Corrigendum: Acceleration of Debris Flow Due to Granular Effect

- 1Key Laboratory of Mountain Hazards and Earth Surface Processes/Institute of Mountain Hazards and Environment, Chinese Academy of Sciences, Chengdu, China

- 2University of Chinese Academy of Sciences, Beijing, China

- 3Center for Excellence in Tibetan Plateau Earth Sciences, Chinese Academy of Sciences, Beijing, China

- 4School of Engineering and Technology, Baoshan University, Baoshan, China

- 5Sichuan Earthquake Administration, Chengdu, China

Pore water pressure has been recognized as an important factor to enhance the mobility of debris flow moving in channel of very gentle slope. The creation and dissipation of pore water pressure are associated with interaction between grains. This study proposes a physical model for the pressure on mobility of flows with different granular configurations: the flow with overlying coarse-grained layer (i.e., inverse grading) and the flow with fully-mixed grains. The flow velocity is derived by the effective stress principle and the relationship between acceleration and pore water pressure is analyzed under different conditions. The results show that a high excess pore water pressure leads to high velocity of flow, and the pressure increases during the movement; and acceleration increases with time and flow depth under given pore water pressure. Moreover, compared with the flow with mixed grains, the flow with overlying coarse-grained layer is more effective to promote the excess pore water pressure and the liquefaction slip surface. Therefore, the internal drag reduction due to pore water pressure produces an acceleration effect on the flow.

Introduction

Debris flow is a complex multi-phase fluid characterized by wide-ranged granular materials; and the viscous debris flow (with density greater than 2.0 t/m3) is the most typical representative for the dynamical appearances (Chen, 1983; Pierson and Costa, 1987; Wu et al., 1990; Scott et al., 1995; Pérez, 2001; Kang et al., 2004). The fact that high-density debris flows move at a high velocity on gentle slopes has attracted general attentions (e.g., Rodine and Johnson, 1976; Pierson, 1981). Resistance to the movement involves two components: the external resistance from the contact surface between flow and boundary materials, and the internal resistance from the friction between grains and the inelastic collision (Zhu et al., 2013). However, calculations of velocity mainly take the external characteristics into consideration. For example, the Manning’s formula based on gradient, hydraulic radius, and roughness coefficient (Wei and Hu, 2009; Tian, 2013) does not incorporate the inherent mechanism of high mobility (Liu and Li, 2016). It is also believed that the residual layer left by the preceding flow makes the channel smooth and reduces the resistance for the subsequent flows (Wang et al., 2001; Zhang et al., 2003). However, the increase in the flow velocity depends not only on the obstruction of the streambed, but also on the granular characteristics of flow.

Granular features are commonly conspicuous in debris flows (Takahashi et al., 1992; Coussot and Meunier, 1996; Iverson, 1997; Sohn, 2000; Shu et al., 2012; Li et al., 2015; Kaitna et al., 2016), which have been especially exemplified by debris flows in Jiangjia Gully (JJG) (Cui et al., 2005; Liu et al., 2008, 2009; Hu et al., 2011; Li et al., 2012; Yang et al., 2019). Grain composition and rheological properties vary continuously during the development of debris flow, and the variation in grain composition is closely related to viscosity, density, and flow velocity (Zhang and Xiong, 1997; Iverson and Denlinger, 2001; Iverson and Vallance, 2001; Li et al., 2015). The interaction between grains, as well as the related inter-grain pore water, is very important for the formation and movement of debris flows (Zhou, 2014). The increase in excess pore water pressure has a significant effect on reducing the anti-sliding strength (Brunsden and Prior, 1984), and thus the key to the high velocity of flow is the generation and maintenance of high-porosity water pressure (Wang and Fei, 1999; Major, 2000; Gabet and Mudd, 2006; Kokelaar et al., 2014). The increase in volume concentration (or density) and the coexistence of coarse and fine grains are two important ways to cause the increase in pore water pressure (Pudasaini et al., 2005; Okada and Ochiai, 2008; Li et al., 2015; Kaitna et al., 2016; Zhou et al., 2018). The excess pore water pressure can support the coarse grains suspension on flow surface. Conversely, the increase in coarse grains causes the compression of the flow space of the pore water, which in turn increases the pore water pressure (Qian and Wan, 1991).

Grain size segregation in debris flow also affects the movement process (Iverson et al., 2010). Studies have shown that grain size segregation has a profound impact on the mobility of immersed granular flows, and is strongly associated with the pore pressure distribution (Bagnold, 1954; Middleton, 1970; Remaitre et al., 2011; Jing et al., 2017; Cui et al., 2020; Zhou et al., 2020). In the granular flow and geophysical flow communities, the mechanism of the development of pore water pressure and its critical role in determining mobility have been widely concerned, and some quantitative relationships have been obtained (Iverson, 2005; Rondon et al., 2011; Meruane et al., 2012; Yang et al., 2020). However, the mechanism of pore water pressure generated by different granular configurations due to grain size segregation has not been systematically studied.

In this paper, based on observations in JJG, we propose the effect of the overlying coarse-grained layer (i.e., the inverse grading structure) on pore water pressure and its implication in mobility maintenance of debris flow, establish the mechanism for the flow acceleration, and conduct a quantitative analysis of the proposed equations. This is expected to be heuristic in developing dynamical theory of debris flow.

Methodology

This study attempts to propose a mechanism of debris flow acceleration based on observation of active debris flows. At first we describe the phenomena of surges in different flow regimes and with different grain compositions, and identify two types of granular configurations, namely, one with overlying coarse-grained layer and the other with fully mixed grains. The basic parameters (density and velocity) are obtained and the flow materials sampled.

Then the difference of stress distribution caused by granular configuration is simulated using finite element method. A simplified model is established by using Geostudio simulation software for stress and deformation analysis (GeoStudio, 2005, v.4). Coupled with GEO-SLOPE/W and Sigma/W modules, the stress redistribution of two loading modes (layered concentrated loading and point dispersed loading) is analyzed. Finally, under the simplified model, the velocity equation is established theoretically, the acceleration mechanism of debris flow under the influence of grain configuration is proposed, and the acceleration levels of the two configurations are compared quantitatively.

Granular Characteristics of Debris Flow

Field Observation

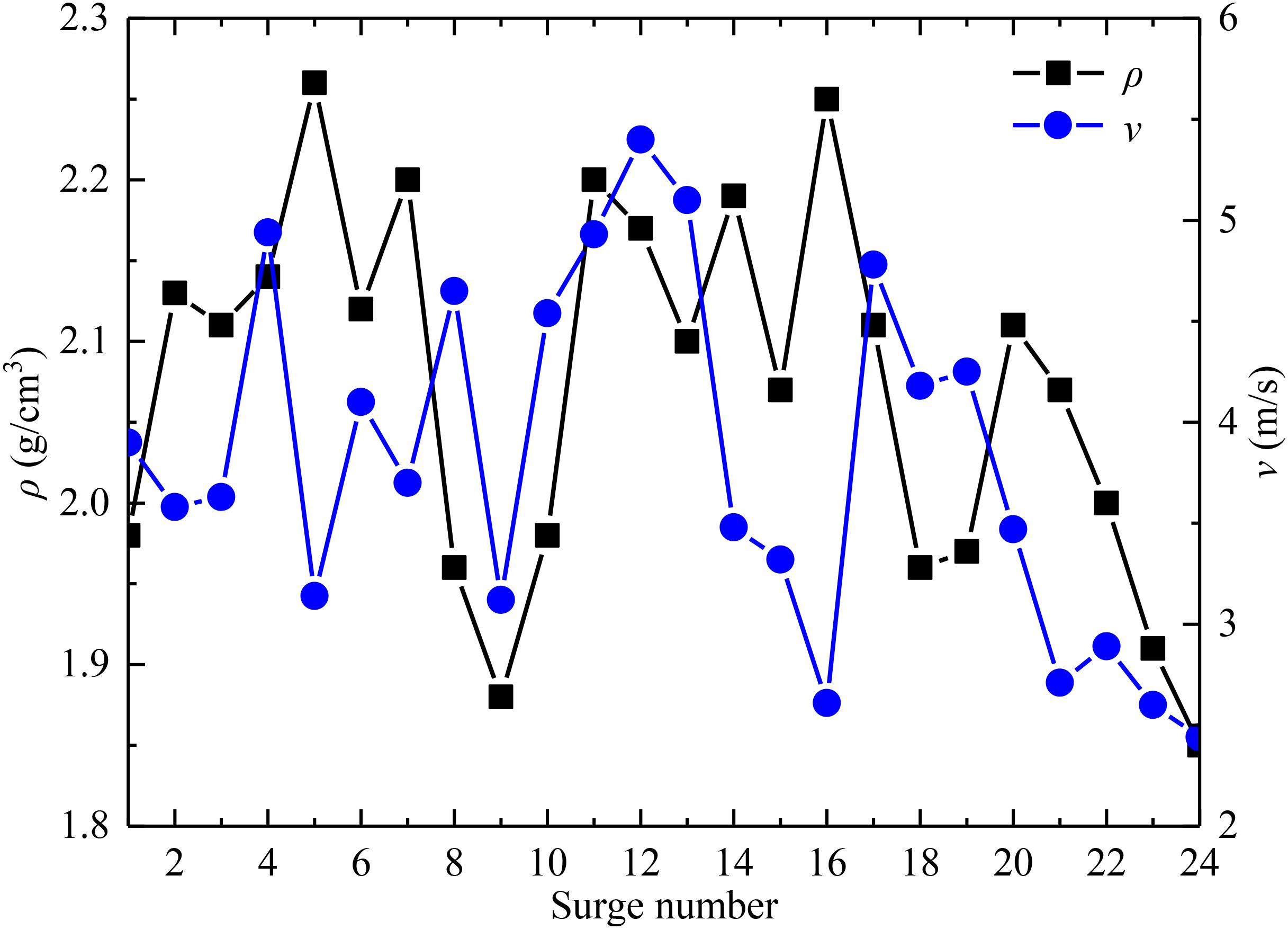

It has been observed that debris flows can move at high velocity in gentle channel, and there exists a power function relationship between the maximum velocity and density, that is, the greater the density, the greater the maximum velocity (e.g., Li et al., 2015). In a small tributary gully in JJG we have witnessed a sequence of surges that well corroborate the observation. In particular, we find how the flow mobility is influenced by the granular configurations of the flow. The streamlength of the gully is 0.8 km, and the downstream is 0.45 km with a slope of 5–10°. In such a gentle channel we observed a total of 24 surges emerging, as shown in Figure 1, which displays the fluctuation of flow density and velocity.

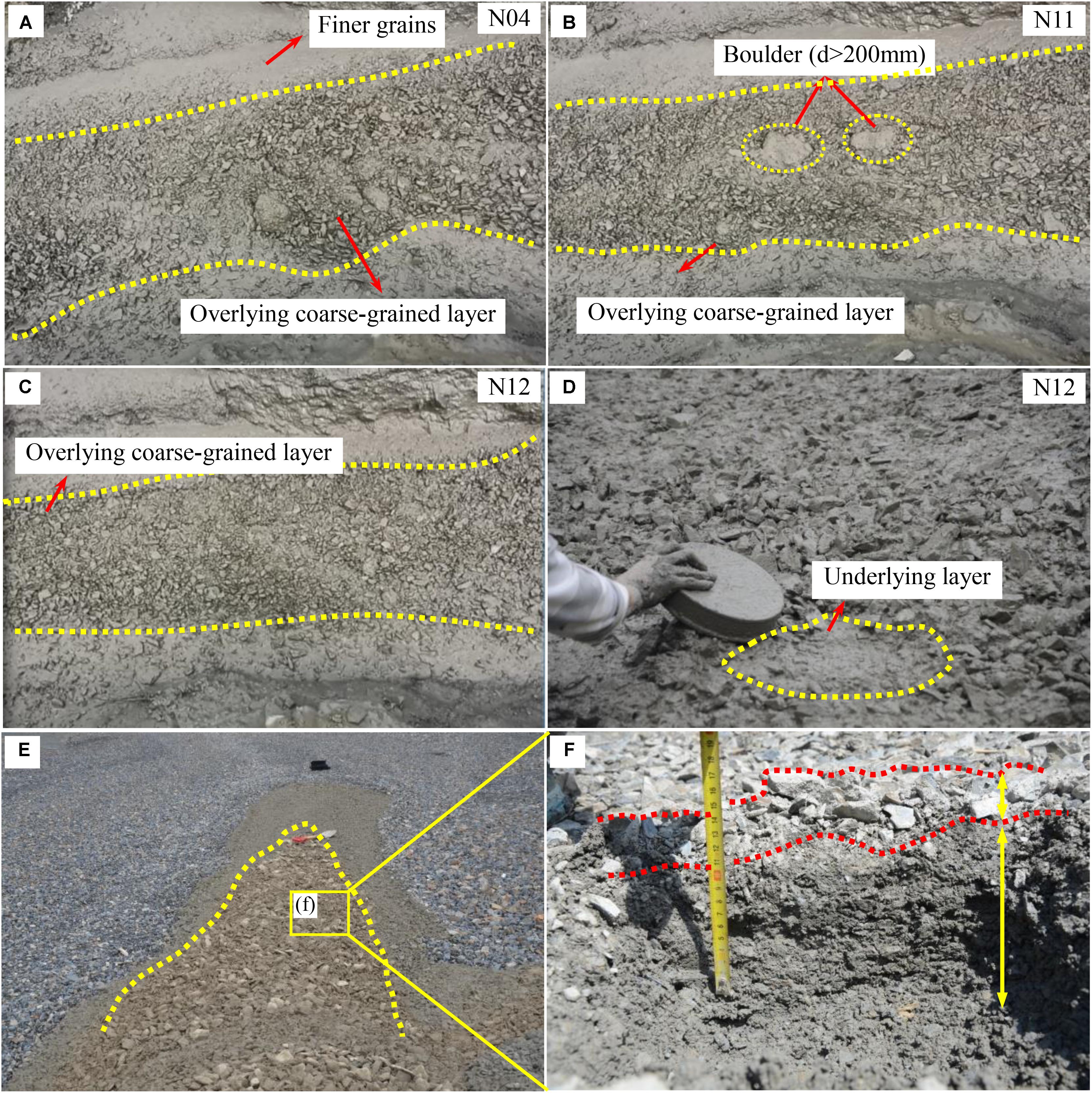

According to our observations, the flows present two typical granular configurations: one with upper coarse-grained layer (case a), and the other with grains completely mixed throughout the body (case b). Among the 24 surges, we find three, i.e., N04, N11, and N12, have high concentration of coarse grains on the surface (Figure 2). The overlying coarse-grained layer seems to float on the surface of the flow, with little change in position. These surges move faster than others, indicating the possible influence of granular configuration on flow mobility.

Figure 2. Field investigation; (A) Surge 04, (B) Surge N11, and (C) Surge N12. (D) After the gravels on the surface of surge N04 is dismantled, the underlying layer with finer grains is revealed. (E) Deposition of overlying coarse-grained layer near the tributary gully. (F) Cross section of the rectangular frame in panel (E), with a depth of 15 cm.

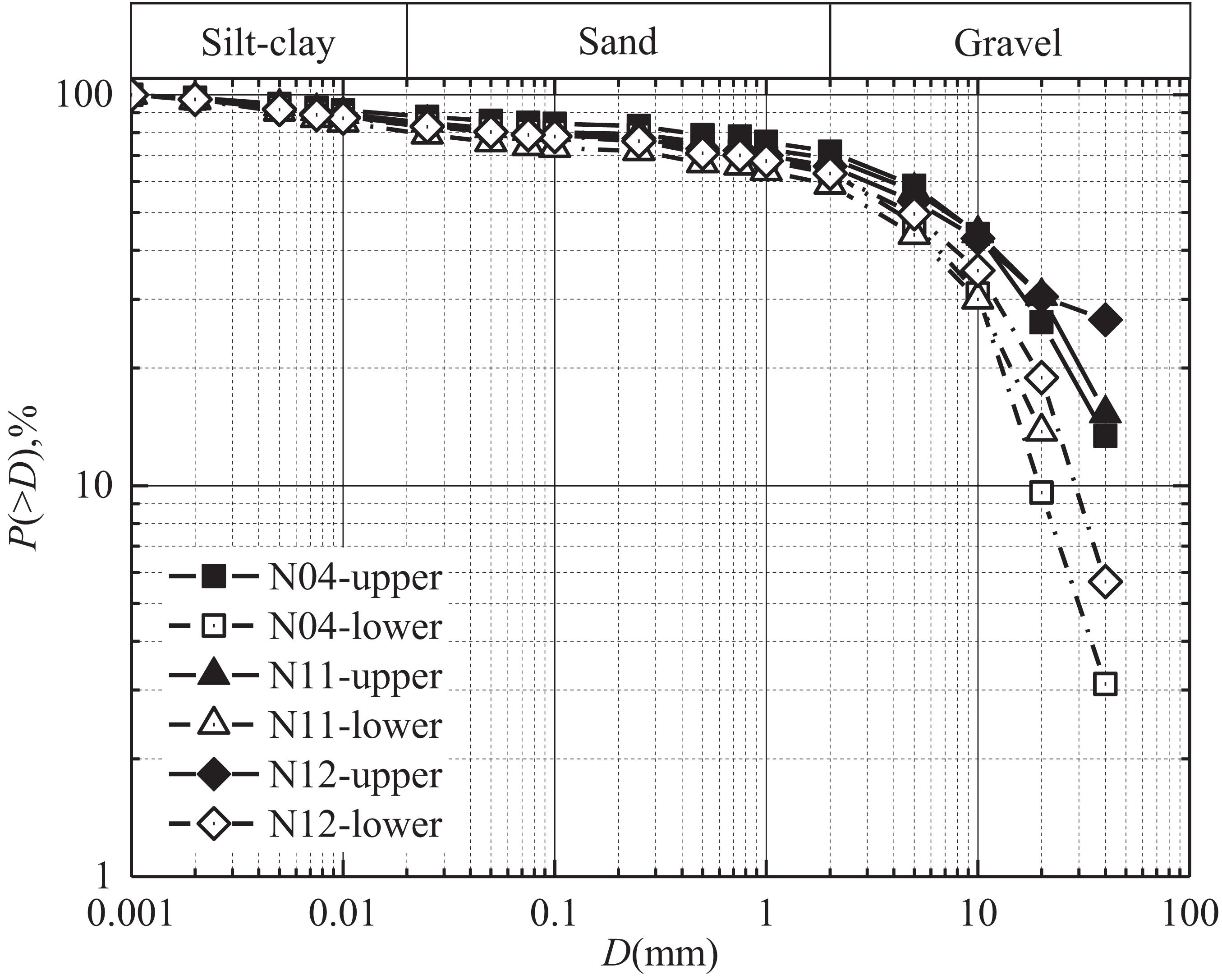

The three surges were sampled on site by firstly scraping the surface of the debris flow and storing it, and then the underlying flow was sampled. Figure 3 compares the grain size distribution (GSD) of the overlying and underlying layers via cumulative curve of grain size frequency.

Grain Size Distribution

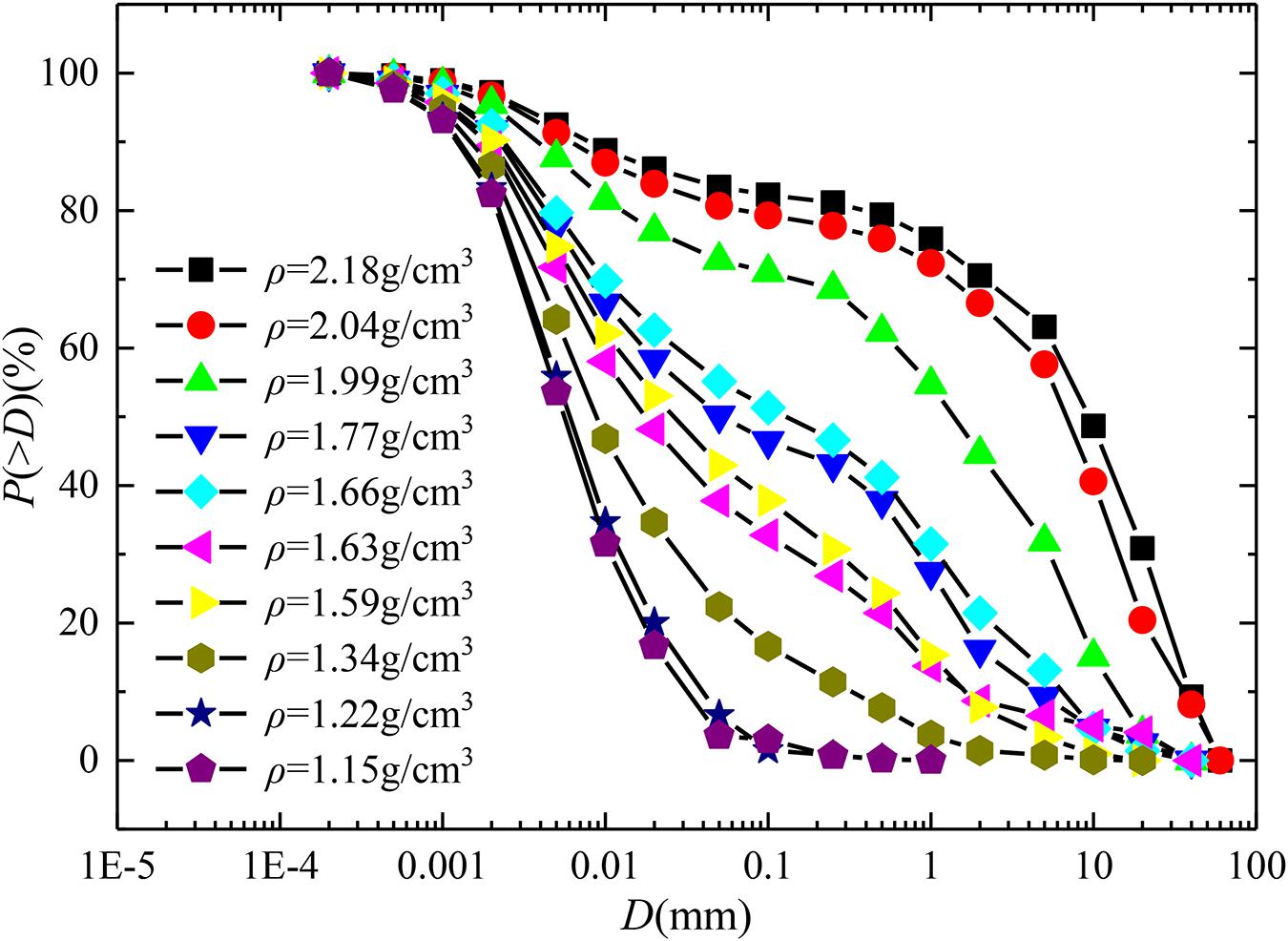

Furthermore, the grain size distribution can be described by the scaling expression (Li et al., 2013):

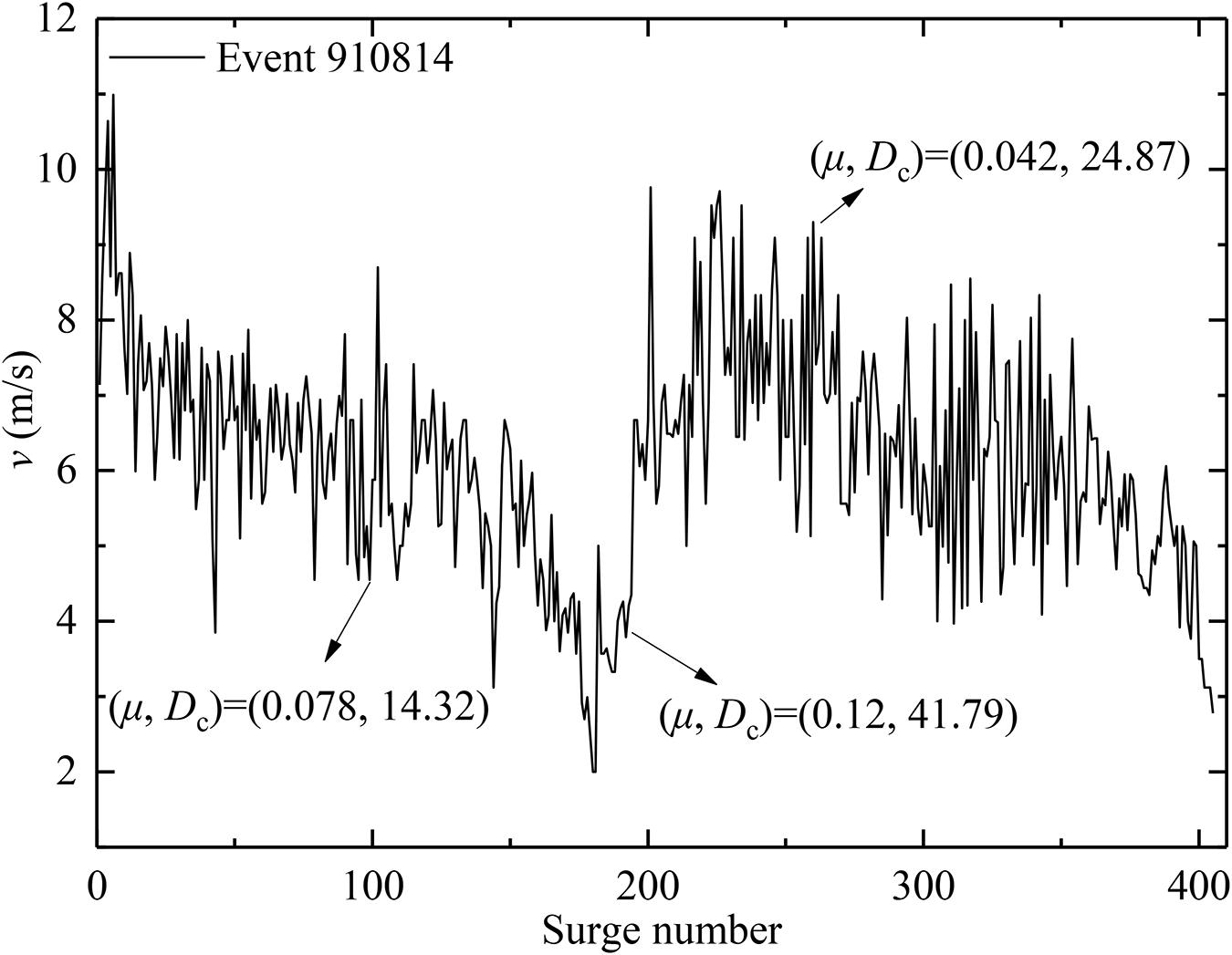

Where C, μ, and Dc are parameters, and D is the grain size (mm). Since C and μ show a definite logarithmic relationship, Eq. 1 can give two parameters: μ and Dc, which can reflect the variation characteristics of GSD. P(D) is the percentage of grains larger than the grain size D, and the GSD is featured by the parameter pair (μ, Dc), in which μ reflects the fine content and Dc is a characteristic grain size reflecting the range of grain composition. The fluctuation of debris flow is found to be closely related to the grain composition (Li et al., 2015, 2016). Figure 4 shows GSD curves for surges at different densities. A debris flow event refers to a series of surges that occur within a certain period of time. The interval between surges usually ranges from tens of seconds to dozens of minutes. Usually, the time of the debris flow snout passing through the cross section of the observation point is taken as the occurrence time of the surge, and the parameters of the surge are arranged according to the occurrence time (or the order of surges), that is, to form a sequence and number (Liu et al., 2009). Figure 5 shows the surge velocity sequence numbered 910,814, which is derived from the time of the debris flow event. Here, it refers to the debris flow event on August 14, 1991. Figure 5 shows the velocity fluctuation of surges with different GSDs in debris flow event 910,814, which contains 405 surges. Recent study (Liu et al., 2020) has further proved that the flow velocity can be calculated more accurately by taking account into the GSD in the Manning formula. Therefore, the GSD parameters (μ, Dc) are adopted to characterize the granular property of the flow.

Granular Effect on Flow Velocity

Effect of Granular Configuration on Sliding Shear Force

The flow characteristics are conspicuous as observed:

(1) Although the flow inevitably moves irregularly in the local area, according to the field observation, the bulk state of the flow is relatively stable, and its flow regime is regarded as laminar flow when it is simplified and analyzed here. So the relative movement between the fluid layers belongs to the plane sliding type, and the slope surface is generally parallel to the moving interface between the layers;

(2) The flow depth ranges between 0.57 and 0.93 m, much smaller than the channel length. So the conceptual model can be simplified as the flow on an infinite long slope (Zhan et al., 2010).

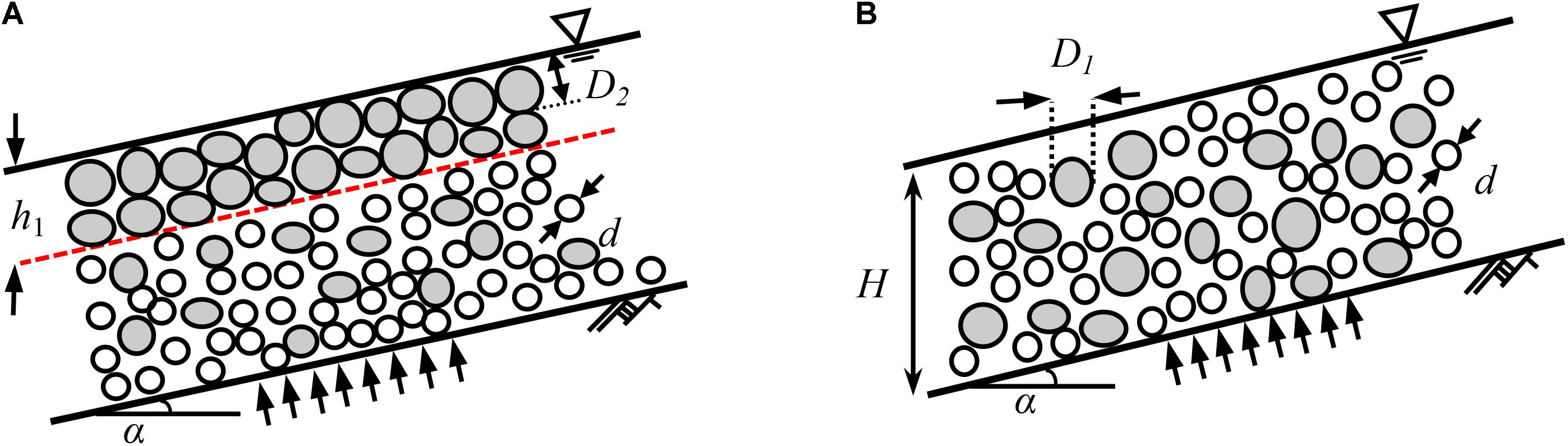

Based on our observations, the two types of granular configurations are sketched as Figures 6A,B. In case (a), the overlying coarse grain layer exhibits an almost negligible shear rate in the confined channel, which can be regarded as the unshearing additional load layer and moves as a whole with the strong shear layer at the bottom. In case (b), the flow is fully mixed with grains and no grain separation occurs. As the increase in coarse grains will elevate the yield stress (Pellegrino and Schippa, 2018), the grains gathering on the surface will inevitably lead to the change of the overall stress due to the change of load form, and ultimately have an impact on the subsequent motion characteristics.

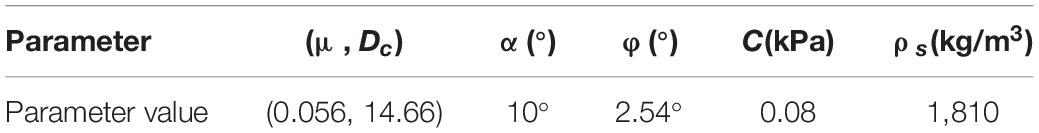

The model consists of two layers of soil. The internal friction angle φ of debris flow is generally less than 10°, and it is assumed that the yield stress of slurry (d < 5 mm) is the cohesion c of debris flow, which is generally less than 0.1 kPa (Schatzmann et al., 2009; Wang et al., 2014). Here, the upper soil defines the strength parameter as (c, φ) = (0.08 kPa, 2.54°), the lower soil strength parameter is (c, φ) = (0.07 kPa, 3.50°), and the slope is 10.5°. In the SIGMA / W module, an elastic modulus of 4 kPa is applied to the upper soil material, the Poisson’s ratio is 0.45, and the unit weight is 2,000 KN / m3. The lower layer has an elastic modulus of 3 kPa, a Poisson’s ratio of 0.45, and a unit weight of 2,500 KN / m3. It should be noted that both small-scale analytical models and numerical models will encounter the problem of similarity with natural events, which has not been well solved (Coussot and Meunier, 1996). It is worth noting that since our aim is to simplify and compare the stress distribution (especially the slip force) produced by the two particle configurations through Finite Element Method (FEM), but not to seek a complete simulation of natural debris flow, we do not examine all possible terms and processes in detail, nor describe all possible debris flow characteristics.

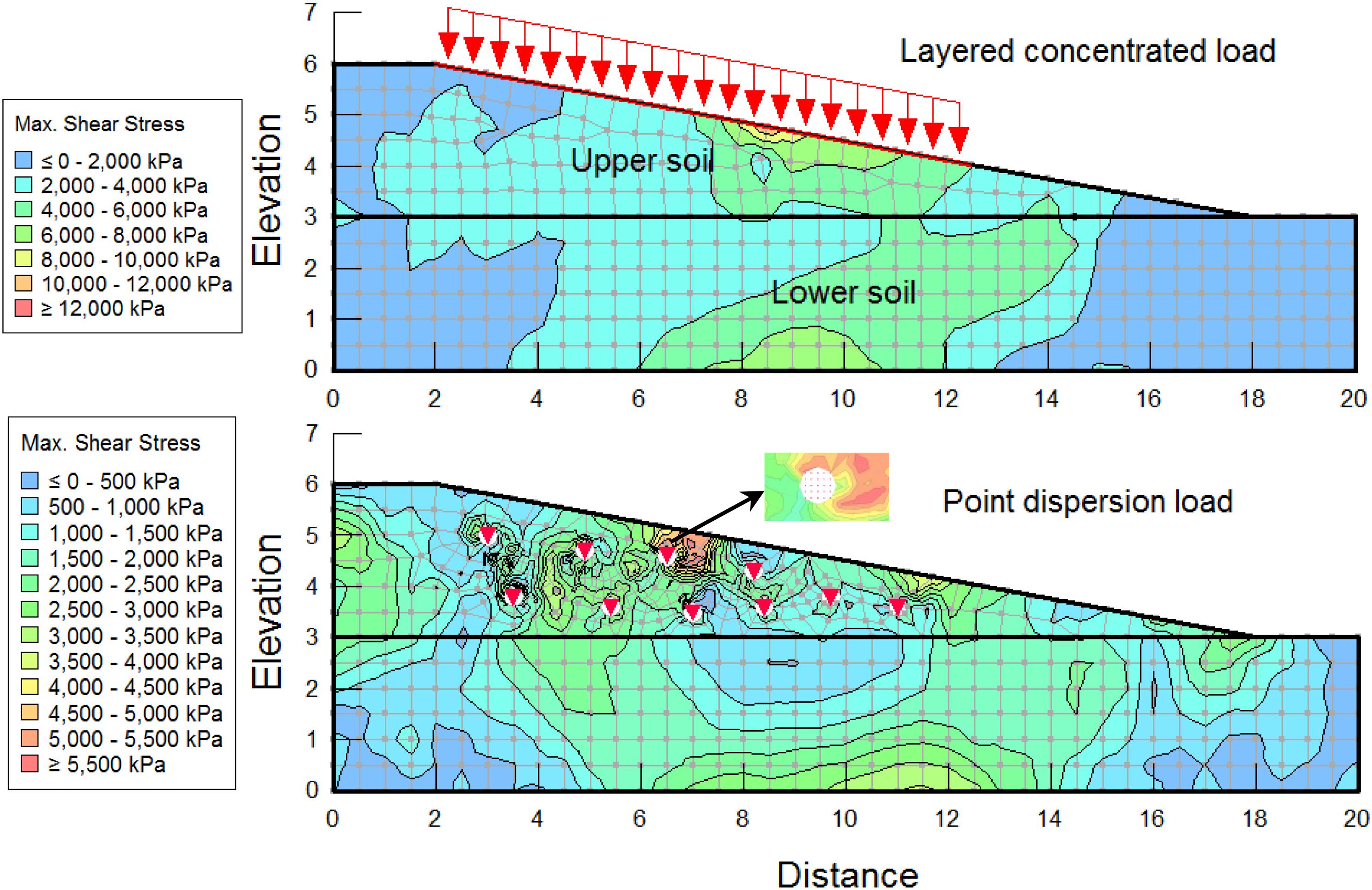

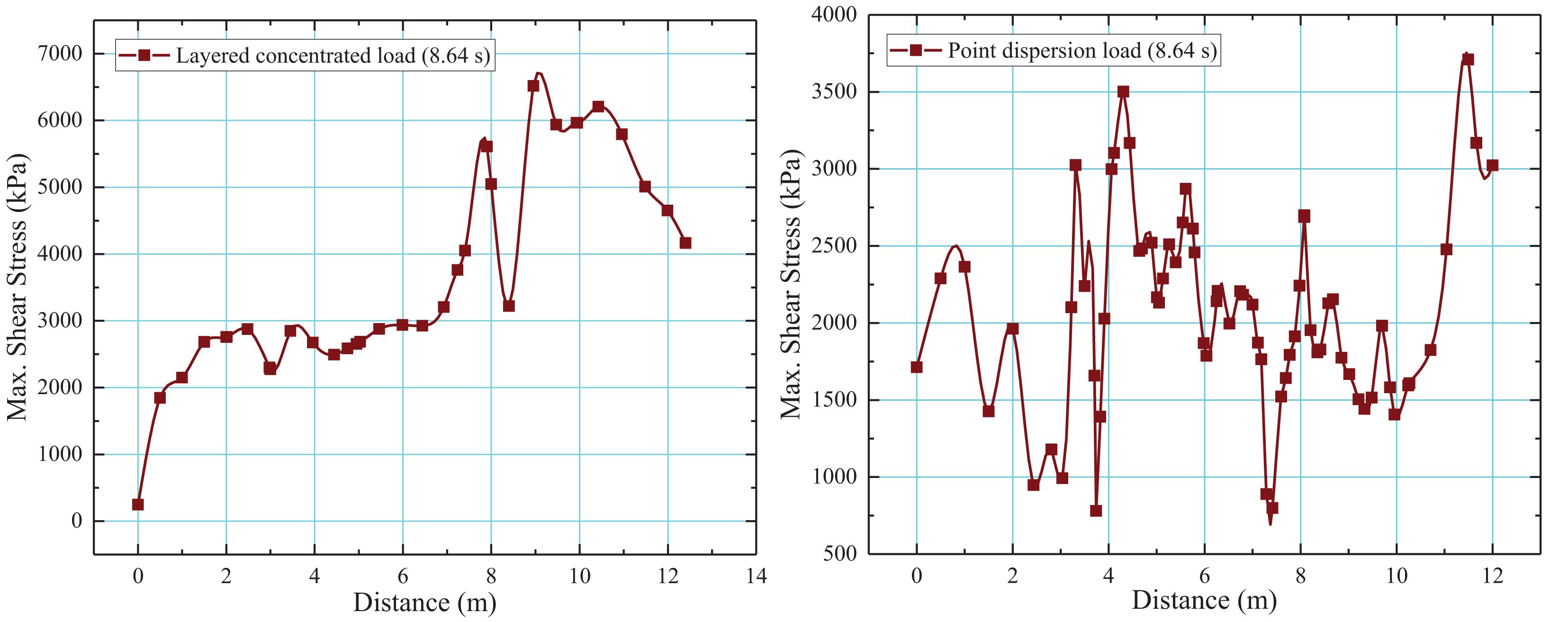

For the case (a), 10 kPa vertical stress (indicated by red arrow) is applied on the slope surface and the solution time is set as 8.64 s; and for case (b), 10 circular areas with a radius of 0.25 m in the material model were drawn, and then 10 kPa load was evenly distributed in the material of the circular area, that is, each circular area has vertical stress 1 kPa. The shear force distribution is shown in Figure 7, from which one can see that the layered concentrated load can cause the stress to be redistributed in a larger range and degree, while the point load can only cause a large local change. Thus, the load applied on the slope surface is more likely to cause the change of the shear force, and the increase is greater. If the load is evenly distributed in the model material body, it will not produce substantive shear slip channel for the model. A monitoring line (blue dotted line in the figure) is set in the model to monitor the transverse shear force, with results shown in Figure 8. It is observed that in two different load forms, the redistributed shear force values caused by layered concentrated load are significantly higher than those caused by the point load. The range of redistributed shear force values caused by layered concentrated load is mainly between 2,000 and 6,000 kPa, and the point load is mainly between 1,000 and 3,500 kPa. The spatial difference after stress redistribution indicates that the layered concentrated load on the surface is more conducive to the generation of shear sliding force.

Granular Configuration and Pore Water Pressure

Case a: Flow With Overlying Coarse-Grained Layer

Now we consider the pore water pressure (Pp) for the two cases. Generally, Up changes with the depth h, i.e.,

For the homogeneous flow (underlying layer) containing solid grains, pore water pressure is:

where ρw and ρm refer to the density of water and the fluid containing solid grains, respectively, and h is the depth of debris flow.

Because the pore pressure is closely related to the solid volumetric concentration (Cv) at the flow depth h, the excess pore pressure can be expressed as:

where ρr is the density of solid grains and ρm refers to the density of the fluid containing solid grains. Here, it is assumed that the solid grains in the fluid are uniformly dispersed, and the fluid density of the underlying layer is ρm. According to the following equation:

Eq. 4 can be rewritten as

Due to high grain concentration, the underlying layer exhibits high buoyancy and is characterized by viscoelasticity. When the coarse-grained skeleton is thoroughly mixed with the viscous medium, both of them carry the stress, and the density of overlying layer is basically regarded as the solid density ρr, and the normal stress in underlying layer is

The effective stress σ1 is

By combining Equations 6–8, the following formula can be obtained:

The overlying coarse-grained layer is supposed to be an unsaturated zone, so

The underlying layer is supposed to be a saturated zone, so we can get

and

where Gr and Gr′ respectively, refer to the relative density of overlying coarse-grained layer and underlying layer; e and e′are, respectively, the void ratio of overlying coarse-grained layer and underlying layer; ω is the saturated water content; St and denote the saturation of overlying coarse-grained layer and underlying layer, respectively. By adding Equations 9–11 to Equation 12, the effective stress can be obtained:

Case b: Flow With Fully Mixed Grains

For case (b), when there is no coarse-grained layer on the surface of the debris flow, the flow is considered to be homogeneously mixed, and the natural density of the soil is ρs. Since the density of this high-density debris flow uniformly mixed with grains can be directly estimated by the GSD parameters (μ, Dc), the above derivation can be simplified as follows for ease of the follow-up analysis of the calculation case, and the derivation process is as follows:

Then,

The shear strength is expressed as:

The sliding force in the shear direction is:

According to the density calculation formula (Wang et al., 2017):

The following equation can be obtained:

Granular Effect on Acceleration

For case (a), according to Coulomb’s theory, the shear strength τf (kPa) of micro-element fluid in the underlying layer can be expressed as:

where c is the cohesion and φ is the angle of internal friction. In order to facilitate the calculation, we assume that the c value is the measured yield stress value of debris flow slurry (d < 5 mm). By adding Eq. 13 to Eq. 20, we can get:

The sliding force of underlying layer is equal to the sum of the component force in the shear direction caused by the gravity of micro-element fluid (G′) and the penetrating force component (J′) of water in solid grains:

It is supposed that a(m/s2) is the flow accelerated velocity and m(kg) is the mass per unit volume, and the viscous resistance in the shear sliding zone is not taken into consideration. According to Newton’s second law, we can know:

For unit volume of debris flow, by combining Equations 22, 23, we can know:

By figuring out the partial derivative with respect to t for Eq. 24, we can get:

The simultaneous formulas (19) and (23) are available:

Then the partial differential with respect to t for Equation 25 gives:

Quantitative Analysis

Case a: Flow With Overlying Coarse-Grained Layer

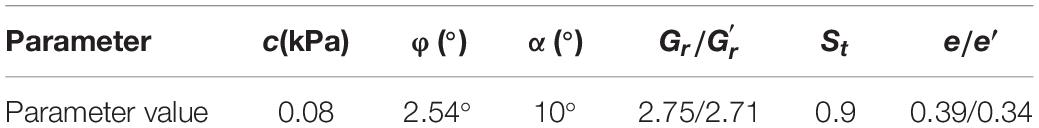

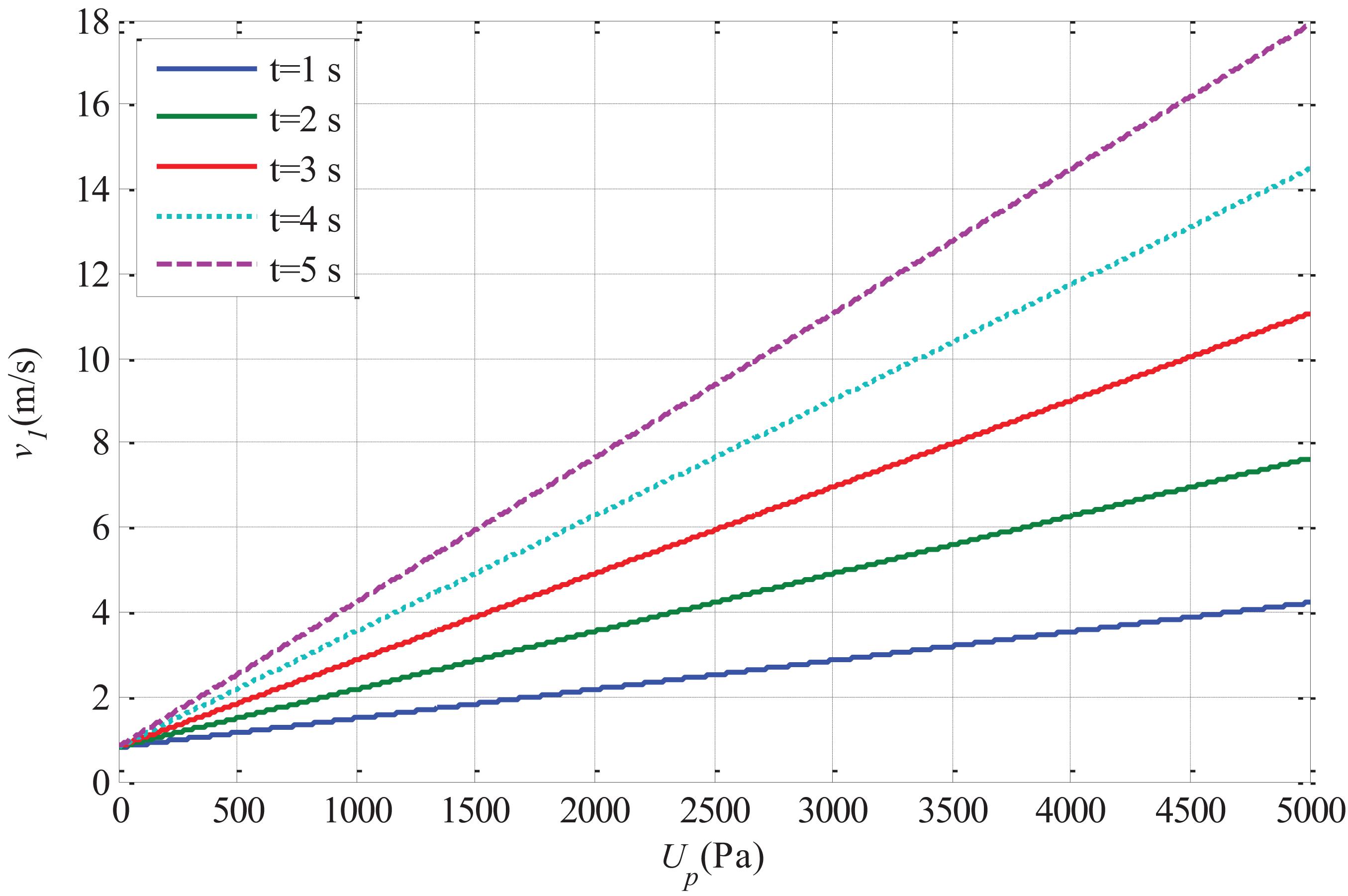

Now we apply the Equations 24, 25 above to the case (a) of the observed debris flows, with parameters listed in Table 1. The mass per unit volume is 2,000 kg, and the initial flow velocity is v0 = 1.5 m/s, assuming the thickness of the overlying coarse layer, h1 = 0.25 m, and the thickness of the underlying layer, h2 = 0.75 m. The basic calculation parameters of the debris flow are shown in Table 2.

Then the “v1-Up” and “a1-Up” relationships can be obtained for surges with overlying coarse-grained layer (Figures 9, 10).

It can be seen that both the velocity and the acceleration are positively correlated with the pore water pressure. The remaining sliding force continues to decrease, and the fluidity increases, greatly reducing the time for the debris flow to move to the channel outlet. However, when the residual sliding force is zero, the debris flow is stable and slow.

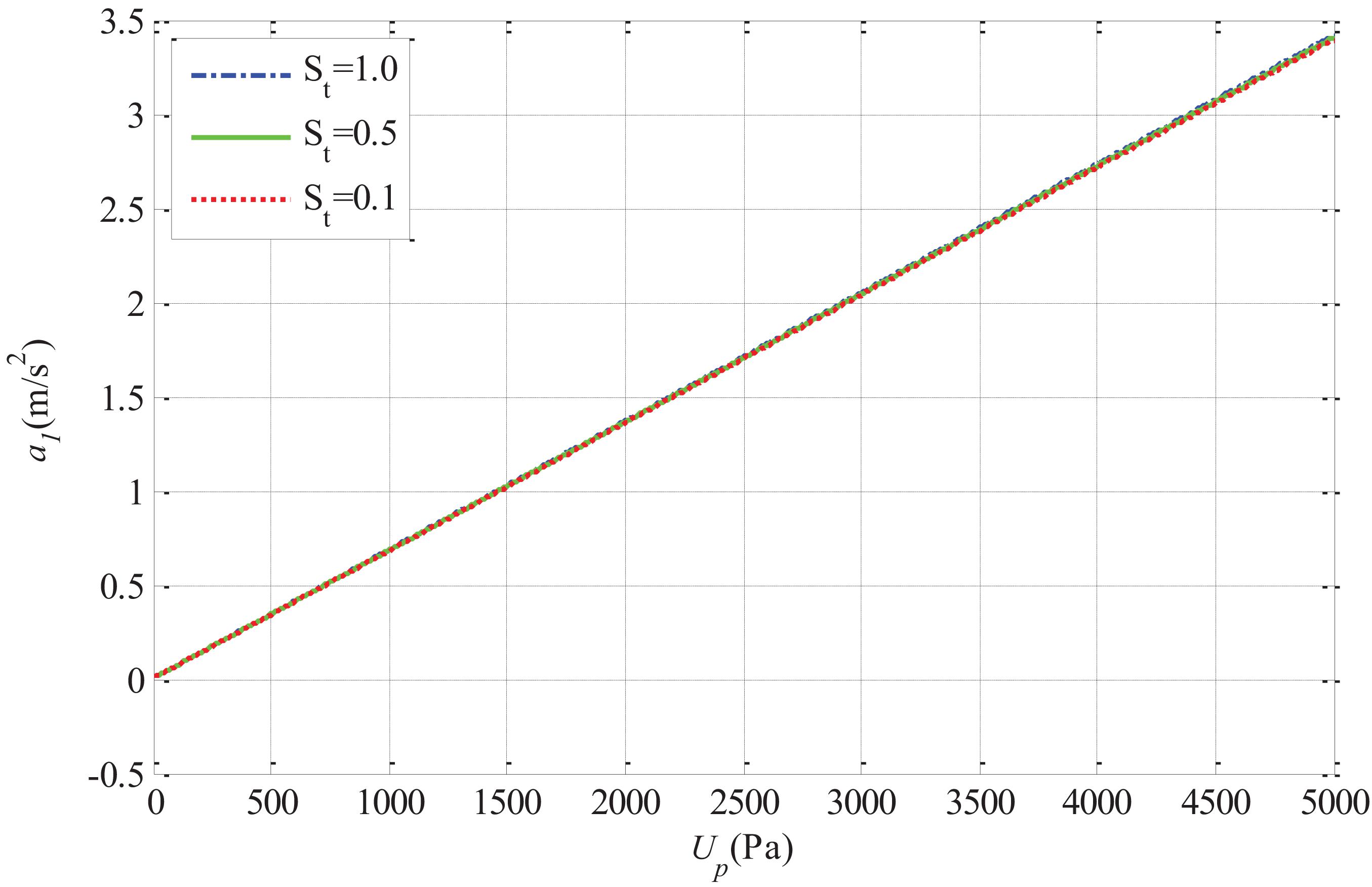

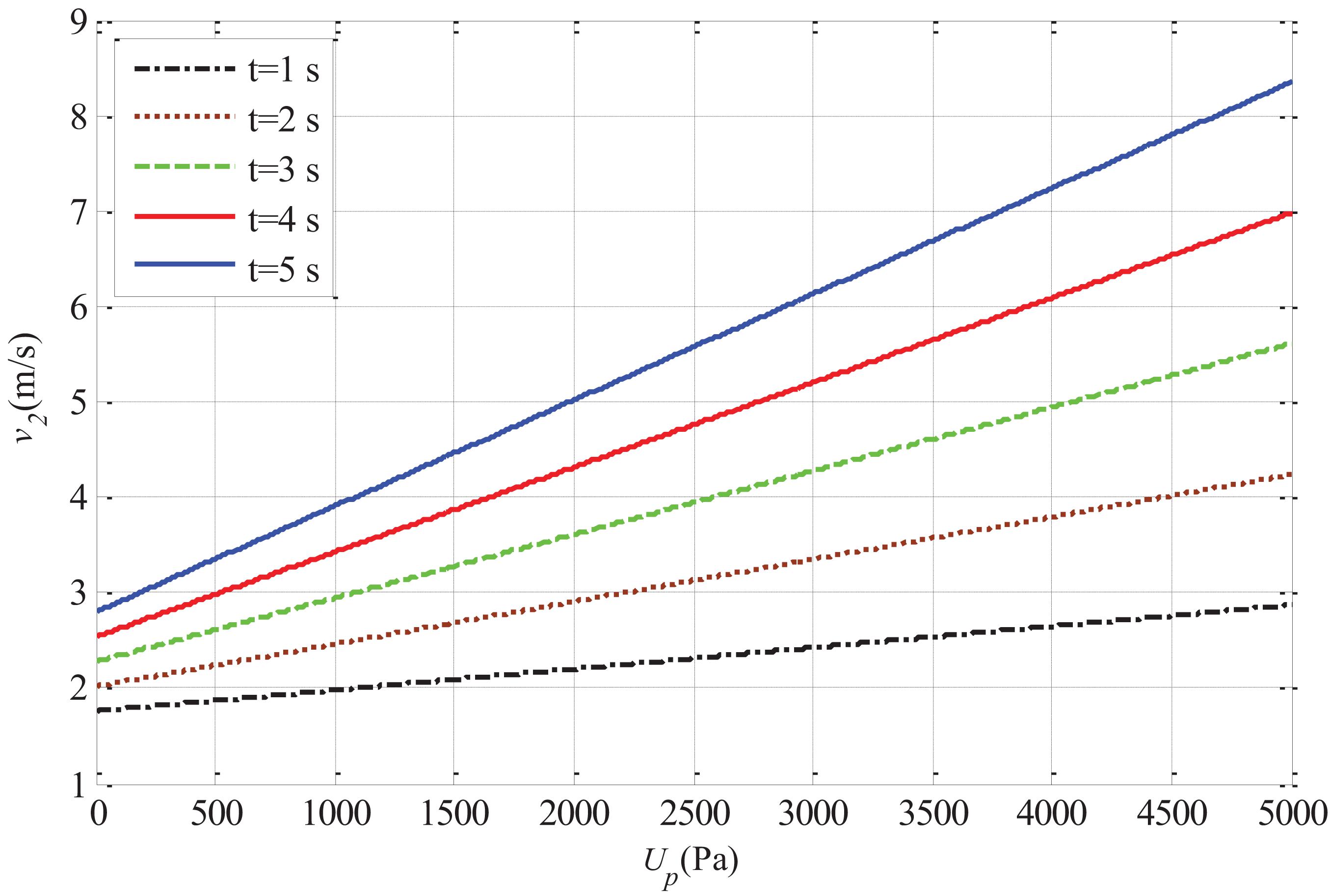

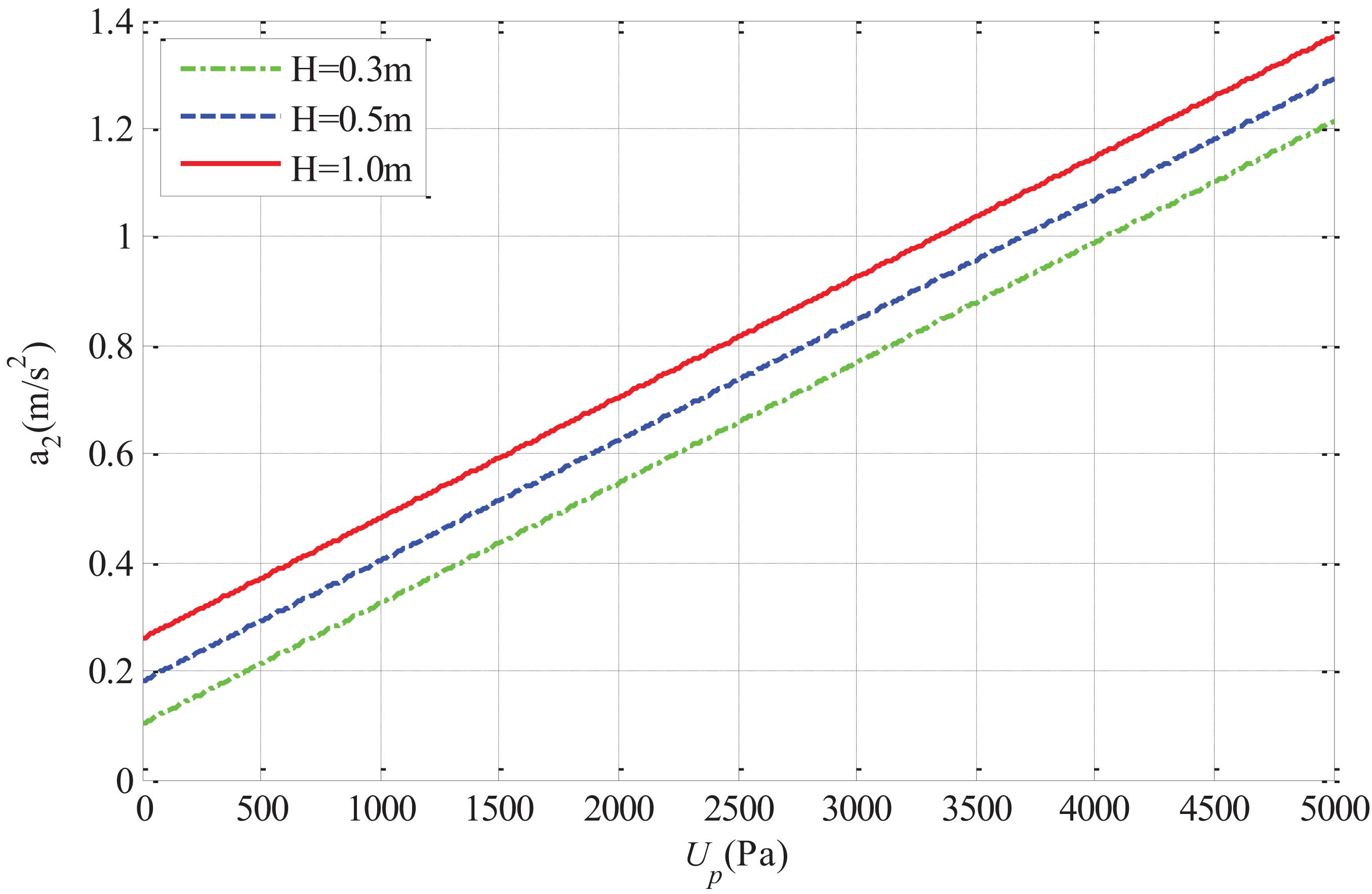

Case b: Flow With Fully Mixed Grains

For the debris flow with mixed grains, the v2-Up relationship is shown in Figure 11, with parameters listed in Table 1.

Figure 12 reflects the acceleration changes at different depths. The vertical load form generated by the aggregation of coarse particles on the surface of the debris flow is beneficial to the formation of high excess pore water pressure and then accelerates the liquefaction of the sliding surface. It can be seen that under the same pore water pressure condition, the larger the flow depth, the greater the acceleration, which is mainly because the increase in the sliding force promotes the acceleration.

Compared with the case (a), the rate of acceleration growth in case (b) is small. If the debris flow appears as a homogeneous fluid with good integrity, and there is no grain separation, the pore pressure does not change much during the movement, the pore water pressure does not continue to increase and be maintained, and therefore does not have an acceleration effect on the flow.

Discussion

Due to the difficulty of obtaining granular properties from active debris flows in the field, grain composition and separation are often neglected despite their profound impact on debris flow dynamics (Scheidl and Rickenmann, 2010; Hürlimann et al., 2015). In this study, we found that granular configuration has a certain influence on mobility, which mainly includes layered configuration (including overlying coarse-grained layer) and mixed configuration (uniform mixing of grains). Both the configurations produce different forms of stress distribution and lead to different level of acceleration. Excess pore water pressure and viscoplastic yield stress are two important processes that cause debris flow deposition (Johnson, 1970; Hutchinson, 1986; Coussot and Proust, 1996). The low dissipation rate of excess pore water pressure and the decrease of viscoplastic yield stress can promote the continuous movement of debris flow. Stress analysis of the two configurations is helpful for better understanding the granular effect in debris flow dynamics.

We know that the excess pore water pressure is caused by the change of the total stress on the soil unit, which is easy to occur in granular materials with larger compressibility and smaller permeability coefficient. Debris flow permeability is related to the grain size, and the wide-graded particle composition is conducive to water confinement and low permeability (Gabet and Mudd, 2006; Sterling and Slaymaker, 2007). There are many narrow pores between grains, and the layered concentrated load formed by conspicuous gravel accumulation in the upper part further facilitates the lower fluid to be compressed and thus generate excess pore water pressure, which makes the debris flow liquefy and accelerates its movement. The bottom of the flow mass first liquefies to form a liquefied sliding surface, which reduces the sliding resistance and accelerates the flow of the debris flow. In addition, the layered concentrated load in the lower part caused by the aggregate surface is more conducive to the shearing and sliding of the debris flow, thereby promoting the continuous movement on the gentle slope. The coarse grains drift toward the top of the shear layer, followed by relatively small grains, and fine and dense grains gather at the bottom. The separation of coarse grains from the bottom fluid helps to reduce the yield stress (Pellegrino and Schippa, 2018). In the meantime, the increase in the content of fine grains contributes to the maintenance of excess pore water pressure (De Haas et al., 2015), while the relative increase in fine grains in the lower part contributes to the drag reduction of the channel bed (Toms, 1948; Gust, 1976; Heywood and Richardson, 1978; Lian and Hong, 1994). All these factors slow down the deposition process of debris flow. The dynamic change of coarse and fine grains affects the rheological properties, for example, when the solid volume concentration of coarse grains is less than that of fine grains, the static and dynamic yield stress will be significantly reduced (Kaitna et al., 2007; Pellegrino and Schippa, 2018).

The separation of coarse grains is conducive to reducing discrete shear resistance. In addition, because coarse grains gather on the surface, the high-density debris flow has a higher normal pressure (or additional pore pressure), which further reduces the effective weight of coarse grains in the lower fluid and weakens the settling speed of laminar grains (Gabet and Mudd, 2006). As thus, the slowing down of the settling speed of the grains in the flow allows the lower fluid to maintain the wide grain size distribution or poor sorting of the granular phase, which contributes to the generation and maintenance of high excess pore water pressure (Pierson, 1981). During the movement of debris flow, the grains will undergo continuous adjustment. This process is generally concomitant with the redistribution of internal stress and excess pore water pressure. The redistribution of the two parameters will in turn affect the velocity of debris flow. Research on debris flow mobility on gentle slopes should not merely consider the external resistance (resistance reduction of the bed), but pay more attention to the self-acceleration effect between grains.

Conclusion

Based on field observations of debris flow surges, this study proposes a dynamical model for debris flow acceleration due to pore water pressure associated with granular configurations. It is found that flow with overlying coarse grains is more likely to give rise to a high pore water pressure and thus obtain a high mobility. Specific conclusions can be drawn as follows: Debris flow movement promotes the separation of different grain sizes, and the segregated grains cause differences in load patterns. When coarse grains separate and accumulate on the surface of debris flow, a layered concentrated load is formed on the surface. This change promotes the redistribution of the internal stress of the flow body and increases the sliding shear force and hence the excess pore water pressure to a greater extent, which intensifies the formation of the liquefaction slip surface in the debris flow. The separation and accumulation of coarse grains on the surface of debris flow is a significant granular configuration that promotes the generation of excess pore water pressure and hence accelerates the debris flow.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author Contributions

TY produced the figures and wrote the manuscript. YL and XG were responsible for the main idea of the manuscript and contributed to the manuscript revision. JZ, YJ, XL, and JL provided input to figure and text editing. All authors contributed to the article and approved the submitted version.

Funding

This research is supported by the CAS Strategic Priority Research Program (XDA23090202) and the Natural Science Foundation of China (Grant Nos. 41790432, 41977257, and 41877261).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

Bagnold, R. A. (1954). Experiments on gravity-free dispersion of large solid spheres in a newtonian fluid under shear. Proc. R. Soc. A. 225, 49–63. doi: 10.1098/rspa.1954.0186

Coussot, P., and Meunier, M. (1996). Recognition, classification and mechanical description of debris flows. Earth Sci. Rev. 40, 209–227. doi: 10.1016/0012-8252(95)00065-8

Coussot, P., and Proust, S. (1996). Slow, unconfined spreading of a mudflow. J. Geophys. Res.: Solid Earth 101, 25217–25229. doi: 10.1029/96JB02486

Cui, K. F., Zhou, G., Jing, L., Chen, X., and Song, D. (2020). Generalized friction and dilatancy laws for immersed granular flows consisting of large and small particles. Phys. Fluids 32:113312. doi: 10.1063/5.0024762

Cui, P., Chen, X. Q., Wang, Y. Y., Hu, K. H., and Li, Y. (2005). Jiangjia Ravine Debris Flows in South-western China. Berlin: Springer.

De Haas, T., Braat, L., Leuven, J. R. F. W., Lokhorst, I. R., and Kleinhans, M. G. (2015). Effects of debris flow composition on runout, depositional mechanisms, and deposit morphology in laboratory experiments. J. Geophys. Res. Earth Surface 120, 1949–1972. doi: 10.1002/2015JF003525

Gabet, E. J., and Mudd, S. M. (2006). The mobilization of debris flows from shallow landslides. Geomorphology 74, 207–218. doi: 10.1016/j.geomorph.2005.08.013

GeoStudio. (2005). v.4 GeoStudio Tutorials Includes Student Edition Lessons, 1st Edn. Calgary: Geo-Slope International Ltd.

Gust, G. (1976). Observations on turbulent-drag reduction in a dilute suspension of clay in sea-water. J. Fluid Mechan. 75, 29–47. doi: 10.1017/S0022112076000116

Heywood, N., and Richardson, J. (1978). “Head loss reduction by gas injection for highly shear-thinning suspensions in horizontal pipe flow,” in Proceedings of the Hydrotransport, (Germany), 146–152.

Hu, K. H., Wei, F. Q., and Li, Y. (2011). Real-time measurement and preliminary analysis of debris-flow impact force at Jiangjia Ravine, China. Earth Surface Processes Landforms 36, 1268–1278. doi: 10.1002/esp.2155

Hürlimann, M., McArdell, B. W., and Rickli, C. (2015). Field and laboratory analysis of the runout characteristics of hillslope debris flows in switzerland. Geomorphology 232, 20–32. doi: 10.1016/j.geomorph.2014.11.030

Hutchinson, J. (1986). A sliding–consolidation model for flow slides. Canadian Geotechn. J. 23, 115–126. doi: 10.1139/t86-021

Iverson, R. (2005). Regulation of landslide motion by dilatancy and pore pressure feedback. J. Geophys. Res. 110, 1–16. doi: 10.1029/2004JF000268

Iverson, R. M. (1997). The physics of debris flows. Rev. Geophys. 35, 245–296. doi: 10.1029/97RG00426

Iverson, R. M., and Denlinger, R. P. (2001). Flow of variably fluidized granular masses across three-dimensional terrain; 1, Coulomb mixture theory. J. Geophys. Res. Solid Earth 106, 537–552. doi: 10.1029/2000JB900329

Iverson, R. M., Logan, M., Lahusen, R. G., and Berti, M. (2010). The perfect debris flow? aggregated results from 28 large-scale experiments. J. Geophys. Res. Earth Surface 115:F03005. doi: 10.1029/2009JF001514

Iverson, R. M., and Vallance, J. W. (2001). New views of granular mass flows. Geology 29, 115–118. doi: 10.1130/0091-7613(2001)029<0115:nvogmf>2.0.co;2

Jing, L., Kwok, F., and Leung, A. (2017). Micromechanical origin of particle size segregation. Phys. Rev. Lett. 118:118001. doi: 10.1103/PhysRevLett.118.118001

Johnson, A. M. (1970). Physical Processes in Geology: A Method for Interpretation of Natural Phenomena—Intrusions in Igneous Rocks, Fractures, and Folds, Flow of Debris and Ice. California, CA: Freeman, Cooper and Co.

Kaitna, R., Palucis, M. C., Yohannes, B., Hill, K. M., and Dietrich, W. E. (2016). Effects of coarse grain size distribution and fine particle content on pore fluid pressure and shear behavior in experimental debris flows. J. Geophys. Res. Earth Surface 121, 415–441. doi: 10.1002/2015jf003725

Kaitna, R., Rickenmann, D., and Schatzmann, M. J. A. G. (2007). Experimental study on rheologic behaviour of debris flow material. Acta Geotech. 2, 71–85. doi: 10.1007/s11440-007-0026-z

Kang, Z., Li, Z., and Ma, A. (2004). Study on Debris Flow in China (in Chinese). Beijing: Science Press.

Kokelaar, B. P., Graham, R. L., Gray, J. M. N. T., and Vallance, J. W. (2014). Fine-grained linings of leveed channels facilitate runout of granular flows. Earth Plan. Sci. Lett. 385, 172–180. doi: 10.1016/j.epsl.2013.10.043

Li, Y., Gou, W. C., Wang, B. L., and Liu, D. C. (2016). Grain composition and the fluctuation of debris flow motion (in Chinese). Mountain Res. 34, 468–475.

Li, Y., Liu, J. J., Hu, K. H., and Su, P. C. (2012). Probability distribution of measured debris-flow velocity in Jiangjia Gully, Yunnan Province, China. Nat. Hazards 60, 689–701. doi: 10.1007/s11069-011-0033-0

Li, Y., Liu, J. J., Su, F. H., Xie, J., and Wang, B. L. (2015). Relationship between grain composition and debris flow characteristics: a case study of the Jiangjia Gully in China. Landslides 12, 19–28. doi: 10.1007/s10346-014-0475-z

Li, Y., Zhou, X. J., Su, P. C., Kong, Y. D., and Liu, J. J. (2013). A scaling distribution for grain composition of debris flow. Geomorphology 192, 30–42. doi: 10.1016/j.geomorph.2013.03.015

Lian, J., and Hong, R. (1994). Resistance characteristics of muddy bed surface (In Chinese). Chinese Sci. Bull. 39, 1796–1798.

Liu, D. C., Li, Y., You, Y., Liu, J. J., Wang, B. L., and Yu, B. (2020). Velocity of debris flow determined by grain composition. J. Hydraulic Eng. 146:06020010. doi: 10.1061/(asce)hy.1943-7900.0001761

Liu, J. J., and Li, Y. (2016). A review of study on drag reduction of viscous debris-flow residual layer. J. Sediment Res. 3, 72–80.

Liu, J. J., Li, Y., Cheng, Z. L., and Dang, C. (2008). Decaying of discharge of intermittent debris flow (in Chinese). J. Graduate School Chinese Acad. Sci. 25, 177–184.

Liu, J. J., Li, Y., Su, P. C., Cheng, Z. L., and Cui, P. (2009). Temporal variation of intermittent surges of debris flow. J. Hydrol. 365, 322–328. doi: 10.1016/j.jhydrol.2008.12.005

Major, J. J. (2000). Gravity-driven consolidation of granular slurries: implications for debris-flow deposition and deposit characteristics. J. Sedimentary Res. 70, 64–83. doi: 10.1306/2dc408ff-0e47-11d7-8643000102c1865d

Meruane, C., Tamburrino, A., and Roche, O. (2012). Dynamics of dense granular flows of small-and-large-grain mixtures in an ambient fluid. Phys. Rev. E. 86:026311. doi: 10.1103/PhysRevE.86.026311

Middleton, G. V. (1970). Experimental studies related to problems of flysch sedimentation. Flysch Sedimentol. North Am. 1970, 253–272.

Okada, Y., and Ochiai, H. (2008). Flow characteristics of 2-phase granular mass flows from model flume tests. Eng. Geol. 97, 1–14. doi: 10.1016/j.enggeo.2007.10.004

Pellegrino, A. M., and Schippa, L. J. E. E. S. (2018). A laboratory experience on the effect of grains concentration and coarse sediment on the rheology of natural debris-flows. Environ. Earth Sci. 77:749. doi: 10.1007/s12665-018-7934-0

Pérez, F. L. (2001). Matrix granulometry of catastrophic debris flows (December 1999) in central coastal Venezuela. Catena 45, 163–183. doi: 10.1016/S0341-8162(01)00149-7

Pierson, T. C. (1981). Dominant particle support mechanisms in debris flows at Mt Thomas, New Zealand, and implications for flow mobility. Sedimentology 28, 49–60. doi: 10.1111/j.1365-3091.1981.tb01662.x

Pierson, T. C., and Costa, J. E. (1987). “A rheologic classification of subaerial sediment–water flows,” in Debris Flows, Avalanches: Process, Recognition, and Mitigation. Geological Society of America Reviews in Engineering Geology, Vol. 7, eds J. E. Costa and G. F. Wieczorek (Boulder, CO: Geological Society of America), 1–12. doi: 10.1130/reg7-p1

Pudasaini, S. P., Wang, Y., and Hutter, K. (2005). Modelling debris flows down general channels. Nat. Hazards Earth System Sci. 5, 799–819. doi: 10.5194/nhess-5-799-2005

Remaitre, A., Malet, J. P., and Maquaire, O. (2011). Geomorphology and kinematics of debris flows with high entrainment rates: a case study in the South French Alps. Comptes Rendus Geosci. 343, 777–794. doi: 10.1016/j.crte.2011.09.007

Rodine, J. D., and Johnson, A. M. (1976). The ability of debris flow, heavily freighted with coarse clastic materials to flow on gentle slopes. Sedimentology 23, 213–234. doi: 10.1111/j.1365-3091.1976.tb00047.x

Rondon, L., Pouliquen, O., and Aussillous, P. (2011). Granular collapse in a fluid: role of the initial volume fraction. Phys. Fluids 23:073301. doi: 10.1063/1.3594200

Schatzmann, M., Bezzola, G., Minor, H. E., Windhab, E., and Fischer, P. J. R. A. (2009). Rheometry for large particulated fluids: analysis of the ball measuring system and comparison to debris flow rheometry. Rheol. Acta 48, 715–733. doi: 10.1007/s00397-009-0364-x

Scheidl, C., and Rickenmann, D. (2010). Empirical prediction of debris-flow mobility and deposition on fans. Earth Surface Processes Landforms 35, 157–173. doi: 10.1002/esp.1897

Scott, K. M., Vallance, J. W., and Pringle, P. T. (1995). Sedimentology, Behavior, and Hazards of Debris Flows at Mount Rainier. Washington: U.S. Geological Survey Professional Paper, 1547.

Shu, A. P., Yang, K., Li, F. H., and Pan, H. L. (2012). Characteristics of grain size and grain order distribution in the deposition processes for non-homogeneous debris flow (in Chinese). J. Hydraulic Eng. 43, 1322–1327. doi: 10.13243/j.cnki.slxb.2012.11.002

Sohn, Y. K. (2000). Coarse-grained debris-flow deposits in the miocene fan deltas, se Korea: a scaling analysis. Sedimentary Geol. 130, 45–64. doi: 10.1016/S0037-0738(99)00099-8

Sterling, S., and Slaymaker, O. (2007). Lithologic control of debris torrent occurrence. Geomorphology 86, 307–319. doi: 10.1016/j.geomorph.2006.09.002

Takahashi, T., Nakagawa, H., Harada, T., and Yamashiki, Y. (1992). Routing debris flows with particle segregation. J. Hydraulic Eng. 118, 1490–1507. doi: 10.1061/(asce)0733-9429(1992)118:11(1490)

Tian, M. (2013). Experimental Study on the Resistance Characteristics of Debris Flow Under Moving Bed Conditions (In Chinese). Master thesis, Huairou: University of Chinese Academy of Sciences.

Toms, B. A. (1948). “Some observations on the flow of linear polymer solutions through straight tubes at large Reynolds numbers,” in Proceedings of the 1st International Congress on Rheology, (North-Holland), 135.

Wang, B. L., Li, Y., Liu, D. C., et al. (2017). Debris flow density determined by grain composition. Landslides 15, 1205–1213. doi: 10.1007/s10346-017-0912-x

Wang, Y. Y., and Fei, X. J. (1999). Particle support mechanism in viscous debris flows at Jiangjia Ravine, Yunnan. China. Sci. China Ser E. 42, 550–555. doi: 10.1007/BF02917409

Wang, Y. Y., Zhan, Q. D., and Yan, B. Y. (2014). Debris-flow Rheology and Movement (in Chinese). Changsha: Hunan Science and Technology Press.

Wang, Z. Y., Cui, P., and Yu, B. (2001). The mechanism of debris flow and drag reduction (in Chinese). J. Nat. Disasters 10, 37–43. doi: 10.3724/SP.J.1077.2006.01357

Wei, F. Q., and Hu, K. H. (2009). Review and trends on debris flow velocity research (in Chinese). J. Mountain Sci. 27, 545–550.

Wu, J. S., Kang, Z. C., and Tian, L. (1990). Observation and Study of Debris Flow in Jiangjia Gully, Yunnan (In Chinese). Beijing: Science Press.

Yang, G., Jing, L., Kwok, F., and Sobral, Y. (2020). Pore-Scale simulation of immersed granular collapse: implications to submarine landslides. J. Geophys. Res. Earth Surface 125:e2019JF005044. doi: 10.1029/2019JF005044

Yang, T. Q., Li, Y., Zhang, Q. S., and Jiang, Y. (2019). Calculating debris flow density based on grain-size distribution. Landslides 16, 515–522. doi: 10.1007/s10346-018-01130-1132

Zhan, L. T., Jia, G. W., Chen, Y. M., and Fredlund, D. G. (2010). Analytical solution for rainfall infiltration into infinite long slopes considering properties of unsaturated soil (In Chinese). Chinese J. Geotechn. Eng. 32, 1214–1220.

Zhang, J., Wu, J. S., You, Y., and Cheng, Z. L. (2003). Formation of residue layer of debris flow and the reduction of resistance (in Chinese). J. Mountain Sci. 21, 223–227. doi: 10.1007/BF02873153

Zhang, J., and Xiong, G. (1997). Data Collection of Kinematic Observation of Debris Flows in Jiangjia Ravine, Dongchuan, Yunnan (in Chinese). Beijing: Science Press.

Zhou, G. (2014). Effect of pore water pressure on the triggering and mobilization of landslides (in Chinese). Chinese J. Nat. 36, 325–335.

Zhou, G., Cui, K. F., Jing, L., Zhao, T., Song, D., and Huang, Y. (2020). Particle size segregation in granular mass flows with different ambient fluids. J. Geophys. Res.: Solid Earth 125, 1–28. doi: 10.1029/2020JB019536

Zhou, Z. H., Ren, Z., Wang, K., Yang, K., Tang, Y. J., Tian, L., et al. (2018). Effect of excess pore pressure on the long runout of debris flows over low gradient channels: a case study of the Dongyuege debris flow in Nu River. China. Geomorphology 308, 40–53. doi: 10.1016/j.geomorph.2018.01.012

Keywords: debris flow, excess pore pressure, stress distribution, mobility, self-acceleration effect

Citation: Yang T, Li Y, Guo X, Zhang J, Jiang Y, Liu X and Liu J (2021) Acceleration of Debris Flow Due to Granular Effect. Front. Earth Sci. 9:660605. doi: 10.3389/feart.2021.660605

Received: 02 February 2021; Accepted: 22 April 2021;

Published: 14 May 2021.

Edited by:

Tao Zhao, Brunel University London, United KingdomReviewed by:

Lu Jing, Northwestern University, United StatesWeigang Shen, Southwest Jiaotong University, China

Copyright © 2021 Yang, Li, Guo, Zhang, Jiang, Liu and Liu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yong Li, ylie@imde.ac.cn; Xiaojun Guo, aaronguo@imde.ac.cn

Taiqiang Yang

Taiqiang Yang Yong Li

Yong Li Xiaojun Guo1,3*

Xiaojun Guo1,3* Jun Zhang

Jun Zhang Xuemei Liu

Xuemei Liu