula’s dimension. However, once developed, most of the knowledge for high-quality production is transmittable to a novice with verbal instruction and/or accurate guide lines on the scapula. Precise force control appeared to be the only aspect that each crafter must practice to accomplish.

High Morphological Variation Despite Consistent Object Style

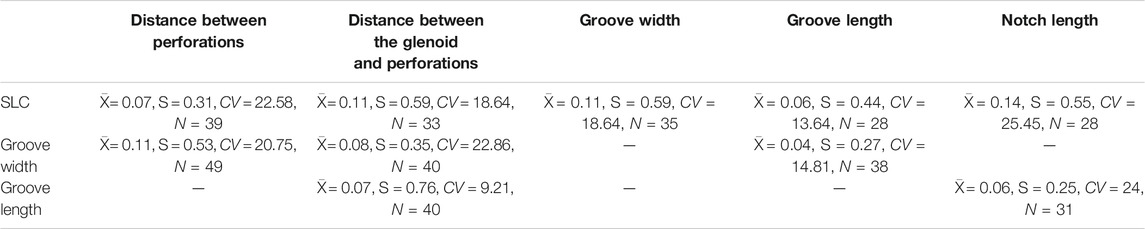

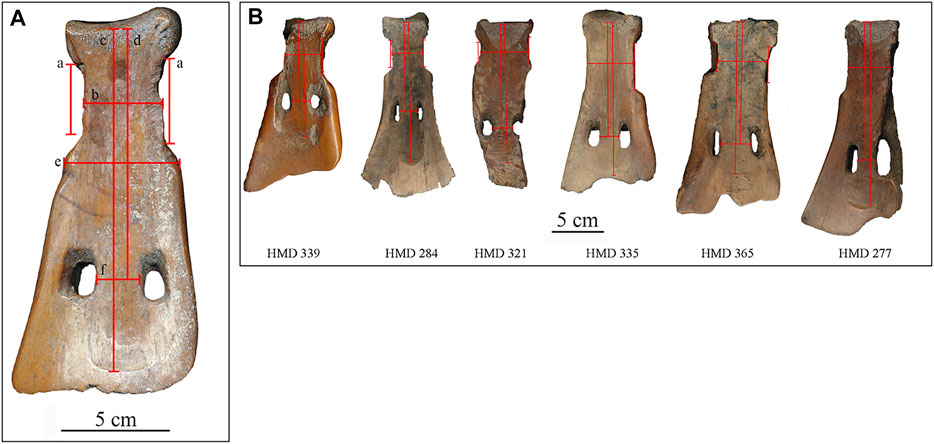

The overall hafting style of scapular earth-working implements appears consistent during the Hemudu period; however, the morphological details of the hafting modifications vary significantly (Figure 6; Table 2). Here, morphological details refer to the hafting modifications’ relative dimensions and relative locations. These are calculated as the ratios of a modification’s dimension (e.g., a hafting groove’s width) or its location (e.g., the perforations’ distance from the glenoid) to the smallest length of the collum scapulae (SLC), the only original dimension that generally survived the tool-manufacturing process. Such relative measurements are more accurate for assessing morphological variance because the exact measurements can be reflective of the varying original dimensions of water buffalo scapulae. Moreover, relative measures capture inaccurate locations and disproportion of hafting modifications in relation to the scapular dimension, indicators of lacking experience highlighted above.

FIGURE 6. Product variation in Hemudu scapular earth-working implements. (A) Measurement points for analysis of morphological variation (illustrated with HMD 271): a. Length of notch; b. Width of groove; c. Length of groove; d. Distance between the glenoid and the perforations; e. SLC (the smallest length of the collum scapulae); f. Distance between perforations. (B) Examples of morphological variations in hafting modifications despite consistent object style.

As the results listed in Table 2 indicate, the CV values of the scapular implements’ hafting modifications at the Hemudu site range 9–25% and averaged 19%. This level of variation is close to that of English Mesolithic microliths with CV values ranging between 5 and 39% and averaging 19% (Eerkens 1997, 1998), which are interpreted as representing low variation (or high standardization) for microliths (Eerkens 2000:667). However, we consider a close CV range among the Hemudu scapular spades an indication of high variation.

Raw materials and technological systems significantly influence the CV values representing low or high variations (Eerkens 2000; Eerkens and Bettinger, 2001). We argue that the CV range indicating low product variation of scapular earth-working implements should be much lower than microliths but probably closer and slightly higher than pottery. This assumption is based on the fact that raw materials that are more difficult to control for transformation and modification tend to inflate CV values (Eerkens and Bettinger, 2001). Bone material is easier to handle than stone but more challenging to control than clay. Scapulae are easier to manage than stone because 1) the original dimensions and shapes of water buffalo scapula provide a great frame of reference to the dimensions of reduction, 2) the dimensional range of the scapulae provides a narrow window for dimensional error of reduction, and 3) as Xie 2018 pointed out, scapulae’s quality is more consistent than stone, rendering predictable fracturing properties across pieces and minimizing manufacturing errors and failures during reduction. In addition, the CV values of scapular implements are more comparable to those of pottery than those of microliths because the measurements of scapula hafting modifications and pot dimensions indicate the original dimensions. Microliths dimensions, on the other hand, may have been altered through use and reshaped. While we are confident that working in the medium of bone lends itself to a CV between stone and pottery, future experiments need to verify the CV ranges of lithic and ceramic products with expanded datasets and specify the CV range of bone tools to validate this argument.

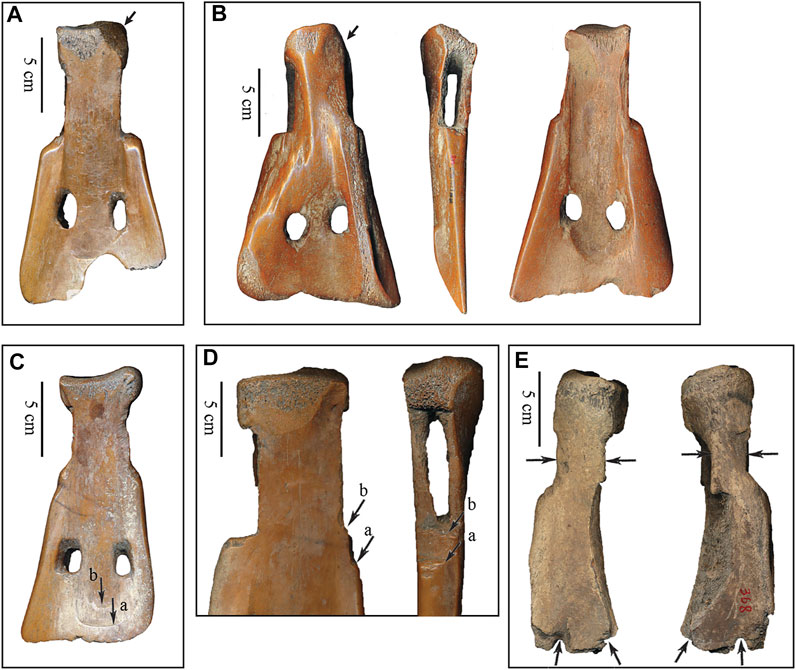

Replicated Manufacturing Mistakes

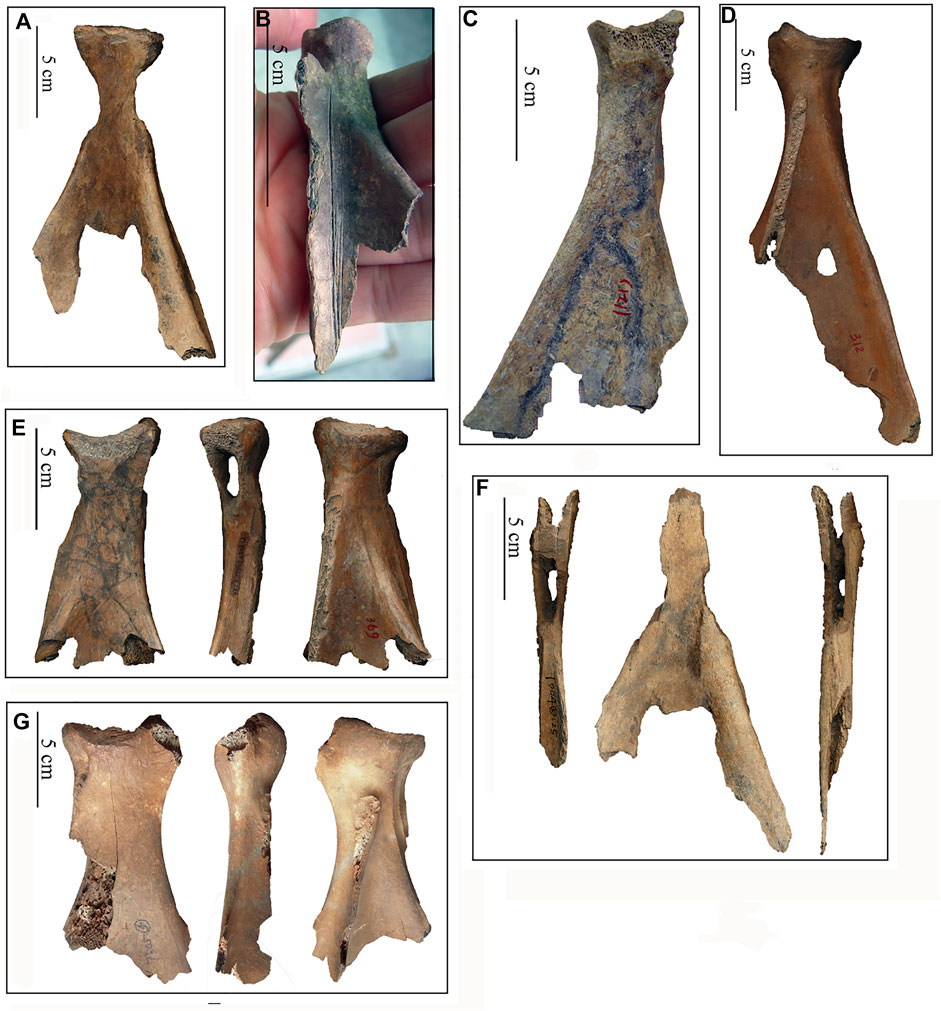

Some morphological variants were caused by failing to apply the right amount of force during the manufacturing process. For example, HMD 283 and HMD 328 display straight sides resulting from misdirected cuts (Figures 7A,B). Such straight sides are fragile because all compact bone is removed from the sides of the neck and the glenoid, and they cannot hold lashing as well as the notches do. Interestingly, a few Hemudu and Tianluoshan specimens show this “style” without evidence of misdirected cuts. Some other specimens show an in-between style: with compact bone on the sides of the glenoid removed while retaining very shallow notches on the sides of the neck, and sometimes the shallow notches were crafted only on the ventral surface. Sometimes the straight sides were further notched to create a morphological similarity of notched sides (e.g., Figure 4B, Figure 7A). We suspect that these samples resulted from either modelling after a flawed specimen or simply from failings of morphological memory. No matter which reason best explains the variation, these variations reflect a group of inexperienced craftspeople.

FIGURE 7. Examples of manufacturing mistakes. (A,B). misdirected cuts: HMD 283 and HMD 328 (dorsal, lateral, and ventral views). (C) HMD 271 retains two hafting grooves, with the longer one (a) mislocated and therefore corrected by the creation of a shorter one (b); (D) The distal portion of HMD 367 (ventral and lateral views) shows a long notch (a) corrected by the addition of a shorter notch (b); (E) HMD 368 (ventral and dorsal views) displays a few mistakes: an extremely deep notch which created an excessively narrow and weak neck (blue arrows) and also caused breakage along one border of the scapula; perforations (yellow arrows) too far from the articulated end, leaving insufficient material for use and eventually leading to edge breakage.

Additional mistakes exhibited by archaeological specimens are diverse and less common. For example, some specimens display prominent, inaccurate locations or disproportions of the hafting modifications. The perforations of TLST302 (8):3 are too large (Figure 4B). HMD 271 retains two hafting grooves, with the longer one being mislocated and, therefore, corrected by creating a shorter one (Figure 7C). HMD 367 has a highly long notch on one side of the neck that was fixed by adding a shorter notch before completion. The compact bone on this side of the neck is wholly removed, forming a straight side instead of a notch (Figure 7D). This is another example of poorly managed force control in the notching process. The directions of perforations are tilted to one side. The overall quality of all modifications suggests the production of a naïve craftsperson. However, intensive hafting wear indicates that the implement had been used, and the missing edge segment probably resulted from use damage. HMD 368 has extremely deep notches on the sides, and so the remaining neck is excessively narrow. Excessive notching of the side caused breakage along one border of the scapula (Figure 7E). HMD 368 also contains perforations too far from the glenoid and thus might have been too close to the edge, leaving insufficient material for use and locating the perforations at a much thinner section of the blade, eventually causing the edge breakage. The edges of the notches are rounded, indicating that the implement was once hafted and likely used.

Diverse Technical Solutions During Production

The Hemudu crafters employed a diverse array of technical solutions during scapular implement production. In particular, the spine was removed by abrading, cutting/smashing, sawing, or a combination of cutting and grinding. The notches were produced either by cutting, abrading/sawing, or a combination of cutting-abrading/sawing off unwanted bone mass from the scapular neck. The grooves were created by chiselling, whittling/shaving, sometimes in combination with abrading. Finally, the perforations were made by chiselling and occasionally expanded by drilling (Xie 2018: Supplementary Table 1).

In addition, some objects’ manufacturing solutions show more control than others. For example, some but not all hafting grooves and notches display a straight distal end, indicating that a guide line was created either by the crafters to help control the propagation of fracture or by a tutor to define the location and dimension of the modification for a pupil. Interestingly, the guide lines are often not at the ideal places.

Furthermore, the archaeological assemblage indicates inconsistent manufacturing procedures, some of which are against the optimum reduction sequence. For example, about a quarter of the archaeological specimens were perforated before grooving, resulting in accidental breakage during manufacture.

Low Ratio of Practice Pieces to Finished Products

The finished products, including the flawed implements, were nonetheless used in Hemudu Culture, suggesting that they were produced for use and unlikely to have been products of training or trial pieces. Archaeological specimens with evidence of being practice pieces are rare compared to the number of finished and used products. Moreover, even when the practice was carried out, it was likely on an individual level and informal. Only four of 62 scapular implements unearthed from the Tianluoshan site and three of 93 studied specimens from the Hemudu site appear to be practice pieces (Figure 8). Unlike the finished products often crafted from old buffalo scapulae, most manufacturing practices were carried out with deer scapulae, and most products were unfinished or finished but used in a way that did not require those modifications.

FIGURE 8. All practice pieces in the studied sample. (A) HMD 311 with extremely deep notches on the sides of the neck, causing breakage of the scapular border. (B) TLST104 (6):G360 with incised lines to both sides of the acromion spine. (C) TLST302 (6):G121 with the projection of the articulating end on the ventral surface and the acromion spine partially removed. (D) HMD 312 showing improper approaches to perforation, also at inappropriate locations. (E) HMD 369 with perforations skewed to one side of the blade, causing lateral breakage. (F) TLST004 (5): 25 with two sets of scored notches. (G) TLST305 (5): SGS1 with the side of the neck slightly modified, the acromion spine removed, and the ventral surfaces of the glenoids cut and ground.

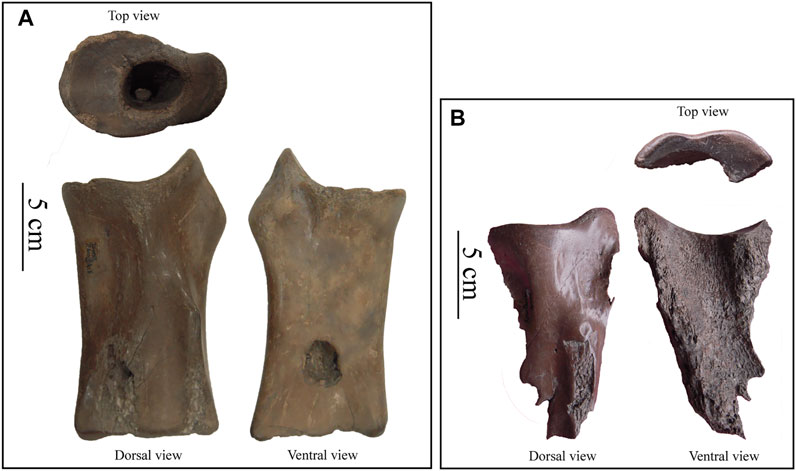

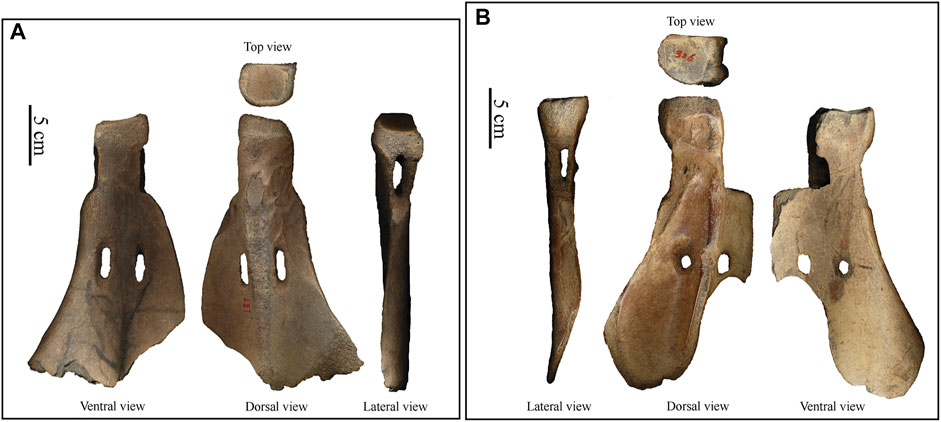

Two bear scapulae (HMD 287 and HMD 326) with all the modifications of a typical Hemudu-style shovel (Figure 9) look awkward for earth working and, therefore, could have been practice pieces. However, they were more likely shovels that played symbolic as opposed to practical roles in earth-working activities. Both “shovels” show rounding on the edge and the hafting area, despite the blades’ overall unsuitable shapes for crafting into a shovel. HMD 326 even displays soil-derived wear along the edge (Xie et al., 2017:Table 6); the cause of the traces on HMD 287’s edge is unclear.

FIGURE 9. Bear scapular implements from the Hemudu site. (A) Hemudu 287. (B) HMD 326. Both have all the modifications of a typical Hemudu-style shovel and show rounding on the edge and the hafting area, despite the blades’ overall unsuitable shapes for crafting into a shovel.

Discussion

The results discussed above indicate that the production of scapular spades may have been carried out by self-sufficient household craftspeople rather than craft specialists. Particularly, these results include the presence of 1) low standardization of final products reflected in varying morphological details and manufacturing solutions, regardless of consistent object style; 2) unequal, low to moderate levels of manufacturing skills observed on the finished products that were used regardless of differences in quality; and 3) replicated mistakes and a low number of practice pieces indicating limited training and practice.

Low Standardization of Final Products Resulted From Inexperienced Production

The CV values of the scapula modifications are higher than expected for specialized production. Ethnoarchaeological studies of Indian, Spanish, Filipino, and Chinese potters reveal that pots bear 2–4% of CVs when produced by full-time specialists and 6–9% of CVs by part-time specialists (Longacre 1999; Roux 2003; Fu 2018); these CV ranges are lower than that of scapula modifications. Even the CV ranges of pots made by beginners of specialists (7–17%) and non-specialists (10–14%) (Longacre 1999) are lower than or at the lower end of the CV range of scapula modifications. Therefore, we consider the product variation among Hemudu scapular implements to be relatively high.

Many factors can lead to high morphological variation among scapular earth-working implements, including infrequent production (Eerkens 2000; Eerkens and Bettinger 2001), low degree of skill (Costin and Hagstrum 1995), high manufacturing tolerances for deviation from a standard template (Ferguson 2008:64), purposive expression of idiosyncrasy (Eerkens and Bettinger 2001), or a combination of these factors. In addition, everything else being equal, a greater number of producers can result in higher product variation within an archaeological assemblage (Costin 1991; Fu 2018). Furthermore, self-teaching relying on trial-and-error can introduce greater product variations than social learning methods that involve specialists’ guidance.

Purposive expression of idiosyncrasy can be ruled out in the Hemudu case because this often happens in creative artwork or similar circumstances when individual producers make a conscious effort to differentiate their products from those of others, which would have resulted in a CV more significant than would occur when production is entirely random. A CV above 58% has been suggested as an indicator of purposeful diversification (Eerkens and Bettinger, 2001). On-site training by specialists is also unlikely to be responsible for the high variation among the Hemudu scapular implements because no workshop has been found at the Hemudu and Tianluoshan sites for scapular implements. While the absence of a workshop could have resulted from sampling biases in excavation and challenges in identifying such features in the field under a water-logged condition, additional evidence suggests that the high morphological variation more likely resulted from the implements’ production pattern. The following sets of evidence jointly led us to conclude that the scapular implements were produced by many unprofessional, inexperienced individuals representing self-sufficient household production: 1) diverse technical solutions employed in scapular tool production suggesting emulation rather than imitation; 2) replicated mistakes revealing a lack of skills, experience, and intervention; 3) heavy utilization of all finished products, including the ones full of manufacturing flaws; and 4) a minimal number of manufacturing practice pieces.

Emulation Rather Than Imitation

The technical variations, including diverse technical solutions and varying levels of procedure management, reflect emulation (i.e. focusing on the outcomes of the manufacturing actions) rather than imitation (i.e. copying the specific set of actions or apprenticeship transfer of actual manufacturing techniques). Furthermore, replicated mistakes and the scarcity of practice pieces suggest that emulation most likely used an artefact as a template or reproduced from a memorized template with limited skills, experience, and little intervention.

Lithic and ceramic studies have demonstrated that emulation relies on the visuals of the final product and generally creates high variance within assemblages (Tehrani and Riede 2008). Experimental results also confirm that crafters who have only the final product to emulate significantly deviated from the template and produced more variance than social learners and process-copying (Derex, Godelle, and Raymond 2013). Through emulation, the traits that end up being the most conserved are those that are highly visible on the final creation (Roux 2015). Emulation often happens when intervention and communities of practice are lacking (Berg 2015).

Replicated Mistakes and Scarcity of Practice Pieces Suggesting Inadequate Training, Intervention, and Practice

The manufacturing mistakes observed from the archaeological scapular implements include all typical novice or unskilled craftspeople indicators Xie witnessed during her replication experiments’ early stage of self-training in becoming a specialist for crafting Hemudu scapular implements. Certainly, the learning circumstances of the Hemudu craftspeople differed from the researcher: the Hemudu craftspersons may have been mentored by artisans with richer experience, but they may not have had the chance to observe as many artifacts as Xie did carefully. However, the similarities in the mistakes still suggest that many Hemudu craftspeople may have produced their implements according to morphological memory or a hafted shovel and did not repeat production even when final products turned out to be flawed. This evidence suggests that the craftspeople only occasionally handled and produced the shovel blades. After all, people working with standard objects daily would have had more accurate mental images of the correct size and shape for a particular object (Eerkens 2000).

Repeated errors in the archaeological assemblage indicate intervention was limited to nonexistent. One may argue that a few artisans might have been better trained and become specialists who produced the relatively high-quality products present in the archaeological assemblage. However, we contend that these were more likely craftspeople with the better natural ability or perhaps who had more practice than the bulk of these craftspeople because archaeological evidence does not (yet) support the hypothesis of the presence of a specialized training system. As mentioned earlier, the knowledge related to accurately locating the spots and proportion of hafting modifications in relation to scapular dimension takes a great deal of experience to accomplish; however, once obtained, the knowledge is easily transmittable to a novice with verbal instruction and/or with accurate guide lines on the object.

Alternatively, infrequent production in the society may have resulted in lacking experienced producers, so even the most experienced who might serve as trainers or consultants did not reach technical competency. The fact that guide lines were rare and often located at less-than-ideal places indicates that even the crafters who created them had not reached technical competency. The low ratio of practice pieces to finished products and the utilization of many flawed products suggest that crafters did not practice manufacturing adequately before crafting actual tools.

Certainly, the unearthed sample may have underrepresented practiced pieces. Of 701 unmodified scapulae unearthed from Tianluoshan, 690 were identified to species, but only one fragment, a scapular proximal end, belongs to buffalo (Xie and Stiner 2018:652). The almost absence of unmodified buffalo scapulae and the scarcity of scapular implements crafted from young adult and prime adult buffalo in the villages significantly contrast with the fact that these buffalo were the primary target of the hunters (Xie and Stiner 2018:651). These missing buffalo scapulae could have been used for manufacturing practices somewhere else and abandoned there, such as the kill sites or unexcavated areas of the villages. Nonetheless, practicing with these less-than-ideal scapulae must not have been sufficient for accomplishing the technical competency for crafting a high-quality shovel from the larger and more robust scapulae of older buffalo.

Overall, the unearthed finished products were evidently produced by inexperienced craftspeople with only low to moderate skill levels. Further, since the manufacture required axes and chisels that could be considered injury-prone for children and teenagers, the crafters likely involved only adolescents and adults.

High technical variation, low to moderate manufacturing skills, and evidence of insufficient manufacturing practice jointly led us to conclude that high product variation among the scapular earth-working implements was caused by the participation of many group members in production despite their inexperience, most likely representing self-sufficient household production. Parent-child intervention might have existed; however, most crafters were inexperienced. While self-sufficient household production was sustained through emulation, frequency-dependent bias toward bone spades reflects the majority’s preferences across society. In other words, crafting mostly relied on trial-and-error through object emulation, but the community influenced the overall style and material choice. Once hafted, the shaft and ligatures would have covered most of the modifications (Figure 4), reducing the visibility of many production flaws on the shovel blade. The hafting arrangement could be adjusted until a shovel reached the desired visual effect.

Further, the lack of careful/high-quality production for an iconic object suggests two possibilities. First, the motivation for keeping this style tradition was primarily ideological and tied to group identity/membership. The scapulae likely mainly served as the armature to create a shovel that could display, conform or dazzle through the physical arrangement. Second, either the implement was not generally used for agricultural practices, or agriculture was not the primary source of subsistence. This last point is supported by previous studies on scapular shovel function (Xie et al., 2017), which found scapular implements to be ineffective in penetrating the ground, even in relatively soft soils. Furthermore, the absence of a training system for ensuring technical consistency and holding high product standards for shovel production suggests that farming activities were not a crucial component of the society’s subsistence activities. This conclusion is consistent with the results of recent paleoethnobotanical research confirming low-level food production in the Hemudu’s subsistence practice. Therefore, scapular shovels were likely a sign of group identity, emphasizing conformity to style, indicating that social conformity is not necessarily linked to specific learning patterns as ethnographic data may suggest.

Conclusion

Most Hemudu scapular spades were likely crafted by household craftspeople, who were adept and familiar with the implements but had insufficient training and practice, resulting in varying qualities of the tools and high variability of end-products. The pattern of self-sufficient household production combined with frequency-dependent bias led to a preference for bone spades and ensured their persistence in Hemudu Culture.

Communities of practice appear to have been minimal to nonexistent among the shovel makers; alternative mechanisms to maintain the technical norms of the scapular shovel tradition or hold a high product standard were also lacking. Therefore, the Hemudu community members developed their knowledge and skills of manufacture primarily through self-teaching and produced low to moderate quality shovel blades. This can be explained by the more profound subsistence background behind technological decision-making—the society did not rely on farming for survival.

This leaves us with ideology. Despite the variability in production, hafting style and material preference remain consistent. A bone shovel gains utility as a signal of group membership, where conformity lies in highly visible traits. This implies that farming activities might have been culturally significant despite minor economic contributions. The binary system of conformist hafting style and material preference mixed with loose quality control in the Hemudu scapular shovel blade production reveals that social conformity and the associated learning pattern are circumstantial and fluid even for a community’s iconic implement.

The case study we presented here demonstrates how studying the learning patterns for osseous technology complements the lithic and pottery studies that dominate the technology literature. Further research with other bone artifact types in the Yangzi Delta would help shed light on whether similar learning patterns were applied besides the creation of scapular shovels and whether this type of implement was unique in its construction. If craft specialization existed in the bone industry of Neolithic Yangzi Delta, what were the causes of exception seen in shovels? Does the intention behind tool creation (e.g. foraging or plant cultivation) drive differences in craft learning? Additional study in this area will further our understanding of the socio-economic development of agriculture in the Yangzi Delta.

Data Availability Statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author Contributions

LX conceptualized the project, collected and analyzed data, developed the methods, acquired funding, and took the lead in drafting the manuscript. CL participated in literature research and manuscript drafting. LJ and GS administrated the project and provided the archaeological resources.

Funding

This research was funded by the Haury Dissertation Fellowship from the School of Anthropology at the University of Arizona and the faculty Start-up Fund at the University of Toronto Mississauga awarded to LX.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Acknowledgments

We thank Wei Lou, Weijun Zheng, Xiao Wang, Xiaoqiang Yao, Weijin Huang, Xuejiao Lu, Jun Shu, and Zhipeng Sun for assistance in access to the Kuahuqiao and Hemudu collections; Ying Zhang for teaching Xie to identify the scapulae to species; Alice Choyke and Petar Zidarov for generously sharing their knowledge and resources on craft learning of bone tools; graduate students in the Anthropology Department at the University of Toronto for stimulating discussions, particularly Natalia Handziuk, Elizabeth Gibbon, Tiziana Gallo, and Arno Glasser. Last but not least, we thank the two reviewers who provided very helpful suggestions.

References

Ahler, S. A. (1989). “Experimental Knapping with KRF and Midcontinent Cherts: Overview and Applications,” in Experiments in Lithic Technology. Editors D. S. Amick, and R. P. Mauldin (Oxford: British Archaeological Reports), 199–234.

Bamforth, D. B., and Finlay., N. (2008). Introduction: Archaeological Approaches to Lithic Production Skill and Craft Learning. J. Archaeol Method Theor. 15, 1–27. doi:10.1007/s10816-007-9043-3

Berg, I. (2015). “Potting Skill and Learning Networks in Bronze Age crete,” in The Transmission of Technical Knowledge in the Production of Ancient Mediterranean Pottery. Editors W. Gauss, G. Klebinder-Gauss, and C. von Ruden (Wien, Austria: Österreichisches Archäologisches Institut), 17–35.

Bowser, B. J., and Patton, J. Q. (2008). “Learning and Transmission of Pottery Style: Women's Life Histories and Communities of Practice in the Ecuadorian Amazon,” in Cultural Transmission and Material Culture: Breaking Down Boundaries. Editors M. T. Stark, B. J. Bowser, and H. Lee (Tucson, Arizona: The University of Arizona Press), 105–129.

Boyd, R., and Richerson, P. J. (1985). Culture and the Evolutionary Process. Chicago: University of Chicago.

Cavalli-Sforza, L. L., and Feldman, M. W. (1981). Cultural Transmission and Evolution: A Quantitative Approach. Princeton, N. J.: Princeton University Press.

Choyke, A. M., Vretemark, M., and Sten, S. (2004). “Levels of Social Identity Expressed in the Refuse and Worked Bone from the Middle Bronze Age Szazhalombatta-Foldvar, Vatya Culture, Hungary,” in Behaviour behind Bones: The Zooarchaeology of Ritual, Religion, Status and Identity. Editors S. J. O'Day, W. Van Neer, and A. Ervynck (Oxford: Oxbow Books), 177–189.

Chudek, M., Brosseau-Liard, P., Birch, S., and Henrich, J. (2013). “Culture-gene Coevolutionary Theory and Children's Selective Social Learning,” in Navigating the Social World: What Infants, Children, and Other Species Can Teach Us. Editors M. R. Banaji, and S. A. Gelman (Oxford: Oxford University Press), 181–185. doi:10.1093/acprof:oso/9780199890712.003.0033

Costin, C. L. (1991). “Craft Specialization: Issues in Defining, Documenting, and Explaining the Organization of Production,” in Archaeological Method and Theory. Editor M. B. Schiffer (Tucson, AZ: The University of Arizona Press), 1–55.

Costin, C. L., and Hagstrum, M. B. (1995). Standardization, Labor Investment, Skill, and the Organization of Ceramic Production in Late Prehispanic Highland Peru. Am. Antiq. 60 (4), 619–639. doi:10.2307/282046

Crown, P. L. (2001). Learning to Make Pottery in the Prehispanic American Southwest. J. Anthropological Res. 57 (4), 451–469. doi:10.2307/363135510.1086/jar.57.4.3631355

Crown, P. L. (2014). The Archaeology of Crafts Learning: Becoming a Potter in the Puebloan Southwest. Annu. Rev. Anthropol. 43, 71–88. doi:10.1146/annurev-anthro-102313-025910

Derex, M., Godelle, B., and Raymond, M. (2013). Social Learners Require Process Information to Outperform Individual Learners. Evolution 67 (3), 688–697. doi:10.1111/j.1558-5646.2012.01804.x

Dorland, S. G. H. (2018). Maintaining Traditions: a Study of Southern Ontario Late Woodland Ceramics through a Communities-Of-Practice Approach. J. Archaeol Method Theor. 25 (3), 892–910. doi:10.1007/s10816-017-9362-y

Eerkens, J. W., and Bettinger, R. L. (2001). Techniques for Assessing Standardization in Artifact Assemblages: Can We Scale Material Variability? Am. Antiq. 66 (3), 493–504. doi:10.2307/2694247

Eerkens, J. W. (2000). Practice Makes within 5% of Perfect: Visual Perception, Motor Skills, and Memory in Artifact Variation. Curr. Anthropol. 41 (4), 663–668.

Eerkens, J. W. (1998). Reliable and Maintainable Technologies: Artifact Standardization and the Early to Later Mesolithic Transition in Northern England. Lithic Tech. 23 (1), 42–53. doi:10.1080/01977261.1998.11720937

Eerkens, J. W. (1997). Variability in Later Mesolithic Microliths of Northern England. J. Lithic Stud. Soc. 1 (17/18), 51–65.

Ellen, R., and Fischer, M. D. (2013). “Introduction: on the Concept of Cultural Transmission,” in Understanding Cultural Transmission in Anthropology: A Critical Synthesis. Editors E. Roy, S. J. Lycett, and S. E. Johns (Berghahn Books), 1–54.

Ferguson, J. R. (2008). The when, where, and How of Novices in Craft Production. J. Archaeol Method Theor. 15 (1), 51–67. doi:10.1007/s10816-007-9047-z

Fu, Y. (2018). “Potting Techniques at the Xizhufeng Site,” in Xizhufeng at Linqu: Excavation and Research of the Shandong Longshan Culture Cemetery (Beijing, China: Wenwu Publishing House), 295–368.

Fuller, D. Q., and Qin, L. (2008). Immature rice and its Archaeobotanical Recognition: a Reply to Pan. Antiquity 82 (316), 1.

Gintis, H. (2011). Gene-culture Coevolution and the Nature of Human Sociality. Phil. Trans. R. Soc. B 366 (1566), 878–888. doi:10.1098/rstb.2010.0310

Gosselain, O. P. (2000). Materializing Identities: An African Perspective. J. Archaeological method Theor. 7 (3), 187–217. doi:10.1023/a:1026558503986

Gosselain, O. P. (2008). “Mother Bella Was Not a Bella: Inherited and Transformed Tradition in Southwestern Niger,” in Cultural Transmission and Material Culture: Breaking Down Boundaries (Tucson, AZ: University of Arizona Press).

Greenfield, P. M. (1999). Cultural Change and Human Development. New Dir. Child Adolesc. Dev. 1999, 37–59. doi:10.1002/cd.23219998305

Hasaki, E. (2012). “Craft Apprenticeship in Ancient Greece: Reaching beyond the Masters,” in Archaeology and Apprenticeship: Body Knowledge, Identity, and Communities of Practice. Editor W. Wendrich (Tucson, AZ: University of Arizona Press), 171–202.

Herbich, I., and Dietler, M. (2008). “The Long Arm of the Mother-In-Law: Learning, Postmarital Resocialization of Women, and Material Cultural Style,” in Cultural Transmission and Material Culture: Breaking Down Boundaries. Editors M. T. Stark, B. J. Bowser, and L. Horne (Tucson, Arizona: The University of Arizona Press), 105–129.

Keith, K. (2005). Childhood Learning and the Distribution of Knowledge in Foraging Societies. Archeological Pap. Am. Anthropological Assoc. 15, 27–41.

Laland, K. N., and Brown., G. R. (2011). “Cultural Evolution,” in Sense and Nonsense: Evolutionary Perspectives on Human Bahaviour. 2nd Edition (New York: Oxford University Press), 139–164.

Laland, K. N. (2008). Exploring Gene-Culture Interactions: Insights from Handedness, Sexual Selection and Niche-Construction Case Studies. Phil. Trans. R. Soc. B 363 (1509), 3577–3589. doi:10.1098/rstb.2008.0132

Lancy, D. F. (2012). "First You Must Master Pain": The Nature and Purpose of Apprenticeship. Anthropol. Work Rev. 33 (2), 113–126. doi:10.1111/j.1548-1417.2012.01084.x

Lave, J. (1991). “Situating Learning in Communities of Practice,” in Perspectives on Socially Shared Cognition. Editors L. B. Resnick, J. M. Levine, and S. D. Teasley (American Psychological Association), 2–63.

Longacre, W. A. (1999). “Standardization and Specialization: What's the Link?” in Pottery and People. Editors J. M. Skibo, and G. M. Feinman (Salt Lake City: University of Utah Press), 44–58.

Mesoudi, A. (2013). “Studying Cultural Transmission within an Interdisciplinary Cultural Evolutionary Framework,” in Understanding Cultural Transmission in Anthropology: A Critical Synthesis. Editors E. Roy, S. J. Lycett, and S. E. Johns (New York: Berghahn Books), 131–147.

Mou, Y. (1980). “A Discussion of the Hemudu Culture,” in Proceedings of the First Annual Meeting of the Chinese Archaeology Society (Beijing: Cultural Relics Publishing House), 97–110.

Nettle, D., and Dunbar, R. I. M. (1997). Social Markers and the Evolution of Reciprocal Exchange. Curr. Anthropol. 38 (1), 93–99. doi:10.1086/204588

Pan, Y. (2011). Resource Production from 10,000 to 6,000 BP on the Yangzi Delta and Qiantangjiang Drainage: Paleoethnobotanical and Human Ecological Studies. Shanghai, China: Fudan University.

Pan, Y., Zheng, Y., and Chen, C. (2017). “Human Ecology of the Early Neolithic Kuahuqiao Culture in East Asia,” in Handbook of East and Southeast Asian Archaeology. Editors J. Habu, V. L. Peter, and W. O. John (New York: Springer-Verlag), 347–377. doi:10.1007/978-1-4939-6521-2_23

Pigeot, Nicole. (1990). Technical and Social Actors: Flintknapping Specialists and Apprentices at Magdalenian Etiolles. Archaeological Rev. Cambridge 9 (1), 126–141.

Puri, R. K. (2013). “Transmitting Penan Basketry Knowloedge and Practice,” in Understanding Cultural Transmission in Anthropology: A Critical Synthesis. Editors E. Roy, S. J. Lycett, and S. E. Johns (New York and Oxford: Berghahn Books), 266–299.

Reyes-García, V., Gallois, S., and Demps, K. (2016). “A Multistage Learning Model for Cultural Transmission: Evidence from Three Indigenous Societies,” in Social Learning and Innovation in Contemporary Hunter-Gatherers. Editors H. Terashima, and B. S. Hewlett (Japan: Springer), 47–60.

Richerson, P. J., Boyd, R., and Henrich, J. (2010). Gene-culture Coevolution in the Age of Genomics. Proc. Natl. Acad. Sci. 107 (Suppl. 2), 8985–8992. doi:10.1073/pnas.0914631107

Roux, V. (2003). Ceramic Standardization and Intensity of Production: Quantifying Degrees of Specialization. Am. Antiq. 68 (4), 768–782. doi:10.2307/3557072

Roux, V. (2015). Standardization of Ceramic Assemblages: Transmission Mechanisms and Diffusion of Morpho-Functional Traits across Social Boundaries. J. Anthropological Archaeology 40, 1–9. doi:10.1016/j.jaa.2015.04.004

Schniter, E., Gurven, M., Kaplan, H. S., Wilcox, N. T., and Hooper, P. L. (2015). Skill Ontogeny Among Tsimane Forager-Horticulturalists. Am. J. Phys. Anthropol. 158 (1), 3–18. doi:10.1002/ajpa.22757

Shelley, P. H. (1990). Variation in Lithic Assemblages: an experiment. J. Field Archaeology 17 (2), 187–193. doi:10.1179/009346990791548349

Shi, J. (2009). “The Nature of the Excavated Areas at Kuahuqiao in the Excavation Seasons II and III,” in Monograph of the Kuahuqiao Culture. Editors H. Lin, and G. Ren (Beijing: People's Publishing House), 9–15.

Shi, W., Ma, C., Jiao, F., Zhu, C., and Wang, F. (2008). Prehistoric Sites, Buried Peat, and Sea-Level Fluctuation on the Ningshao Plain during the Mid-holocene. Acta Oceanologica Sinica 30 (4), 169–175.

Tehrani, J. J., and Riede, F. (2008). Towards an Archaeology of Pedagogy: Learning, Teaching and the Generation of Material Culture Traditions. World Archaeology 40 (3), 316–331. doi:10.1080/00438240802261267

Thulman, D. K. (2014). The Role of Nondeclarative Memory Systems in the Inference of Long-Term Population Continuity. J. Archaeol Method Theor. 21 (4), 724–749. doi:10.1007/s10816-013-9175-6

Wallaert, H. (2008). “The Way of the Potter's Mother: Apprenticeship Strategies Among Dii Potters from Cameroon, West Africa,” in Cultural Transmission and Material Culture: Breaking Down Boundaries. Editors M. T. Stark, B. J. Bowser, and H. Lee (Tucson, Arizona: The University of Arizona Press), 199–222.

Wallaert-Pêtre, H. (2001). Learning How to Make the Right Pots: Apprenticeship Strategies and Material Culture, A Case Study in Handmade Pottery from Cameroon. J. Anthropological Res. 57, 471–493. doi:10.1086/jar.57.4.3631356

Wei, F., Wu, W., Zhang, M., and Han, D. (1990). The Neolithic Fauna at the Hemudu Site, Yuyao County, Zhejiang. Beijing: Ocean Press.

Wendrich, W. (2012). “Archaeology and Apprenticeship: Body Knowledge, Identity, and Communities of Practice,” in Archaeology and Apprenticeship: Body Knowledge, Identity, and Communities of Practice. Editor W. Wendrich (Tucson, AZ: University of Arizona Press), 1–19.

Wenger, E. (1998). Communities of Practice: Learning, Meaning, and Identity. Cambridge, U.K.; New York, N.Y.: Cambridge University Press.

Xie, L. (2014). Early to Middle Holocene Earth-Working Implements and Neolithic Land-Use Strategies on the Ningshao Plain. China: The University of Arizona. Unpublished Ph.D. dissertation, Anthropology.

Xie, L., Lu, X., Sun, G., and Huang, W. (2017). Functionality and Morphology: Identifying Si Agricultural Tools from Among Hemudu Scapular Implements in Eastern China. J. Archaeol Method Theor. 24 (2), 377–423. doi:10.1007/s10816-015-9271-x

Xie, L. (2018). Scapulae for Shovels: Does Raw Material Choice Reflect Technological Ease and Low Cost in Production? J. Archaeological Sci. 97, 77–89. doi:10.1016/j.jas.2018.06.009

Xie, L., and Stiner, M. C. (2018). Raw Material Preferences for Scapular Tools: Evaluating Water buffalo Age Bias in the Early Hemudu Culture, China. Int. J. Osteoarchaeol 28 (6), 645–655. doi:10.1002/oa.2677

Yang, X., and Jiang, L. (2010). Starch Grain Analysis Reveals Ancient Diet at Kuahuqiao Site, Zhejiang Province. Chin. Sci. Bull. 55 (12), 1150–1156. doi:10.1007/s11434-009-0545-0

Zhang, Y., Yuan, J., Huang, Y., Matsui, A., and Sun, G. (2011). “Results of Priliminary Analyses on the Faunal Remains Unearthed at the Tianluoshan Site in 2004,” in An Integrative Study on the Tianluoshan Ecofacts. Center for the Study of Chinese Archaeology in Peking University and the Zhejiang Provincial Institute of Cultural Heritage and Archaeology (Beijing: Cultural Relics Publishing House), 172–205.

Zheng, Y., Sun, G., and Chen, X. (2012). Response of rice Cultivation to Fluctuating Sea Level during the Mid-holocene. Chin. Sci. Bull. 57 (4), 370–378. doi:10.1007/s11434-011-4786-3

Zidarov, P., and Averbouh, A. (2014). “The Production of Bone Figurines in the Balkan Chalcolithic and the Use of Debitage by Extraction,” in An Overview of the Exploitation of Hard Animal Materials during the Neolithic and Chalcolithic. Editors M. Mărgărit, G. Le Dosseur, and A. Averbouh (Tȃrgovişte: Cetatea de Scaun), 183–200.

Keywords: Hemudu Culture, Kuahuqiao Culture, bone tool, household production, Chinese archaeology, neolithic archaeology, craft learning, cultural transmission

Citation: Xie L, Lun C, Jiang L and Sun G (2021) Conservative Style, Liberal Production: Hemudu’s Binary System for Maintaining its Scapular Shovel Tradition in the Southern Yangzi Delta, 7000–6000 BP. Front. Earth Sci. 9:792248. doi: 10.3389/feart.2021.792248

Received: 10 October 2021; Accepted: 25 November 2021;

Published: 21 December 2021.

Edited by:

Yue Zhang, Institute of Vertebrate Paleontology and Paleoanthropology (CAS), ChinaReviewed by:

Amy Margaris, Oberlin College, United StatesPeng Lv, Institute of Archaeology (CASS), China

Copyright © 2021 Xie, Lun, Jiang and Sun. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Liye Xie, bGl5ZS54aWVAdXRvcm9udG8uY2E=

Liye Xie

Liye Xie Casey Lun

Casey Lun Leping Jiang2

Leping Jiang2