Core-shell 3D printed biodegradable calcium phosphate cement—Alginate scaffolds for possible bone regeneration applications

- 1G.E.R.N. Center of Tissue Replacement, Regeneration and Neogenesis, Department of Orthopedics and Trauma Surgery, Medical Center-Albert-Ludwigs-University of Freiburg, Faculty of Medicine, Albert-Ludwigs-University of Freiburg, Freiburg, Germany

- 2Institute for Applied Biomechanics, Faculty of Mechanical and Process Engineering, Offenburg University, Offenburg, Germany

- 3Department of Orthopedics and Trauma Surgery, Medical Center-Albert-Ludwigs-University of Freiburg, Faculty of Medicine, Albert-Ludwigs-University of Freiburg, Freiburg, Germany

- 4Freiburg Center for Interactive Materials and Bioinspired Technologies (FIT), Albert-Ludwigs-University Freiburg, Freiburg, Germany

A Corrigendum on

Core-Shell 3D printed biodegradable calcium phosphate cement – Alginate scaffolds for possible bone regeneration applications

by Schweiker C, Zankovic S, Baghnavi A, Velten D, Schmal H, Thomann R and Seidenstuecker M (2024). Front. Drug Deliv. 4:1407304. doi: 10.3389/fddev.2024.1407304

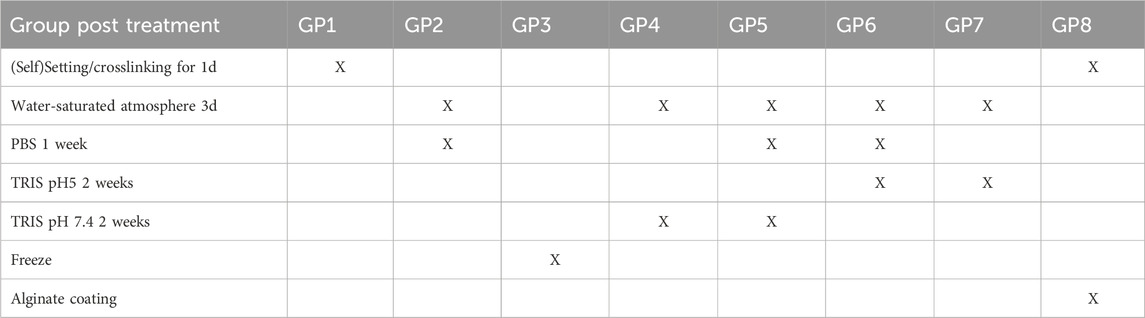

In the published article, there was an error in Table 1 as published. An X was incorrectly placed at GP4 for PBS 1 week. The corrected Table 1 and its caption Table 1: Classification of the groups according to post treatment appear below.

In the published article, there was an error. In several instances, GP4 was incorrectly used instead of GP3.

A correction has been made to Results, 3.2.1 Mechanical properties, Paragraph 1. This sentence previously stated:

“It can be observed that the samples in GP1 (reference) and GP4 (freeze-dried) exhibit significantly lower maximum values.”

The corrected sentence appears below:

“It can be observed that the samples in GP1 (reference) and GP3 (freeze-dried) exhibit significantly lower maximum values.”

A correction has been made to Results, 3.2.1 Mechanical properties, Paragraph 2. This sentence previously stated:

“The non-post-treated sample GP1 showed a 4-fold higher mechanical strength compared to the GP4 freeze-dried sample, which also had no (self) setting/crosslinking time.”

The corrected sentence appears below:

“The non-post-treated sample GP1 showed a 4-fold higher mechanical strength compared to the GP3 freeze-dried sample, which also had no (self) setting/crosslinking time”

A correction has been made to Discusson, 4.3 Mechanical properties, Paragraph 1. This sentence previously stated:

“The reason for the low strength of sample GP4 is that this sample was frozen directly after printing to prevent the (self) setting/crosslinking reaction and to be able to compare it with the other samples.”

The corrected sentence appears below:

“The reason for the low strength of sample GP3 is that this sample was frozen directly after printing to prevent the (self) setting/crosslinking reaction and to be able to compare it with the other samples.”

In the published article, there was an error. Group 12 was incorrectly used instead of Group 8.

A correction has been made to Discusson, 4.2 Surface condition. This sentence previously stated:

“Samples from group 12-1 show no signs of alginate coating in the SEM, as the solution is too thin to be detected in the ESEM. Group 12-2 and 12-3, on the other hand, both show an alginate coating, albeit unevenly.”

The corrected sentence appears below:

“Samples from group 8-1 show no signs of alginate coating in the SEM, as the solution is too thin to be detected in the ESEM. Group 8-2 and 8-3, on the other hand, both show an alginate coating, albeit unevenly.”

The authors apologize for these errors and state that they do not change the scientific conclusions of the article in any way. The original article has been updated.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Keywords: 3D printing, CPC, core-shell printing, alginate, self-setting, scaffold, bone regeneration

Citation: Schweiker C, Zankovic S, Baghnavi A, Velten D, Schmal H, Thomann R and Seidenstuecker M (2024) Corrigendum: Core-shell 3D printed biodegradable calcium phosphate cement – Alginate scaffolds for possible bone regeneration applications. Front. Drug Deliv. 4:1452132. doi: 10.3389/fddev.2024.1452132

Received: 20 June 2024; Accepted: 01 July 2024;

Published: 18 July 2024.

Approved by:

Frontiers Editorial Office, Frontiers Media SA, SwitzerlandCopyright © 2024 Schweiker, Zankovic, Baghnavi, Velten, Schmal, Thomann and Seidenstuecker. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Michael Seidenstuecker, bWljaGFlbC5zZWlkZW5zdHVlY2tlckB1bmlrbGluaWstZnJlaWJ1cmcuZGU=

Clara Schweiker1,2

Clara Schweiker1,2 Dirk Velten

Dirk Velten Michael Seidenstuecker

Michael Seidenstuecker