- 1Clean Energy Research Center, Korea Institute of Science and Technology, Seoul, South Korea

- 2Department of Wood Science, University of British Columbia, Vancouver, BC, Canada

- 3Department of Chemical Engineering, State University of New York College of Environmental Science and Forestry, Syracuse, NY, United States

- 4The Michael M. Szwarc Polymer Research Institute, Syracuse, NY, United States

The increased demands on renewable and sustainable products require enhancing the current conversion efficiency and expanding the utilization of biomass from a single component (i.e., cellulose) to entire biomass components in the biorefinery concept. Pretreatment solvent plays a critical role in various biorefinery processes. Recent pretreatment solvents such as organic co-solvents, acid hydrotropes, ionic liquids and deep eutectic solvents showed effective biomass fractionation as well as preservation of high-quality cellulose and lignin under mild conditions. Despite these significant enhancements in biomass pretreatment solvent, there are still many challenges, such as feedstock variety, valorization of non-cellulose components, and eco-friendliness of the applied catalyst and solvent. These technical, economic and environmental obstacles should be considered in future biomass pretreatment solvents. In particular, the development of feedstock-agnostic solvent with high fractionation performance for high quality and quantity of all three major components (i.e., cellulose, hemicellulose, and lignin) together would be an ideal direction.

Introduction

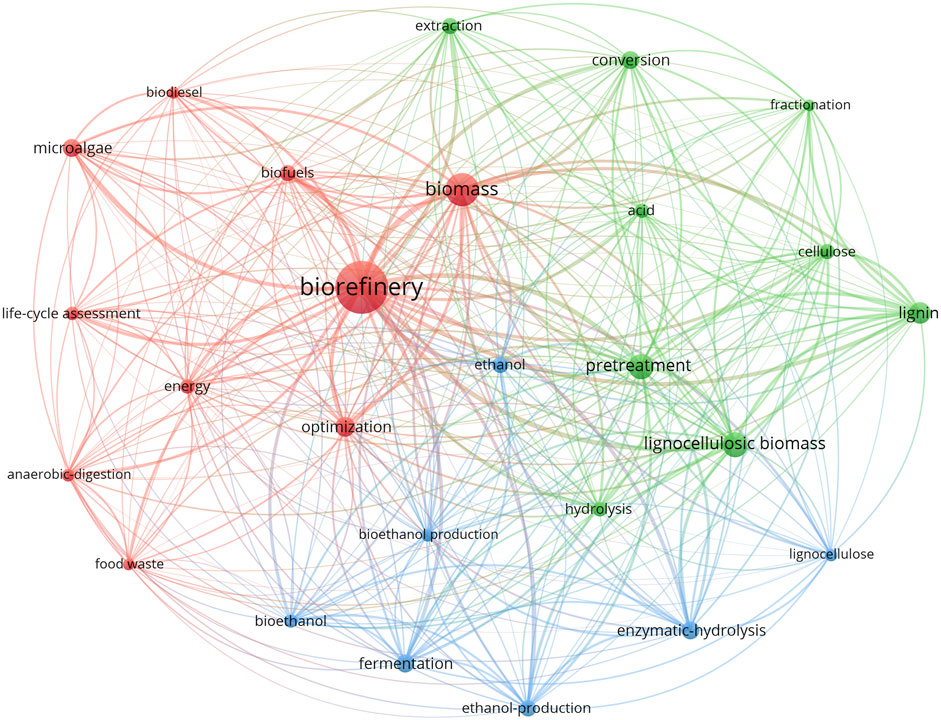

Environmental concern and shortage of petroleum-based resources have increased people’s interests in alternative fuels, chemicals and materials. Lignocellulosic biomass, a heterogeneous polymer mainly composed of carbohydrate fractions such as cellulose and hemicellulose with lignin, a natural aromatic macromolecule, is a promising renewable and sustainable resource in these applications. Due to the structural rigidity and complexity of biomass, diverse pretreatment strategies have been developed in biorefinery processes. Figure 1 shows the network map generated by analysis of keyword co-occurrence in the recent 3,000 scientific publications on “biorefinery” using the full-counting method of VOSViewer (Perianes-Rodriguez et al., 2016). As shown, pretreatment is found to be a major research topic in biorefinery community. Although the processing conditions vary depending on the target products, in general, pretreatment aims to facilitate and maximize the conversion/application of major biomass components. In the pulp and paper industry, for example, the pretreatment fractionates the qualified fibers by removing lignin. Similarly, conventional methods such as hydrothermal, dilute acid, alkaline, and steam explosion pretreatments focus on the conversion/utilization of carbohydrates, in particular, cellulose. However, current biomass-derived products are still challenging to compete with petroleum-based products in terms of their economic compatibility. Recent biomass utilization strategies target not only cellulose but also other major components such as hemicellulose and lignin to overcome this challenge.

FIGURE 1. The network map by analysis of keyword co-occurrence in the recent 3,000 scientific publications on “biorefinery.”

Lignin has been reported as a major recalcitrance factor in biomass conversion. It is an aromatic macromolecule composed of different aromatic units (i.e., syringyl, guaiacyl, and p-hydroxyphenyl units) linked through C-O and C-C linkages. It limits enzyme access to cellulose, decreases enzyme activity by non-productive binding, and reduces microorganism’s activity as an inhibitor (Yoo et al., 2020). Therefore, removal and modification of lignin in the plant cell wall are effective ways to enhance biomass conversion. Alkaline and organosolv pretreatments show significant delignification effects from biomass (Kim et al., 2016; Zhou et al., 2018). However, these conventional pretreatment methods focus on cellulose utilization; therefore, the removed lignin cannot avoid significant condensation and other modifications (Yoo et al., 2017). This is one of the reasons why the recovered lignins from the conventional pretreatments showed limited applications. Hemicellulose is a heterogeneous polysaccharide with xylan, galactan, arabinan, mannan, glucan, and some sugar acids like glucuronic acid and galacturonic acid. This component is relatively easy to remove from the plant cell wall, so hydrothermal treatment without additional catalysts is enough to fractionate. A certain type of pretreatments like ammonia pretreatment can selectively remove lignin while retaining most cellulose and hemicellulose; therefore, these carbohydrates can be hydrolyzed and/or fermented together (Zhao et al., 2020; Hans et al., 2021). However, this pretreatment is not effective on woody biomass (Kim et al., 2016). Also, under severe acidic pretreatment conditions, the hydrolyzed carbohydrates can be degraded and dehydrated to furans like HMF and furfural. These furans can be repolymerized and condensed to the unwanted solids named pseudo lignin because they are measured as acid insoluble lignin in the analysis (Shinde et al., 2018; He J. et al., 2020). Smith et al. reported that lignin and pseudo lignin aggregate onto cellulose surface and inhibit biomass conversion (Smith et al., 2016).

A processing solvent plays a crucial role in biomass pretreatment. Characteristics such as solubility of each component and phase change temperatures (e.g., boiling point and freezing point) of pretreatment solvent are closely associated with pretreatment and fractionation effects as well as separation and recycling of catalysts and solvents. In addition, the feasibility of bioresources for solvent production, biodegradability and low-toxicity are essential to achieve a carbon neutrality and eco-friendly processing system.

Several pretreatment solvents were newly developed to enhance the valorization of all three major components. Firstly, these pretreatment solvents focus on both the quality and quantity of all three components. Solvents are designed to reduce the severity of pretreatment conditions which directly affect degradation and condensation of hemicellulose and lignin during the processes. Secondly, sustainability and environmental impacts of the solvents are considered. It includes toxicity, recyclability, biodegradability, energy consumption for its processing and separation, and bio-derivability. This mini-review summarizes technical features and obstacles of recently developed pretreatment solvents and discusses the remaining challenges and future perspectives.

Recent Biomass Pretreatment Solvents

Organic Co-Solvents

Organosolv pretreatment has been applied to various biomass conversions due to its effective lignin removal. Traditional organosolv pretreatment is a co-solvent method using low boiling point solvents such as ethanol and acetone with water and acid/base catalyst (Huijgen et al., 2010; Yao et al., 2018). Because of their relatively high lignin solubility, those solvents show an effective pretreatment on both woody and herbaceous biomass (Brudecki et al., 2013; Hallac et al., 2010; Pan et al., 2005). However, extensive decomposition and modification of lignin are still observed because of its relatively harsh conditions like elevated temperature (Meng et al., 2020a). Co-solvent enhanced lignocellulosic fractionation (CELF) is a type of organosolv pretreatment applying tetrahydrofuran (THF)-water mixture as a pretreatment solvent. THF, a polar aprotic solvent, significantly enhances the delignification and deconstruction of polysaccharides (Mostofian et al., 2016). THF is miscible with water in the range of pretreatment conditions and limits lignin-lignin interactions by solvating lignin in the hydrophobic (THF) medium. The solvation of lignin in THF facilitates lignin removal during the pretreatment (Smith et al., 2016). For instance, CELF pretreatment significantly reduced enzyme loading to achieve over 95% C5 and C6 sugar production from corn stover (2 mg enzyme/g glucan) compared to dilute acid pretreatment (Nguyen et al., 2015). CELF pretreatment effectively fractionated lignin from biomass with high yield and purity (Cai et al., 2013; Meng et al., 2018), which are important factors for lignin valorization. In addition, this pretreatment drastically reduced the molecular weights of lignin while forming less condensed aromatics than ethanol organosolv pretreatment (Meng et al., 2020a).

γ-Valerolactone (GVL) was also applied as a co-solvent in biomass pretreatment due to its chemical stability, water miscibility and low melting temperature (Raj et al., 2021; Shuai et al., 2016b). GVL is considered a green solvent in many applications such as polymer and pharmaceuticals manufacturing based on its ecotoxicity and biodegradability tests (Kerkel et al., 2021). Luterbacher et al. investigated non-enzymatic saccharification using GVL and resulted in high sugar yields by lowering the activation energy of the hydrolysis of glycosidic bonds (Luterbacher et al., 2014; Mellmer et al., 2014). The combination of mild GVL pretreatment with enzymatic hydrolysis was also tested and resulted in higher total sugar yields. Both glucose and xylose were nearly completely recovered after the pretreatment with high purity of technical lignin. In particular, GVL pretreatment effectively removed hemicellulose and lignin at milder temperatures than other co-solvent processing such as ethanol-organosolv and CELF pretreatments did (Shuai et al., 2016b). This pretreatment preserved more intact structures of native lignin like β-ether units than other co-solvent methods, possibly due to the mild reaction conditions (Luterbacher et al., 2015; Meng et al., 2020a).

These new co-solvents showed superior delignification because of their high lignin dissolution capacity compared to traditional pretreatment solvents. Also, these solvents enhance the catalytic activity by destabilizing acidic protons (Shuai et al., 2016b). Although GVL showed a better pretreatment performance under the same mild pretreatment conditions, its high boiling point (∼207°C) makes solvent recycling and products separation challenging. Recovery of GVL by the combination of precipitation and distillation at reduced pressure and liquid CO2 could make 87–90% recovery yield (Galbe and Wallberg, 2019); however, further study is necessary to answer the economic feasibility. THF and GVL are potentially produced from biomass-derived chemicals, which are available from furfural, 5-hydroxymethylfurfural (HMF) and levulinic acid; therefore, these processes can be sustainable (Ding et al., 2014; Mostofian et al., 2016). However, THF was not recommended as a green solvent from an environmental point because of its high cumulative energy demand and complex production steps at this stage (Capello et al., 2007). Besides, other organic co-solvents such as dioxane and butanol have been applied in biomass pretreatments (An et al., 2017; Teramura et al., 2018); however, further investigation by considering their sustainability, eco-friendliness, and cost-competitivity is necessary.

Acid Hydrotropes

Recently, several acid hydrotropes such as maleic acid, p-toluenesulfonic acid, benzenesulfonic acid and 4-phenolsulfonic acid have been applied for biomass processing (Cai et al., 2020; Chen et al., 2017; He D. et al., 2020; Zhou et al., 2020). A hydrotrope has both lipophilic and hydrophilic ends in the structure and can aggregate above its minimal hydrotrope concentration (MHC) to solubilize lignin, a hydrophobic solute. The lipophilic nonpolar parts of the hydrotrope shield the dissolved lignin through the π−π stacking or hydrophobic interaction to form micellar-like aggregates, while the hydrophilic parts (sulfonic acid moiety) make an effective dissolution (Chen et al., 2017). Therefore, it showed high lignin solubility (Ji and Lv, 2020) and resulted in an effective lignin fractionation from woody biomass (Cai et al., 2020; Chen et al., 2017). Compared to aromatic salt-based hydrotropes treatment conditions in pulping and biorefinery processes (e.g., >150°C, several hours) and long reaction time, acid hydrotrope pretreatment can effectively fractionate biomass under relatively low temperatures (i.e., below water boiling point) and short reaction time (<30 min) (Zhu et al., 2019). Acid hydrotrope treatments selectively dissolve hemicellulose and lignin while preserving cellulose. The dissolved lignin can be readily precipitated by destabilizing the aggregation of acid hydrotrope with water dilution below MHC (Chen et al., 2017). The solubilized hemicellulose in the fractionation liquor after lignin precipitation was further treated at elevated temperature with the presence of hydrotrope and produced furfural. Either membrane separation or distillation can be applied to recover the furans and recycle the hydrotrope (Chen et al., 2017; Cai et al., 2020). Moreover, mild processing conditions, such as low operating temperature and atmospheric pressure, of acid hydrotrope fractionation allow using low-cost equipment. Since the market price of acid hydrotropes ranges higher than common industrial solvents, its efficient recycling is critical for its commercialization. By now, unwanted residual sugar contamination remains a future task. Further investigation about water, solvent and energy consumptions for the recycling of the hydrotrope is necessary. In addition, these pretreatments require high concentrations of the acid hydrotrope (

Ionic Liquids and Deep Eutectic Solvents

A major movement in biomass pretreatment came with the development of ionic liquids (ILs). ILs are organic salts that typically melt below 100°C and are often called green solvents or are connected with green chemistry (van Rantwijk and Sheldon, 2007). The interest of ILs as green solvents resides in their low vapor pressure and high thermal stability, offering advantages such as product recovery and recycling ability (Mallakpour and Dinari, 2012). In modern biorefineries, ILs have been studied as alternative pretreatment reagents, replacing toxic and hazardous chemicals due to their green solvent properties.

Dialkylimidazolium-based, choline-based, and protic ILs have been heavily studied in biomass pretreatment (Zhang et al., 2021). Such ILs can dissolve carbohydrates and lignin via competing for hydrogen bonding, resulting in the disruption of the complex network between biomass components (Agbor et al., 2011; Alvira et al., 2010). The structure of cation and degree of anion charge delocalization of ILs were found to be primary factors affecting the efficiency of biomass pretreatment (Agbor et al., 2011). Although the IL-based biomass pretreatment has opened up new perspectives for the development of the biorefinery sector, there remain several critical scientific challenges that must be addressed before affordable IL-based processes are commercially viable. For example, an energy-intensive recycling process is considered a major technical obstacle. In addition, imidazolium-based ILs that have shown great pretreatment performances are relatively expensive, and many of ILs are mainly obtained from petroleum, which must be addressed to make IL-based biomass pretreatment more sustainable and scalable.

Recently, deep eutectic solvents appeared as a new class of green solvents. Although DESs were often considered a new class of ILs due to their similar properties, they are two different types of solvents (Zhang et al., 2012). An IL is an association of a cation and an anion, whereas DES is a combination of two (binary) or more (ternary or quaternary) solids, forming a eutectic mixture with a strong hydrogen bonding network at a temperature lower than the melting point of each component (Smith et al., 2014). DESs are tailor-made solvents that can be prepared from low-cost and bio-derived sources and have been applied in biomass fractionation due to their outstanding ability to dissolve biomass components.

One of the components frequently used to prepare DESs for biomass pretreatment is choline chloride (ChCl) as a hydrogen bond acceptor (HBA). ChCl is a bio-derived, inexpensive, and nontoxic salt, exhibiting remarkable H-bonds accepting capability. In the biomass pretreatment context, hydrogen bond donors (HBDs) that have been investigated include acids, polyols, amides, monosaccharides, and phenolic compounds. The combination and molar ratio of HBA and HBD, and the mass ratio of DESs to biomass substantially influenced the pretreatment efficiency (Satlewal et al., 2018; Wang et al., 2021; Xu et al., 2020). DESs have great potential to fractionate biomass components; however, there are several technical barriers to overcome to make the DES-mediated process more sustainable. For example, the strong hydrogen bond interaction between biomass components and DESs makes product recovery and purification difficult in downstream processing. Another pillar in the development of successful DES-assisted biomass pretreatment will be the recycling of DESs. Despite the fact that DESs are being studied to replace conventional pretreatment reagents, the recycling and reuse of DESs remain a major technical challenge. Several recycling technologies, including anti-solvent addition, crystallization, ultrafiltration, solid-liquid extraction, and liquid-liquid extraction, have been reported. The recycling process of DES should be selected based on the physicochemical properties of DESs and the nature of the process (Isci and Kaltschmitt, 2021). In addition, it is often discussed that intermediate products after pretreatment bound to DES components reduce the purity of the DES, influencing pretreatment efficiency. Therefore, maintaining the high purity of DES has to be carefully considered when developing a recycling process.

What are Recent Pretreatment Solvents Focusing?

Traditional pretreatment solvents mainly focused on lignin removal, maximizing the release of fermentable sugars for subsequent fermentation. However, because of the carbohydrates-oriented philosophy of conventional biorefineries, strong catalysts and petroleum-derived solvents have been widely used, which are now criticized for their toxicity and non-biocompatibility. Furthermore, relatively poor lignin quality (i.e., condensed lignin) due to harsh reaction conditions makes lignin non-attractive feedstock for further utilization.

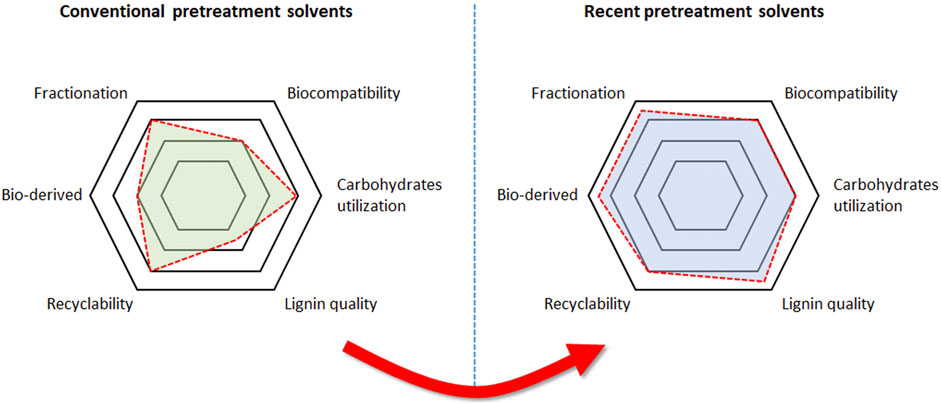

Whereas lignin removal, the yield of fermentable sugars, and recyclability of solvents were the primary metrics of the past, future pretreatment solvents should meet additional metrics, including biocompatibility, bio-derivability, and recovery of high-quality lignin (Figure 2). The biocompatibility of certain ILs and DESs has attracted significant research in developing consolidated biomass conversion processes (e.g., one-pot biomass conversion). Considering that the consolidated process does not require additional steps such as solvent removal and water washes, it would lower capital and operating costs due to the reduced number of unit operations. Modern lignocellulosic biorefineries also aim to replace petroleum-derived organic solvents with bio-derived and renewable green chemicals to develop a sustainable biomass conversion process. Equally important, the pretreatment should have minimal effect on the lignin structure. From a techno-economic standpoint, the success of future biorefineries is highly dependent on lignin valorization (Yu and Kim, 2020). In this respect, preserving native lignin structures targeting minimal lignin condensation is an imperative research topic in this community.

Future Direction of Biomass Pretreatment Solvents

Feedstock-Agnostic Solvent

Biomass pretreatment is the first step in any lignocellulose-based biorefineries to fractionate biomass components, facilitating their subsequent conversion to fuels, chemicals, and other bioproducts. Thus, choosing an appropriate pretreatment method will be critical as it determines subsequent downstream processing steps and the efficiency of the overall biomass conversion process (Saddler and Kumar, 2013). The type of pretreatment highly depends on the nature of the biomass feedstock because the structural diversity of various biomass sources requires a different approach to obtain the desired products. An ideal biomass pretreatment solvent will be feedstock-agnostic. Feedstock-agnostic pretreatment can utilize a wide array of biomass feedstocks, liberating a high yield of the monosaccharides and lignin-derived phenolic intermediates. Several studies revealed that some ILs and DESs exhibited versatility with multiple feedstocks with high pretreatment efficiency (Hennequin et al., 2021). A relatively high capability of ILs and DESs for the dissolution of biomass components makes them promising pretreatment reagents. In addition, IL- and DES-based biomass pretreatments do not typically need additional acid or base catalysts, which can avoid or minimize the formation of fermentation inhibitory compounds. Furthermore, some of the recent IL- and DES-based biomass processes facilitate recovery of high-quality lignin (i.e., highly preserved β-O-4 linkages), providing opportunities in lignin valorization (Dutta et al., 2017; Chen et al., 2020). Developing feedstock-agnostic and economical biomass pretreatment that can effectively separate biomass components with minimum use of chemicals and energy will be a key research area in the biorefinery community.

Lignin-First Biorefinery

The lignin-first biorefinery concept stems from the recognition of unwanted lignin modification (i.e., condensation) and its adverse effect on lignin depolymerization processes (Renders et al., 2017). Lignin-first philosophy implements active stabilization mechanisms in biomass pretreatment and fractionation. This approach is more compatible with relatively severe conditions; therefore, it overcomes the trade-off between lignin fractionation yield and its quality (e.g., condensation and cleavage of β-O-4 linkages). Also, cellulose has a more rigid semi-crystalline structure compared to lignin; thus, it can avoid a significant cellulose loss (Renders et al., 2017). Shuai et al. applied formaldehyde to preserve β-aryl ether linkages by forming a stable six-membered 1,3-dioxane (acetal) structure with α- and γ-hydroxyl groups of lignin side-chains. In addition, hydroxymethylation of aromatic rings with formaldehyde blocks reactive positions as a secondary stabilization. These stabilization reactions significantly improved the subsequential hydrogenolysis yield of lignin (Shuai et al., 2016a). Similar studies applying diols (e.g., 1,4-butanediol, Cyrene, and ethylene glycol) as a co-solvent or DES component resulted in comparable delignification yields and relatively high β-O-4 linkage (Dong et al., 2019; Liu et al., 2021; Meng et al., 2020b). Wu et al. effectively fractionated biomass via a photocatalytic lignin-first approach at room temperature. However, energy-intensive ball-milling was performed prior to the fractionation process (Wu et al., 2018). Besides, Luo et al. recently introduced another lignin-centered strategy by non-alkaline oxidative catalytic fractionation of biomass using a heterogeneous catalyst in acetone. This process simultaneously fractionated lignin and produced oxygenated aromatic monomers and comparable carbohydrates in a single step (Luo et al., 2021). However, this approach is at an early stage and still needs to compromise either yield or quality; therefore, further investigation is necessary to achieve both. In particular, ideal biomass processing solvents require to meet technical (e.g., lignin solubility and stabilization effect), economic (e.g., price, energy consumption, and recyclability), and environmental (e.g., biocompatibility and bio-derivability) aspects.

Hemicellulose Valorization

Even though hemicellulose is one of the major components (20–35%) of lignocellulosic biomass, most pretreatment approaches emphasize either cellulose or lignin or both. The components of hemicellulose, different carbohydrates, can be utilized with cellulose together in biological (e.g., enzymatic hydrolysis and fermentation), thermochemical (e.g., dehydration to furan, pyrolysis to bio-oil) and material (e.g., holocellulose pulp) applications. However, it is mostly extracted and decomposed with lignin in many pretreatments due to its amorphous nature. Therefore, the solubilized hemicellulose and lignin are typically separated based on their characteristics (e.g., solubility of carbohydrates vs. aromatics). While lignin can be precipitated by antisolvent or solvent distillation or extracted by liquid extraction from the hydrolysates, hemicellulose mostly remains with acid/base catalysts and water, which is challenging to isolate it further. Therefore, it is either converted into furans and other products in the hydrolysates or combined with cellulose fraction after enzymatic hydrolysis for the fermentation. This challenge limits the hemicellulose utilization and pretreatment solvent and catalyst recycling efficiency. To minimize the contamination of each fraction and ensure high purity of all three components, multi-stage fractionation has been proposed (Pongchaiphol et al., 2021; Toscan et al., 2019; Yoo et al., 2011); however, the applications of hemicellulose as a separated feedstock are not convincing when the capital and operating costs of this approach are counted. In the future biomass processing solvent development, both primary extraction from biomass and secondary separation from other components solvents and catalysts should be considered.

Computational Design of Biomass Pretreatment Solvents

Diversity of biomass composition and other properties associated with the species, natural variant, processing method and conditions make its utilization challenging. The computational tools can identify the methodologies for fast, consistent, and automated analysis of chemical processes (Seidl and Goulart, 2020). Machine-learning, a type of artificial intelligence, is recently highlighted in many applications, including biomass utilization (Hough et al., 2017; Onsree and Tippayawong, 2021; Phromphithak et al., 2021). This technology would aid the classification of biomass type to the suitable pretreatment solvents and conditions. Also, it is beneficial in technology scale-up of developed processes. However, an in-depth understanding the phenomena between pretreatment solvent and biomass components is essential to develop reliable models to predict and optimize biomass processing. Also, a flexible model for diverse feedstock and solvent systems is ideal for accelerating the industrialization of biomass conversion processes.

Author Contributions

KK and CY jointly contributed to the concept, outline, and contents of manuscript.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Acknowledgments

We acknowledge the support of SUNY ESF and KIST towards this research.

References

Agbor, V. B., Cicek, N., Sparling, R., Berlin, A., and Levin, D. B. (2011). Biomass Pretreatment: Fundamentals Toward Application. Biotechnol. Adv. 29 (6), 675–685. doi:10.1016/j.biotechadv.2011.05.005

Alvira, P., Tomás-Pejó, E., Ballesteros, M., and Negro, M. J. (2010). Pretreatment Technologies for an Efficient Bioethanol Production Process Based on Enzymatic Hydrolysis: A Review. Bioresour. Technol. 101 (13), 4851–4861. doi:10.1016/j.biortech.2009.11.093

An, S., Li, W., Liu, Q., Li, M., Ma, Q., Ma, L., et al. (2017). A Two-Stage Pretreatment Using Acidic Dioxane Followed by Dilute Hydrochloric Acid on Sugar Production from Corn stover. RSC Adv. 7 (52), 32452–32460. doi:10.1039/c7ra05280d

Brudecki, G., Cybulska, I., and Rosentrater, K. (2013). Optimization of Clean Fractionation Process Applied to Switchgrass to Produce Pulp for Enzymatic Hydrolysis. Bioresour. Technol. 131, 101–112. doi:10.1016/j.biortech.2012.12.118

Cai, C., Hirth, K., Gleisner, R., Lou, H., Qiu, X., and Zhu, J. Y. (2020). Maleic Acid as a Dicarboxylic Acid Hydrotrope for Sustainable Fractionation of wood at Atmospheric Pressure and ≤100°C: Mode and Utility of Lignin Esterification. Green. Chem. 22 (5), 1605–1617. doi:10.1039/c9gc04267a

Cai, C. M., Zhang, T., Kumar, R., and Wyman, C. E. (2013). THF Co-Solvent Enhances Hydrocarbon Fuel Precursor Yields from Lignocellulosic Biomass. Green. Chem. 15 (11), 3140–3145. doi:10.1039/c3gc41214h

Capello, C., Fischer, U., and Hungerbühler, K. (2007). What Is a Green Solvent? A Comprehensive Framework for the Environmental Assessment of Solvents. Green. Chem. 9 (9), 927–934. doi:10.1039/b617536h

Chen, L., Dou, J., Ma, Q., Li, N., Wu, R., Bian, H., et al. (2017). Rapid and Near-Complete Dissolution of wood Lignin at ≤80°C by a Recyclable Acid Hydrotrope. Sci. Adv. 3 (9), e1701735. doi:10.1126/sciadv.1701735

Chen, Z., Bai, X., Lusi, A., Zhang, H., and Wan, C. (2020). Insights into Structural Changes of Lignin Toward Tailored Properties during Deep Eutectic Solvent Pretreatment. ACS Sustain. Chem. Eng. 8, 9783–9793. doi:10.1021/acssuschemeng.0c01361

Ding, D., Wang, J., Xi, J., Liu, X., Lu, G., and Wang, Y. (2014). High-Yield Production of Levulinic Acid from Cellulose and its Upgrading to γ-Valerolactone. Green. Chem. 16 (8), 3846–3853. doi:10.1039/c4gc00737a

Dong, C., Meng, X., Yeung, C. S., Tse, H.-Y., Ragauskas, A. J., and Leu, S.-Y. (2019). Diol Pretreatment to Fractionate a Reactive Lignin in Lignocellulosic Biomass Biorefineries. Green. Chem. 21 (10), 2788–2800. doi:10.1039/c9gc00596j

Dutta, T., Isern, N. G., Sun, J., Wang, E., Hull, S., Cort, J. R., et al. (2017). Survey of Lignin-Structure Changes and Depolymerization during Ionic Liquid Pretreatment. ACS Sustain. Chem. Eng. 5 (11), 10116–10127. doi:10.1021/acssuschemeng.7b02123

Galbe, M., and Wallberg, O. (2019). Pretreatment for Biorefineries: A Review of Common Methods for Efficient Utilisation of Lignocellulosic Materials. Biotechnol. Biofuels 12, 294. doi:10.1186/s13068-019-1634-1

Hallac, B. B., Sannigrahi, P., Pu, Y., Ray, M., Murphy, R. J., and Ragauskas, A. J. (2010). Effect of Ethanol Organosolv Pretreatment on Enzymatic Hydrolysis of Buddleja Davidii Stem Biomass. Ind. Eng. Chem. Res. 49 (4), 1467–1472. doi:10.1021/ie900683q

Hans, M., Garg, S., Pellegrini, V. O. A., Filgueiras, J. G., de Azevedo, E. R., Guimaraes, F. E. C., et al. (2021). Liquid Ammonia Pretreatment Optimization for Improved Release of Fermentable Sugars from Sugarcane Bagasse. J. Clean. Prod. 281, 123922. doi:10.1016/j.jclepro.2020.123922

He, D., Wang, Y., Yoo, C. G., Chen, Q.-J., and Yang, Q. (2020a). The Fractionation of Woody Biomass under Mild Conditions Using Bifunctional Phenol-4-Sulfonic Acid as a Catalyst and Lignin Solvent. Green. Chem. 22 (16), 5414–5422. doi:10.1039/d0gc01722a

He, J., Huang, C., Lai, C., Huang, C., Li, M., Pu, Y., et al. (2020b). The Effect of Lignin Degradation Products on the Generation of Pseudo-lignin during Dilute Acid Pretreatment. Ind. Crops Prod. 146, 112205. doi:10.1016/j.indcrop.2020.112205

Hennequin, L. M., Polizzi, K., Fennell, P. S., and Hallett, J. P. (2021). Rhododendron and Japanese Knotweed: Invasive Species as Innovative Crops for Second Generation Biofuels for the ionoSolv Process. RSC Adv. 11 (30), 18395–18403. doi:10.1039/d1ra01943k

Hough, B. R., Beck, D. A. C., Schwartz, D. T., and Pfaendtner, J. (2017). Application of Machine Learning to Pyrolysis Reaction Networks: Reducing Model Solution Time to Enable Process Optimization. Comput. Chem. Eng. 104, 56–63. doi:10.1016/j.compchemeng.2017.04.012

Huijgen, W. J. J., Reith, J. H., and den Uil, H. (2010). Pretreatment and Fractionation of Wheat Straw by an Acetone-Based Organosolv Process. Ind. Eng. Chem. Res. 49 (20), 10132–10140. doi:10.1021/ie101247w

Isci, A., and Kaltschmitt, M. (2021). Recovery and Recycling of Deep Eutectic Solvents in Biomass Conversions: a Review. Biomass Convers. Biorefinery 11, 1–30. doi:10.1007/s13399-021-01860-9

Ji, H., and Lv, P. (2020). Mechanistic Insights into the Lignin Dissolution Behaviors of a Recyclable Acid Hydrotrope, Deep Eutectic Solvent (DES), and Ionic Liquid (IL). Green. Chem. 22 (4), 1378–1387. doi:10.1039/c9gc02760b

Kerkel, F., Markiewicz, M., Stolte, S., Müller, E., and Kunz, W. (2021). The green Platform Molecule Gamma-Valerolactone - Ecotoxicity, Biodegradability, Solvent Properties, and Potential Applications. Green. Chem. 23 (8), 2962–2976. doi:10.1039/d0gc04353b

Kim, J. S., Lee, Y. Y., and Kim, T. H. (2016). A Review on Alkaline Pretreatment Technology for Bioconversion of Lignocellulosic Biomass. Bioresour. Technol. 199, 42–48. doi:10.1016/j.biortech.2015.08.085

Liu, Y., Deak, N., Wang, Z., Yu, H., Hameleers, L., Jurak, E., et al. (2021). Tunable and Functional Deep Eutectic Solvents for Lignocellulose Valorization. Nat. Commun. 12 (1), 1–15. doi:10.1038/s41467-021-25117-1

Luo, H., Weeda, E. P., Alherech, M., Anson, C. W., Karlen, S. D., Cui, Y., et al. (2021). Oxidative Catalytic Fractionation of Lignocellulosic Biomass under Non-Alkaline Conditions. J. Am. Chem. Soc. 143, 15462–15470. doi:10.1021/jacs.1c08635

Luterbacher, J. S., Azarpira, A., Motagamwala, A. H., Lu, F., Ralph, J., and Dumesic, J. A. (2015). Lignin Monomer Production Integrated into the γ-Valerolactone Sugar Platform. Energy Environ. Sci. 8 (9), 2657–2663. doi:10.1039/c5ee01322d

Luterbacher, J. S., Rand, J. M., Alonso, D. M., Han, J., Youngquist, J. T., Maravelias, C. T., et al. (2014). Nonenzymatic Sugar Production from Biomass Using Biomass-Derived γ-Valerolactone. Science 343 (6168), 277–280. doi:10.1126/science.1246748

Mallakpour, S., and Dinari, M. (2012). “Ionic Liquids as green Solvents: Progress and Prospects,” in Green Solvents II. Editor. Mohammad, A., and Inamuddin, D. (Dordrecht: Springer), 1–32. doi:10.1007/978-94-007-2891-2_1

Mellmer, M. A., Martin Alonso, D., Luterbacher, J. S., Gallo, J. M. R., and Dumesic, J. A. (2014). Effects of γ-valerolactone in Hydrolysis of Lignocellulosic Biomass to Monosaccharides. Green. Chem. 16 (11), 4659–4662. doi:10.1039/c4gc01768d

Meng, X., Bhagia, S., Wang, Y., Zhou, Y., Pu, Y., Dunlap, J. R., et al. (2020a). Effects of the Advanced Organosolv Pretreatment Strategies on Structural Properties of Woody Biomass. Ind. Crops Prod. 146, 112144. doi:10.1016/j.indcrop.2020.112144

Meng, X., Parikh, A., Seemala, B., Kumar, R., Pu, Y., Christopher, P., et al. (2018). Chemical Transformations of poplar Lignin during Cosolvent Enhanced Lignocellulosic Fractionation Process. ACS Sustain. Chem. Eng. 6 (7), 8711–8718. doi:10.1021/acssuschemeng.8b01028

Meng, X., Pu, Y., Li, M., and Ragauskas, A. J. (2020b). A Biomass Pretreatment Using Cellulose-Derived Solvent Cyrene. Green. Chem. 22 (9), 2862–2872. doi:10.1039/d0gc00661k

Mostofian, B., Cai, C. M., Smith, M. D., Petridis, L., Cheng, X., Wyman, C. E., et al. (2016). Local Phase Separation of Co-Solvents Enhances Pretreatment of Biomass for Bioenergy Applications. J. Am. Chem. Soc. 138 (34), 10869–10878. doi:10.1021/jacs.6b03285

Nguyen, T. Y., Cai, C. M., Kumar, R., and Wyman, C. E. (2015). Co-Solvent Pretreatment Reduces Costly Enzyme Requirements for High Sugar and Ethanol Yields from Lignocellulosic Biomass. ChemSusChem 8 (10), 1716–1725. doi:10.1002/cssc.201403045

Onsree, T., and Tippayawong, N. (2021). Machine Learning Application to Predict Yields of Solid Products from Biomass Torrefaction. Renew. Energ. 167, 425–432. doi:10.1016/j.renene.2020.11.099

Pan, X., Arato, C., Gilkes, N., Gregg, D., Mabee, W., Pye, K., et al. (2005). Biorefining of Softwoods Using Ethanol Organosolv Pulping: Preliminary Evaluation of Process Streams for Manufacture of Fuel-Grade Ethanol and Co-products. Biotechnol. Bioeng. 90 (4), 473–481. doi:10.1002/bit.20453

Perianes-Rodriguez, A., Waltman, L., and Van Eck, N. J. (2016). Constructing Bibliometric Networks: A Comparison between Full and Fractional Counting. J. Informetrics 10 (4), 1178–1195. doi:10.1016/j.joi.2016.10.006

Phromphithak, S., Onsree, T., and Tippayawong, N. (2021). Machine Learning Prediction of Cellulose-Rich Materials from Biomass Pretreatment with Ionic Liquid Solvents. Bioresour. Technol. 323, 124642. doi:10.1016/j.biortech.2020.124642

Pongchaiphol, S., Chotirotsukon, C., Raita, M., Champreda, V., and Laosiripojana, N. (2021). Two-Stage Fractionation of Sugarcane Bagasse by a Flow-Through Hydrothermal/Ethanosolv Process. Ind. Eng. Chem. Res. 60, 12629–12639. doi:10.1021/acs.iecr.1c00669

Raj, T., Chandrasekhar, K., Banu, R., Yoon, J.-J., Kumar, G., and Kim, S.-H. (2021). Synthesis of γ-Valerolactone (GVL) and Their Applications for Lignocellulosic Deconstruction for Sustainable green Biorefineries. Fuel 303, 121333. doi:10.1016/j.fuel.2021.121333

Renders, T., Van den Bosch, S., Koelewijn, S.-F., Schutyser, W., and Sels, B. F. (2017). Lignin-First Biomass Fractionation: The Advent of Active Stabilisation Strategies. Energ. Environ. Sci. 10 (7), 1551–1557. doi:10.1039/c7ee01298e

Saddler, J., and Kumar, L. (2013). Special Issue from the NSERC Bioconversion Network Workshop: Pretreatment and Fractionation of Biomass for Biorefinery/biofuels. Biotechnol. Biofuels 6, 17. doi:10.1186/1754-6834-6-17

Satlewal, A., Agrawal, R., Bhagia, S., Sangoro, J., and Ragauskas, A. J. (2018). Natural Deep Eutectic Solvents for Lignocellulosic Biomass Pretreatment: Recent Developments, Challenges and Novel Opportunities. Biotechnol. Adv. 36 (8), 2032–2050. doi:10.1016/j.biotechadv.2018.08.009

Seidl, P. R., and Goulart, A. K. (2020). Application of Computational Methods for Pretreatment Processes of Different Biomass Feedstocks. Curr. Opin. Green Sustain. Chem. 26, 100366. doi:10.1016/j.cogsc.2020.100366

Shinde, S. D., Meng, X., Kumar, R., and Ragauskas, A. J. (2018). Recent Advances in Understanding the Pseudo-Lignin Formation in a Lignocellulosic Biorefinery. Green. Chem. 20 (10), 2192–2205. doi:10.1039/c8gc00353j

Shuai, L., Amiri, M. T., Questell-Santiago, Y. M., Héroguel, F., Li, Y., Kim, H., et al. (2016a). Formaldehyde Stabilization Facilitates Lignin Monomer Production during Biomass Depolymerization. Science 354 (6310), 329–333. doi:10.1126/science.aaf7810

Shuai, L., Questell-Santiago, Y. M., and Luterbacher, J. S. (2016b). A Mild Biomass Pretreatment Using γ-Valerolactone for Concentrated Sugar Production. Green. Chem. 18 (4), 937–943. doi:10.1039/c5gc02489g

Smith, E. L., Abbott, A. P., and Ryder, K. S. (2014). Deep Eutectic Solvents (DESs) and Their Applications. Chem. Rev. 114 (21), 11060–11082. doi:10.1021/cr300162p

Smith, M. D., Mostofian, B., Cheng, X., Petridis, L., Cai, C. M., Wyman, C. E., et al. (2016). Cosolvent Pretreatment in Cellulosic Biofuel Production: Effect of Tetrahydrofuran-Water on Lignin Structure and Dynamics. Green. Chem. 18 (5), 1268–1277. doi:10.1039/c5gc01952d

Teramura, H., Sasaki, K., Oshima, T., Kawaguchi, H., Ogino, C., Sazuka, T., et al. (2018). Effective Usage of Sorghum Bagasse: Optimization of Organosolv Pretreatment Using 25% 1-Butanol and Subsequent Nanofiltration Membrane Separation. Bioresour. Technol. 252, 157–164. doi:10.1016/j.biortech.2017.12.100

Toscan, A., Fontana, R. C., Andreaus, J., Camassola, M., Lukasik, R. M., and Dillon, A. J. P. (2019). New Two-Stage Pretreatment for the Fractionation of Lignocellulosic Components Using Hydrothermal Pretreatment Followed by Imidazole Delignification: Focus on the Polysaccharide Valorization. Bioresour. Technol. 285, 121346. doi:10.1016/j.biortech.2019.121346

van Rantwijk, F., and Sheldon, R. A. (2007). Biocatalysis in Ionic Liquids. Chem. Rev. 107 (6), 2757–2785. doi:10.1021/cr050946x

Wang, Y., Kim, K. H., Jeong, K., Kim, N.-K., and Yoo, C. G. (2021). Sustainable Biorefinery Processes Using Renewable Deep Eutectic Solvents. Curr. Opin. Green Sustain. Chem. 27, 100396. doi:10.1016/j.cogsc.2020.100396

Wu, X., Fan, X., Xie, S., Lin, J., Cheng, J., Zhang, Q., et al. (2018). Solar Energy-Driven Lignin-First Approach to Full Utilization of Lignocellulosic Biomass under Mild Conditions. Nat. Catal. 1 (10), 772–780. doi:10.1038/s41929-018-0148-8

Xu, H., Peng, J., Kong, Y., Liu, Y., Su, Z., Li, B., et al. (2020). Key Process Parameters for Deep Eutectic Solvents Pretreatment of Lignocellulosic Biomass Materials: A Review. Bioresour. Technol. 310, 123416. doi:10.1016/j.biortech.2020.123416

Yao, L., Chen, C., Yoo, C. G., Meng, X., Li, M., Pu, Y., et al. (2018). Insights of Ethanol Organosolv Pretreatment on Lignin Properties of Broussonetia Papyrifera. ACS Sustain. Chem. Eng. 6 (11), 14767–14773. doi:10.1021/acssuschemeng.8b03290

Yoo, C. G., Lee, C. W., and Kim, T. H. (2011). Optimization of Two-Stage Fractionation Process for Lignocellulosic Biomass Using Response Surface Methodology (RSM). Biomass and Bioenergy 35 (12), 4901–4909. doi:10.1016/j.biombioe.2011.10.015

Yoo, C. G., Li, M., Meng, X., Pu, Y., and Ragauskas, A. J. (2017). Effects of Organosolv and Ammonia Pretreatments on Lignin Properties and its Inhibition for Enzymatic Hydrolysis. Green. Chem. 19 (8), 2006–2016. doi:10.1039/c6gc03627a

Yoo, C. G., Meng, X., Pu, Y., and Ragauskas, A. J. (2020). The Critical Role of Lignin in Lignocellulosic Biomass Conversion and Recent Pretreatment Strategies: A Comprehensive Review. Bioresour. Technol. 301, 122784. doi:10.1016/j.biortech.2020.122784

Yu, O., and Kim, K. H. (2020). Lignin to Materials: A Focused Review on Recent Novel Lignin Applications. Appl. Sci. 10 (13), 4626. doi:10.3390/app10134626

Zhang, J., Zou, D., Singh, S., and Cheng, G. (2021). Recent Developments in Ionic Liquid Pretreatment of Lignocellulosic Biomass for Enhanced Bioconversion. Sustain. Energ. Fuels 5, 1655–1667. doi:10.1039/d0se01802c

Zhang, Q., De Oliveira Vigier, K., Royer, S., and Jérôme, F. (2012). Deep Eutectic Solvents: Syntheses, Properties and Applications. Chem. Soc. Rev. 41 (21), 7108–7146. doi:10.1039/c2cs35178a

Zhao, C., Shao, Q., and Chundawat, S. P. S. (2020). Recent Advances on Ammonia-Based Pretreatments of Lignocellulosic Biomass. Bioresour. Technol. 298, 122446. doi:10.1016/j.biortech.2019.122446

Zhou, X., Liu, J., Huang, T., Bian, H., Wang, R., Sha, J., et al. (2020). Near-Complete Enzymatic Hydrolysis Efficiency of Miscanthus Using Hydrotropic Fractionation at Atmospheric Pressure. Ind. Crops Prod. 149, 112365. doi:10.1016/j.indcrop.2020.112365

Zhou, Z., Lei, F., Li, P., and Jiang, J. (2018). Lignocellulosic Biomass to Biofuels and Biochemicals: A Comprehensive Review with a Focus on Ethanol Organosolv Pretreatment Technology. Biotechnol. Bioeng. 115 (11), 2683–2702. doi:10.1002/bit.26788

Keywords: biorefinery, biocompatibility, sustainability, lignin, fractionation

Citation: Kim KH and Yoo CG (2021) Challenges and Perspective of Recent Biomass Pretreatment Solvents. Front. Chem. Eng. 3:785709. doi: 10.3389/fceng.2021.785709

Received: 29 September 2021; Accepted: 15 October 2021;

Published: 02 November 2021.

Edited by:

Jun Zhao, Hong Kong Baptist University, Hong Kong, SAR ChinaReviewed by:

Xinxing Zhou, Shanxi Transportation Technology Research & Development Co., Ltd., ChinaGuoyong Song, Beijing Forestry University, China

Copyright © 2021 Kim and Yoo. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Chang Geun Yoo, Y3lvbzA1QGVzZi5lZHU=

Kwang Ho Kim

Kwang Ho Kim Chang Geun Yoo

Chang Geun Yoo