95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

PERSPECTIVE article

Front. Clim. , 07 April 2021

Sec. Carbon Dioxide Removal

Volume 3 - 2021 | https://doi.org/10.3389/fclim.2021.636657

This article is part of the Research Topic Scaling-Up Negative Emissions: The Power of Leveraging Policy, Philanthropy, Purchasing and Investment View all 12 articles

David Izikowitz1,2*

David Izikowitz1,2*Natural and engineered carbon dioxide removal have become regular features of climate models which limit warming to 1.5°C or even 2°C above pre-industrial levels. This gives rise to an assumption that solutions, for example direct air capture (DAC)—involving the direct removal of carbon dioxide from ambient air—can be commercialised and deployed at the necessary speed and scale to have a material impact, in the order of gigatonnes, by mid-century. Modular, solid-sorbent DAC on a gigatonne scale will require the mass mobilisation of supply chains to manufacture millions of modular DAC units−20 million of the present state of the art 50 tonne/year modules to deliver 1 gigatonne per year, as well as the large-scale production of novel chemical sorbents. To achieve a climate relevant DAC industry will demand innovative procurement models, for example carbon purchase agreements (CPAs), and dedicated DAC manufacturing facilities or dactories. In addition, insight is offered through the work of DAC start-up Carbon Infinity into the industry supply-chain position, adopting lessons from computing, and energy technologies. In particular, we look at approaches to drive demand and scale-up DAC module production, and opportunities presented in the development of an integrated DAC manufacturing industry.

In conjunction with economy-wide decarbonisation, carbon dioxide removal (CDR) has shifted from a desirable component to an invaluable element in the formula of addressing runaway global temperature rise. The Intergovernmental Panel on Climate Change's (IPCC) 2018 Special Report found a remaining carbon budget of 420 gigatonnes of carbon dioxide (GtCO2)—further depleted to <350 GtCO2 by the start of 2020—to have a likely (>66%) chance of limiting warming to 1.5°C above pre-industrial levels (IPCC, 2018; Le Quéré et al., 2018; Friedlingstein et al., 2019). Increasingly broad consensus exists within the scientific community with respect to the necessity of widespread carbon removal to limit temperature rise within “safe” levels, aligned with the purview of the Paris Agreement. This is evidenced in models reviewed by the IPCC where all pathways that limit global warming to 1.5°C with limited or no overshoot project the use of CDR on the order of up to 1,000 GtCO2, that is 1 trillion tonnes of carbon dioxide, over the twenty-first century (IPCC, 2018). Ambition on such a scale candidly demands the development of a globally consequential carbon removal industry.

Engineered approaches to CDR include direct air capture of CO2 or DAC (Breyer et al., 2019; Hou et al., 2019), bio-energy with carbon capture and storage or BECCS (Fridahl and Lehtveer, 2018; Hanssen et al., 2020), and enhanced rock weathering (Strefler et al., 2018; Beerling et al., 2020), alongside more widely recognised nature-based solutions including reforestation, afforestation, soil carbon sequestration, and peatland restoration (Seddon et al., 2020). Regardless of individual perspective concerning the respective merits and limitations of engineered or nature-based carbon removal pathways (land-use, permanence, energy requirements, cost), a comprehensive suite of CDR solutions will be necessary to achieve carbon removal resembling anything close to a climate consequential scale; although the scope of this perspective is centred on scaling-up modular DAC technology.

There are two dominant technical approaches to conduct DAC. One uses a solid chemical sorbent to capture CO2 and the other uses a liquid solvent. Commercial liquid solvent-based systems typically resemble a large-scale industrial plant and the technology has been pioneered by the Canadian firm Carbon Engineering. Solid sorbent-based systems are more modular in nature, involving a standardised and highly-scalable manufacturing process to produce air capture modules. This approach is therefore the technical focus of this paper, as well as the Swiss firm Climeworks, Global Thermostat in the US, and the China-based Carbon Infinity.

While DAC is not without its sceptics, the technology has garnered increasing policy, investor, and media attention for its potential to scale-up to become a valuable carbon removal solution (Scott and Geden, 2018; Cox et al., 2020; Sekera and Lichtenberger, 2020). The scale of the scale-up challenge however should not be underestimated. Alongside the IPCC's findings of up to 1,000 GtCO2 of cumulative CDR over the twenty-first century, complementary literature estimates 10–20 Gt/year of CDR by 2100, and multiple gigatonnes from now to 2050 (Gasser et al., 2015; Fuss et al., 2018; National Academies of Sciences, Engineering and Medicine, 2019). Assuming solid sorbent-based modular DAC technology accounts for a conservative 1 gigatonne of this suite of global CDR capacity, this would represent a “wartime level of effort” in the mobilisation of human, energy, material, financial, and importantly, supply-chain capacity.

There are 15 DAC facilities operating worldwide capturing a meagre 9,000 tCO2/year or 0.000009 GtCO2/year (IEA, 2020), while an unbuilt plant has ambitions to capture 36,500 tCO2/year (Malo, 2019), and another industrial-scale plant with the intention to capture 1 MtCO2/year (Carbon Engineering, 2020)—or only 0.001 GtCO2/year—are currently in the design phase. To put the scale of the challenge further into perspective, to scale-up from 9,000 tonnes of CO2/year in 2020 to a capture capacity of 1 billion tonnes (Gt) of CO2/year in 2050, i.e., to grow by 111,111 times in 30 years, will represent a compound annual growth rate (CAGR) of 47.3%. To take one of the most successful examples of “blitzscaling” growth from the technology industry, Instagram took nearly 10 years to acquire 1 billion users (Constine, 2018). Although the comparison between developing an additional tonne of DAC capacity to an additional user of a social network is extreme, the “wartime” analogy for DAC deployment appears appropriate for the level of ambition the science suggests is necessary.

While numerous studies have focused on the techno-economic feasibility of DAC technology (Socolow et al., 2011; Smith et al., 2016; National Academies of Sciences, Engineering and Medicine, 2019; Realmonte et al., 2019), we do not aim to replicate such research. Rather, this perspective explores the fundamental considerations around what it will take in practise to scale-up DAC to the gigatonne scale. For example, Realmonte et al. (2019) discuss how deployment at such a scale “requires a major refocusing of the manufacturing and chemical industries for sorbent production,” however they fail to mention the monumental manufacturing capacity needed to deliver ~20 million DAC modules of the current state of the art 50 t/year. Put simply, the DAC industry will need to develop the cumulative manufacturing capacity of a year of the combined output of Ford, Toyota, Daimler, and Tesla, through dedicated DAC factories, or dactories.

There are three crucial pillars to addressing the inherent questions of scaling-up DAC technology to the gigatonne scale by mid-century:

• Lessons from the laws: potential for DAC cost and performance improvement using examples of historical innovation and “learning by doing” to move down the cost-curve;

• Chicken or egg: the barriers to scaling-up manufacturing and supply-chain capacity in the absence of demand-side drivers for DAC technology; and

• REAP rewards: resilience and efficiency aligned policies (REAP) developing integrated yet resilient supply chains, addressing resource constraints, and supporting the scale-up of a globally consequential DAC industry.

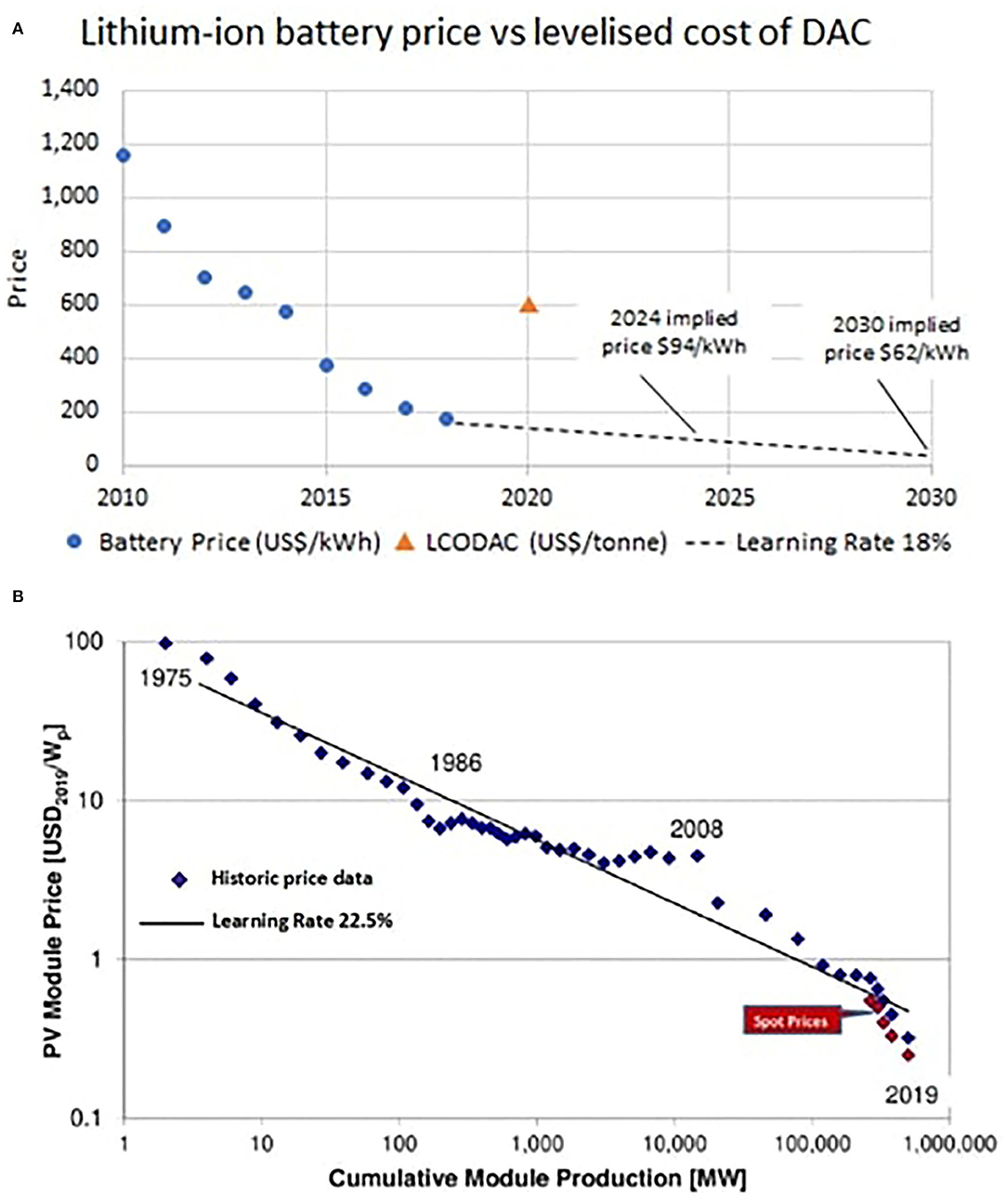

Quantifiable technological progress has been recorded for decades, if not centuries. The most well-known is arguably Moore's law, documenting that the capacity of transistors on microprocessors doubles every 2 years. More recently, Swanson's law observes that for every doubling of cumulative production volume, the price of solar PV modules declines by 20% (Figure 1B). Both are grounded in lessons from the lesser-known Wright's law, outlined in Theodore P. Wright's 1936 paper Factors affecting the costs of airplanes (Wright, 1936). While Moore's law describes technological change as a function of time, and observations for solar are a reflection of experience, Wright's law combines innovation and economies of scale in a “we learn by doing” approach.

Figure 1. (A) Lithium-ion battery cost-curve and forecast alongside levelised cost of DAC. Graph by Carbon Infinity, based on Bloomberg New Energy Finance (Goldie-Scot, 2019) Graph and BloombergNEF Data. (B) Solar PV module cost curve illustrating Swanson's law and the corresponding learning curve for solar PV. Graph by Carbon Infinity, based on European Commission's PV Status Report (Jäger-Waldau, 2019) Graph and BloombergNEF and PV News Data.

The evolution of the DAC industry will need to embrace the characteristics of all three laws. Variables from chemistry governing carbon capture efficiency, development of advanced nanomaterials (metal-organic frameworks, zeolites), and the physics governing air flow through a contactor will—through continuous R&D, advanced design, and manufacturing—need to reflect some of the dynamics seen in the laws. For example, material science and thermodynamic advances resulting in a doubling of carbon capture capacity per square metre of sorbent material every 5 years, with the subsequent capital and operating cost implications on the levelised cost of direct air capture (LCODAC). Although the learning rate of DAC is uncertain given the lack of meaningful deployment, the economies of scale and cumulative experience elements of Swanson's and Wright's laws for the scale-up of modular DAC are potentially pronounced—especially drawing lessons from lithium-ion battery and solar module production as illustrated in the cost-curves in Figure 1.

DAC industry practitioners are largely in consensus on the economies of scale and learning effects from ramping up DAC deployment. Christoph Gebald, one of the founders and directors of Climeworks, in 2017 indicated his company's aspiration to bring costs down three-fold in 3-5 years through a combination of “purchasing higher volumes, professionalising our production infrastructure and automation of production steps” (Evans, 2017). Presumably in conjunction with that cost reduction target, Climeworks set an ambitious goal of capturing 225 MtCO2/year by 2025—or nearly 1% of global CO2 emissions. As Climeworks' modular DAC collector units have a capture capacity of 50 t/year (Beuttler et al., 2019), 4.5 million collector modules would need to be produced. Given that the production line in 2017 had an annual capacity of a mere 600 units—which has likely since been scaled-up—Climeworks and other aspiring DAC technology start-ups have some way to go before experiencing anything resembling the “production hell” famously associated with ramping-up manufacturing capacity to the necessary millions of DAC modules. Experience in moving down the cost-curve by the likes of solar and battery technologies, and the associated lessons of the laws, should be front and centre in the minds of DAC scientists, engineers, and entrepreneurs, while upholding the words of wisdom offered by Friedmann (2019): to embrace the necessary ambition to make progress and wield it with humility.

While it appears Climeworks is well-behind the necessary deployment schedule to capture 225 MtCO2/year by 2025—illustrated by its August 2020 announcement of its biggest facility to date capturing 4,000 tCO2/year (or 80 modules worth of the necessary 4.5 million) (Climeworks AG, 2020), this is somewhat due to commercialisation factors beyond its direct control: demand.

What comes first: an increase in affordability promoting demand, or demand driving down costs which increases affordability? In 1962, the first year that semiconductors shipped, the US government purchased every single one of them. In fact, from 1955 to 1977, government procurement accounted for 38% of all semiconductors produced in the US (The Engine, 2020). This supported the semiconductor industry in its infancy as a first and major customer, and created a demand environment in which companies had incentives to advance the state of the art. These advancements, alongside the economies of large-scale production, subsequently contributed to the rapid cost decline from US$32 for a single chip in 1961, to US$1.25 just a decade later (Kaplan, 2009). The US may no longer be in the midst of a space or arms race, however a world war in carbon removal against the slow-moving enemy that is climate change is surely worth waging.

To date, North American businesses have pioneered interest and advance-purchasing of DAC-derived carbon removal. Funds from technology companies including Stripe (Stripe, 2020), Microsoft (Smith, 2020), Shopify (Kauk, 2020), and Amazon (Amazon, 2020) have kickstarted what needs to be a concerted effort to achieve the scale of DAC the science suggests is necessary. While DAC shares its origins in space with computing and solar technologies, coupling DAC to CO2 utilisation—whether in diamonds, concrete, vodka, or remote fuel synthesis—will accelerate deployment today, support its downward cost-curve trajectory, and further expand commercial applications. Climeworks' upcoming 4,000 tCO2/year facility resulting from demand for a consumer carbon offset subscription, alongside some fiscally modest initiatives from the Federal US and United Kingdom governments to directly subsidise and fund DAC technology, and New York State legislation incentivising the procurement of low-carbon concrete utilising CO2 capture and utilisation technologies are some promising signs (US Senate, 2017; Johnson, 2020; New York State Senate, 2020).

Meanwhile, the UK government has projected it will exceed its own legally binding carbon budget for the period 2023–2027 by between 70 and 230 MtCO2e (UK Department for Business, Energy and Industrial Strategy, 2019). The UK is certainly not unique in their faltering trajectory towards a net-zero goal. Much like what US government procurement of early computing technologies did for the technology industry, governments, and businesses in this carbon conundrum can make a significant contribution to the emergence of a climate consequential carbon removal and DAC industry with mechanisms like carbon purchase agreements (CPAs). Similar to the power purchase agreements (PPAs) which have become ubiquitous in the deployment of renewable energy, CPAs can offer demand-side certainty for start-ups in the field to invest in R&D, develop the supply-chain capacity, and manufacturing process innovation to provide for the nascent carbon removal industry what Germany's solar PV gift delivered for the world.

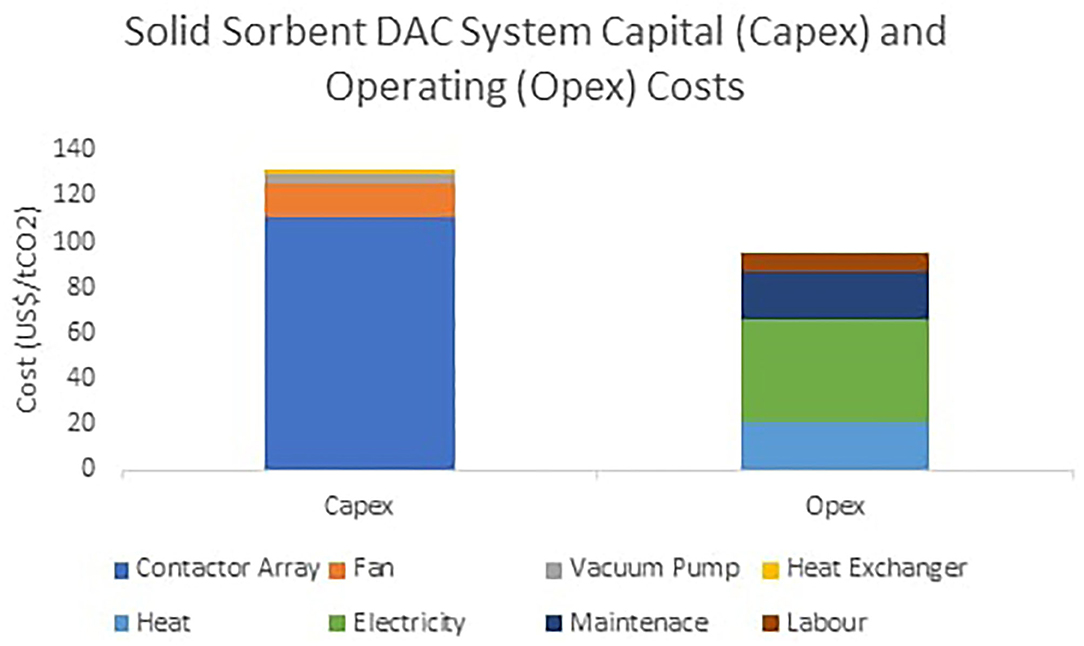

Irrespective of sufficient demand-drivers and adoption of CPAs, scaling-up manufacturing capacity from the hundreds to the millions of DAC modules will be a monumental task. The principal components of a solid sorbent-based DAC module involve a contactor and adsorbent array, industrial fan/blower, vacuum pump, and a heat exchanger, as highlighted in Figure 2. While most of these are technologically mature components, the contactor array—including the novel sorbent material—is the area with the most potential for capital and operating cost improvement, alongside optimisation of supply chains, and manufacturing innovation. Furthermore, the highly integrated nature of DAC module systems can enable quick capital and operating cost wins through industrial design innovation of novel (sorbent) components working alongside more mature (fan, pump) equipment.

Figure 2. Estimated annualised capital (Capex) and operating (Opex) costs for a solid sorbent direct air capture system with a capacity of 1 Mt/year of CO2 removal. Graph by Carbon Infinity, based on Wilcox (2019) Graph and National Academies of Sciences, Engineering and Medicine (2019) Data.

In the meantime, the chemical engineering innovation and retooling of production for dedicated sorbent manufacturing ought not to be derided. Gigatonne-scale DAC deployment will require upwards of five million tonnes of specialist sorbent production, evidenced by a recent life cycle assessment of Climeworks' facilities (Deutz and Bardow, 2021). While not unprecedented, the utilisation of “spare capacity” is simply out of the question for chemical manufacturing at such a scale; especially for relatively new metal-organic framework (MOF)-based sorbent technologies that Carbon Infinity, Climeworks, and Global Thermostat (among others) are developing. The chemical industry therefore ought to be on notice for the chemical synthesis demands in the millions of tonnes required—from around 700,000 tonnes of ethanolamine production in the US in 2019 for more traditional monoethanolamine (MEA)-based sorbents (Garside, 2020)—to achieve gigatonne-scale DAC deployment.

The efficient and continuous improvement of resource utilisation, encompassing energy, financial capital, material, and human resources will be critical to enable the rapid scale-up of DAC technology and reap the associated climate stabilisation rewards. Resilience and efficiency aligned policies (REAP) around supply chains are seeing renewed interest, not least due to the vulnerabilities exposed by the COVID-19 pandemic. The theoretical resilience of DAC supply chains have relatively strong foundations. Global chemical production is well-distributed globally, with BASF (Germany), the Dow Chemical Company (USA), and Sinopec (China) among the three largest chemical producers which could feasibly expand into mass MOF or MEA-based sorbent production. These countries also represent developed industrial hubs from where strong regionalised, rather than globalised, DAC supply chains should be established, alongside dedicated DAC module manufacturing to initially serve the European, Americas, and Asia-Pacific markets.

The efficient evolution and scale-up of the DAC industry can again benefit from models pioneered by the computing industry. The emergence of specialised semiconductor fabrication facilities enabled the division and specialisation of skills and supply chains which can be replicated in the DAC industry. For example, Apple now designs the architecture of their chips with fabrication contracted out to Taiwan Semiconductor Manufacturing Company (TSMC). We could conceivably see R&D labs and universities focused on developing specialised sorbents and components for a contract manufacturer with dedicated dactories to fabricate; further enabling the DAC industry to develop the specialisation, economies of manufacturing scale, and deployment know-how to move down the cost-curve.

These foundations can be further developed by highly resource-efficient and innovative financing mechanisms, blending public R&D funding with private capital, and future procurement of air captured CO2. NASA's pioneering Commercial Crew Program, initiated in 2010 and leading to the first crewed space operation by a private company (SpaceX) just a decade later, offers a valuable case study into cost-effective blended-finance routes for the mass scale-up of DAC deployment. The program offered progressively greater funding while simultaneously whittling down prospective suppliers based on achieving certain milestones—culminating in awarding the crew transportation contracts to two companies—Boeing and SpaceX. This fixed-cost, public-private model incentivised commercial partners to reduce delivery costs—forecast by NASA to have saved US$20–30 billion in taxpayer money (McAlister, 2020). Such a model can undoubtedly be replicated for DAC. For example, a fixed-cost, government procurement process, through a government or group of governments with fiscal capacity—potentially via Mission Innovation or the Clean Energy Ministerial. This would take the form of CPAs for the purchase of 100 MtCO2 in 2027 for US$100/tonne (US$10 billion contract)—a price within the realm of possibility, especially if complemented by a structured investment program. Such a program, like that adopted by NASA or the XPRIZE competitions could catalyse the mobilisation of private capital, the acceleration of innovation, and a wartime-like scale-up of dactories, kickstarting the development of a climate consequential global DAC industry.

We must wake up to the unfortunate reality that we are not doing enough, nor at the necessary speed, to both transition away from our fossil-fuelled economic systems and develop a portfolio of solutions to draw down carbon dioxide from the air and prevent the worst effects of climate change. The COVID-19 pandemic has illustrated our ability to mobilise trillions of dollars in public capital, and use advance purchase agreements to repurpose and retool supply chains to develop vaccines, masks, and ventilators in the face of an invisible enemy. Developing carbon removal capacity needs to be approached in a similar vein: future generations will not excuse today's inconsequential action.

While net-zero goals are valuable signals, this needs to be accompanied by a carbon purchasing and investment agenda today to advance carbon removal solutions—in particular DAC technology, if they are to be available at a material scale by mid-century. Scientists, engineers, and entrepreneurs are assembling in increasing numbers to accelerate innovation and develop cutting-edge air capture technologies. However, this must be complemented by sufficient demand-side certainty, led by governments' or conscious corporations' balance sheets and purchasing power, for DAC technology to benefit from the economies of scale and manufacturing innovation dotted across the recent history of computing and energy technology deployment.

The science suggests we need a wartime-like mobilisation of supply chains, manufacturing capacity, and innovation. It is time we start listening and rekindle that spirit of ambition.

The original contributions generated for the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author/s.

The author confirms being the sole contributor of this work and has approved it for publication. Any opinions and calculations presented in this article are the views of DI only and are not necessarily shared by his affiliations.

The author is the Founder and a Director of Carbon Infinity.

The author would like to thank the editors of this journal, the reviewers of this article, and Stripe Inc., for sponsoring this important research topic.

Amazon (2020). Amazon Announces First Recipients of Investments from $2 Billion Climate Pledge Fund. Amazon, September 17, 2020. Available online at: https://press.aboutamazon.com/news-releases/news-release-details/amazon-announces-first-recipients-investments-2-billion-climate? (accessed November 22, 2020).

Beerling, D. J., Kantzas, E. P., Lomas, M. R., Wade, P., Eufrasio, R. M., Renforth, P., et al. (2020). Potential for large-scale CO2 removal via enhanced rock weathering with croplands. Nature 583, 242–248. doi: 10.1038/s41586-020-2448-9

Beuttler, C., Charles, L., and Wurzbacher, J. (2019). The role of direct air capture in mitigation of anthropogenic greenhouse gas emissions. Front. Clim. 1:10. doi: 10.3389/fclim.2019.00010

Breyer, C., Fasihi, M., Bajamundi, C., and Creutzig, F. (2019). Direct air capture of CO2: a key technology for ambitious climate change mitigation. Joule 3, 2053–2057, doi: 10.1016/j.joule.2019.08.010

Carbon Engineering (2020). Oxy Low Carbon Ventures, Rusheen Capital Management Create Development Company 1PointFive to Deploy Carbon Engineering's Direct Air Capture Technology. Carbon Engineering, August 19, 2020. Available online at: https://carbonengineering.com/news-updates/new-development-company-1pointfive-formed/ (accessed November 22, 2020).

Climeworks AG (2020). Climeworks, ON Power and Carbfix Lay the Foundation to Scale Up Carbon Dioxide Removal Significantly to 4000 Tons Per Year. Climeworks AG, August 26, 2020. Available online at: https://climeworks.com/news/climeworks-has-signed-groundbreaking-agreements-with (accessed November 22, 2020).

Constine, J. (2018). Instagram Hits 1 Billion Monthly Users, Up From 800M in September. Techcrunch, June 20, 2018. Available online at: https://techcrunch.com/2018/06/20/instagram-1-billion-users/ (accessed November 22, 2020).

Cox, E., Spence, E., and Pidgeon, N. (2020). Public perceptions of carbon dioxide removal in the United States and the United Kingdom. Nat. Clim. Chang. 10, 744–749. doi: 10.1038/s41558-020-0823-z

Deutz, S., and Bardow, A. (2021). Life-cycle assessment of an industrial direct air capture process based on temperature-vacuum swing adsorption. Nat Energy. 6, 203–213. doi: 10.1038/s41560-020-00771-9

Evans, S. (2017). The Swiss Company Hoping to Capture 1% of Global CO2 Emissions by 2025. Carbon Brief, June 22, 2017. Available online at: https://www.carbonbrief.org/swiss-company-hoping-capture-1-global-co2-emissions-2025 (accessed November 22, 2020).

Fridahl, M., and Lehtveer, M. (2018). Bioenergy with carbon capture and storage (BECCS): global potential, investment preferences, and deployment barriers. Energy Res. Soc. Sci. 42,155–165. doi: 10.1016/j.erss.2018.03.019

Friedlingstein, P., Jones, M. W., O'Sullivan, M., Andrew, R. M., Hauck, J., Peters, G. P., et al. (2019). Global carbon budget, earth syst. Sci. Data 11, 1783–1838. doi: 10.5194/essd-11-1783-2019

Friedmann, S. J. (2019). Engineered CO2 removal, climate restoration, and humility. Front. Clim. 1:3. doi: 10.3389/fclim.2019.00003

Fuss, S., Lamb, W. F., Callaghan, M. W., Hilaire, J., Creutzig, F., Amann, T., et al. (2018). Negative emissions—part 2: costs, potentials and side effects. Environ. Res. Lett. 13:6. doi: 10.1088/1748-9326/aabf9f

Garside, M. (2020). U.S. Ethanolamines Production Volume 1990-2019. Statista, August 13, 2020. Available online at: https://www.statista.com/statistics/974755/us-ethanolamines-production-volume/ (accessed November 22, 2020).

Gasser, T., Guivarch, C., Tachiiri, K., Jones, C. D., and Ciais, P. (2015). Negative emissions physically needed to keep global warming below 2 °C. Nat. Commun. 6:7958. doi: 10.1038/ncomms8958

Goldie-Scot, L. (2019). A Behind the Scenes Take on Lithium-ion Battery Prices. BloombergNEF. Available online at: https://about.bnef.com/blog/behind-scenes-take-lithium-ion-battery-prices/ (accessed March 25, 2021).

Hanssen, S. V., Daioglou, V., Steinmann, Z. J. N., Doelman, J. C., Van Vuuren, D. P., and Huijbregts, M. A. J. (2020). The climate change mitigation potential of bioenergy with carbon capture and storage. Nat. Clim. Chang. 10, 1023–1029. doi: 10.1038/s41558-020-0885-y

Hou, C., Wu, Y., Wang, T., Wang, X., and Gao, X. (2019). Preparation of quaternized bamboo cellulose and its implication in direct air capture of CO2. Energy Fuels 33, 1745–1752. doi: 10.1021/acs.energyfuels.8b.02821

IEA (2020). Direct Air Capture. Paris: IEA. Available online at: https://www.iea.org/reports/direct-air-capture (accessed March 25, 2021).

IPCC (2018). Global Warming of 1.5°C. Available online at: https://www.ipcc.ch/sr15/ (accessed March 25, 2021).

Jäger-Waldau, A. (2019). PV Status Report 2019. European Commission. Luxembourg: Publications Office of the European Union. doi: 10.2760/326629

Johnson, B. (2020). PM: A New Deal for Britain. Prime Minister's Office, London, United Kingdom. Available online at: https://www.gov.uk/government/news/pm-a-new-deal-for-britain (accessed March 25, 2021).

Kauk, S. (2020). Shopify's Sustainability Fund: How We're Investing to Reverse Climate Change. Shopify, September 14, 2020. Available online at: https://www.shopify.co.uk/blog/sustainability-fund (accessed November 22, 2020).

Le Quéré, C., Andrew, R. M., Friedlingstein, P., Sitch, S., Hauck, J., Pongratz, J., et al. (2018). Global carbon budget. Earth Syst. Sci. Data 10, 2141–2194, doi: 10.5194/essd-10-2141-2018

Malo, S. (2019). Do ‘Mechanical Trees' Offer the Cure for Climate Change? Thomson Reuters Foundation, April 30, 2019. Available online at: https://www.reuters.com/article/us-usa-climatechange-carboncapture-idUSKCN1S52CG (accessed November 22, 2020).

McAlister, P. (2020). Commercial Crew Program Status to NAC. NASA Headquarters, Washington, DC. Available online at: https://www.nasa.gov/sites/default/files/atoms/files/ccp_status_to_nac_-_may_2020_1.pdf (accessed November 22, 2020).

National Academies of Sciences Engineering and Medicine. (2019). Negative Emissions Technologies and Reliable Sequestration: A Research Agenda. Washington, DC: The National Academies Press. doi: 10.17226/25259

New York State Senate (2020). The New York State Low Embodied Carbon Concrete Leadership Act. New York State Senate, New York, NY. Available online at: https://www.nysenate.gov/legislation/bills/2019/s8965 (accessed March 25, 2021).

Realmonte, G., Drouet, L., Gambhir, A., Glynn, J., Hawkes, A., Köberle, A., et al. (2019). An inter-model assessment of the role of direct air capture in deep mitigation. Nat. Commun. 10:3277. doi: 10.1038/s41467-019-10842-5

Scott, V., and Geden, O. (2018). The challenge of carbon dioxide removal for EU policy-making. Nat. Energy 3, 350–352. doi: 10.1038/s41560-018-0124-1

Seddon, N., Chausson, A., Berry, P., Girardin, C. A. J., Smith, A., and Turner, B. (2020). Understanding the value and limits of nature-based solutions to climate change and other global challenges. Philos. Trans. R. Soc. B 375:20190120. doi: 10.1098/rstb.2019.0120

Sekera, J., and Lichtenberger, A. (2020). Assessing carbon capture: public policy, science, and societal need. Biophys. Econ. Sust. 5:14. doi: 10.1007/s41247-020-00080-5

Smith, B. (2020). Microsoft Will Be Carbon Negative by 2030. Microsoft, January 16, 2020. Available online at: https://blogs.microsoft.com/blog/2020/01/16/microsoft-will-be-carbon-negative-by-2030/ (accessed November 22, 2020).

Smith, P., Davis, S. J., Creutzig, F., Fuss, S., Minx, J., Gabrielle, B., et al. (2016). Biophysical and economic limits to negative CO2 emissions. Nature Clim. Change 6, 42–50. doi: 10.1038/nclimate2870

Socolow, R., Desmond, M., Aines, R., Blackstock, J., Bolland, O., Kaarsberg, T., et al. (2011). Direct Air Capture of CO2 with Chemicals: A Technology Assessment for the APS Panel on Public Affairs. College Park, MD: American Physical Society.

Strefler, J., Amann, T., Bauer, N., Kriegler, E., and Hartmann, J. (2018). Potential and costs of carbon dioxide removal by enhanced weathering of rocks. Environ. Res. Lett. 13:3. doi: 10.1088/1748-9326/aaa9c4

Stripe (2020). Climate. Available online at: https://stripe.com/climate (accessed November 22, 2020).

The Engine (2020). Tough Tech Publication 06. The Engine, Built by MIT. October, 2020. Available online at: https://www.engine.xyz/wp-content/uploads/2020/11/TT06_digital.pdf (accessed March 25, 2021).

UK Department for Business Energy and Industrial Strategy. (2019). Updated Energy and Emissions Projections: 2018. London: UK Department for Business, Energy and Industrial Strategy.

US Senate (2017). FUTURE Act. Washington, DC: US Senate. Available online at: https://www.congress.gov/bill/115th-congress/senate-bill/1535 (accessed March 25, 2021).

Wilcox, J. (2019). Direct Air Capture. Workshop on Deep Decarbonization, National Academy of Sciences. Available online at: https://sites.nationalacademies.org/cs/groups/depssite/documents/webpage/deps_195085.pdf (accessed March 25, 2021).

Keywords: carbon purchase agreements, direct air capture policy, dactories, supply-chain innovation, manufacturing innovation, government procurement, modular direct air capture

Citation: Izikowitz D (2021) Carbon Purchase Agreements, Dactories, and Supply-Chain Innovation: What Will It Take to Scale-Up Modular Direct Air Capture Technology to a Gigatonne Scale. Front. Clim. 3:636657. doi: 10.3389/fclim.2021.636657

Received: 01 December 2020; Accepted: 12 March 2021;

Published: 07 April 2021.

Edited by:

Keith Paustian, Colorado State University, United StatesReviewed by:

Dilip Khatiwada, Royal Institute of Technology, SwedenCopyright © 2021 Izikowitz. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: David Izikowitz, ZGF2aWRAY2FyYm9uaW5maW5pdHkuY29t

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.