- 1School of Civil Engineering, Institute of Engineering, Suranaree University of Technology, Nakhon Ratchasima, Thailand

- 2Center of Excellence in Innovation for Sustainable Infrastructure Development, Suranaree University of Technology, Nakhon Ratchasima, Thailand

- 3Program in Civil and Infrastructure Engineering, Institute of Engineering, Suranaree University of Technology, Nakhon Ratchasima, Thailand

The expansive development of infrastructure has led to increased consumption of virgin aggregates in road construction, resulting in significant environmental impacts. To address this issue, there is a pressing need for sustainable alternatives that utilize recycled materials in pavement applications. This paper presents a comprehensive review of a decade-long research program focused on the development and evaluation of sustainable pavement materials, such as recycled and waste aggregates, industrial by-products, and natural fibers. The research encompassed a wide range of innovative materials and technologies, such as geopolymer-stabilized recycled aggregates, cement-stabilized waste materials, natural additive-modified cement stabilization, and recycled aggregate-geogrid reinforcement systems. The experimental framework employed a combination of mechanical testing, durability assessment, microstructural analysis, and environmental safety evaluation to assess the performance and sustainability of these materials. The key findings demonstrated the superior mechanical properties, improved durability, and environmental suitability of the recycled materials compared to conventional virgin aggregates. The successful implementation of these sustainable solutions in real-world projects highlights their potential to reduce the environmental footprint of road infrastructure development. Furthermore, the paper discussed the practical implications of the research outcomes for pavement design and construction, as well as future research directions to further advance the field of sustainable pavement engineering. The findings of this research report can be used as guidance for researchers, practitioners, and policymakers seeking to upcycle the widespread adoption of recycled materials in road application and contribute to the development of a more sustainable and resilient transportation infrastructure.

1 Introduction

The growth of infrastructure networks has exacerbated the environmental impact of the construction industry, largely attributed to the extensive consumption of virgin aggregates. Conventional road construction methods primarily depend on the extraction and processing of natural resources such as crushed rock, sand, and gravel, contributing to environmental degradation, ecosystem disruption, air and water pollution, and increased greenhouse gas emissions (Huang, Bird and Heidrich, 2007). There is an urgent need for a paradigm shift towards sustainable construction practices.

Recognizing the environmental implications of conventional road construction practices, the industry is increasingly exploring the use of recycled materials as alternatives to virgin aggregates. Numerous studies have demonstrated the potential of recycled aggregates such as recycled concrete aggregate (RCA), recycled asphalt pavement (RAP), steel slag (SS), and other waste materials like bricks, glass, and plastics, along with industrial byproducts including fly ash (FA) and blast furnace slag (BFS), have been used as sustainable substitutes in road applications (AzariJafari, Yahia and Ben Amor, 2016).

This Brief Research Report presented a comprehensive synthesis of our decade-long research endeavor focused on the integration of various reclaimed materials in rigid and flexural pavements. Our central hypothesis has been that utilizing locally sourced recycled materials can significantly enhance the sustainability and resource efficiency of road construction practices. This approach not only preserves natural resources but also reduces the environmental impacts associated with their extraction, processing, and transportation (Salehi, Arashpour, Kodikara and Guppy, 2021).

Our research has encompassed a wide array of recycled materials, including Construction and Demolition (C&D) materials, industry by-product wastes, and natural materials like hemp fibers in road construction applications. A comprehensive methodological approach was employed to assess the sustainability of these materials in road construction. This involved extensive laboratory experiments, analytical modeling, and field performance monitoring. The experimental framework included various tests to assess the mechanical properties, durability, and environmental compatibility of the recycled materials. Advanced microstructural analysis provided deep insights into their fundamental properties, while environmental safety assessments ensured their suitability for use in road construction.

Key findings of this systematic study included the superior performance of recycled materials in pavement applications, novel testing methods, and successful implementation of sustainable materials in real-world projects. The research findings have greatly advanced sustainable road construction practices and offered valuable insights for policymakers and engineers aiming to reduce the environmental footprint of road infrastructure development.

This Brief Research Report synthesizes the major outcomes of our decade-long research program, providing a concise overview of our contributions to the field of sustainable pavement materials. By presenting this comprehensive summary, we aim to offer practical guidelines for researchers and practitioners, highlight areas for future research, and underscore the potential for widespread adoption of recycled materials in road construction.

2 Materials and methods

2.1 Materials

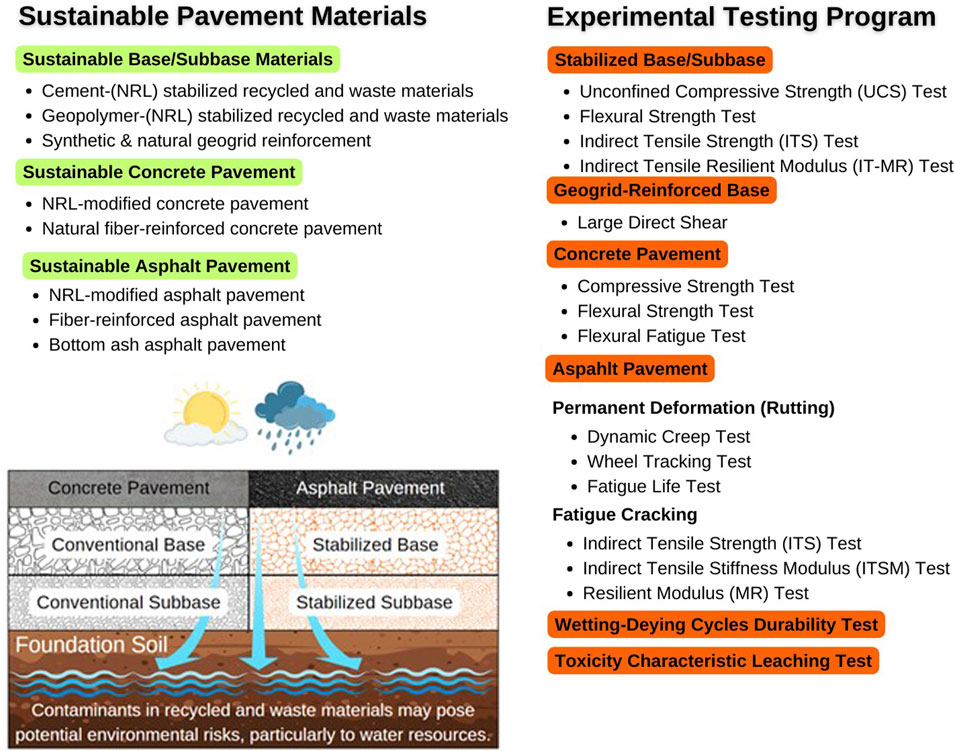

Figure 1 summarizes sustainable pavement materials and experimental testing programs for evaluating eco-friendly alternatives in road construction. The research covered sustainable base/subbase materials, concrete pavements, and asphalt pavements, utilizing recycled and waste materials and industrial by-products. Recycled aggregates including recycled concrete aggregate (RCA), recycled asphalt pavement (RAP), steel slag (SS), Melamine debris (MD), Polyethylene Terephthalate (PET) plastic, and crumb rubber (CR). Industrial by-products include fly ash (FA), bottom ash (BA), and blast furnace slag (BFS). Natural Rubber Latex (NRL), derived from the Hevea brasiliensis, was a key modifier across various materials. The key chemical properties of NRL include a total solid content of 55.11%, dry rubber content of 52.04%, non-rubber content of 3.07%, and a pH of 10.4.

2.2 Mix designs

This research investigates various sustainable mix designs for pavement applications, including:

• Sustainable base/subbase materials

o Geopolymer stabilized recycled and waste materials

o Cement-stabilized recycled and waste materials

o NRL-modified cement stabilized recycled and waste materials

• Sustainable concrete pavement

o NRL-modified concrete pavement incorporating recycled and waste materials

• Sustainable asphalt pavement

o NRL-modified asphalt pavement

o Fiber-reinforced asphalt pavement

o BA-modified asphalt pavement

2.3 Experimental testing programs

A comprehensive testing program (Figure 1) evaluated sustainable pavement materials across three categories, following international standards:

2.3.1 Base/subbase materials

• Mechanical properties: unconfined compressive strength (UCS) (ASTM D2166), flexural strength, indirect tensile strength (ITS) (ASTM D6931), and indirect tensile resilient modulus (IT-MR) (AASHTO T307)

• Durability: wetting-drying (w-d) cycles (ASTM D559)

• Microstructural analysis: X-ray fluorescence (XRF), X-ray diffraction (XRD), and scanning electron microscopy (SEM)

• Environmental safety: toxicity characteristic leaching test (TCLT) (EPA Method 1311)

2.3.2 Concrete pavement materials

• Mechanical properties: Compressive strength (ASTM C39), flexural strength (ASTM C78)

• Performance: Flexural fatigue (AASHTO T321)

• Microstructural analysis: XRD and SEM

2.3.3 Asphalt pavement materials

• Mechanical properties: ITS (AASHTO T283), IT-MR (ASTM D7369)

• Performance: Dynamic creep (BS EN 12697-25), wheel tracking (AASHTO T324), fatigue life (AASHTO T321)

• Durability: Moisture sensitivity (AASHTO T283)

3 Results and discussion

3.1 Sustainable pavement base/subbase materials

3.1.1 Geopolymer stabilized base/subbase materials

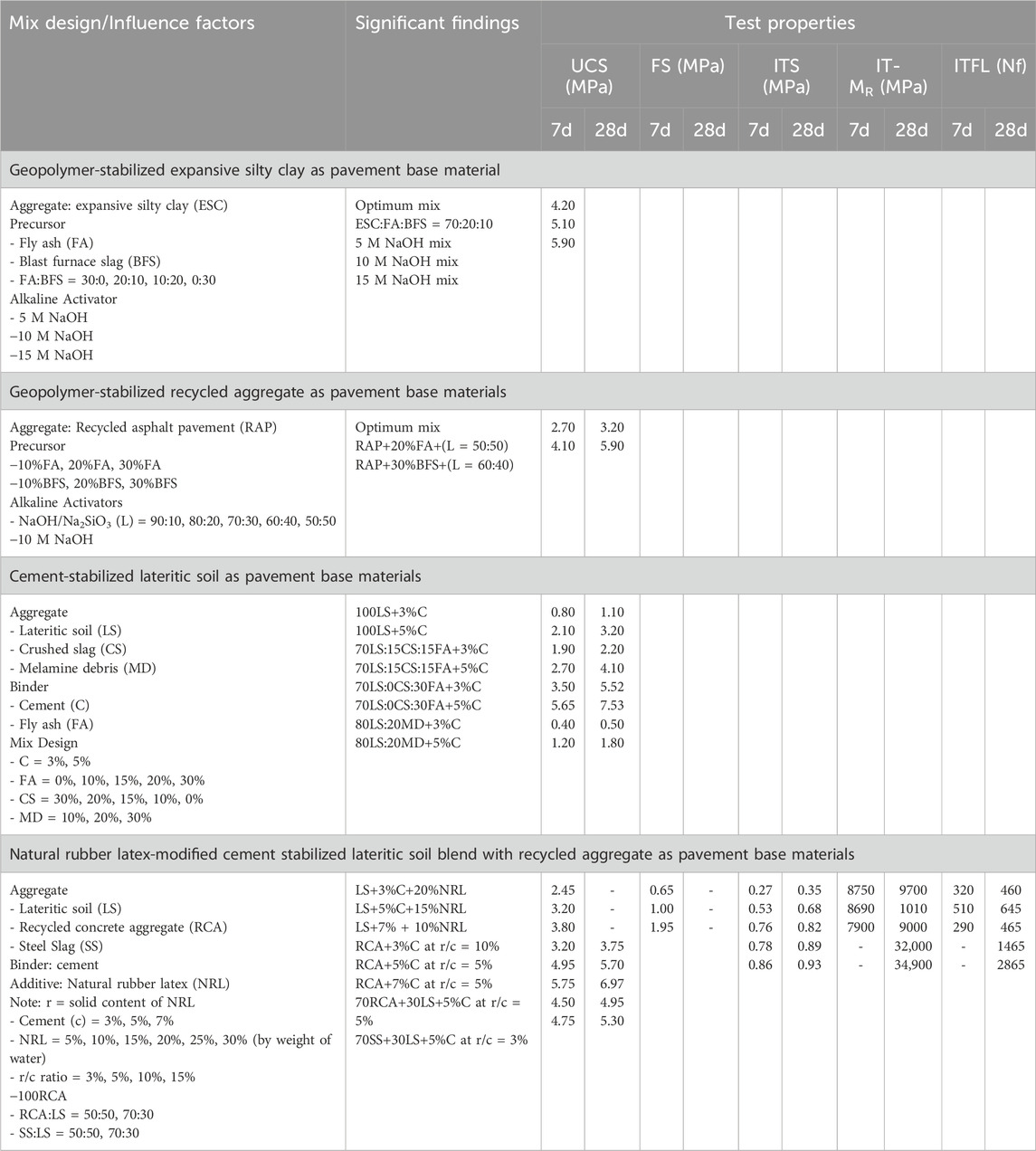

Table 1 summarizes the key findings from our investigation into sustainable geochemical stabilized pavement base materials. The UCS of the FA-based geopolymer stabilized expansive silty clay (ESC), and BFS blends were significantly influenced by the FA:BSF ratio and NaOH concentration. UCS increased with higher NaOH concentration (5M–15 M) for all FA:BFS ratios due to enhanced geopolymerization. The optimal ESC:FA:BFS ratio was 70:20:10, exhibiting the highest UCS. The BFS replacement at this ratio reduced the specific surface area, resulting in higher interparticle forces (Sukprasert et al., 2021). However, excessive BFS content decreased UCS due to reduced geopolymerization products. The optimal ESC:FA:BFS mixtures had 7-day UCS values higher than the UCS requirement (UCS >2.413 MPa) for base materials set by the Department of Highways (DOH), Thailand, demonstrating the potential of utilizing FA and BFS for sustainable pavement applications.

The NaOH/Na2SiO3 ratios, curing time, and curing temperature were found to influence the mechanical properties of RAP-FA based geopolymer mixtures. The geopolymer mixtures had UCS values higher than non-geopolymer mixtures. The UCS values of geopolymer mixtures increased with decreasing NaOH/Na2SiO3 ratio. The XRD and SEM analysis indicated that the higher CaO and MgO contents in RAP reacted with SiO2 and Al2O3 in FA to form C-S-H and C-A-H. These products increased over time, resulting in increased UCS values for RAP-FA mixtures. In RAP-FA geopolymers, the highly soluble silica in Na2SiO3 accelerated geopolymerization reactions, producing more N-A-S-H. The co-existing N-A-S-H and C-S-H filled the pores, densifying the RAP-FA structures and increasing UCS with a decreasing NaOH/Na2SiO3 ratio (Hoy et al., 2016a; Hoy et al., 2016b; Hoy et al., 2017). A similar study on BFS-based geopolymer stabilized RAP indicated that its UCS was also significantly influenced by the NaOH/Na2SiO3 ratio, BFS content, and curing time. The optimal blend was determined to be RAP+20%BFS with a NaOH/Na2SiO3 of 60:0, providing the highest UCS values. Microstructural analyses revealed that the primary geopolymerization product was C-A-S-H, whose formation and growth led to the increase in UCS. The absence of Na2SiO3 resulted in a slow reaction and lowered early strength, while excess Na2SiO3 hindered the reaction due to thick silica films (Hoy et al., 2018).

3.1.2 Cement-stabilized and NRL-modified cement stabilized base/subbase materials

This research also investigated the feasibility of using waste melamine derbies (MD) and crushed slag (CS) as replacement materials and FA as a cement substitution to improve lateritic soil (LS) for pavement applications (Donrak et al., 2016; Jeerapan et al., 2022; Sudla et al., 2020; Sudla et al., 2018). MD is a by-product from the melamine manufacturing process, consisting primarily of melamine resin particles. CS is a granular material produced from the rapid cooling of molten iron slag from steel production. The replacement of MD in the mixture decreased the fine particles and prevented aggregate breakage while enhancing the strength and dimensional stability of LS. It was found that higher cement increased the rate of strength development of all cement-LS-MD mixtures. However, the UCS decreased with higher MD content. This was likely because MD absorbed more water than LS, leading to a higher optimum water content. Consequently, the water-to-cement ratio increased, which negatively affected the UCS. It was found that optimizing the CS replacement ratio is crucial for achieving the desired physical and mechanical properties that meet the specifications set by road authorities (7 d UCS >294, 700, and 1750 kPa for stabilised sub-grade, sub-base and base, respectively). CS replacement enhanced these properties of LS by reducing plasticity, particle breakage, and swelling while increasing durability and soaking CBR. Higher CS contents minimized the fines generated during compaction due to its higher abrasion resistance, resulting in better mechanical characteristics for the compacted LS/CS mixtures. XRD and SEM analyses revealed that the pozzolanic materials FA co-existed with cement hydration to generate additional cementitious products over time. The FA contributed to strength gain by filling pores with C-S-H gels, while the CS minimized swelling and improved the mechanical performance of the mixtures. The CS/FA mixed with LS resulted in a denser matrix compared to pure cement-LS mixtures.

UCS results of NRL-modified cement-stabilized LS were illustrated in Table 1. It revealed that NRL significantly enhanced the mechanical properties of cement-stabilized mixes. This improvement was most notable at specific NRL contents for each cement percentage, showing a trend where lower cement content required higher NRL to achieve optimal results. The optimal NRL replacement ratios were 20%NRL, 15%NRL, and 10%NRL, respectively for 3%, 5%, and 7% cement mixtures. In addition, the optimal NRL content for maximum flexural strength aligned with that for UCS, reinforcing the effectiveness of NRL in enhancing both compressive and flexural strengths. XRD and SEM analyses revealed the NRL films infiltrated the pore spaces, led to a denser and stronger structure. Beyond these optimal ratios, excessive NRL content led to reduce compatibility and strength due to the formation of weak, jelly-like structures (Buritatun et al., 2023a; Buritatun et al., 2022b; Buritatun et al., 2020; Kantatham et al., 2021).

The addition of NRL to cement-stabilized mixtures significantly enhanced both pure RCA and blends of LS/SS and LS/RCA. For pure RCA mixtures, NRL improved compressive and tensile strength, ductility, toughness, fatigue life, and rutting resistances (Hoy et al., 2023a; Hoy et al., 2023b; Nhieu et al., 2023). The optimal dry rubber to cement (r/c) ratios varied with cement content: 10% NRL for 3% cement, 5% NRL for both 5% and 7% cement.

In the case of LS blends with SS or RCA, the optimal r/c ratios were 3% for cement-LS/SS and 5% for cement-LS/RCA mixtures, providing the highest UCS, ITS, and IT-MR (Hoy et al., 2023c; Hoy et al., 2023d; Tran et al., 2022). This improved performance can be attributed to better stiffness properties of recycled materials (SS and RCA) compared to LS. For both pure RCA and blends, maintaining NRL content within optimal ranges was crucial for maximizing benefits.

Cement-NRL mixtures consistently showed significant improvements in fatigue life and rutting resistance compared to mixtures without NRL. The incorporation of NRL reduced permanent deformation and improved ductility, enhancing resistance to fatigue cracking and rutting. These improvements were observed across all studied mixtures. Microstructural analysis provided insights into the mechanisms behind these improvements. SEM revealed that NRL films enhanced cohesion and bonding strength by connecting cement hydration products and filling pore spaces. However, XRD indicated that excessive NRL content could hinder cement hydration, thus reducing mechanical strength. This finding emphasizes the importance of maintaining optimal NRL content.

Overall, the synergetic effect of NRL and recycled materials in cement-stabilized mixtures enhanced both mechanical and fatigue properties, providing a sustainable solution for pavement applications. This approach not only improves performance but also contributes to more environmentally friendly road construction practices.

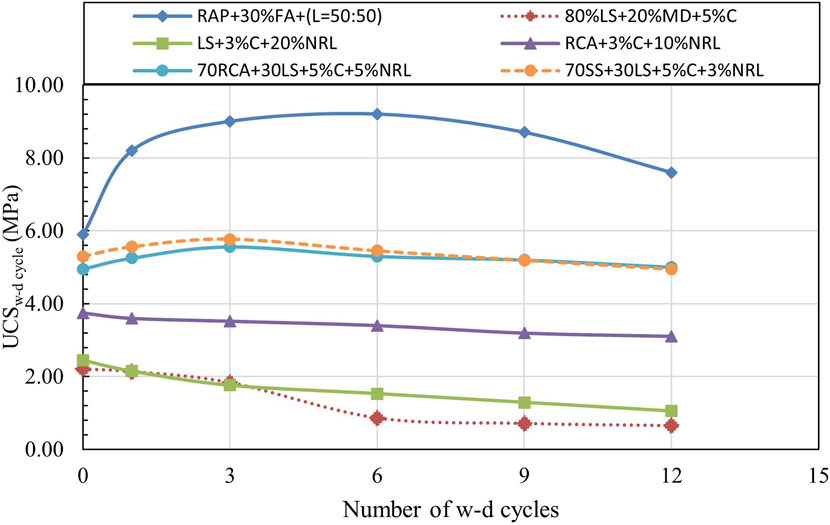

Figure 2 summarizes the strength development of the mixtures against the wetting and drying (w-d) cycles. FA-based geopolymerization significantly improved the durability of RAP-FA materials. This improvement was attributed to the higher temperature during the drying stage, which enhanced geopolymer reactions and generated more N-A-S-H gels in addition to C-A-S-H gels. When the number of w-d cycles was fewer than 6, the higher rate of geopolymer reaction governed the strength development. However, with more than 6 w-d cycles, external deterioration of the sample became dominant, leading to a reduction in strength.

The use of NRL in cement-SS/LS and cement-RCA/LS mixes remarkably improved their durability and mechanical strength against wetting and drying (w-d) cycles. The early strength development during the initial w-d cycle was attributed to the accelerated hydration of cement at high temperatures, forming more C-S-H and CH compounds that strengthen the mixes. NRL additive was found to reduce weight loss and water absorption by forming hydrophobic barriers around cement particles, preventing water ingress. Additionally, the NRL film bridges within the matrix, preventing the propagation of microcracks, which resulted in higher crack resistance. The subsequent decrease in UCS after the third cycle was due to the leaching of Ca2+ ions and the dissolution of cementitious products during the soaking stages, leading to the formation of microcracks and strength reduction. SS/LS blends had higher initial UCS values against the w-d cycles than RCA/LS blends due to the high mechanical properties of SS over RCA.

The UCS values for NRL-modified cement-stabilized RCA (RCA+3%C+10%NRL) decreased with the number of w-d cycles. Even though the SEM and XRD analysis confirmed NRL films contributed to the strength development by enhancing interparticle bonding and reducing voids within the matrix, the external crack was notably developed, and the continuous crack propagation resulted in strength reduction at a later stage of w-d cycles. Similar behavior was found for NRL-modified cement stabilized LS (LS+3%C+20%NRL). However, its UCS values were lower than the cement-NRL-RCA mixture at the same w-d cycles. The cement-LS-MD mixtures indicated the lowest UCS w-d durability performance. However, the use of MD replacements could prolong the performance even after 12 w-d cycles.

To ensure the environmental safety of the recycled materials, the Toxicity Characteristic Leaching Procedure (TCLP) test was conducted. Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) was used to detect trace metal levels in the leachate, providing a sensitive and accurate analysis of potential contaminants. TCLP test results showed that metal concentrations in the leachate were below regulatory limits, indicating no significant environmental risk. Therefore, recycled and waste materials can be safely used in road construction without adverse environmental effects.

3.2 Sustainable concrete pavement materials

NRL was used as a natural polymer to enhance the bending properties and flexural fatigue resistance of concrete pavement (Yaowarat et al., 2021). This research examined w/c ratios and dry rubber content-to-cement (r/c) ratios and curing times to determine the optimal mix for strength enhancement. Concrete specimens mixed with various w/c ratios (0.3, 0.4, and 0.5) and r/c ratios (0.58, 1.16, 1.73, 2.31, 2.89, 3.47, 4.63, and 5.78). A mixed design method was adopted from the experimental data and the Portland Cement Association (PCA, 1984) design method. Compressive and flexural strengths were determined at 7, 14, and 28 days of curing.

Adding NRL to the cement paste causes a delay in the setting time of NRL-cement mixtures. Higher w/c ratio and r/c ratio led to longer delays in initial and final setting times. For all NRL-modified concrete, the compressive strength was decreased with increasing amount of NRL content. However, its flexural strength was found to increase to the highest values at the optimal r/c ratio. Optimal r/c ratios were 0.58%, 1.16%, and 1.73% for w/c ratios of 0.3, 0.4, and 0.5, respectively. Notably, the mixtures at these optimal r/c ratios exhibited higher fatigue life and deformation resistance compared to normal concrete. Microstructural analysis indicated that NRL films reinforced the concrete matrix, increasing flexural strength, toughness, and fatigue life while reducing deformation under cyclic loading. Excessive NRL content resulted in a significant reduction in cementitious products and a decrease in both compressive and flexural strengths.

Implementing this in a PCA-based design method showed that the thinner NRL-concrete pavement can provide cost savings over normal concrete despite the higher material cost of NRL (Suddeepong et al., 2022). An optimized mix design procedure was proposed considering the interactions between NRL content, concrete properties, pavement thickness, and costs. Key steps include: 1) determine optimal r/c for target w/c based on flexural strength; 2) select thickness for the NRL-concrete flexural strength using PCA method; 3) compute material and operating costs for the selected mix and thickness; and 4) repeat to find mix and thickness with lowest total cost.

Building upon these finding, a subsequent study (Samingthong et al., 2023) investigated the incorporation of waste materials into NRL-concrete. This research examined the use of Polyethylene Terephthalate (PET) plastic (average particle size of 10 mm as coarse aggregate) and crumb rubber (CR) (average particle size = 2–3 mm as fine aggregate) in NRL-concrete. It aimed to determine the mechanical properties, modulus of rupture, stiffness, and toughness of NRL-modified concrete with PET/CR replacement at an optimal r/c ratio of 0.58. Various combinations of PET/CR were used to substitute natural aggregates in percentages of 5%, 10%, and 15%.

NRL-modified concrete with PET + CR exhibited reduced mechanical strength properties compared to the control sample. The reduction in strength increased with higher replacement ratios. At 28 days, compressive strength was 8.3%, 15%, and 28.5% lower than normal concrete for NRL+5%PET+5%CR, NRL+10%PET+10%CR, and NRL+15%PET+15%CR, respectively. At 28 days, flexural strength was 5.2%, 25%, and 37% lower than normal concrete for NRL+5%PET+5%CR, NRL+10%PET+10%CR, and NRL+15%PET+15%CR, respectively.

NRL modification reduced the compressive strength of concrete by generating film networks that delayed hydration product development. However, these films also bridged and enhanced bonding between cement hydrates and aggregates, improving the flexural strength and toughness of NRL-modified concrete compared to normal concrete.

PET and CR are hydrophobic, non-polar materials that create a weak interface with the cement paste when used as aggregate replacements. This resulted in a more porous, loose microstructure and reduced both compressive strength and modulus of rupture of the NRL-modified concrete. The strength reduction increased with higher PET + CR replacement levels.

However, PET and CR can also enhance the energy absorption, toughness, and ductility of NRL-modified concrete due to their plastic deformation characteristics. The flexural toughness improvement was notable and increased with PET + CR content, which could benefit the impact and fatigue resistance of concrete pavements under traffic loading.

Balancing the strength reduction and toughness enhancement, the results indicated that 5%PET+5%CR replacement in NRL-modified concrete provided acceptable mechanical properties for rigid pavement, which met the strength requirements (32 MPa of 28-day UCS and 4.2 MPa of 28-day flexural strength) specified by DOH, Thailand.

3.3 Sustainable asphalt pavement materials

3.3.1 Natural rubber-modified asphalt concrete (NRMA)

Table 2 provides a comprehensive overview of the test properties for the studied asphalt mixtures. This table presents key performance indicators including Marshall stability, flow, indirect tensile strength (ITS), indirect tensile resilient modulus (IT-MR), and indirect tensile fatigue life (ITFL) for various asphalt concrete mixtures. The table is structured to show the performance of NRL-modified asphalt concrete (NRMA), fiber-reinforced asphalt concrete with various binders, bottom ash-modified asphalt concrete, and hemp fiber-modified asphalt concrete with RAP aggregate.

This section presents the impact of NRL on the performance of natural rubber-modified asphalt (NRMA) concrete mixtures and compares it with conventional asphalt concrete mixtures using AC60/70 binder (Hoy et al., 2024). The study employed granite, limestone, and basalt aggregates, with conventional asphalt binder AC60/70 modified with NRL at rubber-to-binder (R/B) ratios of 3%, 5%, 7%, and 9%. The effects of NRL and different aggregate properties on NRMA mixtures’ mechanistic performance were investigated. The results are summarized in Table 2.

This research confirmed that NRL significantly enhanced the performance of asphalt mixtures. It was found that the optimal R/B ratio was 3%, yielding superior mechanical properties and performance, regardless of the aggregate type. Each type of aggregate offered specific performance benefits. Statistical analysis indicated that aggregate strength parameters, such as Los Angeles abrasion, soundness, and crushing value, significantly influenced the NRMA mixtures’ stability. Mixtures with basalt and granite aggregates indicated superior IT-MR, rutting resistance, and permanent deformation resistance due to their high strength properties. The improvement percentage in (indirect tensile fatigue life (ITFL) was highest for NRMA mixtures with granite aggregate, attributed to its favorable strength and shape characteristics. The mineral compounds CaO, MgO, and SiO2 in limestone notably influenced the ITS and skid resistance of NRMA mixtures.

3.3.2 Fiber-reinforced asphalt concrete with various asphalt binders

Asphalt concrete pavements are subjected to increasing traffic loads and environmental stresses, leading to premature failures and reduced service life. This research presented the potential of fiber reinforcement as a cost-benefit solution to improve the performance and durability of asphalt concrete mixture (Takaikaew et al., 2021; Takaikaew et al., 2018). This approach can significantly enhance pavement performance and extend the lifespan of pavements, thereby decreasing the overall demand for new materials over time and reducing the frequency of road maintenance and reconstruction.

The mixtures were prepared with a 0.05% fiber blend composed of 60% polyolefin and 40% aramid by total mass of the mixture. A comprehensive laboratory testing program was conducted on fiber-reinforced asphalt concrete (FR-AC) mixtures using various commonly used asphalt binders in Thailand, including AC60/70, NRMA, and PMA. Additionally, field assessments were performed to assess the performance of FR-AC under real traffic conditions.

The results revealed that fiber reinforcement is significantly superior to the mechanical characteristics of asphalt mixtures, regardless of the binder type. The FR-AC mixtures exhibited increased stability, strength, and stiffness and reduced permanent deformation, fatigue cracking, and resistance to rutting when benchmarked with the control sample. Notably, the AC60/70 mixture with fibers achieved performance levels comparable to the more expensive PMA mixture without fibers. Field trials confirmed the laboratory findings, with FR-AC sections demonstrating lower roughness, rutting depths, and better durability than sections without fibers after 1–2 years under heavy traffic.

The addition of fibers benefits both AC60/70 and PMA binders benefited from the addition of fibers, with PMA + Fiber mixtures offering the highest performance gains. The economic analysis indicated that fiber-reinforced AC60/70 was a cost-effective solution for improving pavement durability.

3.3.3 Bottom ash-modified asphalt concrete

The utilization of bottom ash (BA) in asphalt concrete (AC) mixes presents a sustainable solution to waste management while enhancing pavement performance. This study presents the fatigue behavior of BA-AC mixture with various types of aggregate, which is commonly used in Thailand, such as basalt, granite, and limestone (Buritatum et al., 2022a). AC samples were prepared with varying BA replacement ratios (0%, 10%, 15%, 20%, and 25% by weight of fine aggregate). The Marshall method was used for sample compaction and performance tests.

The results demonstrate that BA can enhance the engineering properties of AC, including Marshall stability, ITS, and IT-MR. The optimum ratios of BA replacement ratios are 15% for 20% for granite, 15% for basalt, and 5% for limestone BA-AC mixtures. The relationship between IT-MR and ITFL was linear, indicating that higher resilient modulus leads to better fatigue resistance. The ITFL of BA-modified AC increased significantly, particularly for the basalt mixture, which showed the biggest improvement.

This study confirmed the potential of BA as a sustainable additive in AC, enhancing its mechanical properties and fatigue performance. The findings supported the use of BA in road construction, contributing to sustainable infrastructure and effective waste management.

The improvement in AC with BA as a fine aggregate replacement is mainly due to the ash’s high angularity, which enhances interlocking, and its pozzolanic properties, which contribute to additional binding phases, improving strength and durability. However, the chemical composition of BA can vary significantly depending on the source, affecting its reactivity and performance in AC. Future research should focus on understanding this variability and its impact on AC properties, developing standardized testing protocols, and conducting long-term studies on the durability and environmental effects of BA in road construction to ensure consistent performance across different applications.

3.3.4 Hemp fiber-modified asphalt concrete with RAP aggregate

Natural hemp fiber (HF) is derived from the stalks of the hemp plant (Cannabis sativa). As a renewable material, HF aligns with sustainability goals in road construction. Its use in asphalt concrete (AC) mixtures, particularly those incorporating RAP, represents an innovative approach to enhancing pavement performance while promoting environmental sustainability.

This study investigates the mechanical properties of AC modified with RAP and reinforced with HF (Akkharawongwhatthana et al., 2024; Buritatum et al., 2023b; Suddeepong et al., 2024). Before being utilized in the AC mixtures, HF underwent a chemical treatment process involving sodium hydroxide (NaOH). This treatment improves the durability of the fibers by reducing their biodegradability and enhancing their bonding with the asphalt binder, thereby making them more suitable for long-term use in pavement applications. The effects of varying HF lengths (20 mm, 22 mm, 24 mm) and content (0%, 0.05%, 0.1%, 0.25%) on mechanical properties were assessed through a series of static and cyclic tests.

HF notably improved the mechanical performance of RAP-AC. The optimal performance was observed at 0.05% HF content for all types of HF lengths. The performance of HF-AC mixtures improves with the length of the HF. The 0.05% HF-AC mixture with 24 mm fibers exhibits the best overall performance across all critical parameters, followed by the 22 mm and 20 mm fibers. Longer fibers contribute to higher stability, strength index, ITS, IT-MR, ITFL, and rut-resistance, making them more suitable for low-traffic road applications. The findings support the use of HF-RAP-AC in promoting sustainable infrastructure development and contributing to economic and environmental sustainability policies.

4 Conclusion

This research highlighted significant advancements in the development and application of sustainable pavement materials over the past decade. Our findings demonstrated the viability and superior performance of recycled materials, including construction and demolition waste, industrial by-products, and natural hemp fibers, as alternatives to virgin aggregates in road construction.

The study explored various innovative stabilization techniques, such as geopolymerization, cement stabilization, and natural rubber latex modification. These methods showed remarkable improvements in the mechanical performance, durability, and environmental compatibility of recycled and waste materials.

The experimental findings underscored the importance of optimizing mix designs and considering the synergistic effects of different recycled materials and stabilization methods. The microstructural analyses provided valuable insights into the mechanisms underlying the enhanced performance of sustainable pavement materials, such as the formation of cementitious products, improved bonding, and reduced porosity. The environmental assessments confirmed that the utilization of waste materials in road applications poses no significant ecological risks, supporting their suitability for widespread adoption.

The practical implementation of these sustainable solutions in real-world projects demonstrates their readiness for application and their potential to significantly reduce the environmental footprint of road infrastructure development. The research offers practical guidelines for engineers, researchers, and decision-makers, providing evidence-based recommendations for incorporating recycled materials into pavement design and construction projects.

However, further research is needed to address the remaining challenges and knowledge gaps. Future work should focus on the long-standing performance and life cycle assessment of sustainable pavement materials under various climatic and traffic conditions. The development of standardized mix design procedures and specifications for recycled materials in road construction is also crucial to facilitate their wider acceptance and implementation.

Data availability statement

Publicly available datasets were analyzed in this study. This data can be found here: For further inquiries, please direct your questions to the corresponding author.

Author contributions

MH: Conceptualization, Methodology, Project administration, Writing–original draft. SH: Conceptualization, Formal Analysis, Funding acquisition, Writing–review and editing. AC: Writing–review and editing. AS: Writing–review and editing. AB: Writing–review and editing. TY: Writing–review and editing. PC: Conceptualization, Methodology, Writing–review and editing. AU: Writing–review and editing. KK: Writing–review and editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This work was financially supported by Suranaree University of Technology and the NSRF via the Program Management Unit for Human Resource and Institutional Development, Research, and Innovation (PMU-B) (grant number B13F660067). This research was also funded by the National Research Council of Thailand (NRCT) under the Chair Professor program (Grant No. N42A670631) and under the Young Researcher Genius program (Grant No. N42A650210).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Akkharawongwhatthana, K., Buritatum, A., Suddeepong, A., Horpibulsuk, S., Pongsri, N., Yaowarat, T., et al. (2024). Mechanistic performance of hybrid asphalt concretes with recycled aggregates and hemp fiber for low traffic roads. J. Mater. Civ. Eng., 36(4), 04024004. doi:10.1061/JMCEE7.MTENG-16864

AzariJafari, H., Yahia, A., and Ben Amor, M. (2016). Life cycle assessment of pavements: reviewing research challenges and opportunities. J. Clean. Prod. 112, 2187–2197. doi:10.1016/j.jclepro.2015.09.080

Buritatum, A., Aiamsri, K., Yaowarat, T., Suddeepong, A., Horpibulsuk, S., Arulrajah, A., et al. (2023a). Improved fatigue performance and cost-effectiveness of natural rubber latex–modified cement-stabilized pavement base at raised temperatures. J. Mater. Civ. Eng., 35(3), 04022461. doi:10.1061/(ASCE)MT.1943-5533.0004637

Buritatum, A., Suddeepong, A., Akkharawongwhatthana, K., Horpibulsuk, S., Yaowarat, T., Hoy, M., et al. (2023b). Hemp fiber-modified asphalt concretes with reclaimed asphalt pavement for low-traffic roads. Sustainability 15 (8), 6860. doi:10.3390/su15086860Available at: https://www.mdpi.com/2071-1050/15/8/6860.

Buritatum, A., Suddeepong, A., Horpibulsuk, S., Akkharawongwhatthana, K., Yaowarat, T., Hoy, M., et al. (2022a). Improved performance of asphalt concretes using bottom ash as an alternative aggregate. Sustainability 14 (12), 7033. doi:10.3390/su14127033Available at: https://www.mdpi.com/2071-1050/14/12/7033.

Buritatum, A., Suddeepong, A., Horpibulsuk, S., Udomchai, A., Arulrajah, A., Mohammadinia, A., et al. (2022b). Improvement of tensile properties of cement-stabilized soil using natural rubber latex. J. Mater. Civ. Eng. 34 (4), 04022028. doi:10.1061/(ASCE)MT.1943-5533.0004173

Buritatun, A., Takaikaew, T., Horpibulsuk, S., Udomchai, A., Hoy, M., Vichitcholchai, N., et al. (2020). Mechanical strength improvement of cement-stabilized soil using natural rubber latex for pavement base applications. J. Mater. Civ. Eng. 32 (12), 04020372. doi:10.1061/(ASCE)MT.1943-5533.0003471

Donrak, J., Rachan, R., Horpibulsuk, S., Arulrajah, A., and Du, Y. J. (2016). Improvement of marginal lateritic soil using Melamine Debris replacement for sustainable engineering fill materials. J. Clean. Prod. 134, 515–522. doi:10.1016/j.jclepro.2015.12.038

Hoy, M., Horpibulsuk, S., and Arulrajah, A. (2016a). Strength development of Recycled Asphalt Pavement – fly ash geopolymer as a road construction material. Constr. Build. Mater. 117, 209–219. doi:10.1016/j.conbuildmat.2016.04.136

Hoy, M., Horpibulsuk, S., Arulrajah, A., and Mohajerani, A. (2018). Strength and microstructural study of recycled asphalt pavement: slag geopolymer as a pavement base material. J. Mater. Civ. Eng. 30 (8), 04018177. doi:10.1061/(ASCE)MT.1943-5533.0002393

Hoy, M., Horpibulsuk, S., Rachan, R., Chinkulkijniwat, A., and Arulrajah, A. (2016b). Recycled asphalt pavement – fly ash geopolymers as a sustainable pavement base material: strength and toxic leaching investigations. Sci. Total Environ. 573, 19–26. doi:10.1016/j.scitotenv.2016.08.078

Hoy, M., Nhieu, D. V., Horpibulsuk, S., Suddeepong, A., Chinkulkijniwat, A., Buritatum, A., et al. (2023a). Effect of wetting and drying cycles on mechanical strength of cement-natural rubber latex stabilized recycled concrete aggregate. Constr. Build. Mater. 394, 132301. doi:10.1016/j.conbuildmat.2023.132301

Hoy, M., Rachan, R., Horpibulsuk, S., Arulrajah, A., and Mirzababaei, M. (2017). Effect of wetting–drying cycles on compressive strength and microstructure of recycled asphalt pavement – fly ash geopolymer. Constr. Build. Mater. 144, 624–634. doi:10.1016/j.conbuildmat.2017.03.243

Hoy, M., Suddeepong, A., Horpibulsuk, S., Akkharawongthattana, K., Arulrajah, A., Buritatum, A., et al. (2024). Improved performance of natural rubber latex–modified asphalt concretes with various types of aggregates. J. Mater. Civ. Eng., 36(1), 04023495. doi:10.1061/JMCEE7.MTENG-16274

Hoy, M., Tran, N. Q., Suddeepong, A., Horpibulsuk, S., Buritatum, A., Yaowarat, T., et al. (2023b). Wetting-drying durability performance of cement-stabilized recycled materials and lateritic soil using natural rubber latex. Constr. Build. Mater. 403, 133108. doi:10.1016/j.conbuildmat.2023.133108

Hoy, M., Tran, N. Q., Suddeepong, A., Horpibulsuk, S., Mobkrathok, M., Chinkulkijniwat, A., et al. (2023c). Improved fatigue properties of cement-stabilized recycled materials – lateritic soil using natural rubber latex for sustainable pavement applications. Transp. Geotech. 40, 100959. doi:10.1016/j.trgeo.2023.100959

Hoy, M., Vinh Nhieu, D., Suddeepong, A., Horpibulsuk, S., Arulrajah, A., Deng, Y., et al. (2023d). Stiffness, rutting, and fatigue performance evaluation of cement-natural rubber latex stabilized recycled concrete aggregate. Int. J. Pavement Eng. 24 (2), 2276204. doi:10.1080/10298436.2023.2276204

Huang, Y., Bird, R. N., and Heidrich, O. (2007). A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conservation Recycl. 52 (1), 58–73. doi:10.1016/j.resconrec.2007.02.002

Jeerapan, D., Menglim, H., Suksun, H., Arul, A., Mehdi, M., and A, R. A. S. (2022). Environmental assessment of cement-stabilised lateritic soil/melamine debris for Thailand’s pavement. Environ. Geotech. 9 (6), 383–389. doi:10.1680/jenge.18.00195

Kantatham, K., Horpibulsuk, S., Suddeepong, A., Buritatum, A., Hoy, M., and Takaikaew, T. (2021). Effect of Natural Rubber Latex on the compressive strength and durability of cement stabilized soil. Suranaree J. Sci. and Technol. 28 (3).

Nhieu, D. V., Hoy, M., Horpibulsuk, S., Karntatam, K., Arulrajah, A., and Horpibulsuk, J. (2023). Cement – natural rubber latex stabilised recycled concrete aggregate as a pavement base material. Road Mater. Pavement Des. 24 (6), 1636–1650. doi:10.1080/14680629.2022.2072755

Salehi, S., Arashpour, M., Kodikara, J., and Guppy, R. (2021). Sustainable pavement construction: a systematic literature review of environmental and economic analysis of recycled materials. J. Clean. Prod. 313, 127936. doi:10.1016/j.jclepro.2021.127936

Samingthong, W., Hoy, M., Ro, B., Horpibulsuk, S., Yosthasaen, T., Suddeepong, A., et al. (2023). Natural rubber latex-modified concrete with PET and crumb rubber aggregate replacements for sustainable rigid pavements. Sustainability 15 (19), 14147. doi:10.3390/su151914147Available at: https://www.mdpi.com/2071-1050/15/19/14147.

Suddeepong, A., Buritatum, A., Horpibulsuk, S., Yaowarat, T., Hoy, M., Arulrajah, A., et al. (2024). Fatigue performance evaluation of bottom ash-modified asphalt concretes using various aggregate types. Clean Technol. Environ. Policy 26 (3), 741–754. doi:10.1007/s10098-023-02646-5

Suddeepong, A., Buritatum, A., Hoy, M., Horpibulsuk, S., Takaikaew, T., Horpibulsuk, J., et al. (2022). Natural rubber latex–modified concrete pavements: evaluation and design approach. J. Mater. Civ. Eng. 34 (9), 04022215. doi:10.1061/(ASCE)MT.1943-5533.0004364

Sudla, P., Donrak, J., Hoy, M., Horpibulsuk, S., Arulrajah, A., Rashid, A. S. A., et al. (2020). Laboratory investigation of cement-stabilized marginal lateritic soil by crushed slag–fly ash replacement for pavement applications. J. Mater. Civ. Eng. 32 (2), 04019353. doi:10.1061/(ASCE)MT.1943-5533.0003011

Sudla, P., Horpibulsuk, S., Chinkulkijniwat, A., Arulrajah, A., Liu, M. D., and Hoy, M. (2018). Marginal lateritic soil/crushed slag blends as an engineering fill material. Soils Found. 58 (3), 786–795. doi:10.1016/j.sandf.2018.03.007

Sukprasert, S., Hoy, M., Horpibulsuk, S., Arulrajah, A., Rashid, A. S. A., and Nazir, R. (2021). Fly ash based geopolymer stabilisation of silty clay/blast furnace slag for subgrade applications. Road Mater. Pavement Des. 22 (2), 357–371. doi:10.1080/14680629.2019.1621190

Takaikaew, T., Hoy, M., Horpibulsuk, S., Arulrajah, A., Mohammadinia, A., and Horpibulsuk, J. (2021). Performance improvement of asphalt concretes using fiber reinforcement. Heliyon 7 (5), e07015. doi:10.1016/j.heliyon.2021.e07015

Takaikaew, T., Tepsriha, P., Horpibulsuk, S., Hoy, M., Kaloush, K. E., and Arulrajah, A. (2018). Performance of fiber-reinforced asphalt concretes with various asphalt binders in Thailand. J. Mater. Civ. Eng. 30 (8), 04018193. doi:10.1061/(ASCE)MT.1943-5533.0002433

Tran, N. Q., Hoy, M., Suddeepong, A., Horpibulsuk, S., Kantathum, K., and Arulrajah, A. (2022). Improved mechanical and microstructure of cement-stabilized lateritic soil using recycled materials replacement and natural rubber latex for pavement applications. Constr. Build. Mater. 347, 128547. doi:10.1016/j.conbuildmat.2022.128547

Keywords: sustainable pavement materials, recycled aggregates, geopolymer stabilization, cement stabilization, natural rubber latex, geogrid reinforcement, durability, microstructure

Citation: Hoy M, Horpibulsuk S, Chinkulkijniwat A, Suddeepong A, Buritatum A, Yaowarat T, Choenklang P, Udomchai A and Kantatham K (2024) Innovations in recycled construction materials: paving the way towards sustainable road infrastructure. Front. Built Environ. 10:1449970. doi: 10.3389/fbuil.2024.1449970

Received: 16 June 2024; Accepted: 12 September 2024;

Published: 24 September 2024.

Edited by:

Jie Han, University of Kansas, United StatesReviewed by:

Xiaoming Yang, Georgia Southern University, United StatesYu Qian, University of South Carolina, United States

Copyright © 2024 Hoy, Horpibulsuk, Chinkulkijniwat, Suddeepong, Buritatum, Yaowarat, Choenklang, Udomchai and Kantatham. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Menglim Hoy, bWVuZ2xpbUBnLnN1dC5hYy50aA==

Menglim Hoy

Menglim Hoy Suksun Horpibulsuk

Suksun Horpibulsuk Avirut Chinkulkijniwat

Avirut Chinkulkijniwat Apichat Suddeepong2

Apichat Suddeepong2