- 1Department of Chemical Engineering and Chemistry, Eindhoven University of Technology, Eindhoven, Netherlands

- 2Sustainable Materials Management, Flemish Institute for Technological Research, Mol, Belgium

- 33D-cat B.V., Bergen, Netherlands

Additive manufacturing of catalyst and sorbent materials promises to unlock large design freedom in the structuring of these materials, and could be used to locally tune porosity, shape and resulting parameters throughout the reactor along both the axial and transverse coordinates. This contrasts catalyst structuring by conventional methods, which yields either very dense randomly packed beds or very open cellular structures. Different 3D-printing processes for catalytic and sorbent materials exist, and the selection of an appropriate process, taking into account compatible materials, porosity and resolution, may indeed enable unbounded options for geometries. In this review, recent efforts in the field of 3D-printing of catalyst and sorbent materials are discussed. It will be argued that these efforts, whilst promising, do not yet exploit the full potential of the technology, since most studies considered small structures that are very similar to structures that can be produced through conventional methods. In addition, these studies are mostly motivated by chemical and material considerations within the printing process, without explicitly striving for process intensification. To enable value-added application of 3D-printing in the chemical process industries, three crucial requirements for increased process intensification potential will be set out: i) the production of mechanically stable structures without binders; ii) the introduction of local variations throughout the structure; and iii) the use of multiple materials within one printed structure.

1 Introduction

Catalysis is a field in chemical engineering which has made tremendous progress in the past decades. A variety of technological innovations, such as the scale-up of high throughput experimentation and increasing computational power for theoretical calculations, has led to a vast increase in both fundamental understanding and commercialization of novel catalytic processes (Derouane et al., 2000; Van der Borght et al., 2015; Friend and Xu, 2017). From the chemist’s perspective, the development of a catalyst is commonly concluded with a validation of the catalyst in its intended reactive conditions, on a (sub-) Gram scale. However, after the optimally performing catalytic material is selected, engineering considerations relating to the catalyst’s incorporation into a reactor remain. More specifically, the shaping of the catalytic material or, along the same line of reasoning, sorbent materials, takes the challenges from the molecular scale to the scale of the reactor, imposing new demands related to reactor engineering and process intensification (Bellefon, 2002; Mitchell et al., 2012, 2013). These engineering requirements revolve around designing the reactor and overall process such, that the productivity is high, energy demand low, and footprint small. This is done in an effort to reduce the capital expenditures, the utility consumption and the CO2 emissions and to accommodate for the limited space at chemical plant facilities. Critical design variables in addressing these challenges are the heat and mass transfer properties and the mixing behavior of the reactor, along with the regular operating parameters. All of these variables are heavily influenced by the configuration of the reactor and the shape of the catalyst (Akhtar et al., 2014; Gascon et al., 2015).

In packed bed reactors, the catalyst geometry is directly related to the catalyst weight per volume of reactor, the fluid-solid interfacial area and the macro-porosity or gas holdup (in this work we will consider heterogeneous gas phase reactions, but similar arguments equally apply to heterogeneous liquid phase reactions). This impacts the observed reaction rates, as the reaction rate generally depends on the catalyst weight and/or interfacial area (Pangarkar et al., 2008; Vervloet et al., 2013). In addition, the macro-porosity governs the ratio of reactant to catalyst, which impacts the residence time and in turn, the Weight Hourly Space Velocity (WHSV). In general, this parameter is optimized to ensure that the products do not spend more time in the reactor than required, since high productivity is crucial. Specifically for systems of multiple reactions, tuning these operating variables is critical, since the selectivity towards a desired product is heavily dependent on the residence time (Silla, 2003). Another relevant effect of the catalyst geometry is the degree of dispersion and backmixing it causes, which determines the Residence Time Distribution (RTD). Often, the degree of backmixing is expressed in relation to two limiting situations; complete backmixing and no backmixing, represented by the Continuously Stirred Tank Reactor (CSTR) and the Plug Flow Reactor (PFR), respectively (Barnard, 1985). The latter is usually preferred for its improved conversion of any reaction with a positive order, as well as improved selectivity towards the targeted product (depending on the reaction orders of the main and consecutive or parallel reactions). However, reactors rarely attain true PFR behavior in practice. Therefore, a consideration of the residence time distribution and its effect on the conversion and selectivity is required (Levenspiel and Bischoff, 1959; Nauman, 1981; Waldram, 1985).

These parameters determine the direct effects of catalyst structuring on the kinetic performance of a reaction. For a complete analysis, however, operating characteristics that are vital to the engineering design need to be considered. Firstly, the influence that a reactor internal has on macroscopic fluid flow is not just limited to the residence time distribution. As the catalyst geometry guides the flow of the fluid, the transfer of mass and heat through the reactor are influenced. The first of these phenomena, mass transfer, is critical since it has the potential to lower the observed reaction rate. In certain situations, the transport of mass to the active sites is slower than the kinetic rate and hence the observed rate is lower (Rezaei and Webley, 2010). In addition, the heat transfer is important since a mismatch in thermal reaction effects and effective heat transfer coefficient may introduce unwanted temperature gradients inside the catalyst and the reactor. In turn, these temperature gradients may be detrimental to conversion and selectivity (Lerou and Froment, 1977). In addition, hot spot formation may lead to thermal runaway, material degradation or perhaps even reactor clogging due to coking (Kapteijn and Moulijn, 2020).

A final parameter vital to the reactor performance and overall process efficiency is the pressure drop, which represents the amount of resistance that the reactor internals offer against the fluid flow. This parameter plays a key role in optimizing the mechanical engineering aspects of the process design; a high pressure drop requires higher energy input for the feed compressors and pumps and this may decrease the overall process efficiency and increase the CO2 footprint (Afandizadeh and Foumeny, 2001). Process equipment should also be constructed to handle the higher pressure, which increases the capital expenditures. More delicate is the influence of pressure drop on reaction rates; many gas phase reactions have kinetic rate equations with pressure dependency, and a pressure gradient along the reactor may influence the conversion and selectivity.

In addition, considerations regarding safety may come into play in the selection of a catalyst geometry. For example, a lower apparent catalyst density may require oversizing of the reactor for the same throughput. This is directly related to process safety, as a larger reactor with a larger amount of reactant brings along increased risks (Etchells, 2005; Hendershot, 2018).

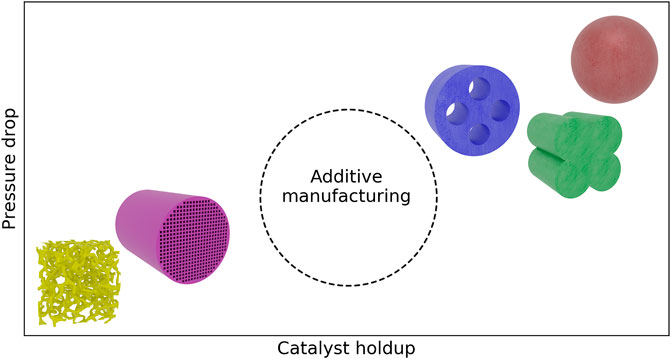

Having introduced the relevant variables that play a role in catalyst (and sorbent) shaping considerations, the various shaping options available can be discussed. In this review, granules, pellets, extrudates, honeycomb monoliths and foams will be considered as established techniques. An attractive alternative to these conventional shaping technologies, additive manufacturing (AM), or 3D-printing, of catalysts and sorbents (where they are considered as ceramic materials) has only taken off in the last couple of years. One of the major advantages of AM is its disruptive approach to the economy of scale and the ability to produce custom components to order, which, for example, makes it ideal for manufacturing in space (Prater et al., 2018). For the structuring of catalysts and sorbents specifically, this technology holds potential for providing a very high degree of design freedom, which allows for the tailoring of structures to specific operating windows and overcome the limitations of conventional shaping methods. Most interesting in this regard is the spatial variations of catalyst geometry that can be created throughout the reactor. One of the reasons this is an interesting approach is that it can, amongst others, mitigate hot spots that are often found in conventional packed bed reactors. The literature already contains quite a number of excellent reviews on the potential of additive manufacturing for chemical engineering, but many of these publications tend to focus on the chemical aspect of the printing process (Bara et al., 2015; Zhou and Liu, 2017; Parra-Cabrera et al., 2018; Gupta et al., 2019b; Kotz et al., 2019; Gordeev and Ananikov, 2020; Zentel et al., 2020; Agrawaal and Thompson, 2021; Lawson et al., 2021b). This includes detailed studies and their considerable scope on the formulation of the printing ink, optimization of the printing process and assessment of the chemical and mechanical properties of the printed structures. Whilst these are important technological aspects to consider, the main objective of a novel shaping technology should be kept in mind: process intensification. Hence, the current work will only provide a brief introduction to mature technologies, along with a general idea of the sort of structures that can be created with them. Subsequently, an analysis will be provided of the literature on benchmarking 3D-printed catalyst structures against their conventional counterparts, packed bed reactors, in an effort to achieve process intensification. Since 3D-printing technologies for ceramic materials are not yet deployed on a truly commercial scale, there is little concrete knowledge on the windows of operation. However, with the reviewed cases and process intensification principles in mind, the potential operating benefits of 3D-printed structures over conventional technologies can be considered. Such an analysis is vital, since it should be realized that the use of additive manufacturing to produce components in bulk is not an obvious choice. Currently, 3D-printing of catalysts and sorbents is more expensive and labor-intensive than conventional processes for the shaping of these materials. Hence, the operational benefits of using 3D-printed structures should outweigh the additional cost to provide a viable addition to the shaping technologies currently available. These benefits are likely found in a “sweet spot” of medium catalyst holdup, low pressure drop and tunable transport properties as this combination is difficult to achieve through the use of conventional methods. The “sweet spot” concept will be used in the coming sections to discern between the possibilities of additive manufacturing and conventional methods in terms of process intensification potential.

In the remainder of this work, the potential for shaping sorbents will be discussed alongside shaping catalysts, and the word catalyst will be used to represent sorbent materials as well. This is done since they are generally in a similar class of materials and feature similar printing protocols. Sorbent materials can be used in various processes as a means of process intensification, through the integration of reaction and separation (Barelli et al., 2008; Zhu et al., 2020). It will be argued that 3D-printing of sorbent and catalyst, either as separate structures or in an integrated multi-material configuration, holds potential for key applications in the chemical process industries.

2 Conventional Shaping Methods

To provide a benchmark of the available technologies against which a 3D-printed catalyst can be compared for application in a packed bed reactor, five classes of conventionally shaped catalyst are reviewed in this section. The basic working principles of the shaping technologies are given, discussing the properties of the shaped body, along with possible constraints on materials, size, porosity and mechanical stability. This will be followed by considerations on the incorporation of the shaped catalyst in a reactor. Finally, qualitative operating windows for the process intensification design parameters are defined to provide a basis for comparison between the different shaping technologies. With regard to the latter, there is no quantitative information readily available for the more complex shapes produced by pelleting or extrusion, since exact geometries are often proprietary information, as they are mostly developed and manufactured within industrial R&D rather than academic catalysis research (Akhtar et al., 2014; Lakiss et al., 2020).

An initial consideration for every shaping technology is that the shaped body, also called the green structure, needs to be post-processed. The post-processing sequence usually starts in a low temperature process with a high heating rate for debinding. This is followed by a high temperature process with a relatively low heating rate for sintering or calcining the material. These operations are accompanied by a significant degree of shrinkage (in the order of 20–30%) and porosity changes, and should be conducted carefully to tune the product properties (Kuang et al., 1997; Shang et al., 2015; Li H. et al., 2020; Somton et al., 2020). For shaping by whichever technology, the catalyst or sorbent powder is generally not cohesive enough, and does not possess the mechanical strength required to maintain the shape intended. Hence, binders are added to maintain the shape and achieve the desired mechanical strength. Organic compounds, such as plasticizers, lubricants and peptizers, may be added to ensure that the green structure holds its shape and that the formulation has the desired viscoelastic properties for its shaping method (Mitchell et al., 2013). These organic compounds, however, are inevitably combusted as the structure is post-processed, although organic compounds do not necessarily have to be removed in case of some low temperature sorbent applications (Kraushaar-Czarnetzki and Müller, 2009; Whiting et al., 2019; Grande et al., 2020). Hence, inorganic binders are included to provide rigidity and mechanical strength after post-processing (Akhtar et al., 2014). These inorganic binders are known to slightly reduce the porosity of a catalyst as pores are blocked. In addition, unwanted chemical effects may be introduced. In the first place, the observed reaction rate may be lower, as the catalyst is diluted with binder material (Li Z. et al., 2020). A second effect may be introduced by the chemical nature of these binders. Especially at high temperatures, common binder materials such as silica, alumina or clay may exhibit catalytic effects which can influence the intended chemical nature of the catalyst (Fougerit et al., 1994; Choudhary et al., 1999; Jasra et al., 2003; Hargreaves and Munnoch, 2013; Bingre et al., 2018; Shen et al., 2019; Vajglová et al., 2019). Considering potentially adverse binder effects and determining the right balance, amount and type of inorganic and organic additives is an essential part of all shaping methods, both for conventional and 3D-printing techniques.

2.1 Granules

Spherical particles, or so-called granules or beads, represent the most basic geometry used in fixed bed reactors. Typically, synthesis of catalytic material does not yield crystals of the desired shape and size or adequate mechanical strength and hence, achieving spherical particles requires a separate granulation process. The principle of granulation is relatively simple; wet particles increase in size by rolling amongst catalytic material, much like a rolling snowball (Kraushaar-Czarnetzki and Müller, 2009). Granulation processes differ in their working mechanism, as either a rotating pan, an immersed mixer or a fluidized bed can be used. Illustrations of the working mechanisms of these processes can be found in the literature, for example the review by Shanmugam (2015). Whilst these variations may have implications on the production process (e.g., determining whether the particles can be produced continuously or in batches), the product properties that are relevant within the scope of this review are quite similar (Litster and Ennis, 2004). Following granulation, post-processing is required to completely dry the particles and sinter or calcine them. The obtained particles will likely feature a particle size distribution, as granulation processes are not ideal and induce a residence time distribution on rolling particles. In addition, different granulation processes may have an influence on the sphericity of the particle, but this is a rather delicate issue with many parameters involved (Butensky and Hyman, 1971; Téllez-Medina et al., 2010). The granulation process is suitable for a wide range of catalytic materials, but the porosity may be altered slightly due to particle consolidation (in addition to the general changes that are introduced as a consequence of post-processing) (Iveson et al., 2001; Litster and Ennis, 2004; Pérez-Ramírez et al., 2011).

In some instances, incorporation of the particles into a reactor can be as simple as pouring them in. However, there is often a more detailed protocol available for achieving adequate packing, which is important to avoid particle breakage and attrition (Afandizadeh and Foumeny, 2001). In addition, the packing influences the porosity (profiles) within the bed and an inconsistent packing, especially at low reactor-to-particle diameter ratios, may lead to channelling (Salvat et al., 2005; Duan et al., 2014). This phenomenon is caused by certain pathways presenting less resistance to the fluid travelling through the reactor and therefore becoming preferential. This is problematic since it leads to broadening of the residence time distribution and uneven usage of the bed, which may shift the selectivity or negatively influence the process in general. This phenomenon may increase in severity when multi-tubular reactors are used, as slight differences in packing may lead to maldistribution of the flow between the different tubes (Afandizadeh and Foumeny, 2001). The use of a multi-tubular configuration is, however, often required as radial heat transfer in a packed bed is low and causes hot spots to arise in larger diameter vessels (Shinnar et al., 1992; Vervloet et al., 2013).

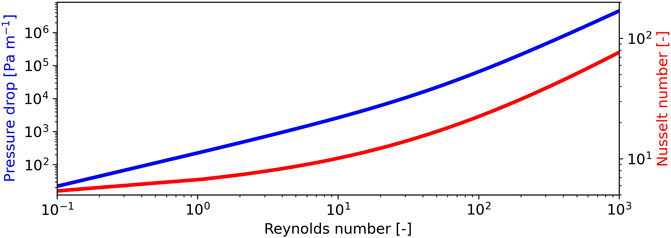

If the reactor is packed properly, the performance in terms of process intensification metrics is largely determined by the gas holdup and size and shape of the particles. Whilst particle parameters may be varied, the gas holdup generally attains a value between 35 and 40% regardless of particle size. These values hold for perfect spheres without particle size distribution, and may differ significantly for poly-disperse systems (Allen et al., 2013; Pottbäcker and Hinrichsen, 2017). As stated, all other parameters relevant to the reactor scale depend on particle size and abundant correlations are available to describe the relevant phenomena. Granulation processes do not impose a practical limit on particle size, which can range from microns to centimeters. Generally, particles in industrial processes are in the millimeter scale (Litster and Ennis, 2004; Hagen, 2015). The choice of particle size is often motivated by two contradictory requirements: the minimization of the internal mass transfer limitations and the minimization of the pressure drop. The first objective, minimizing the internal mass transfer limitations, requires small particles, as diffusion of reactants through large particles is very slow, leading to a lower observed reaction rate and uneven utilization of the particle (Thiele, 1939). On the other hand, a decrease in particle size always leads to an increase in pressure drop, which can decrease the overall process efficiency. A similar design conflict is shown in Figure 1, where the pressure drop and Nusselt number (the dimensionless heat transfer rate) are plotted as a function of the Reynolds number for a packed bed of spheres. In the ideal case, a reactor should be operated with high heat transfer rates and low pressure drop. This, however, can not be achieved simultaneously in a packed bed of spheres, as shown in Figure 1.

FIGURE 1. Dependence of pressure drop and heat transfer on the Reynolds number for a packed bed of spheres. Values calculated using the Ergun equation for pressure drop and the Gunn correlation for heat transfer, using the physical properties of nitrogen, a bed porosity of 40% and a particle size of 1 mm (Ergun, 1952; Gunn, 1978).

2.2 Pellets

Pellets are cylinder-like geometries, often hollow or with multiple channels, as shown in Figure 2. Forming them is straightforward; catalyst powder is pressed into a millimeter-sized mould with a pressurized die, forcing it to take the shape of the mould (Hagen, 2015). An image of such equipment can be found in the book chapter by Kraushaar-Czarnetzki and Müller (2009). This method can be used to compact the powder so densely that there is no additional need for binder materials, but this depends largely on the physical properties of the powder feed (Ewsuk, 2001). The mechanical strength and structural integrity of the product is very much dependent on the pressure applied, which needs to be rather high. In practice, it is observed that exerting this pressure may break down larger crystals and disrupt existing pore systems (Yakubovich et al., 1984; Li et al., 1991; Ovsienko, 2009; Bingre et al., 2018). Unlike possible particle size distributions introduced through the granulation process, a dry compacting process yields the intended geometry at all times.

FIGURE 2. Impression of different conventional catalyst bodies for dense randomly packed beds; spherical particles in red, cylinder-like pellets in blue and multi-lobe structures in green.

Pellets are incorporated in the reactor similarly to particles: by random packing. However, since pellets are often non-symmetrical structures, packing requires more careful attention and the quality of packing affects the reactor performance to a high degree (Cheng et al., 2010; Moghaddam et al., 2019; George et al., 2021).

The main advantage that pellets offer over spherical granules is the more lenient trade-off between pressure drop and internal mass transfer limitations. The pressure drop often still follows an Ergun-like dependency, albeit with compensation for the non-sphericity and altered packing characteristics (Zou and Yu, 1996; Ozahi et al., 2008). However, the design of cylindrical pellets allows for decoupled tuning of the relevant parameters in both phenomena. By the introduction of internal features into the pellet, the mean path length within the shaped material may be decreased without varying the overall diameter of the pellet. In addition, the freedom of determining the exact shape allows for the tuning of the porosity and fluid-solid interfacial area, important parameters in determining the pressure drop and reactor performance in general.

2.3 Extrudates

Extrudates represent a class of shaped catalyst materials that is widely applied in industry, such as in large-scale refinery operations. For extrusion, a slurry of catalyst, additives and water is passed through screw extruder and a die to produce a certain shape. A schematic of the working principle of extrusion can be found in the review by Akhtar et al. (2014). Whilst the basic principle is simple, complexity arises when considering the exact composition of the slurry, as it requires the balanced use of, firstly, agents to improve the rheological behavior, secondly, agents to de-agglomerate the particles and, finally, binder materials (Akhtar et al., 2014; Hagen, 2015). This may also restrict the potential applications of extrusion, as the slurry and its constituents may have specific requirements on properties such as pH, which impacts the possibility of using certain materials (Whiting et al., 2019). An advantage of this technology compared to pelleting is that the composition of the slurry, and specifically the liquid-solid ratio, can be tuned to provide additional porosity for the shaped body (Yakubovich et al., 1984; Kraushaar-Czarnetzki and Müller, 2009). The use of dies, generally with millimeter sized features, allows for additional geometrical freedom compared to granules and pellets. Development of the actual shape of the catalyst has largely been an industrial endeavour and therefore, the geometries used are often proprietary information (Ebner and Keppel, 1991; Bazer-Bachi et al., 2014; Lai et al., 2018). Some of the base geometries that are in use are cylinder-like structures that can also be produced by pelleting and multi-lobe structures (also shown in Figure 2), possibly also with helical variations.

Much like pellets and granules, extrudates are often in the millimeter to centimeter scale, and are randomly packed in reactors. The challenge of achieving consistent packing with these often asymmetrical bodies is exacerbated due to the larger degree of geometric freedom, and, again, the quality of the packing may impact the process significantly (Bazmi et al., 2013). Packing procedures and their impact have been the subject of computational studies, which have aided in providing correlations for the flow behavior of randomly packed extrudates (Marek, 2013). The added benefit of using extrudates rather than granules is, as mentioned above, to have flexibility in the surface-to-volume ratio and gas holdup and to tune the pressure drop. As there is no single extrudate shape, it is difficult to show the advantage of this shaping technology in a quantitative way. However, cases from the literature, for example studying trilobe geometry, demonstrate the decreased pressure drop relative to packed beds of spheres (Bambrick, 1986; Novak and Mateer, 1986; Bazmi et al., 2013; Ravindran and Madhu, 2020).

2.4 Honeycomb Monoliths

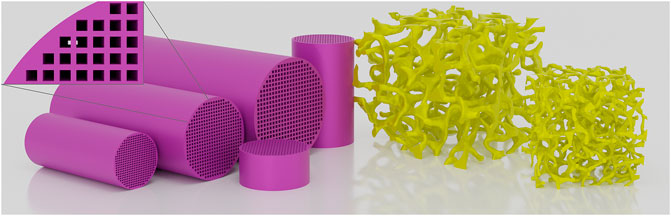

In this work, a distinction is made between honeycomb monoliths and extrudates. While honeycomb monoliths are generally produced by extrusion, their intended application is within standalone reactors rather than as randomly packed beds. Apart from extrusion of catalytic material, monoliths can also be produced from an inert material (either ceramic or metal) and subsequently be washcoated with catalyst (Hagen, 2015; Govender and Friedrich, 2017; Nijhuis et al., 2001). This latter option is often preferred, since the use of solely catalytic material may yield relatively brittle monoliths with a low thermal conductivity, which are relatively expensive as the bulk of the structure is not catalytically utilized. The main design parameters include the shape of the channels, the cell density, the thickness of the walls and possibly, the thickness of the washcoat. Generally, the individual channels are square in geometry (as shown in Figure 3), but circular or more complex geometries are also described. Typical values for the other parameters include a cell density of tens to hundreds of cells per square inch, a wall thickness of hundreds of microns and a washcoat thickness in the order of tens of microns (Boger et al., 2004; Colombo, 2006; Stutz and Poulikakos, 2008). Whatever the size, significant difficulties can be expected when trying to achieve a uniform coating in all channels due to the interplay of various forces (Nijhuis et al., 2001).

FIGURE 3. Impression of two conventional cellular structures; honeycomb monoliths in purple and foams in yellow. The foam model is based on a. stl file of Michael Chadband on gradcad.com.

A washcoat configuration does ensure a short diffusive path towards the active sites, but this also implies that the amount of active material per volume of reactor is low. Hence, this configuration is mostly suited for processes that feature severe external or internal mass transfer limitations (Heck et al., 2001). From a reactor engineering point of view, monolith structures present a strong PFR-like character, but this comes at the cost of zero transverse dispersion (unless the walls are permeable) (Kreutzer et al., 2005; Yawalkar et al., 2005). The latter implies that severe temperature gradients over the transverse coordinate may be observed (Tomašić and Jović, 2006). This can be aided by the use of a coated metal monolith, which has high thermal conductivity that can realize effective radial heat transfer, as demonstrated in studies by Groppi et al. (2012); Groppi and Tronconi (2000). The main advantage of a honeycomb monolith is its low pressure drop. Its combined characteristics have motivated the application of this shaped catalyst in fields with high throughput and stringent pressure drop requirements, such as automotive exhaust catalysis or gas separation with sorbents (Boger et al., 2004; Roy et al., 2004; Rezaei and Webley, 2010). The fact that both internal mass transfer limitations and pressure drop can be separately tuned, and near-isothermal operation can be achieved for a washcoated metallic honeycomb monolith, is promising, but for kinetically-limited reaction systems, the reactor may need to be oversized simply due to the low weight of catalyst per unit volume (Arab et al., 2014; Kapteijn and Moulijn, 2020).

2.5 Foams

Foams, like honeycombs monoliths, are cellular materials. Likewise, the intended application is as a fixed internal rather than a random packing, which aids in providing consistent packing for multi-tubular configurations (Twigg and Richardson, 2002). The main difference between the two is that foams are 3D-cellular materials rather than the 2D channels in monoliths. Geometrically, this means that the structure features an interconnected pore network, as shown in Figure 3. This network is established by the foaming process, in which voids are created throughout the catalytic material. This process can be rather complex, and various approaches exist to achieve the foam structure. Often, a sacrificial template (such as organic particles or a polymer sponge) is introduced into a slurry of catalytic material, which is then burned off to create macroscopic voids (Thijs et al., 2004; Studart et al., 2006). Another way of achieving this is by encapsulating gas bubbles (or gas generating materials) into the paste (Colombo, 2006). These technologies have parallels with the generation of meso- or macropores to avoid diffusion limitations in zeolitic materials, albeit several length scales larger (Schwieger et al., 2016). The exact geometry of a foam is often described through idealized repeating units, but it should be kept in mind that the processes described may introduce small spatial inhomogeneities (Lucci et al., 2017; Gancarczyk et al., 2019). Much like the honeycomb monolith, a foam is also often formed from inert material, to be washcoated with catalytic material. Again, this is desired since foams produced entirely from catalytic material may be quite fragile and relatively expensive.

The resulting structures feature very high porosities (typically 75–90%) and small pores of millimeter size (Thijs et al., 2004; Twigg and Richardson, 2007). The openness of the structure enables transport in the radial direction and as a result of this, hot spots can effectively be suppressed (Li et al., 2015). The heat transfer performance can be further enhanced by exploiting the excellent conductivity of a coated metallic foam (Gascon et al., 2015). The transport of heat and mass in foams have been an active area of research in academia, as demonstrated by numerous publications (Dukhan et al., 2014; Bianchi et al., 2012; Giani et al., 2005a,b; Groppi et al., 2007). Going into the exact correlations is beyond the scope of this review, but it is generally found that heat transfer in a foam is of similar order as in packed beds, at very low pressure drop and moderate mass transfer rates (Patcas et al., 2007; Dietrich, 2012). Intensified heat and mass transfer enables foams to provide true process intensification opportunities, but as was mentioned above, the amount of catalytic material is relatively low which could negatively affect the productivity per volume of reactor (Rezaei and Webley, 2010; Gancarczyk et al., 2019). The advantages have been successfully demonstrated in similar applications as selected for the honeycomb monoliths. However, large scale deployment does not seem imminent (Pestryakov et al., 1996; Patcas et al., 2007; Rezaei and Webley, 2010; Gancarczyk et al., 2018).

A final interesting concept within this class of shaped materials is the use of so-called packed foams, where particles are loaded into a metallic foam. In this way, the enhanced heat management can be combined with a high weight of catalyst per unit volume, albeit at increased pressure drop (relative to the foam) (Vervloet et al., 2013; Gascon et al., 2015; Visconti et al., 2016; Balzarotti et al., 2020). This concept can also be applied by using other reactor internals such as corrugated sheets, wire meshes and static mixers, as in principle, any metallic reactor internal can be filled with catalyst particles (Rezaei and Webley, 2010; Kapteijn and Moulijn, 2020).

The reviewed techniques can roughly be divided into two categories; dense randomly packed beds and cellular structures. The division between the two categories is shown qualitatively in Figure 4. The former class has a high catalyst holdup and is therefore the concept of choice for kinetically-limited reactions. However, achieving proper heat management and acceptable pressure drop are generally challenging with this type of packing. The latter class, in contrast, exhibits very low pressure drop and excellent thermal management, which benefits process economics, but the low catalyst content limits application to specific high-throughput applications. For application of cellular structures in kinetically-limited reactions, the reactor would need to be oversized and this would impact the safety aspects of the chemical process. Hence, there is a “sweet spot” of moderate catalyst holdup and tunability in transport properties, the area in the center of Figure 4, that is yet untouched by current shaping methods, but can likely be achieved with structures produced by additive manufacturing techniques. Operating characteristics such as these have the potential to aid many reaction systems, but one should realize that it is not a solution for all reactor engineering challenges. Some processes indeed require a very high catalyst holdup or extremely low pressure drop, and then it is more reasonable to go with more mature conventional shaping technologies rather than the relatively expensive additive manufacturing. In the next section, the additive manufacturing process is discussed and its ability to produce structures within this “sweet spot”, and perhaps in other, yet unexplored, operating regimes, is assessed.

FIGURE 4. Qualitative comparison of the two classes of conventional catalyst packings in terms of pressure drop and catalyst holdup, alongside the potential 3D-printing “sweet spot”. Structures are not shown to scale.

3 Mature Additive Manufacturing Techniques for Catalyst and Sorbent Materials

Additive manufacturing by means of 3D-printing was introduced in a series of research developments and resulting patents in the 1980s and early 1990s (Gupta et al., 2019b). In the decades following these works, the innovations have found their way in a variety of applications, ranging from simple consumer machines for printing household objects (mainly from polymers) to the production of custom components for aerospace applications (mainly from metals) (Nickels, 2015; Ngo et al., 2018). The terms additive manufacturing and 3D-printing cover a multitude of technologies for the shaping of a variety of materials, which can roughly be divided into three classes: polymers, metals and ceramics. Within the different technologies, the main distinction is between direct and indirect shaping methods. The former class of methods contains technologies where material is deposited locally in the amount that is required. In contrast, the latter class features technologies in which layers of material sized to the print surface are present, producing only certain patterns, for example by local sintering, photocuring or application of binder (Guo and Leu, 2013; Zocca et al., 2015). Past works in the field of chemical engineering have seen the utilization of all of the three material classes mentioned. Firstly, one of the most innovative applications is the use of polymers to manufacture (transparent) microflow devices (Kitson et al., 2012; Kitson et al., 2016; Gupta et al., 2019a; Sagandira et al., 2020; Sans, 2020). This is a key utilization of the ability of 3D printing to manufacture one-off components and rapidly prototype without the economy of scale, and the feedstock flexibility allows for the tuning of the chemical inertness to the intended reaction environment (Manzano et al., 2017; Kotz et al., 2019). The widespread use of polymer-based 3D-printers has also led to an increased interest in the technology within educational environments, enabling the production of cheap laboratory equipment, ranging from simple laboratory vessels to microscopes and fully functional distillation columns (Mardani et al., 2016; Collins et al., 2020; Gordeev and Ananikov, 2020). Secondly, AM of metals is successfully utilized in a chemical engineering context for more demanding processes, such as reactors with custom internals (Sun et al., 2018; Zentel et al., 2020) and is proposed as a viable alternative to the just-in-time production of spare parts in the industry (Durão et al., 2017). Finally, in heterogeneous catalysis and structuring of sorbents, the class of ceramic materials is the most appropriate; this will therefore be the main focus of this chapter. This class of materials, however, has as of yet the lowest level of technological maturity in the AM field due to various complexities (Willemsen and De Boer, 2020). To date, the 3D-printing of ceramics has mostly found applications in the medical field, such as the production of custom teeth and bones. This exploits the AM philosophy by using both the level of detail achievable and the possibility of custom components (Zocca et al., 2015). Specifically for the 3D-printing of ceramics, some additional questions can be asked that set apart the different printing technologies: firstly, can a fully dense product be achieved? secondly, how much ceramic material is present in the initial paste? and thirdly, what is the degree of complexity in the post-processing steps? For a complete overview of the different technologies for AM of ceramics, excellent reviews are available in the literature (Travitzky et al., 2014; Hurt et al., 2017; Chen et al., 2019). Within the framework of 3D-printing of catalysts and sorbents, some constraints limit the choice of an appropriate technology. For example, several AM technologies, such as selective laser melting, locally heat up a powder bed until the melting point (or near the melting point for solid state sintering). For ceramics, this requires very high temperatures (typically higher than 1,000°C), which may alter the catalytic nature of the material. In addition, the melting and solidification steps are likely to have an effect on the (hierarchical) pore structure of the material and its recrystallisation into the desired form (Kruth et al., 2005; Qian and Shen, 2013). With these restrictions in mind, Direct Ink Writing (DIW) and Digital Light Processing (DLP) are considered the technologies with most practical potential. The former technology represents the majority of cases relevant to catalyst structuring in the literature and is relatively mature. Highlighting both technologies allows for an interesting view on two widely different additive manufacturing methods, their benefits and drawbacks. In this section, the two technologies will be introduced with specific focus on the limitations in terms of geometrical freedom and materials that can be used. This is followed by an overview of the possibilities of implementation at the reactor scale. This provides the relevant fundamental context of the different shaping methods to consider the increased process intensification that additive manufacturing may enable.

3.1 Direct Ink Writing

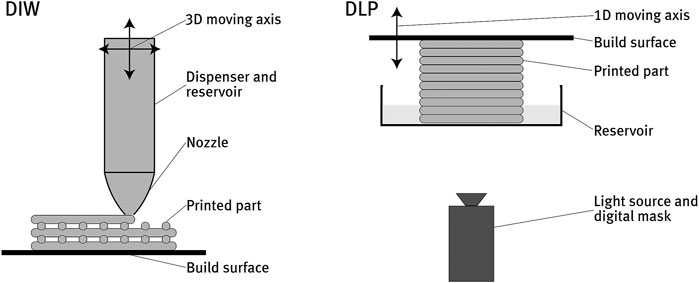

DIW is one of the many synonyms that exist for extrusion-based methods, all of which function on the same principle, but with subtle differences (Travitzky et al., 2014). The use of this method for the current purpose historically stems from the cornerstone work of Smay et al. (2002), Lewis (2006) and Lewis et al. (2006). The printing paste for DIW is prepared by mixing catalyst powder with binders, additives and a diluent, similarly to the slurry used in extrusion (Lefevere et al., 2017). The viscous paste is then loaded into the printer and extruded through a nozzle, as shown schematically in Figure 5. The rheological properties, and specifically the viscosity, are critical variables, since it is vital that the paste extrudes properly whilst the structure does not collapse or sag while printing (M’Barki et al., 2017; Chen et al., 2019). To influence these properties, the diluent content is varied (a typical amount would be 10%) and dispersing agents may be added (Faes et al., 2015). The exact composition generally depends on the properties of the initial powder, which can influence the printability significantly for any AM technology (Shakor et al., 2020; Zhou et al., 2021). For structures printed using DIW, some degree of sagging is often observed, as the freshly printed features weigh down on the rest of the structure and dent the previous layer (Bellini et al., 2005). This effect increases in severity as print time passes and the height of the structure increases. After printing, the structure is dried, possibly debinded, and calcined according to a specific protocol. Performing this post-processing step in a reliable way has proven a challenge, since the conditions of both drying and calcining should be selected with care to ensure a structure that is mechanically stable and retains its intended geometry (Travitzky et al., 2014; Lefevere et al., 2017).

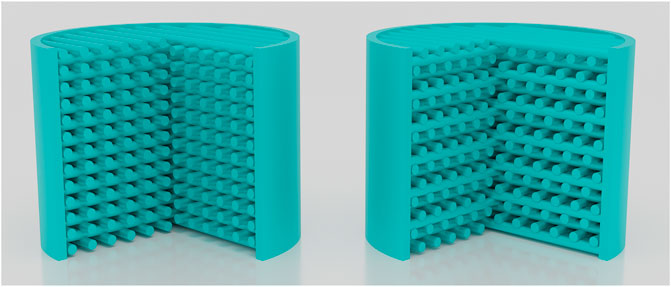

The design possibilities that can be achieved with extrusion-based methods have some constraints. First of all, the size and shape of the nozzle used dictate the size and shape of the features. Previous works in the literature solely use a circular nozzle, and hence the structural features were cylindrical (this is generally true, variations in printing parameters may result in features that better resemble a rectangular prism). The size of the nozzle is generally between 0.1 and 1.5 mm (Peng et al., 2018; Lefevere et al., 2018). In the literature, this printing method has mostly been used to produce structures which are described as pseudo-monoliths or logpile structures. These structures mostly exist in two basic variations; straight and staggered configurations, as illustrated in Figure 6. The catalyst holdup can be varied by changing the gap between the cylinders, which generally results in a gas holdup between 50 and 80%, exactly in the “sweet spot” that is hard to achieve with conventional shaping methods (Lefevere et al., 2018). The overall size of the sample may be partially constrained by the aforementioned denting of the structure over time, and to a lesser degree by the build surface of the printer. Most produced samples in the current literature are in the order of centimeters, but it can certainly be hypothesized that larger structures are possible when optimizing the rheological properties; the small size may be due to the proof-of-concept stage of the technology, without any scale-up attempts. It is likely that there is potential for scaling, albeit with a possible loss of printing resolution, thanks to successful developments of ceramic 3D-printing on the meter scale being undertaken in other fields of research (Zocca et al., 2015; Ngo et al., 2018). The degree of shrinkage in the finished product, due to diluent and organic binder removal, is limited as the solid fraction of the 3D-printing paste is fairly high (Chen et al., 2018; Peng et al., 2018). One of the drawbacks of this technology for other applications is its inability to produce fully dense products (Chen et al., 2019). However, specifically for catalyst and sorbent materials, densification during sintering would be detrimental to the pore system and is thus not pursued. The removal of organic binders may introduce some residual porosity and hence it is emphasized that careful consideration of the post-processing protocol is required to ensure that the finished product is dimensionally accurate and possesses the intended pore structure (Shang et al., 2015; Lefevere et al., 2017).

FIGURE 6. Impression of the two variations of 3D-printed logpile structures, straight on the left side and staggered on the right side.

The printing speed depends on a variety of factors, and is often not stated in the literature. From operating experience at the Flemish Institute for Technological Research, a general guideline is that the printing of centimeter-sized structures through DIW requires tens of minutes to hours. Again, this value only serves as a rough indication for comparative purposes, as printing times may vary across different machines and may be decreased through scale-up progress and higher industrial experience with the technology.

Extrusion methods are generally suitable for a broad range of catalytic and sorbent materials. As will be shown in the next section, in particular the DIW of zeolites and Metal Organic Framework materials (MOFs) has been well researched to date. From a chemical point of view, the printing does not seem to influence the material drastically. As mentioned, some porosity changes are observed for the printed material compared to the initial powder. This, in turn, affects the active surface area of the material. These considerations are largely related to catalyst-binder selection, the challenges of which are no different for 3D-printing than for conventional shaping methods.

3.2 Digital Light Processing

DLP is a stereolithographical method, employing photopolymerization to enable the shaping of material. For application in DLP, the catalyst is mixed with (acrylate) monomers, dimers, oligomers and photoinitiator compounds to form a low-viscosity ink, also called resin. Shaping occurs by local setting of a layer of this ink by the application of UV light through a mask. The light activates the photopolymerization locally, setting a polymeric network and trapping the catalyst inside the intended geometry. The light is guided by the aforementioned mask, which consists of thousands of pixels (Gordeev and Ananikov, 2020). The printing is conducted upside down, meaning that the structure is pulled up layer by layer from the bath of ink, as shown schematically in Figure 5 (Zocca et al., 2015). The formulation of the ink has stringent requirements on total content, size and the dispersion of solids, as these properties influence the optical and rheological properties which are important to ensure proper operation of the printer. As a general guideline, a maximum of approximately 60% solid content in the ink is possible to achieve (An et al., 2017; Varghese et al., 2018; Li H. et al., 2020). During post-processing, the polymeric network is combusted, which is required since it is not stable at high temperatures, and therefore needs to be removed before use. Whilst this holds for many zeolite catalysts, sorbents do not typically operate at such high temperatures and thus the polymeric matrix does not have to be removed for this application. Removal of the polymeric network is likely to introduce significant shrinkage and additional porosity. In addition, anisotropic shrinkage is reported, i.e. a larger degree of shrinkage along a certain axis (An et al., 2017).

The feature size that can be reached with DLP is governed by the size of the pixels. These are generally a few microns, depending on the printer, but in any case, this is orders-of-magnitude lower than DIW (Zocca et al., 2015). In the literature, the overall size of the sample is in the order of centimeters. This is comparable to DIW, but it should be noted that DLP print surfaces are generally smaller than DIW-type machines. Operating experience with this technology shows that the printing speed is much lower, and a structure similar to the DIW benchmark structure takes approximately ten times longer to complete. Besides the capability of DLP to yield more complex geometries, an additional advantage that this technology offers in scale-up considerations is that the time required to construct a layer is independent of layer size, as it solely depends on its curing times. This may allow for a more favourable comparison of printing times at larger scales.

Structural design through DLP may be limited by two factors. One constraint in design freedom arises from the fact that the structure is pulled up from the bath of ink. This imposes slight limitations on geometries that can be achieved, as crevices where liquid is trapped inside the structure should be avoided. In addition, samples are reported to be affected by the staircase effect (Ngo et al., 2018; Zimmer et al., 2021). This phenomenon is a result of the layered AM process, and introduces small imperfections, as curved features are always stepped (although developments in the relatively new continuous DLP enable enhanced surface finishing) (Janusziewicz et al., 2016). These limitations are minimal and in the literature, it is seen that DLP is used to produce a far greater variety of structures compared to DIW (Papetti et al., 2018). These are mostly produced from alumina, silica, zirconia or silicon carbide (Chartier et al., 2002; Zakeri et al., 2020; Bai et al., 2021; Sun et al., 2021). Whilst these are potential catalyst support materials, the use of DLP for the shaping of actual catalytic material and application in reactive environments is less widespread in the literature, with some notable studies in activation and liquid phase chemistry (Manzano et al., 2017; Santoliquido et al., 2017; Zhakeyev et al., 2017; Simon and Dimartino, 2019; Wang et al., 2020; Zhang et al., 2020). There are potential limitations on materials when they are influenced by the conditions of the ink, e.g., for photoresin the pH, balance between viscosity and copolymerization and exposure/curing parameters need to be accounted for when selecting solid materials. Since problems of this nature have not yet been fully addressed, it can be concluded that DLP currently suffers from more practical issues than the more mature DIW. However, if these are resolved, current developments demonstrate that the geometrical freedom has good potential for realizing the promise of process intensification.

3.3 The Reactor Scale

As mentioned, the field of AM of catalysts is fairly young and hence most developments are on the R&D lab scale, with centimeter-sized structures. In fact, the initial testing of printed catalyst is often done by crushing printed samples to ensure that the printed powder has maintained similar catalytic activity compared to the original powder (Middelkoop et al., 2019b). For the application of these relatively small structures in industrial processes, two strategies are currently described in the literature. The first is the numbering up of multiple smaller reactor vessels. A strategy similar to this is the use of multi-tubular reactors in large-scale chemical processes. This reactor configuration is mostly used for reactions with strong heat effects, as heat transfer to the catalytic bed may be limiting in reactor tubes of larger diameter. Conventionally, these tubes are randomly packed with particles. A complication that is often encountered is packing inconsistencies amongst the different tubes that manifest themselves in a maldistribution of the flow caused by differences in pressure drop (Shinnar et al., 1992). One notable benefit that a 3D-printed catalyst may offer is consistency; as the printed structures are identical, the pressure drop over the different tubes is exactly the same and thus the even distribution of reactants is facilitated. An example of this scaling strategy that is perhaps more relevant is the use of numbering up for the scale-up of (photo-catalytic) microflow applications. In recent decades, microflow chemistry has emerged as an efficient way of producing chemicals with multiple step syntheses without the need for separate batch reactors (Mizuno et al., 2016). However, due to the relatively small size of an individual production unit (much like the current size of 3D-printed catalyst structures), the use of multiple units is required. When scaling up, challenges exist in evenly distributing reactant flows amongst multiple microflow devices, as was the case for large scale multitubular reactors in industry. Some loss may be experienced as the economy of scale does not work one-to-one for numbering up, but the concept provides great opportunities for distributed production (Dong et al., 2021).

A second scale-up strategy described by Danaci et al. (2019) is to make a longer vessel and stack multiple 3D-printed structures to fill it. This concept is simple and does not require additional equipment, but care is likely to be required to ensure that the different elements are aligned. The 3D-printing of connector pieces as part of the different elements may aid in this challenge.

Both of these approaches have the potential to live up to the potential of 3D-printing, as structure placement can be consistent which allows for even performance. This is in contrast to a random packing approach commonly used for extrudates and pellets. One key aspect that needs to be taken into account in both approaches is the fact that structures can be quite brittle and that shrinkage may influence the dimensional accuracy, which may give rise to sealing issues upon incorporation in the reactor.

Finally, some caution is necessary when considering the reactor scale, as the current scale of printing is relatively slow and the process requires many manual steps. This is in contrast to an industrial screw extruder or granulation process, which can operate in a more continuous manner. In addition, it is good to take into account other technologies which are currently in development as well as more mature scaling of metallic 3D-printing, as these potentially enable more facile printing of large-scale structures.

4 Application of 3D-Printed Structures in Chemical Processes and Potential Process Intensification

The literature features many works in which formulation and operating parameters are optimized for the 3D-printing of specific materials for application in chemical processes. A large portion of the research scope in these studies is typically dedicated to chemical optimization; looking into morphological changes in the pore system due to the printing and sintering operations, assessing any adverse catalytic influences of binders and establishing whether the printed and post-processed structure is mechanically stable. Often, this is concluded with a proof-of-concept, where the novel geometry is benchmarked against a reference case (often a packed bed or a crushed structure). Before reviewing some of these benchmarking results, it is useful to establish some common reasons for ambiguity in the comparison. This information is vital to take into account, since it may obscure the observed benefits of the 3D-printing technology.

Firstly, it is often seen that 3D-printed structures are compared at constant WHSV or flow rate. This is not necessarily bad practice. However, it should be realized that the gas holdup is often different for 3D-printed structures compared to packed beds, so that a WHSV value does not represent the same residence time in a packed bed as it does in a 3D-printed structure.

Secondly, it should be acknowledged that many 3D-printed structures include a binder. This lowers the amount of catalytic material per mass of solid and the binder material may induce unwanted catalytic effects. This has already been discussed above, but is vital to reiterate, since some works reported in the literature directly compare results of a powder without binder to a 3D-printed structure with binder, without decoupling the effects of 3D printing and inclusion of binder.

Thirdly, it may occur that a reaction is tested which is operated in the internal mass transfer limited regime as a benchmark. The availability of active sites thanks to additional porosity may then strongly impact the reaction rate. On the other hand, binder material may also block existing pore systems, leading to lower accessibility of active sites. In the analysis of the results, macroscopic effects such as improved residence time distribution and mixing behavior have to be decoupled from microscopic effects within the catalytic pore system.

Finally, the authors wish to stress that actual information about operating windows in terms of mixing behavior, dispersion, pressure drop and heat- and mass transfer is not as readily available as for the conventional shaping technologies. Hence, the observed results may be explained by a variety of effects which have yet to be assessed concretely. For example, logpile structures, which are pseudo-monolithic structures, can be expected to exhibit transverse dispersion at an intermediate level between honeycomb monoliths and packed beds, but this cannot be put into quantitative terms with the current information available. Quantitative information is solely available for the gas holdup and solid weight per volume, which is also at an intermediate level between the two model reactor types.

With these considerations in mind, relevant cases can be reviewed. This is done in two sections. The first section summarizes developments where ceramic catalyst is shaped into logpile structures, since these represent the majority of relevant studies in the field. The second section looks beyond this, and considers the structuring of (coated) reactor internals from different materials through the use of AM. Whilst these latter developments may not be directly related to catalysis, and may not succeed in achieving the “sweet spot” of catalyst holdup, process intensification is realized nonetheless. Looking into these concepts can aid in the further exploration of the potential of the shaping technology, and perhaps some of the postulated benefits can be translated to the shaping of catalysts as well.

4.1 Logpile Structures

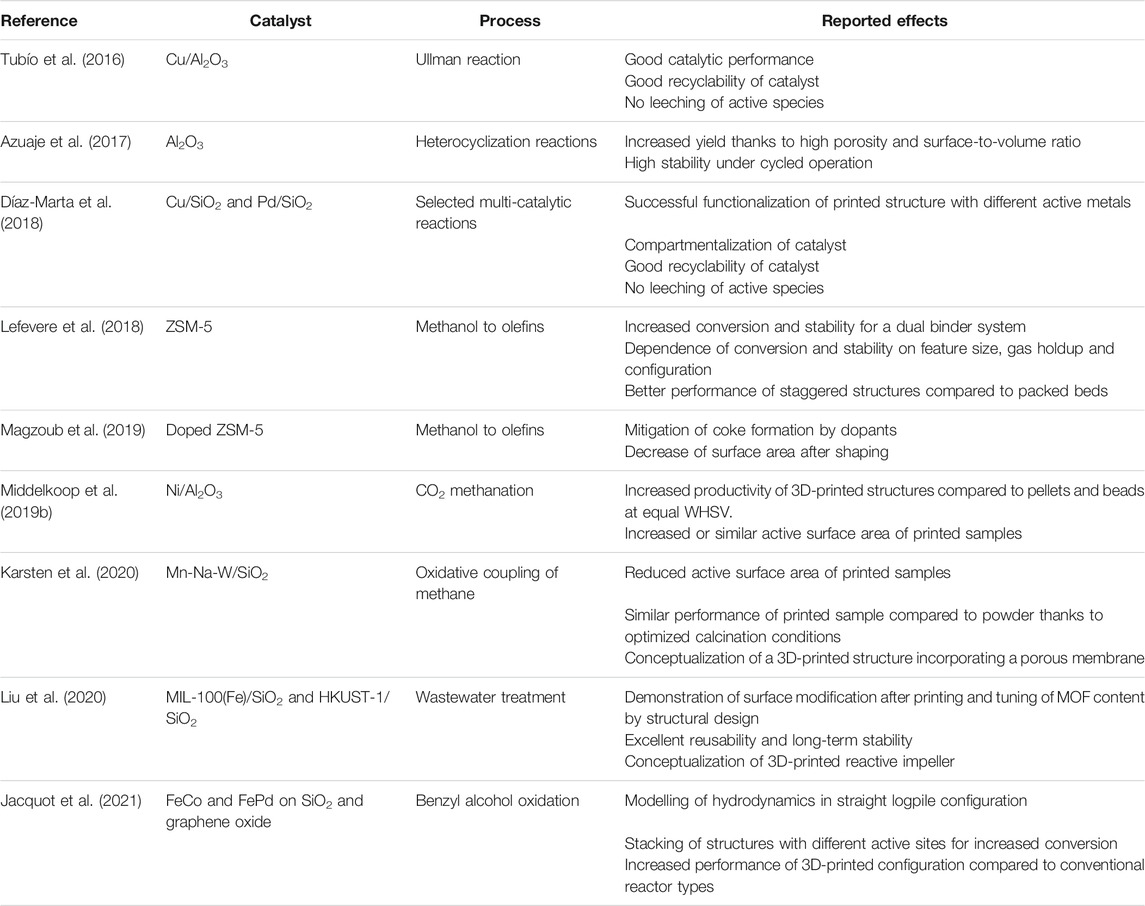

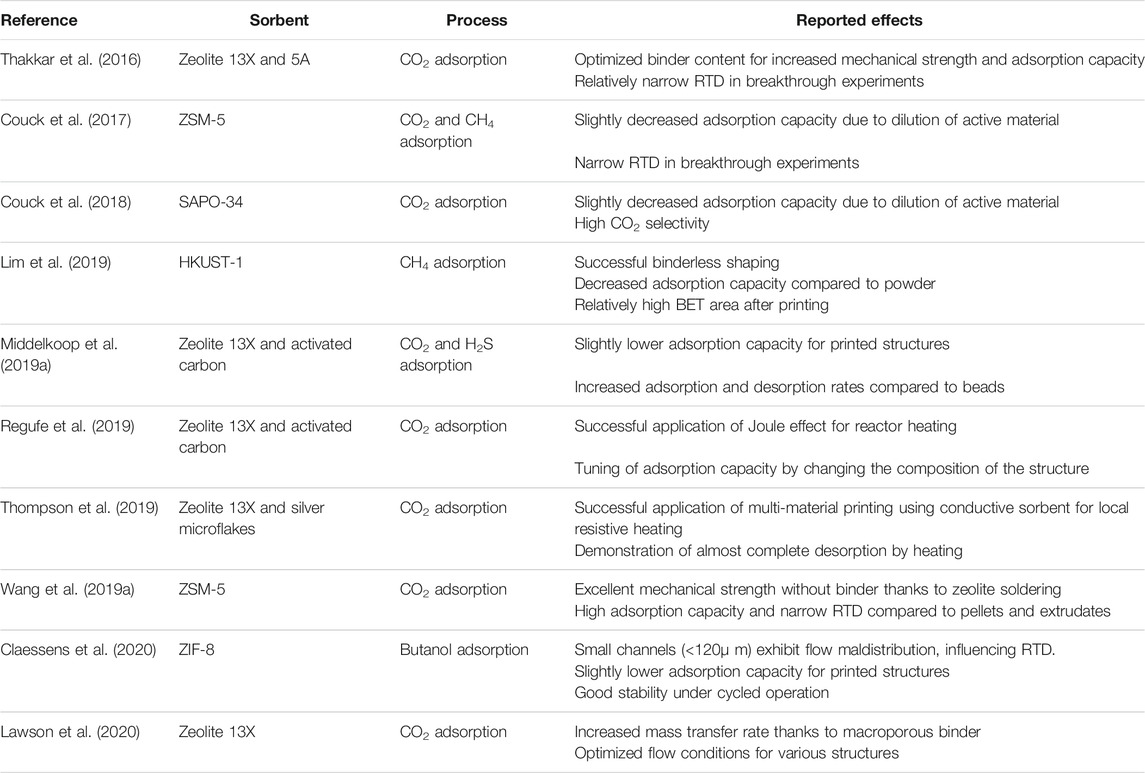

Tables 1, 2 outline some of the highlights of the work pertinent to logpile structures shaped by DIW for catalytic and sorption applications, respectively. Please note that dozens of additional studies exist, of which many are referenced in this work, however from an engineering point of view they are deemed out of the scope of the current highlights. In the text following this table, several cases are further elaborated upon in the assessment of successful process intensification.

Two separate groups, at the University of Santiago de Compostela and Missouri University of Science respectively, are noteworthy for their pioneering work. The work by the University of Santiago de Compostela, and in particular the publications by Tubío et al. (2016) and Díaz-Marta et al. (2018), deserves great attention. In these works, the shaping of copper-based catalysts is investigated. Application of these catalysts is done for different model reactions in the liquid phase, but this is a proof-of-concept for versatility of the catalyst rather than an in-depth reactor engineering study. The developments from a chemical perspective, however, are very relevant. In the two works, various impregnation strategies are employed. Both the wet impregnation of alumina with copper species prior to printing and the activation and impregnation of a silica monolith after printing were attempted. It was shown that both methods of impregnation were successful, and that the active metal was distributed throughout the structure. Whilst the latter method did take significantly longer due to the various steps of post-processing, activation and impregnation, it is an important development for the application of the 3D-printing concept in catalysis; in the first place because impregnation of the shaped body unlocks a larger variety of catalyst holdups compared to washcoating; and secondly, because the ability to apply chemical functionality after printing allows for the production of more generic structures that can be tailored for specific reactions by impregnation. This has the potential to simplify the printing process since structures from only a handful of standard support materials are required to enable the application of dozens of catalysts. In addition, good recyclability and stability of the structures is reported, which is important since the structured catalyst (and the active metal) likely represents a significant portion of the operating costs. A testament to the versatility of these techniques is the multi-catalysis concept that relies on the impregnation of the same support material with different active metals, and the stacking of the two catalysts to combine their catalytic action (Díaz-Marta et al., 2018). In a follow-up publication, the compartmentalization concept was enhanced by the use of magnetic nanoparticles that allows for facile separation of the various immobilized catalytic functions (Díaz-Marta et al., 2019). In addition, a polypropylene vial for conducting catalytic tests, customized to the size of the structures, was fabricated by 3D-printing (Díaz-Marta et al., 2020).

Within the same area of study, researchers from the Flemish Institute for Technological Research have brought advances in the field of 3D-printing of catalysts and sorbents, providing a sound basis for potential process intensification. The work of Lefevere et al. (2017, 2018) features ZSM-5, a catalyst, shaped by DIW, presenting an illustrative investigation into the influence of binders and geometry on the catalyst activity. It was concluded that a mixture of silica and AlPO4 provides optimal results for methanol to olefins, which was used as test reaction. During single binder experiments, AlPO4 was found to increase performance thanks to the relatively low specific surface area. The stability and catalyst lifetime, however, also decreased and this was compensated for by the addition of silica. Following this optimization, the influence of feature size and configuration was assessed. An increasing fiber diameter was found to correlate with a decrease in performance. In addition, lower gas holdup was found to result in an increase in conversion. It was concluded that the 3D-printed logpile structures with a staggered configuration outperform their straight counterparts, and both 3D-printed structures (with features of 1.5 mm) outperformed a conventional packed bed of 2 mm spheres at equal weights of solid. Whilst the work presented has definitely touched upon the various relevant aspects, it should be noted that the flow rate of (diluted) methanol was constant throughout the experiments. In the context of the different bed configurations investigated, the gas holdup varied and hence, the residence time varied. From the publication, it is unclear if this variation in residence time may contribute to the positive effects observed for the 3D-printed structures. In addition, the described effect of feature size may simply be due to varying internal mass transfer resistances, and further investigation is required to attribute the observed effects to the actual geometry enabled by the 3D-printing technology.

A third experimental effort which has received much attention in the literature is the 3D-printing of zeolites and MOFs for the separation of small molecules. This area of research is well represented in Table 2, and most of these studies show similar effects: a decreased adsorption capacity and a narrow RTD during breakthrough experiments. The former is mostly due to the use of binder, as reported in these studies. The latter may enable process intensification. For detailed discussion, the work of Lawson et al. (2020) is considered. This work considers the use of zeolite 13X as sorbent for CO2 separation. In tuning the binder composition, it was observed that the use of methylcellulose is an effective way to generate additional porosity after calcining, and that this increased the mass transfer rate. Furthermore, the gas holdup was varied by producing structures with a varying number of cells per square inch. A detailed study, combining experiments and a fitting procedure, was then conducted to investigate the effect of structural parameters and superficial velocity on the breakthrough curve. The influence of humidity was also assessed. It was shown that for a high number of cells per square inch, a low superficial velocity is optimal, but that the structures with low density are superior in dynamic adsorption performance. The extensive work, along with a fundamental understanding of phenomena involved leads the way to an a priori design of an optimal structure and is thus exemplary for this field of research.

These developments demonstrate that many hurdles have been overcome and that printing of catalyst or sorbent materials can be done successfully. In addition, a range of reactive applications has been tested, in which comparable structures are often employed. The reported studies, however, also reinforce the conclusion that current research has been largely motivated by considerations from chemistry and materials science rather than reactor engineering. Hence, the added benefit in a process intensification context has not objectively been achieved in the current works.

4.2 Washcoated and Metal Structures

One particularly relevant area of research in non-ceramic AM for process intensification is research in which the (supported) catalyst is not a ceramic material, but a metal. Various studies have employed the catalytic effect that metals exhibit at high temperatures to produce so-called selfcatalytic reactors (SCR’s). Wei et al. (2020) have conducted an excellent experimental work in which they employed Selective Laser Sintering (SLS) to produce honeycomb monolith SCR’s with variations of channel geometry. More specifically, iron, cobalt and nickel alloys were investigated for use in CO2 hydrogenation, Fischer-Tropsch synthesis and dry reforming of methane. All of these yielded promising results, with a performance close to or higher than conventional reactors. From an engineering perspective, it was concluded that the thermal conductivity of these materials was orders-of-magnitude higher than conventional (ceramic) support materials and thus the heat management of the reactor was intensified. In addition, the nickel structure was well able to withstand the high-temperature reaction environment. For the Fischer-Tropsch process specifically, it was shown that selectivity may be steered by the configuration of the structure. However, a critical note needs to be made here as, due to the different porosities, the residence time was not constant throughout the different experiments.

Similar work has been conducted by Agueniou et al. (2021), who washcoated a stainless steel honeycomb monolith (also produced through SLS) with supported nickel catalyst. It was shown that the nickel present in the stainless steel already provided some catalytic activity for dry reforming of methane, but that the addition of the washcoat greatly enhanced conversion. In addition, it was shown that a stainless steel structure enables far better heat management compared to a cordierite structure and that the AM process introduces some surface roughness which positively influences heat transfer rates.

Another work of interest in this context is the catalytic static mixer concept as utilized by Nguyen et al. (2018). In this study, electron beam melting is employed to shape stainless steel into a static mixer geometry. This structure is then coated with either nickel or palladium for application in a hydrogenation reaction. The excellent heat and mass transfer abilities of the concept were demonstrated.

All of these studies were able to successfully produce the metal structures with 3D-printing and quantitatively showed the added benefit of the catalyst geometry. However, the first two structures described are essentially honeycomb monoliths, which can already be created through conventional shaping technologies. It is therefore questionable if the 3D-printing aspect provides much novelty in this regard.

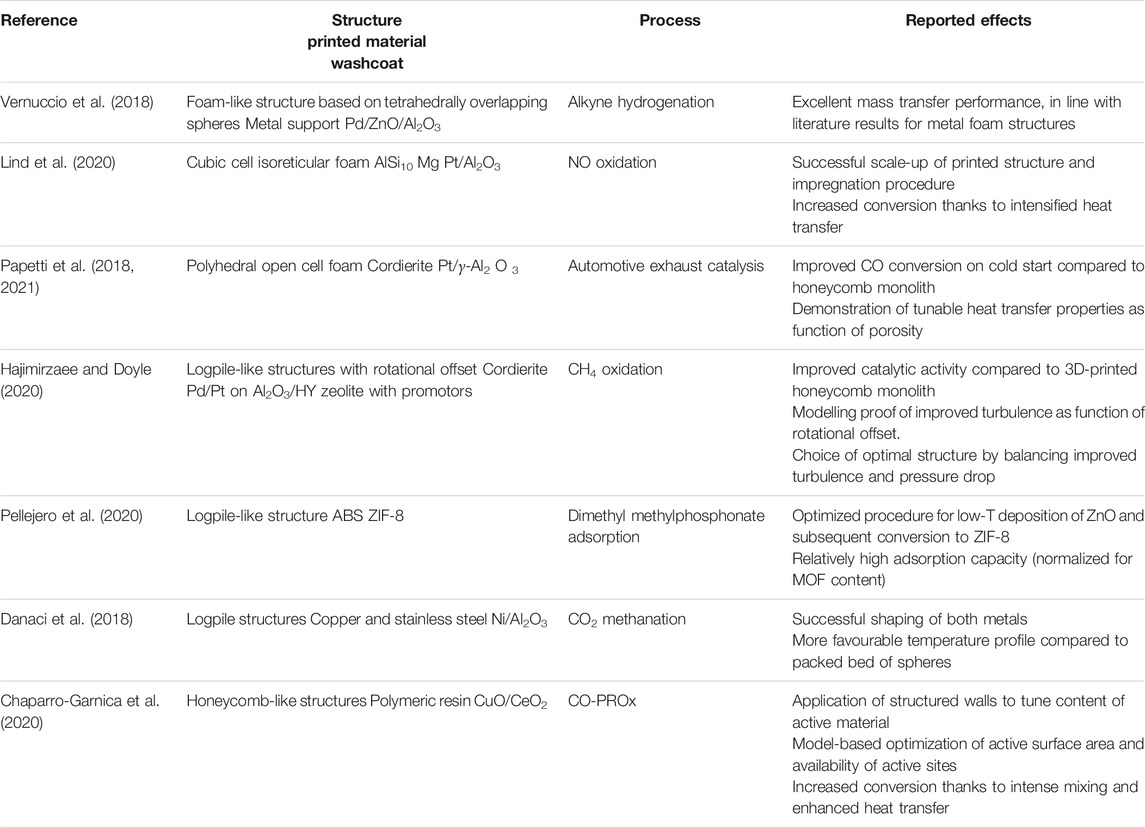

Another concept that has received a lot of attention is that of additively manufactured cellular materials from either ceramic material or metal, to be washcoated with catalyst. This concept is generally reported as Periodic Open Cellular Structures (POCS). These foam-like structures have a highly regular structure, which differentiates them from regular foams with a pore size distribution. Various researchers have looked into this concept, and report the high specific surface area and excellent heat transfer performance at low pressure drop (Klumpp et al., 2014; Bianchi et al., 2016; Busse et al., 2018; Lämmermann et al., 2018; Bracconi et al., 2020; Do et al., 2020). The prime advantage of these structures is the tunability of the these parameters as a function of cell geometry and size. The concept is published under a variety of different names for different foam-like geometries, such as aluminium cubic iso-reticular foams by Bastos Rebelo et al. (2018), periodic cellular ceramics with rotated cube unit cell by Santoliquido et al. (2017) or triple periodic minimal surface packings by Zimmer et al. (2021). None of the aforementioned sources feature reactive application of the structure, but various other researchers have looked into this. Several of these studies and their findings are summarized in Table 3.

The critical note to be made with regard to the studies listed in Table 3 is that the weight of catalyst per volume of reactor is very limited for the washcoat configuration employed, much like the situation for honeycomb monoliths and foams. Whilst this has its inherent disadvantages, many of the studies mentioned do realize significant process intensification. More specifically, the use of modelling to decide upon the ideal structure is reported for several of these applications (Chaparro-Garnica et al., 2020; Hajimirzaee and Doyle, 2020); a consideration which is mostly absent in the studies listed in Tables 1 and 2. At the same time, these works demonstrate that the highly regular structures with custom unit cells are able to provide quantitative benefits over the more randomly structured foams. This is a direct result of the AM strategy applied. Scale-up is also considered to a larger degree compared to the DIW logpile studies, with structures in the order of tens of centimeters being reported (Lind et al., 2020). This is already in the relevant length scale for applications such as automotive exhaust catalysis and hence, the potential for short-term application is very much present.

A final work of interest that demonstrates the excellent heat transfer characteristics of an AM-structured POCS for a reactive application is that of Fratalocchi et al. (2020). They shaped AlSi7Mg0.6 by selective laser melting for application as a packed foam for Fischer-Tropsch synthesis. Reactive experiments showed that the performance of the packed foam configuration was comparable to a packed bed of spheres without further internals. In addition, it was shown that the structure provided a level of temperature control that could not be achieved in a packed bed of spheres and presented near-isothermal conditions. In addition, co-printing the reactor wall was shown to greatly enhance the heat transfer properties (Fratalocchi et al., 2021). It was also mentioned that acceptable pressure drop could be achieved by tuning the flow properties. Hence, all aspects of process intensification through the structuring of reactor internals are touched upon in this excellent work.

Apart from the reactive studies mentioned, there has also been much work reported on the shaping of metals to achieve high heat transfer in heat exchanger applications (Hansjosten et al., 2018). The exact performance parameters are out of the scope of this review, but these insights are likely to aid in designing optimal structures for heat transfer, or to be employed in a packed foam-like approach. Other relevant developments are studies where the flexibility and ease-of-use of polymeric AM was used to do detailed hydrodynamics studies on model foams which provided validation data for computational fluid dynamics (Gładyszewski and Skiborowski, 2018; Bracconi et al., 2019). A good example of this is the work by Kramer et al. (2018), who used ABS cylinders as a model of ceramic or metallic substrates for Steam Methane Reforming and optimized the channel geometry of a monolith-like structure. Developments such as these, where modelling and experimental studies are combined to aid in the conceptualization of tailored operating windows, are key in realizing the process intensification potential of the AM technology.

5 Potential for Increased Process Intensification

It has been shown in the previous section that the 3D-printed structures currently produced in a research context may offer some degree of process intensification, and possibly achieve the previously introduced “sweet spot”, but in general these geometries are fairly similar to structures that can be created using conventional methods. Hence, it is questionable whether this small gain is able to justify the cost and complexity added in the production process. It is therefore interesting to provide perspective and outline enabling developments in 3D-printing which maximize the process intensification potential of this technology. This section introduces the three most relevant concepts and considers the process intensification that can be achieved.

All of these options would benefit greatly from better scaling perspective, as ultimately, large scale implementation requires large structures. This is not a process intensification principle on its own, but should be considered as an underlying determinant for the successful implementation of any 3D-printing innovation.

5.1 Binderless Printing

In the previous section it was advocated that the current studies into 3D-printed catalyst and sorbent structures have an inherent disadvantage over virgin powders, as they are diluted with binder materials. Enabling binderless printing would aid in addressing this obvious limitation, both by enabling a higher productivity per volume and eliminating possible adverse side-reactions promoted by binder materials. Different researchers have already made efforts towards realizing this concept, both in the context of 3D-printing as in conventional shaping technologies (Xu et al., 2012; Elkoro and Casanova, 2018; Wang S. et al., 2019; Lim et al., 2019; Li Z. et al., 2020; Lawson et al., 2021c). In assessing these results, precaution is required as the developments are often highly specific to a certain catalyst within a specific process. The major reason why protocols are not widely applicable is the fact that the ability of a binderless body to be mechanically stable is determined by the cohesive strength of the powder, the degree of porosity required and the post-processing procedure. In addition, the required mechanical stability also depends on the intended application and the shape of the body (Akhtar et al., 2014; Besser et al., 2017; Xu et al., 2017; Kong et al., 2018). This complex interplay of factors demands for a large amount of research for every single application. Within the 3D-printing technology, however, it is deemed an essential development. Especially since for kinetically-limited processes, it is important that the catalyst weight per volume of reactor is high to achieve a small footprint of the process, which is desired from the point of view of both process safety and economics. These sort of processes are generally unsuitable for intensified reactor internals such as monoliths and foams, and thus optimization of binderless 3D-printed catalyst structures may enable operation in the “sweet spot”; medium catalyst holdup and ample catalytic material without thermal mismanagement or unacceptably high pressure drop.

5.2 Local Variations

Throughout this review, the potential for local catalyst structuring has been mentioned as one of the key advantages of the additive manufacturing technology compared to conventional shaping technologies. However, to the knowledge of these authors, this feature has only been used to provide process intensification in one previous work (Davó-Quiñonero et al., 2019). Without requiring advanced simulations or detailed experiments, it is possible to postulate some advantages of the local structuring of catalyst to introduce porosity profiles.