- Building Materials, Department of Civil, Environmental and Natural Resources Engineering, Lulea University of Technology, Luleå, Sweden

Machine learning techniques have been used in different fields of concrete technology to characterize the materials based on image processing techniques, develop the concrete mix design based on historical data, and predict the behavior of fresh concrete, hardening, and hardened concrete properties based on laboratory data. The methods have been extended further to evaluate the durability and predict or detect the cracks in the service life of concrete, It has even been applied to predict erosion and chemical attaches. This article offers a review of current applications and trends of machine learning techniques and applications in concrete technology. The findings showed that machine learning techniques can predict the output based on historical data and are deemed to be acceptable to evaluate, model, and predict the concrete properties from its fresh state, to its hardening and hardened state to service life. The findings suggested more applications of machine learning can be extended by utilizing the historical data acquitted from scientific laboratory experiments and the data acquitted from the industry to provide a comprehensive platform to predict and evaluate concrete properties. It was found modeling with machine learning saves time and cost in obtaining concrete properties while offering acceptable accuracy.

Introduction

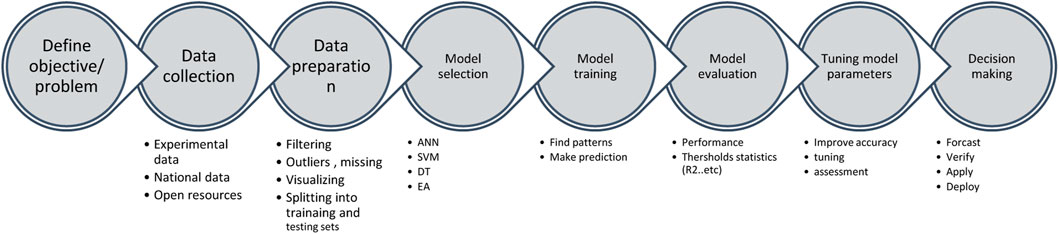

Machine learning (ML) is part of a subset of artificial intelligence which is the study of computer algorithms that can learn and develop on their own with experience and historical data (Mitchell et al., 2013; Jordan and Mitchell, 2015; Bonaccorso, 2017). It produces a model based on training data to make predictions or judgments without having to be explicitly programmed to do so (Ghahramani, 2015). It offers rapid solutions in modeling complex systems (Khambra and Shukla, 2021). ML algorithms are used in a broad range of applications, including business optimization (Apte, 2010), agriculture (Liakos et al., 2018), medicine (Rajkomar et al., 2019), email filtering (Dada et al., 2019), speech recognition (Padmanabhan and Johnson Premkumar, 2015), and computer vision (Sebe et al., 2005), while using traditional algorithms to do the required tasks is difficult or impossible and time-consuming (Wang et al., 2009). ML has been extended to be used in the built environment in different areas (Rachele et al., 2021) either to predict the concrete properties (Asteris et al., 2021) or to predict the failure of structural elements based on historical data (Taffese and Sistonen, 2017). ML modes can be classified into four main models which include artificial neural networks (ANN), support vector machines (SVM), decision trees (DT), and evolutionary algorithms (EA) (Chaabene et al., 2020) and these models are commonly used to predict the mechanical properties of concrete. The finest steps involving developing a ML model consists of eight major steps which are summarized in Figure 1.

FIGURE 1. General steps in ML model development (Reich, 1997; Bonaccorso, 2017; Lehr and Ohm, 2017).

Concrete is a complex material because it contains different materials and their proportions in the mix produce different properties, hence the properties acquisition is rather costly, and requires heavy machines and expertise (Roussel, 2011; Fiore et al., 2014; Sgobba et al., 2015). ML has been used to improve the understanding of concrete behavior and to develop new methods for predicting its properties based on learning from historical data (Ziolkowski and Niedostatkiewicz, 2019; Chaabene et al., 2020; Xie et al., 2020; Nunez and Nehdi, 2021). ML can be used to analyze the physical and chemical properties of concrete (Cheng et al., 2012; Taffese and Sistonen, 2017; Han et al., 2020), as well as its performance in various environments (Nguyen et al., 2020; Tanyildizi et al., 2020; Xie et al., 2020). It can also be used to develop new models for predicting the strength and durability of concrete and to optimize the design of concrete structures (Abuodeh et al., 2020; Ahmad et al., 2021; Güçlüer et al., 2021). It is further extended to develop new methods for detecting and diagnosing defects in concrete and to develop new methods for predicting the service life of concrete structures (Taffese and Sistonen, 2017). Moreover, ML can be used to detect cracks in concrete (Son et al., 2012; Yokoyama and Matsumoto, 2017; Nasrollahi et al., 2019; Deng et al., 2020; Słoński et al., 2020), which can help engineers identify potential problems before they become serious. By using machine learning algorithms, engineers can utilize prediction models to detect cracks in concrete more quickly and accurately, reducing the need for costly repairs.

In concrete technology which deals with the study of concrete materials characterization, fresh and hardened properties, behaviors, and its applications (Neville and Brooks, 1987), ML has been used extensively to evaluate, predict and model the properties of fresh, hardening, and hardened concrete (Chaabene et al., 2020). Not only that but it has also been applied to optimizing environmentally friendly materials used to replace cement using a prediction technique of the impact of adding these materials such as fly ash on the performance of concrete (Khambra and Shukla, 2021). Moreover, it has been used during the construction and after construction (Gamil and Cwirzen, 2022a), for example, Son et al. (Son et al., 2012) used ML to detect concrete on-site using automated color model images with neural networks, and that helped to measure the construction process and also monitor the structural health.

A huge amount of data has been produced by scientific methods either on the laboratory scale or at the full scale (Buyya et al., 2013) and these historical data are of great asset to be used to the maximum advantage using ML to produce platforms for judging the concrete properties (Kamath et al., 2022). The main process of data analysis in machine learning involves different steps the first is data ingestion where data are collected and imported into the assigned analysis platform, while the second step is processing these data by filtering cleaning the data, or even data manipulation, the third is data analysis by choosing the best-fit model either optimization or prediction, train the model, evaluate the model and the last step is data visualization or making the prediction (Bhattacharya, 2021).

In this extensive review, the current trends, and applications of ML in concrete technology are systematically reviewed aiming to draw a road map for further extension of ML application in areas of concrete technology which were not covered in the literature.

Bibliometric analysis of machine learning applications in concrete

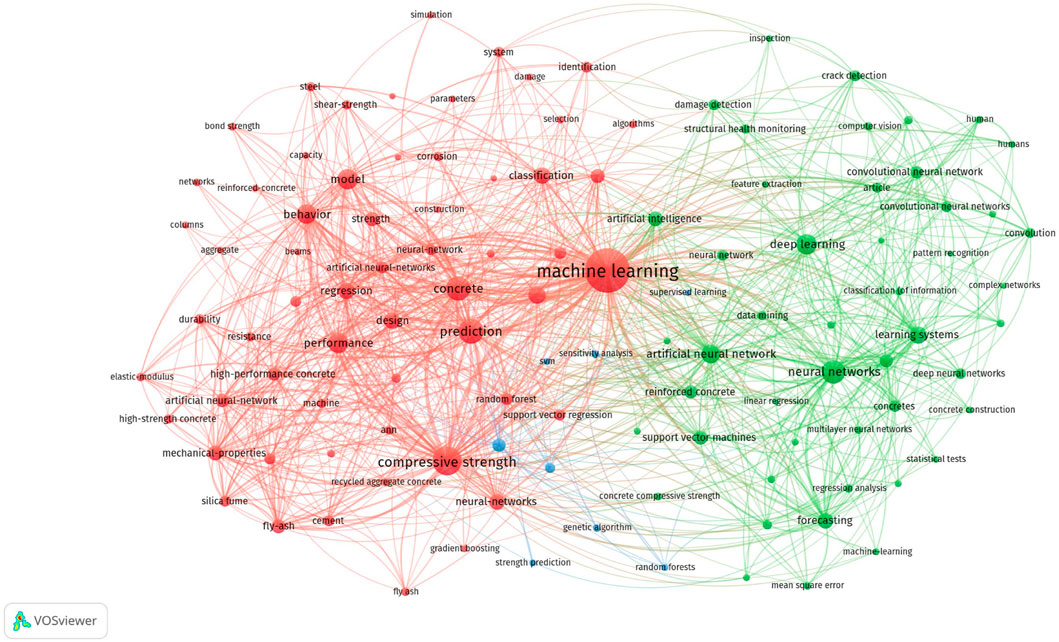

A bibliometric analysis was performed to understand what extent and attention have been put to the literature. The timeline of the analysis is for publications from 2000–2023. During the search, two keywords were used which are “machine learning in concrete” and “application of machine learning in concrete technology.” Results from Figure 2 helps to structure the review article by addressing the most recurring keywords in the application of machine learning in concrete.

From Figure 2, the results showed that ML has been used in different parts of concrete technology and the intensity of the studies differs. For instance, more studies were observed when focusing on compressive strength because it is crucial for the industry and depends more on historical data making it possible to use the ML technique. The studies extended even to structural health monitoring, corrosion in steel rebars, durability, etc. (Rosso et al., 2022).

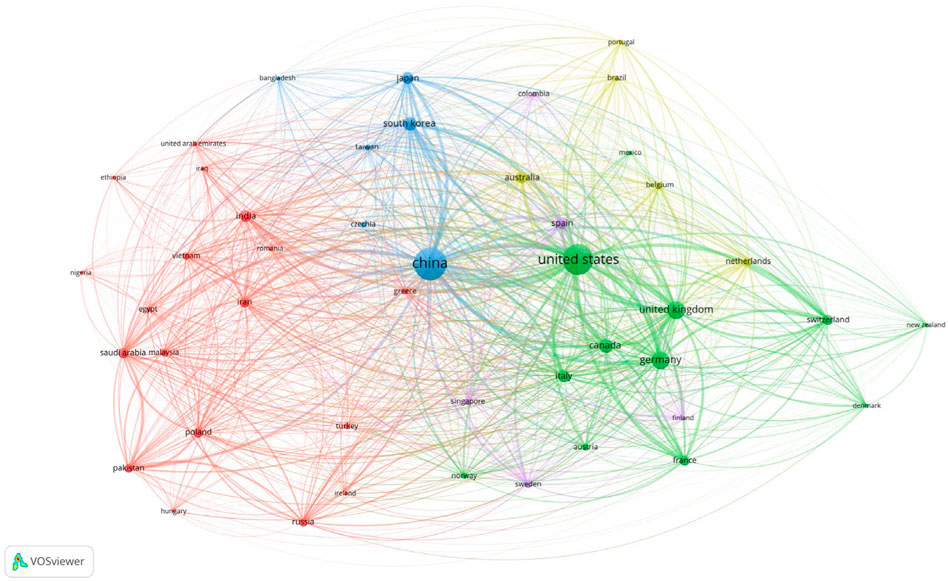

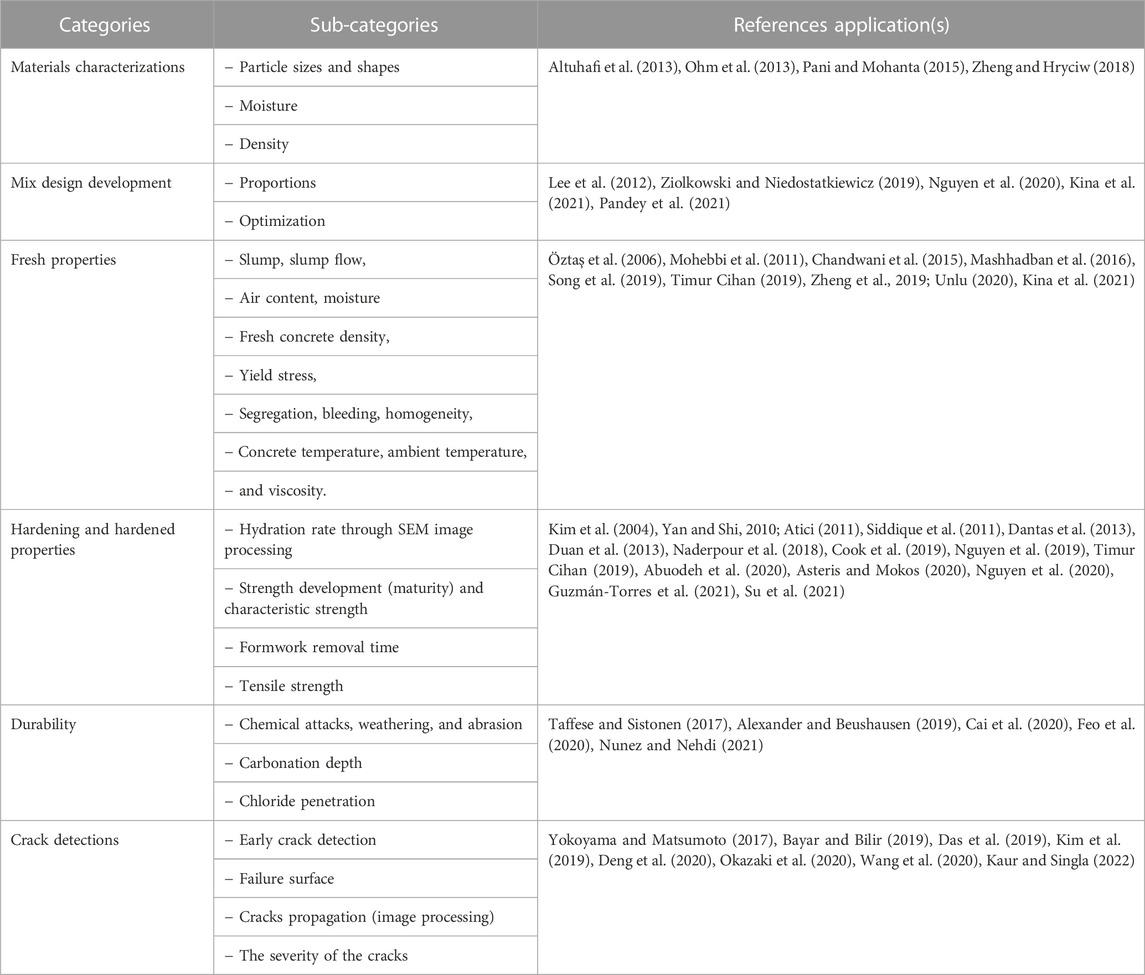

Figure 3 shows the publications densities in different countries which is indicated that China and the United States have published and studied or applied ML in concrete technologies more than other countries. Figure 2 shows the different fields of concrete technologies that ML can be used to accelerate the results acquisitions. It is shown that more areas are still scarce in terms of using ML and that requires further expansion to achieve acceptable digitalization. The common areas are presented in Table 1.

The categories presented in Table 1 are studied separately aiming to offer concluding remarks on the areas that need further studies to leverage the ML techniques to predict or model the properties.

Concrete materials characterization

Raw concrete materials characterization is an essential part of concrete technology and without that no scientific understanding of the concrete final product. Hence knowing the material’s structures, and physical and chemical properties when they are in the raw state would define lately the performance when working in composite to concrete (Gamil and Cwirzen, 2022b). ML has been employed to study concrete materials characterization. An investigative study by (Rafiei et al., 2016) employed ML to characterize the concrete materials and demonstrated the possibility of utilizing statistical historical data to estimate the concrete properties such as slump, flow, strength, and serviceability.

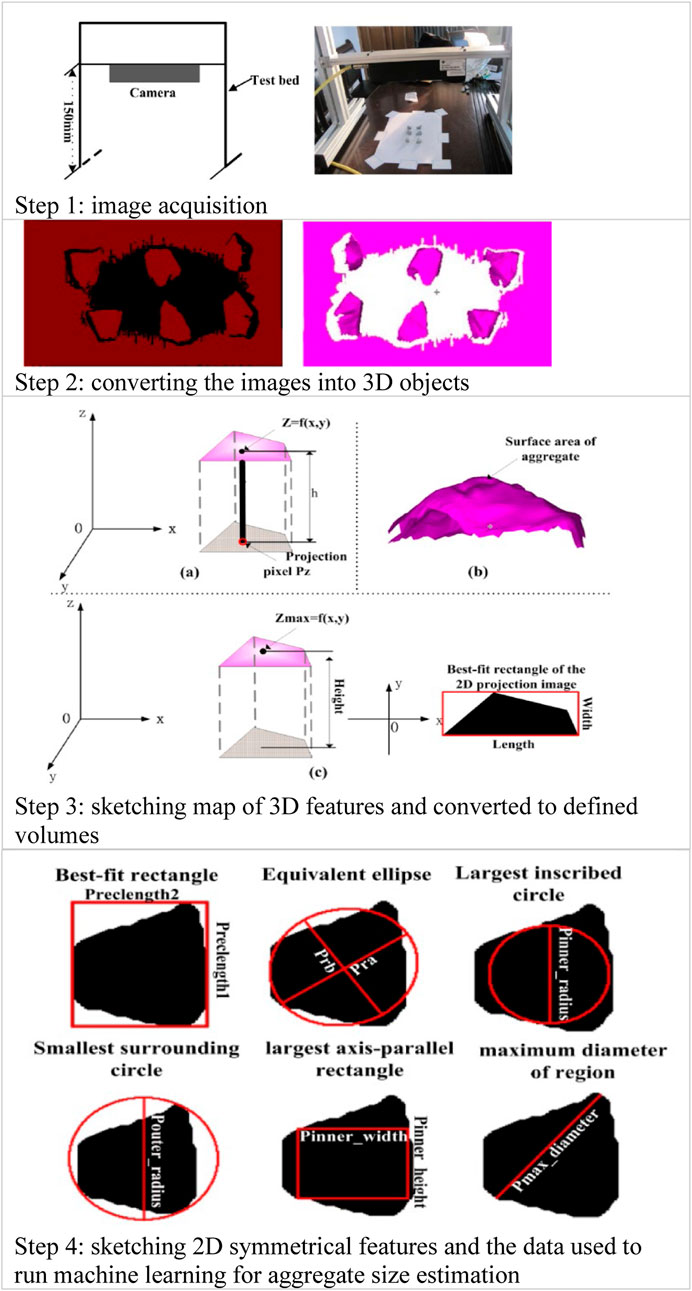

The study of particle morphology is an important topic to address when characterizing the aggregates and sand, especially for the shape and sizes because both play an important part in concrete properties and performance. The coarse aggregate size is an important physical property when designing the concrete mix, Sun et al. (Sun et al., 2021) used an importance-based machine learning feature to define the aggregate size distribution using a measured 3D binocular system instead of sampling and sieving the machine learning provides an invasive measurement of the aggregate size where the accuracy of determining the size was 95.06% and that would help to save a lot of time taken to determine the aggregate size. The process is rearranged in Figure 4.

FIGURE 4. Importance-based machine learning feature to define the aggregate size distribution using measured 3D binocular system, rearranged after (Sun et al., 2021). Step 1: Image acquisition. Step 2: Converting the images into 3D objects. Step 3: Sketching map of 3D features and converted to defined volumes. Step 4: Sketching 2D symmetrical features and the data used to run machine learning for aggregate size estimation

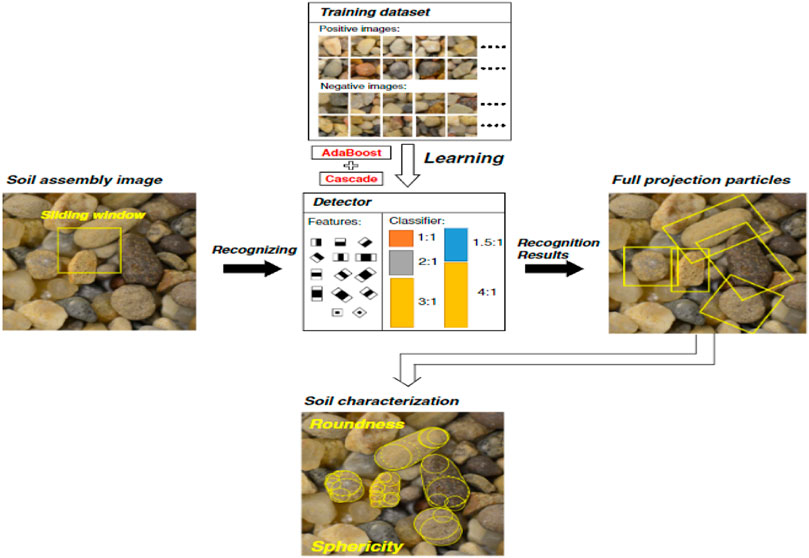

In a different study of the particle shapes of sands was also possible to characterize using pattern recognition by a similar method of using 3D images, the pattern recognition of about 850,000 images to train the program and was conceivable to determine the roundness and sphericity, the method is presented in Figure 4 (Zheng and Hryciw, 2018) as demonstarted in Figure 5. Different method using image method to quantify the size and shape of sands was also possible by digitized image analysis algorithms (Altuhafi et al., 2013). The size distribution of coarse aggregate has also been identified by sed-imaging which is an image-based method test by analyzing the image of soil that is rapidly sedimented through water and can be sorted by size where the percentage of the fine was determined by analyzing the images through learning process ranging size between 0.075–2.0 mm (Ohm and Hryciw, 2014). A similar method using image analysis was also used for particle size characterization showing faster and more accurate results (Ohm et al., 2013). Earlier the method was used to determine the volume of aggregates and the estimation showed very good agreement with the manual measurements (Rao and Tutumluer, 2000).

FIGURE 5. Method of pattern recognition for shape characterization, from (Zheng and Hryciw, 2018).

Concrete mix design

Development of appropriate mix design is a time-consuming and cost-incurred process. ML techniques have been used to develop the mix designs based on collective historical data (Esmaeilkhanian et al., 2017; Ziolkowski and Niedostatkiewicz, 2019; Chaabene et al., 2020). The process has gained more acceptance and applications (Ziolkowski and Niedostatkiewicz, 2019; Pandey et al., 2021). The process utilized historical data to predict the best and wanted mix design with the stipulated performance requirements. For example, (Ziolkowski and Niedostatkiewicz, 2019) used ML to develop mix design based on extensive databases of concrete recipes, the data was used to feed the optimal architecture of neural networks which resulted in to develop of an equation enabling the prediction of mix design and compressive strength as a performance indicator. ML can be used to optimize certain proportions of specific materials in the mix, for example, (Nunez et al., 2020) used hybrid ML to optimize the mix design for recycled aggregate concrete to use more recycled concrete that is believed to be a partial substitute of natural aggregate and that made possible with ML and the results deemed to be robust for predicting the mix performance. In different attempt, Zhang et al. (Zhang et al., 2020) used ML and metaheuristic algorithms to optimize the mix proportions of concrete and that was based on the multiple objectives to be achieved the slump, cost and strength. That helped to predict these parameters even before the construction of the project based on historical data.

The methods of ML can vary but the concept remains similar which is based on a collection of historical data to predict the best mix design possesses acceptable fresh, hardening, and hardened properties. For instance (Golafshani and Behnood, 2019), estimated the optimal mix when using silica fume in concrete based on biogeography-based programming and the results showed good prediction accuracy. In high-performance concrete (Lee et al., 2012), used a heuristic algorithm to predict the mix proportions. To summarize, ML has been used to develop and optimize the concrete mix design, and it can be further extended to emerge new environmental materials that have been extensively studied and proved to have acceptable properties such as slag, fly ash, and other supplementary cementitious materials.

Fresh concrete properties

A key benefit of ML techniques is their ability to generalize the data structure and capture the underlying mechanisms even in the absence of some information (Das et al., 2019) hence it can be possible to use for predicting the concrete properties because it is data-driven method (Chaabene et al., 2020). When casting concrete, several properties are needed to judge the quality and applicability of concrete such as slump for normal concrete, slump flow for Self-compacting concrete (SCC), T500 for SCC, density, air content, yield stresses, concrete temperature, ambient temperature, and viscosity. These parameters are needed for specific equipment and expertise (Gamil et al., 2021; Gamil et al., 2023). It comes with the need for machine learning to substitute manual testing using historical databases owned by corporate or research institutions.

The concrete temperature is an important parameter for fresh concrete which helps to relate that with the curing time. Xie et al. (Xie et al., 2020) have developed an ML system to predict the development trajectory of concrete quality and the temperature changes at the center and surface of the cross-section. Radio-frequency identification (RFID) temperature sensors to record temperature data. The results indicate that the system has over 98 percent reliability on the correlation coefficients between the predicted temperatures and actual temperatures. This thorough study sheds light on how big data analytics and machine learning can help engineers and construction managers oversee the curing of concrete and put preventative measures in place to avoid concrete surface fractures.

The slump flow as an important fresh concrete property for high-performance concrete has been assessed using a machine learning model using four mathematical methods to obtain the best results which are Support Vector Regression, M5P Trees, Random Forest, and Multilayer Perceptron Regressor (MLPReg) and the findings showed that MLPReg algorithm produced the best optimum results for slump assessment (Unlu, 2020). In a different method Kina et al. (Kina et al., 2021) compared extreme ML with deep learning to predict the fresh properties of SCC reinforced with fiber, the method is called long short-term memory (LSTM) where 48 mixes were developed in the laboratory as a learning data and the LSTM methods helped to predict the slump flow, T500 and J-ring for SCC with high accuracy. The moisture content in the concrete is an important parameter to monitor, an innovative percussion-based technique was developed by (Zheng et al., 2019) to document the concrete moisture content using Mel-Frequency Cepstral Coefficients to extract the features and to categorize the various moisture levels in the concrete, Support Vector Machine (SVM) was used.

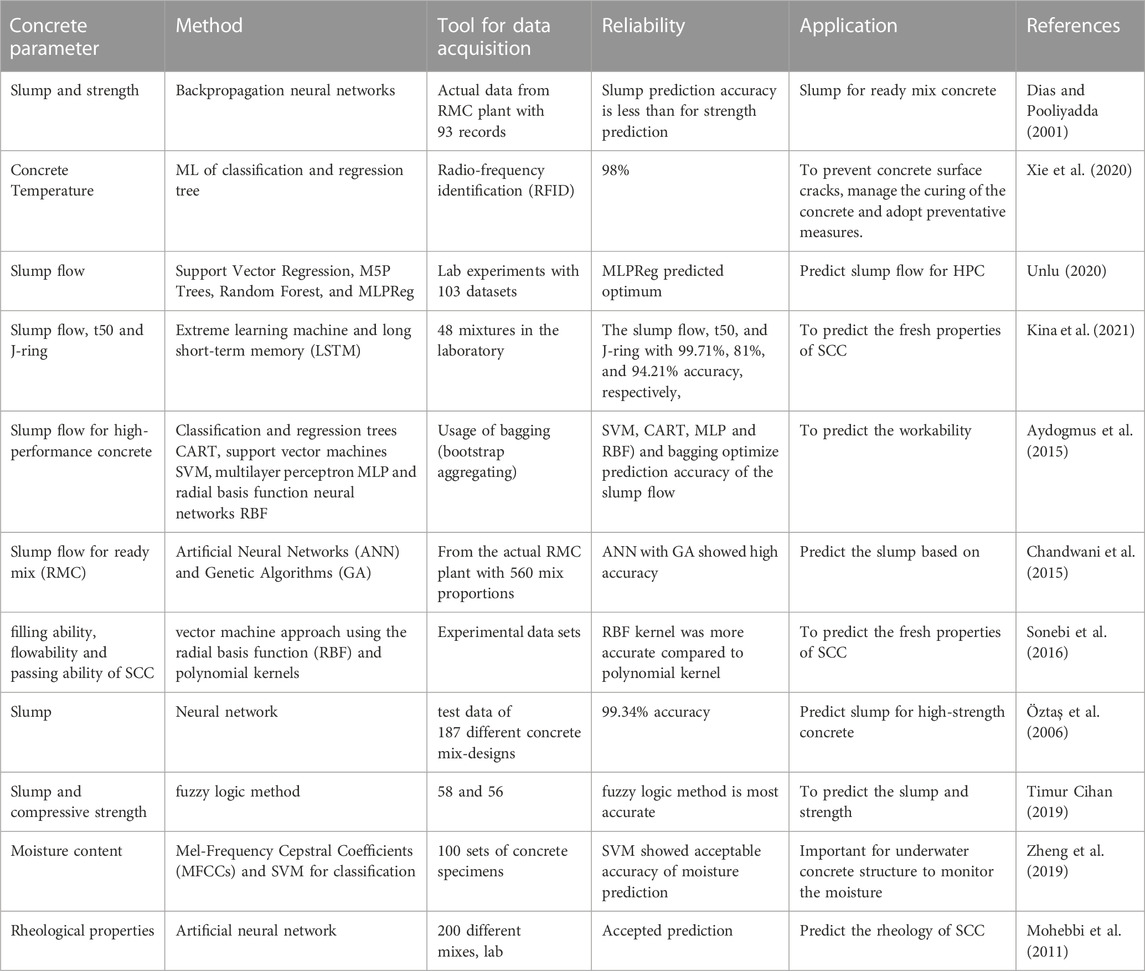

According to the information described in Table 2 more possible expansion of using ML methods to use the big data obtained in laboratories and research publications to develop more data-driven models that can predict concrete properties. These models can save time and help researchers and industry players to make proper decisions on the concrete mix proportions.

Prediction of mechanical properties

Determining the compressive, flexural, and tensile strengths is a time-consuming task and requires machinery and personnel. These properties are of interest to engineers and concrete makers onsite especially compressive strength because it defines the concrete grades (Ziolkowski and Niedostatkiewicz, 2019; Aloisio et al., 2022). ML has been used to predict the compressive strength based on the input of mix design (Chou et al., 2014; Abuodeh et al., 2020; Chaabene et al., 2020). What makes it promising, ML and other modeling techniques are non-destructive and do not need laboratory work if historical data are available.

The application of machine learning for strength prediction was first introduced in 1998 by (Yeh, 1998) where linear regression with ANN emerged to predict the strength of high-performance concrete using historical data (Nunez et al., 2021). Then acceptance has been raised in applying advanced methods to predict the strength. For instance (Deng et al., 2018), used deep learning method to predict the compressive strength of recycled concrete based on five inputs include water to cement ratio, the amount of replaced coarse aggregate, the amount of replaced fine aggregate, and the amount of fly ash, the methods use the ratios of each input and the results show the method offers high efficiency and accuracy for strength prediction. While (Ghasemzadeh et al., 2016) utilized multi-objectives genetic programming (MOGP) to predict the long-term compressive strength and creep using nine input variables which seems to affect the strength and the model possessed an acceptable prediction accuracy. For recycled aggregate concrete (Duan et al., 2013) used a neural network to forecast the strength and that was also the same concepts when (Dantas et al., 2013) used NN to predict the strength of concrete containing demolition waste. But (Luo and Paal, 2018) used the backbone curve model (BCV) to stimulate the force deformation behavior of the structure under cyclic loading. Another modeling method called decision trees and random was used to determine the load capacity of bridges using the national bridge inventory database and that enabled forecasting any failure of the bridges after casting (Alipour et al., 2017). In a different study (Contento et al., 2022), used a probabilistic axial capacity model to estimate the load eccentricity and debonding, the model showed very good accuracy.

A critical review developed by (Chaabene et al., 2020) on the application of ML to predict the mechanical properties found that the models developed by ML based on an accurate data tends to produce more acceptable prediction model of the mechanical properties of concrete. The ML was also extended to be used in the evaluation of bond strength between reinforcement, for example, fiber reinforced polymers (FRPs) and concrete (Gao et al., 2020). Another attempt by (Valikhani et al., 2021) applied ML and image processing to estimate the surface roughness of concrete which is a good indicator of the sufficient bonds between concrete casting at different times. The model helped to distinguish the coarse aggregate from the cement paste using images with relation to the surface area, the results showed that the model can estimate the surface roughness with more than 93% accuracy. Table 3 demonstrates a summary of different publications when ML is applied to predict the mechanical properties of concrete.

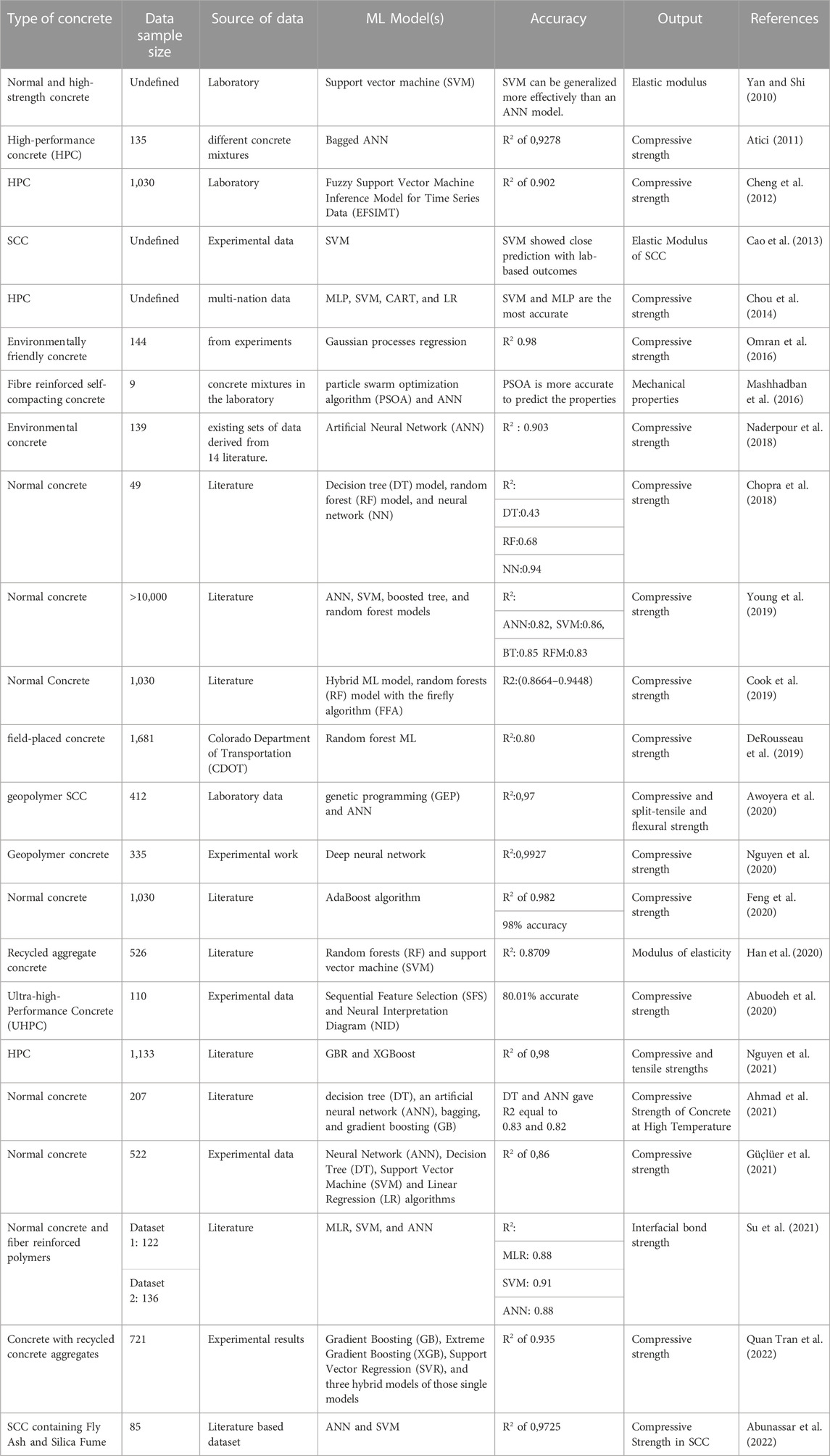

Table 3 shows studies on the application of different ML models to determine the mechanical properties of different types of concrete. The data used to develop these models are classified into different sources some are collected in the laboratory while some are collected from the literature. The accuracy of the models is tested using the coefficient of determination R2, which is the amount of variance of the dependent variable that is predicted from the independent variable and is used to measure the relationship between the predicted values outputted from the model (Güçlüer et al., 2021; Su et al., 2021).

Durability and service life

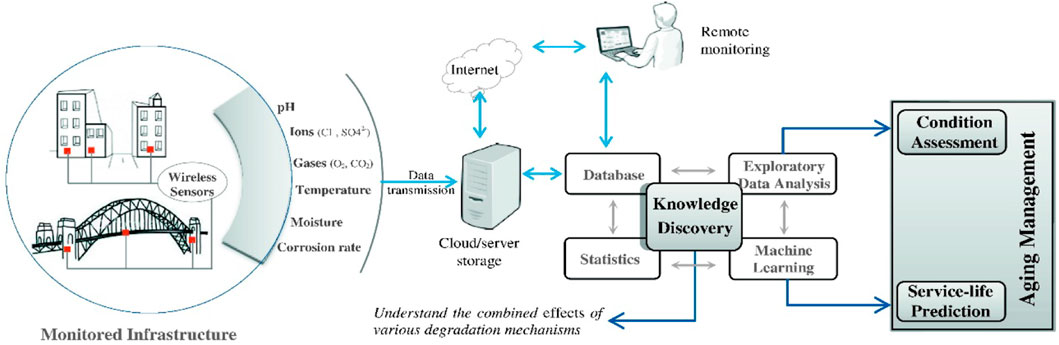

The durability of concrete concerns researchers and engineers which is the ability of concrete to resist chemical attacks, weathering, and abrasion while maintaining the desired concrete properties (Feo et al., 2020; Lalitha et al., 2020). While the service life refers to the expectation of concrete life (Alexander and Beushausen, 2019). Both the durability and service life of the concrete are necessary parameters to evaluate the quality of concrete. ML as a time-saving data-driven method has been implemented to forecast the durability and service life of the concrete. For instance, Nunez and Nehdi (Nunez and Nehdi, 2021) used 713 data recorded on carbonation for recycled aggregate concrete, the model developed by machine learning can capture the parameters that influence the carbonation depth, the model opted to run the process called gradient boosting regression tree (GBRT) which demonstrated exceptional performance in predicting the depth of carbonation. That gives a good indication of the carbonation level and helps to predict that and act when it is over the limits. Another study by Omran et al. (Yinfeng et al., 2008) used ML to assess the non-linear structural response of the structure and managed to obtain and predict the future displacement of the structure when a non-linear load is applied. The durability and service life of reinforced concrete were assessed by ML (Taffese and Sistonen, 2017), which managed to accurately plan the repair measures when required and help to predict the service life based on historical data. The assessment method is presented in Figure 6. The method is denoted by the use of sensors that are left on the structure to provide spatial changes and send these data to the cloud using the mean of data loggers. The ML technique can use these data to learn from the historical and real-time data.

FIGURE 6. Assessment of durability and service life of reinforced structure (Taffese and Sistonen, 2017).

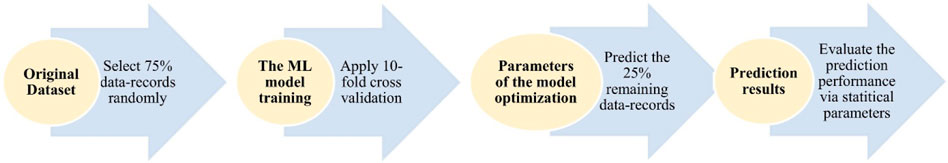

The chloride penetration in high-performance concrete was evaluated by (Song and Kwon, 2009) using a neural network algorithm, chloride penetration is one of the main causes of concrete deterioration. The NN algorithms were built based on actual experimental data, the algorithm type is back-propagation, and the model was able to predict the chloride penetration over time. Similarly, ML was used to predict chloride concentration in marine concrete (Cai et al., 2020) using 642 records of field exposure data of surface chloride concentration, these data were used to train five standalone ML models called, linear regression (LR), Gaussian process regression (GPR), support vector machine (SVM), multilayer perceptron artificial neural network (MLP-ANN) and random forests (RF) models and trained as demonstrated in Figure 7.

FIGURE 7. The process of training and developing ML models (Cai et al., 2020)

The model produced acceptable accuracy and was able to predict the chloride concentration in marine concrete. The highest coefficient of determination R2 is 0.83 for an ensembled model of RF + MLP + SVM. The model can be used to forecast the surface chloride intensity of marine concrete. In a different study (Morcous and Lounis, 2005), used neural networks and case-based reasoning to predict the corrosion in concrete bridges and proposed a method to perform the prediction. The technique showed good feasibility and adequate reliability to predict corrosion. Another recent finding (Rosso et al., 2022), used non-linear analysis to model the corrosion and ductility of concrete used in half-joint bridges, the finding showed discussed two case studies behavior which possessed different behavior whereby the first showed a significant reduction of capacity and ductility while the second didn’t behave similarly, the study managed to model the corrosion of the joints. In a different approach (Di Trapani et al., 2020), used a generic algorithms-based framework to optimize the jacking retrofitting in reinforced concrete columns and the findings showed the framework enabled the effecting modeling of retrofitting costs and can be used by practitioners as a tool for retrofitting modeling.

Concrete crack detections

Concrete crack detection is the process of sensing the cracks in a structure using different technologies which can be classified as destructive and non-destructive methods (Pham et al., 2022). ML and image processing are classified as non-destructive method to predict the cracks in concrete (Gamil and Cwirzen, 2022a; Kaur and Singla, 2022), these methods use images and historical data to make an accurate prediction of the cracks based on data-driven models. Different ML algorithms were also adopted to monitor the concrete structural elements based on real-time sensor acquitted data which includes the Gaussian mixture model for color image detection which helps to detect unusual cracks in the concrete surfaces (Son et al., 2012). The ML is even extended to provide guidelines on repairing materials, for instance (Jiao et al., 2019), used ML to check the repairing materials called high-performance fiber reinforced to repair the concrete structure.

Concrete crack detection using machine learning is a promising area of research. Machine learning algorithms can be used to detect cracks in concrete structures (Nasrollahi et al., 2019). By using data from images of concrete structures (Son et al., 2012), the algorithms can be trained to recognize the patterns of cracks and identify them accurately. The algorithms can also be used to predict the severity of the cracks and provide an estimate of the repair costs. This technology can be used to improve the safety of concrete structures and reduce maintenance costs.

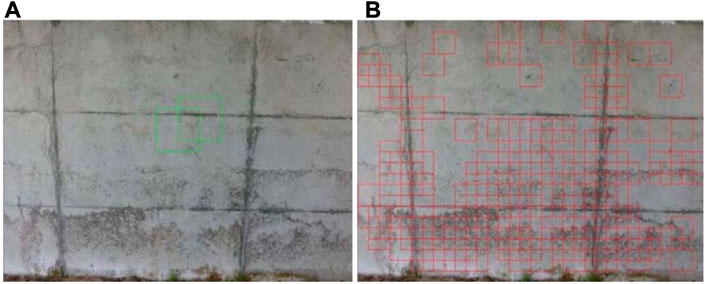

An automatic detector of the crack in concrete was developed using ML (Yokoyama and Matsumoto, 2017) using images of concrete structure, the modeling method is called convolution neural network which is a deep learning method, the images with cracked parts are marked, and the images were classified into five classes and an automatic detector was developed using these five classifiers. The features of cracks are extracted by partitioning the images into different color intensities and then transformed into understandable crack patterns as shown in Figure 8.

FIGURE 8. Crack detection using ML, (A) source data (B) crack detection from source (Yokoyama and Matsumoto, 2017)

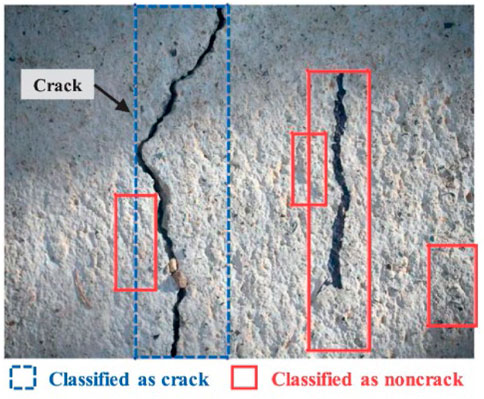

Different ML methods were compared to model the concrete failure surface (Reuter et al., 2018), three methods called 1) Artificial neural networks, 2) support vector machines, and 3)support vector regression, using 88 experimental datasets, the results showed that regression produced the best results in comparison with the two methods. It was rather difficult to determine cracked and crack-free areas on the surface. That is critically studied by (Kim et al., 2019) using ML to classify both cracked and crack-free surfaces. The method helps to determine the cracked areas on the surface, an example demonstrated in Figure 9, the automated crack detection of concrete structures offers a high promise for the suggested machine-learning-based cracks identification approach.

FIGURE 9. Classification of cracked and crack-free surfaces (Kim et al., 2019)

For bridge structure, ML can be used to detect the cracks based on image processing (Okazaki et al., 2020) applied ML to model the cracks in bridges, a regression model was developed to model the formation and propagation of the crack based on actual site data.

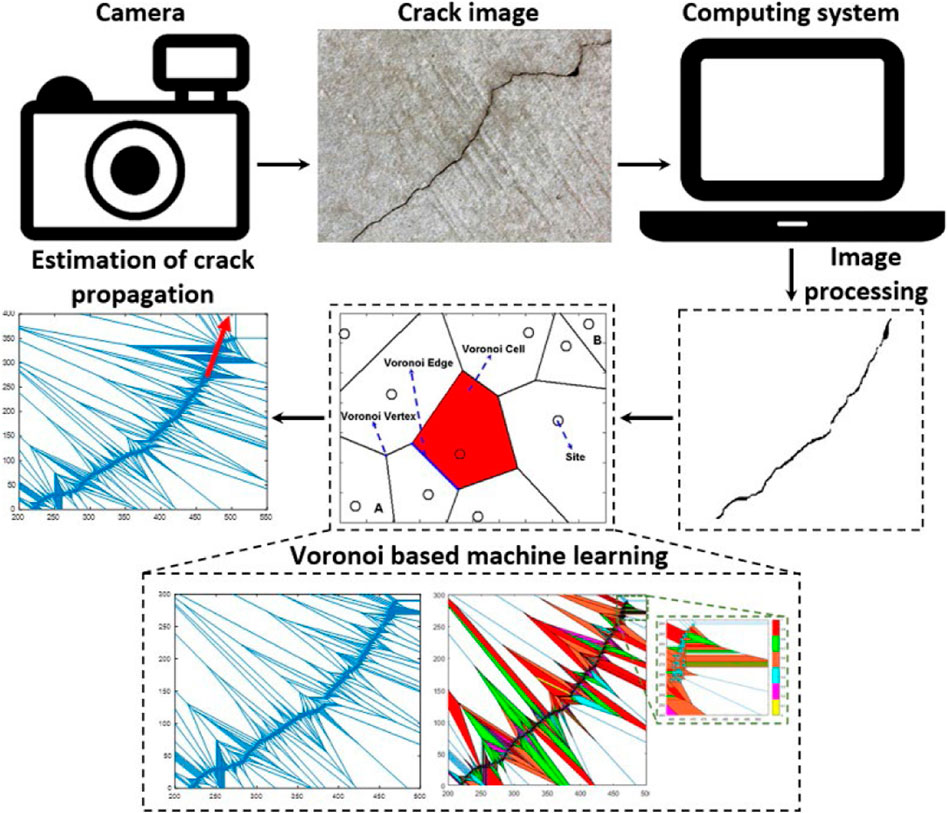

Crack propagation in concrete structure can lead to detrimental effects, that is possible to predict using ML. A study by (Bayar and Bilir, 2019) used ML to predict the crack extension using digital image processing embedded with the Voronoi machine learning algorithm, the crack patterns and propagations were examined using a collection of images, the method helps to predict the crack extension making it possible for engineers to take corrective measures before a catastrophe happens. The method is presented in Figure 10.

FIGURE 10. ML method for crack pattern and propagation detection (Bayar and Bilir, 2019)

Challenges, and future recommendations

The application of ML in concrete technologies has been noticeable however, there have been some challenges addressed by different researchers. Of that (Thai, 2022), summarized the challenges when applying ML in structural engineering and these can be common to concrete technology as well, of these challenges is the difficulty to select the appropriate ML algorithm hence they are expanding over the different application and that makes it tedious process to select the efficient one. The second challenge is the nature of understanding ML and how they work which can be difficult for engineers and policymakers. The third challenge would be the acquisition of data and the quantity of data required for training the model.

Some recommendations are to be addressed to optimize the use of ML in concrete technology, the first one would be the selection of an appropriate and efficient ML algorithm and that can be done before through an intensive review of the former applications and the accuracy of the output. The second recommendation is to explain the model in a more understandable language for engineers to assimilate how efficient and productive ML can be in terms of producing an effective decision-making platform. The third would be producing banks of databases by involving research institutes to continuously feed the system with more data. ML has a variety of approved applications in the field of concrete. Here are a few recommendations.

1. Optimization of mix design: ML algorithms can be used to analyze data on the properties of different types of concrete and the performance of concrete mixes under different conditions. This can help optimize the mix design of concrete for different applications.

2. Proactive casting: ML can be used to predict the formwork pressure when casting allowing acceleration of casting and avoiding accidents when pressure is off the limit.

3. Quality control: ML algorithms can be used to analyze data from concrete production processes to identify patterns that may indicate problems with the quality of the concrete. This can help improve the consistency and reliability of concrete products.

4. Predictive maintenance: ML algorithms can be used to predict the cracks at early age allowing for proactive maintenance and reducing downtime and minimizing accidents.

5. Structural analysis: ML algorithms can be used to analyze data on the structural performance of concrete structures, such as bridges and buildings, under different loading conditions. This can help predict the behavior of these structures and identify potential problems.

Conclusion

A wide range of concrete technology applications has seen the emergence of ML as a promising forecasting tool, making it a potential alternative for often employed empirical models and time-saving methods. The exponential rise in recent years in the number of pertinent literature is proof that the use of ML in concrete technology is growing. An ambitious and thorough review of ML applications for concrete technology has been provided in this article. The review addresses different themes of ML applications in concrete technology which includes materials characterization, concrete mix design, fresh concrete properties, prediction of mechanical properties, durability and service life, and crack detections, to assist the community of concrete industry who are not familiar with machine learning to create their ML models for use in practical applications. The difficulties and potential outcomes of this developing topic are also emphasized and debated.

Long-term inclusion of fundamental ML-related topics in the curricula of university-level civil courses is necessary to facilitate and advance the application of ML in the concrete industry. This research can be a helpful resource for concrete researchers and engineers, practitioners and to start this field of research utilizing the open source ML codes that are available for everyone even those with little programming and coding skills. Overall, the manufacturers and concrete suppliers can benefit from using machine learning to increase productivity, dependability, and performance.

In conclusion, the effectiveness of learning algorithms and the methods of the training databases utilized substantially influence the accuracy of ML prediction models. Because of this, concrete industry players are still hesitant to use ML techniques for concrete properties prediction.

Author contributions

YG has initiated the concepts, analysed and wrote the article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abunassar, N., Alas, M., and Ali, S. I. A. (2022). Prediction of compressive strength in self-compacting concrete containing fly ash and silica fume using ANN and SVM. Arab. J. Sci. Eng. doi:10.1007/s13369-022-07359-3

Abuodeh, O. R., Abdalla, J. A., and Hawileh, R. A. (2020). Assessment of compressive strength of Ultra-high Performance Concrete using deep machine learning techniques. Appl. Soft Comput. 95, 106552. doi:10.1016/j.asoc.2020.106552

Ahmad, A., Ostrowski, K. A., Maślak, M., Farooq, F., Mehmood, I., and Nafees, A. (2021). Comparative study of supervised machine learning algorithms for predicting the compressive strength of concrete at high temperature. Materials 14 (15), 4222. doi:10.3390/ma14154222

Alexander, M., and Beushausen, H. (2019). Durability, service life prediction, and modelling for reinforced concrete structures – review and critique. Cem. Concr. Res. 122, 17–29. doi:10.1016/j.cemconres.2019.04.018

Alipour, M., Harris, D. K., Barnes, L. E., Ozbulut, O. E., and Carroll, J. (2017). Load-capacity rating of bridge populations through machine learning: Application of decision trees and random forests. J. Bridge Eng. 22 (10), 04017076. doi:10.1061/(asce)be.1943-5592.0001103

Aloisio, A., Pasca, D. P., Battista, L. D., Rosso, M. M., Cucuzza, R., Marano, G. C., et al. (2022). Indirect assessment of concrete resistance from FE model updating and Young’s modulus estimation of a multi-span PSC viaduct: Experimental tests and validation. Structures 37, 686–697. doi:10.1016/j.istruc.2022.01.045

Altuhafi, F., O’sullivan, C., and Cavarretta, I. (2013). Analysis of an image-based method to quantify the size and shape of sand particles. J. Geotechnical Geoenvironmental Eng. 139 (8), 1290–1307. doi:10.1061/(asce)gt.1943-5606.0000855

Apte, C. (2010). “The role of machine learning in business optimization,” in Proceedings of the 27th International Conference on Machine Learning (ICML-10), Haifa, Palestine, 1–2.

Asteris, P. G., and Mokos, V. G. (2020). Concrete compressive strength using artificial neural networks. Neural Comput. Appl. 32 (15), 11807–11826. doi:10.1007/s00521-019-04663-2

Asteris, P. G., Skentou, A. D., Bardhan, A., Samui, P., and Pilakoutas, K. (2021). Predicting concrete compressive strength using hybrid ensembling of surrogate machine learning models. Cem. Concr. Res. 145, 106449. doi:10.1016/j.cemconres.2021.106449

Atici, U. (2011). Prediction of the strength of mineral admixture concrete using multivariable regression analysis and an artificial neural network. Expert Syst. Appl. 38 (8), 9609–9618. doi:10.1016/j.eswa.2011.01.156

Awoyera, P. O., Kirgiz, M. S., Viloria, A., and Ovallos-Gazabon, D. (2020). Estimating strength properties of geopolymer self-compacting concrete using machine learning techniques. J. Mater. Res. Technol. 9 (4), 9016–9028. doi:10.1016/j.jmrt.2020.06.008

Aydogmus, H. Y., Erdal, H. I., Karakurt, O., Namli, E., Turkan, Y. S., and Erdal, H. (2015). A comparative assessment of bagging ensemble models for modeling concrete slump flow. Comput. Concr. 16 (5), 741–757. doi:10.12989/cac.2015.16.5.741

Bayar, G., and Bilir, T. (2019). A novel study for the estimation of crack propagation in concrete using machine learning algorithms. Constr. Build. Mater. 215, 670–685. doi:10.1016/j.conbuildmat.2019.04.227

Bhattacharya, S. (2021). “Basic steps in machine learning-based modeling,” in A primer on machine learning in subsurface geosciences (Springer), 45–79.

Bonaccorso, G. (2017). Machine learning algorithms. Birmingham, United Kingdom: Packt Publishing Ltd.

Buyya, R., Vecchiola, C., and Thamarai Selvi, S. (2013). “Chapter 8 - data-intensive computing: MapReduce programming,” in Mastering cloud computing. Editors R. Buyya, C. Vecchiola, and S. T. Selvi (Boston: Morgan Kaufmann), 253–311.

Cai, R., Han, T., Liao, W., Huang, J., Li, D., Kumar, A., et al. (2020). Prediction of surface chloride concentration of marine concrete using ensemble machine learning. Cem. Concr. Res. 136, 106164. doi:10.1016/j.cemconres.2020.106164

Cao, Y. F., Wu, W., Zhang, H. L., and Pan, J. M. (2013). “Prediction of the elastic modulus of self-compacting concrete based on SVM,” in Applied mechanics and materials (Bäch SZ, Switzerland: Trans Tech Publ), 1023–1026.

Chaabene, W. B., Flah, M., and Nehdi, M. L. (2020). Machine learning prediction of mechanical properties of concrete: Critical review. Constr. Build. Mater. 260, 119889. doi:10.1016/j.conbuildmat.2020.119889

Chandwani, V., Agrawal, V., and Nagar, R. (2015). Modeling slump of ready mix concrete using genetic algorithms assisted training of Artificial Neural Networks. Expert Syst. Appl. 42 (2), 885–893. doi:10.1016/j.eswa.2014.08.048

Cheng, M.-Y., Chou, J.-S., Roy, A. F. V., and Wu, Y.-W. (2012). High-performance concrete compressive strength prediction using time-weighted evolutionary fuzzy support vector machines inference model. Automation Constr. 28, 106–115. doi:10.1016/j.autcon.2012.07.004

Chopra, P., Sharma, R. K., Kumar, M., and Chopra, T. (2018). Comparison of machine learning techniques for the prediction of compressive strength of concrete. Adv. Civ. Eng. 2018, 1–9. doi:10.1155/2018/5481705

Chou, J.-S., Tsai, C.-F., Pham, A.-D., and Lu, Y.-H. (2014). Machine learning in concrete strength simulations: Multi-nation data analytics. Constr. Build. Mater. 73, 771–780. doi:10.1016/j.conbuildmat.2014.09.054

Contento, A., Aloisio, A., Xue, J., Quaranta, G., Briseghella, B., and Gardoni, P. (2022). Probabilistic axial capacity model for concrete-filled steel tubes accounting for load eccentricity and debonding. Eng. Struct. 268, 114730. doi:10.1016/j.engstruct.2022.114730

Cook, R., Lapeyre, J., Ma, H., and Kumar, A. (2019). Prediction of compressive strength of concrete: Critical comparison of performance of a hybrid machine learning model with standalone models. J. Mater. Civ. Eng. 31 (11). doi:10.1061/(asce)mt.1943-5533.0002902

Dada, E. G., Bassi, J. S., Chiroma, H., Adetunmbi, A. O., and Ajibuwa, O. E. (2019). Machine learning for email spam filtering: Review, approaches and open research problems. Heliyon 5 (6), e01802. doi:10.1016/j.heliyon.2019.e01802

Dantas, A. T. A., Leite, M. B., and de Jesus Nagahama, K. (2013). Prediction of compressive strength of concrete containing construction and demolition waste using artificial neural networks. Constr. Build. Mater. 38, 717–722. doi:10.1016/j.conbuildmat.2012.09.026

Das, A. K., Suthar, D., and Leung, C. K. (2019). Machine learning based crack mode classification from unlabeled acoustic emission waveform features. Cem. Concr. Res. 121, 42–57. doi:10.1016/j.cemconres.2019.03.001

Deng, F., He, Y., Zhou, S., Yu, Y., Cheng, H., and Wu, X. (2018). Compressive strength prediction of recycled concrete based on deep learning. Constr. Build. Mater. 175, 562–569. doi:10.1016/j.conbuildmat.2018.04.169

Deng, J., Lu, Y., and Lee, V. C. S. (2020). Concrete crack detection with handwriting script interferences using faster region-based convolutional neural network. Computer-Aided Civ. Infrastructure Eng. 35 (4), 373–388. doi:10.1111/mice.12497

DeRousseau, M. A., Laftchiev, E., Kasprzyk, J. R., Rajagopalan, B., and Srubar, W. V. (2019). A comparison of machine learning methods for predicting the compressive strength of field-placed concrete. Constr. Build. Mater. 228, 116661. doi:10.1016/j.conbuildmat.2019.08.042

Di Trapani, F., Malavisi, M., Marano, G. C., Sberna, A. P., and Greco, R. (2020). Optimal seismic retrofitting of reinforced concrete buildings by steel-jacketing using a genetic algorithm-based framework. Eng. Struct. 219, 110864. doi:10.1016/j.engstruct.2020.110864

Dias, W., and Pooliyadda, S. (2001). Neural networks for predicting properties of concretes with admixtures. Constr. Build. Mater. 15 (7), 371–379. doi:10.1016/s0950-0618(01)00006-x

Duan, Z.-H., Kou, S.-C., and Poon, C.-S. (2013). Prediction of compressive strength of recycled aggregate concrete using artificial neural networks. Constr. Build. Mater. 40, 1200–1206. doi:10.1016/j.conbuildmat.2012.04.063

Esmaeilkhanian, B., Khayat, K., and Wallevik, O. H. (2017). Mix design approach for low-powder self-consolidating concrete: Eco-SCC—content optimization and performance. Mater. Struct. 50 (2), 124–218. doi:10.1617/s11527-017-0993-y

Feng, D.-C., Liu, Z.-T., Wang, X.-D., Chen, Y., Chang, J.-Q., Wei, D.-F., et al. (2020). Machine learning-based compressive strength prediction for concrete: An adaptive boosting approach. Constr. Build. Mater. 230, 117000. doi:10.1016/j.conbuildmat.2019.117000

Feo, L., Ascione, F., Penna, R., Lau, D., and Lamberti, M. (2020). An experimental investigation on freezing and thawing durability of high performance fiber reinforced concrete (HPFRC). Compos. Struct. 234, 111673. doi:10.1016/j.compstruct.2019.111673

Fiore, A., Marano, G. C., Marti, C., and Molfetta, M. (2014). On the fresh/hardened properties of cement composites incorporating rubber particles from recycled tires. Adv. Civ. Eng. 2014, 1–12. doi:10.1155/2014/876158

Gamil, Y., and Cwirzen, A. (2022). Digital transformation of concrete technology – A review. Front. Built Environ. - Sustain. Des. Constr. 8. doi:10.3389/fbuil.2022.835236

Gamil, Y., and Cwirzen, A. (2022). Digital transformation of concrete technology—a review. Front. Built Environ. 8. doi:10.3389/fbuil.2022.835236

Gamil, Y., Nilimaa, J., Emborg, M., and Cwirzen, A. (2021). Lateral formwork pressure for self-compacting concrete—a review of prediction models and monitoring technologies. Materials 14 (16), 4767. doi:10.3390/ma14164767

Gamil, Y., Cwirzen, A., Nilimaa, J., and Emborg, M. (2023). The impact of different parameters on the formwork pressure exerted by self-compacting concrete. Materials 16 (2), 759. doi:10.3390/ma16020759

Gao, J., Koopialipoor, M., Armaghani, D. J., Ghabussi, A., Baharom, S., Morasaei, A., et al. (2020). Evaluating the bond strength of FRP in concrete samples using machine learning methods, Smart Structures and Systems. Int. J. 26 (4), 403–418. doi:10.12989/sss.2020.26.4.403

Ghahramani, Z. (2015). Probabilistic machine learning and artificial intelligence. Nature 521 (7553), 452–459. doi:10.1038/nature14541

Ghasemzadeh, F., Manafpour, A., Sajedi, S., Shekarchi, M., and Hatami, M. (2016). Predicting long-term compressive creep of concrete using inverse analysis method. Constr. Build. Mater. 124, 496–507. doi:10.1016/j.conbuildmat.2016.06.137

Golafshani, E. M., and Behnood, A. (2019). Estimating the optimal mix design of silica fume concrete using biogeography-based programming. Cem. Concr. Compos. 96, 95–105. doi:10.1016/j.cemconcomp.2018.11.005

Güçlüer, K., Özbeyaz, A., Göymen, S., and Günaydın, O. (2021). A comparative investigation using machine learning methods for concrete compressive strength estimation. Mater. Today Commun. 27, 102278. doi:10.1016/j.mtcomm.2021.102278

Guzmán-Torres, J. A., Domínguez-Mota, F. J., and Alonso-Guzmán, E. M. (2021). “Estimating the flexural strength of concrete using compressive strength as input value in a deep learning model,” in International Conference on Material Science and Engineering Technology (ICMSET 2021), Jeju Island, Korea, March 12–14, 2021.

Han, T., Siddique, A., Khayat, K., Huang, J., and Kumar, A. (2020). An ensemble machine learning approach for prediction and optimization of modulus of elasticity of recycled aggregate concrete. Constr. Build. Mater. 244, 118271. doi:10.1016/j.conbuildmat.2020.118271

Jiao, P., Roy, M., Barri, K., Zhu, R., Ray, I., and Alavi, A. H. (2019). High-performance fiber reinforced concrete as a repairing material to normal concrete structures: Experiments, numerical simulations and a machine learning-based prediction model. Constr. Build. Mater. 223, 1167–1181. doi:10.1016/j.conbuildmat.2019.07.312

Jordan, M. I., and Mitchell, T. M. (2015). Machine learning: Trends, perspectives, and prospects. Science 349 (6245), 255–260. doi:10.1126/science.aaa8415

Kamath, M. V., Prashanth, S., Kumar, M., and Tantri, A. (2022). Machine-Learning-Algorithm to predict the High-Performance concrete compressive strength using multiple data. J. Eng. Des. Technol. doi:10.1108/JEDT-11-2021-0637

Kaur, H., and Singla, S. (2022). Non-Destructive testing to detect multiple cracks in reinforced concrete beam using electromechanical impedance technique. Mater. Today Proc. 65, 1193–1199. doi:10.1016/j.matpr.2022.04.175

Khambra, G., and Shukla, P. (2021). Novel machine learning applications on fly ash based concrete: An overview. Mater. Today Proc. doi:10.1016/j.matpr.2021.07.262

Kim, J.-I., Kim, D. K., Feng, M. Q., and Yazdani, F. (2004). Application of neural networks for estimation of concrete strength. J. Mater. Civ. Eng. 16 (3), 429–438. doi:10.1007/bf02841997

Kim, H., Ahn, E., Shin, M., and Sim, S.-H. (2019). Crack and noncrack classification from concrete surface images using machine learning. Struct. Health Monit. 18 (3), 725–738. doi:10.1177/1475921718768747

Kina, C., Turk, K., Atalay, E., Donmez, I., and Tanyildizi, H. (2021). Comparison of extreme learning machine and deep learning model in the estimation of the fresh properties of hybrid fiber-reinforced SCC. Neural Comput. Appl. 33 (18), 11641–11659. doi:10.1007/s00521-021-05836-8

Lalitha, G., Sasidhar, C., and Ramachandrudu, C. (2020). Durability Performance of Concrete (M-60) Fine Aggregate Partially Replaced With Crushed Waste Glass. Int. j. adv. eng. technol. 11 (2), 1–9.

Lee, J.-H., Yoon, Y.-S., and Kim, J.-H. (2012). A new heuristic algorithm for mix design of high-performance concrete. KSCE J. Civ. Eng. 16 (6), 974–979. doi:10.1007/s12205-012-1011-0

Lehr, D., and Ohm, P. (2017). Playing with the data: What legal scholars should learn about machine learning. UCDL Rev. 51, 653.

Liakos, K. G., Busato, P., Moshou, D., Pearson, S., and Bochtis, D. (2018). Machine learning in agriculture: A review. Sensors 18 (8), 2674. doi:10.3390/s18082674

Luo, H., and Paal, S. G. (2018). Machine learning–based backbone curve model of reinforced concrete columns subjected to cyclic loading reversals. J. Comput. Civ. Eng. 32 (5), 04018042. doi:10.1061/(asce)cp.1943-5487.0000787

Mashhadban, H., Kutanaei, S. S., and Sayarinejad, M. A. (2016). Prediction and modeling of mechanical properties in fiber reinforced self-compacting concrete using particle swarm optimization algorithm and artificial neural network. Constr. Build. Mater. 119, 277–287. doi:10.1016/j.conbuildmat.2016.05.034

Mitchell, R., Michalski, J., and Carbonell, T. (2013). An artificial intelligence approach. Springer.

Mohebbi, A., Shekarchi, M., Mahoutian, M., and Mohebbi, S. (2011). Modeling the effects of additives on rheological properties of fresh self-consolidating cement paste using artificial neural network. Comput. Concr. 8 (3), 279–292. doi:10.12989/cac.2011.8.3.279

Morcous, G., and Lounis, Z. (2005). Prediction of onset of corrosion in concrete bridge decks using neural networks and case-based reasoning. Computer-Aided Civ. Infrastructure Eng. 20 (2), 108–117. doi:10.1111/j.1467-8667.2005.00380.x

Naderpour, H., Rafiean, A. H., and Fakharian, P. (2018). Compressive strength prediction of environmentally friendly concrete using artificial neural networks. J. Build. Eng. 16, 213–219. doi:10.1016/j.jobe.2018.01.007

Nasrollahi, M., Bolourian, N., and Hammad, A. (2019). “Concrete surface defect detection using deep neural network based on lidar scanning,” in Proceedings of the CSCE Annual Conference, Laval, Greater Montreal, QC, Canada, June 2019, 12–15.

Neville, A. M., and Brooks, J. J. (1987). Concrete technology. Longman Scientific & Technical England.

Nguyen, T., Kashani, A., Tuan, B., and Bordas, S. (2019). Deep neural network with high-order neuron for the prediction of foamed concrete strength. Computer-Aided Civ. Infrastructure Eng. 34 (4), 316–332. doi:10.1111/mice.12422

Nguyen, K. T., Nguyen, Q. D., Le, T. A., Shin, J., and Lee, K. (2020). Analyzing the compressive strength of green fly ash based geopolymer concrete using experiment and machine learning approaches. Constr. Build. Mater. 247, 118581. doi:10.1016/j.conbuildmat.2020.118581

Nguyen, H., Vu, T., Vo, T. P., and Thai, H.-T. (2021). Efficient machine learning models for prediction of concrete strengths. Constr. Build. Mater. 266, 120950. doi:10.1016/j.conbuildmat.2020.120950

Nunez, I., Marani, A., and Nehdi, M. L. (2020). Mixture optimization of recycled aggregate concrete using hybrid machine learning model. Materials 13 (19), 4331. doi:10.3390/ma13194331

Nunez, I., Marani, A., Flah, M., and Nehdi, M. L. (2021). Estimating compressive strength of modern concrete mixtures using computational intelligence: A systematic review. Constr. Build. Mater. 310, 125279. doi:10.1016/j.conbuildmat.2021.125279

Nunez, I., and Nehdi, M. L. (2021). Machine learning prediction of carbonation depth in recycled aggregate concrete incorporating SCMs. Constr. Build. Mater. 287, 123027. doi:10.1016/j.conbuildmat.2021.123027

Ohm, H.-S., and Hryciw, R. D. (2014). Size distribution of coarse-grained soil by sedimaging. J. Geotechnical Geoenvironmental Eng. 140 (4), 04013053. doi:10.1061/(asce)gt.1943-5606.0001075

Ohm, H.-S., Sahadewa, A., Hryciw, R. D., Zekkos, D., and Brant, N. (2013). Sustainable soil particle size characterization through image analysis. Geotechnical Geol. Eng. 31 (6), 1647–1652. doi:10.1007/s10706-013-9657-z

Okazaki, Y., Okazaki, S., Asamoto, S., and Chun, P. j. (2020). Applicability of machine learning to a crack model in concrete bridges. Computer-Aided Civ. Infrastructure Eng. 35 (8), 775–792. doi:10.1111/mice.12532

Omran, B. A., Chen, Q., and Jin, R. (2016). Comparison of data mining techniques for predicting compressive strength of environmentally friendly concrete. J. Comput. Civ. Eng. 30 (6), 04016029. doi:10.1061/(asce)cp.1943-5487.0000596

Öztaş, A., Pala, M., Özbay, E. a., Kanca, E. a., Çagˇlar, N., and Bhatti, M. A. (2006). Predicting the compressive strength and slump of high strength concrete using neural network. Constr. Build. Mater. 20 (9), 769–775. doi:10.1016/j.conbuildmat.2005.01.054

Padmanabhan, J., and Johnson Premkumar, M. J. (2015). Machine learning in automatic speech recognition: A survey. IETE Tech. Rev. 32 (4), 240–251. doi:10.1080/02564602.2015.1010611

Pandey, S., Kumar, V., and Kumar, P. (2021). Application and analysis of machine learning algorithms for design of concrete mix with plasticizer and without plasticizer. J. Soft Comput. Civ. Eng. 5 (1), 19–37. doi:10.22115/SCCE.2021.248779.1257

Pani, A. K., and Mohanta, H. K. (2015). Online monitoring and control of particle size in the grinding process using least square support vector regression and resilient back propagation neural network. ISA Trans. 56, 206–221. doi:10.1016/j.isatra.2014.11.011

Pham, T.-H., Kim, K.-H., and Hong, I.-P. (2022). A study on millimeter wave SAR imaging for non-destructive testing of rebar in reinforced concrete. Sensors 22 (20), 8030. doi:10.3390/s22208030

Quan Tran, V., Quoc Dang, V., and Si Ho, L. (2022). Evaluating compressive strength of concrete made with recycled concrete aggregates using machine learning approach. Constr. Build. Mater. 323, 126578. doi:10.1016/j.conbuildmat.2022.126578

Rachele, J. N., Wang, J., Wijnands, J. S., Zhao, H., Bentley, R., and Stevenson, M. (2021). Using machine learning to examine associations between the built environment and physical function: A feasibility study. Health & Place 70, 102601. doi:10.1016/j.healthplace.2021.102601

Rafiei, M. H., Khushefati, W. H., Demirboga, R., and Adeli, H. (2016). Neural network, machine learning, and evolutionary approaches for concrete material characterization. ACI Mater. J. 113 (6). doi:10.14359/51689360

Rajkomar, A., Dean, J., and Kohane, I. (2019). Machine learning in medicine. N. Engl. J. Med. 380 (14), 1347–1358. doi:10.1056/nejmra1814259

Rao, C., and Tutumluer, E. (2000). Determination of volume of aggregates: New image-analysis approach. Transp. Res. Rec. 1721 (1), 73–80. doi:10.3141/1721-09

Reich, Y. (1997). Machine learning techniques for civil engineering problems. Computer-Aided Civ. Infrastructure Eng. 12 (4), 295–310. doi:10.1111/0885-9507.00065

Reuter, U., Sultan, A., and Reischl, D. S. (2018). A comparative study of machine learning approaches for modeling concrete failure surfaces. Adv. Eng. Softw. 116, 67–79. doi:10.1016/j.advengsoft.2017.11.006

Rosso, M. M., Asso, R., Aloisio, A., Di Benedetto, M., Cucuzza, R., and Greco, R. (2022). Corrosion effects on the capacity and ductility of concrete half-joint bridges. Constr. Build. Mater. 360, 129555. doi:10.1016/j.conbuildmat.2022.129555

Sebe, N., Cohen, I., Garg, A., and Huang, T. S. (2005). Machine learning in computer vision. Springer Science & Business Media.

Sgobba, S., Borsa, M., Molfetta, M., and Marano, G. C. (2015). Mechanical performance and medium-term degradation of rubberised concrete. Constr. Build. Mater. 98, 820–831. doi:10.1016/j.conbuildmat.2015.07.095

Siddique, R., Aggarwal, P., and Aggarwal, Y. (2011). Prediction of compressive strength of self-compacting concrete containing bottom ash using artificial neural networks. Adv. Eng. Softw. 42 (10), 780–786. doi:10.1016/j.advengsoft.2011.05.016

Słoński, M., Schabowicz, K., and Krawczyk, E. (2020). Detection of flaws in concrete using ultrasonic tomography and convolutional neural networks. Materials 13 (7), 1557. doi:10.3390/ma13071557

Son, H., Kim, C., and Kim, C. (2012). Automated color model–based concrete detection in construction-site images by using machine learning algorithms. J. Comput. Civ. Eng. 26 (3), 421–433. doi:10.1061/(asce)cp.1943-5487.0000141

Sonebi, M., Cevik, A., Grünewald, S., and Walraven, J. (2016). Modelling the fresh properties of self-compacting concrete using support vector machine approach. Constr. Build. Mater. 106, 55–64. doi:10.1016/j.conbuildmat.2015.12.035

Song, H.-f., Cui, W., and Yan, W.-s. (2019). Analysis of tangential stress between fresh self-compacting concrete and wall based on thixotropy theory. Constr. Build. Mater. 196, 126–133. doi:10.1016/j.conbuildmat.2018.11.116

Song, H.-W., and Kwon, S.-J. (2009). Evaluation of chloride penetration in high performance concrete using neural network algorithm and micro pore structure. Cem. Concr. Res. 39 (9), 814–824. doi:10.1016/j.cemconres.2009.05.013

Su, M., Zhong, Q., Peng, H., and Li, S. (2021). Selected machine learning approaches for predicting the interfacial bond strength between FRPs and concrete. Constr. Build. Mater. 270, 121456. doi:10.1016/j.conbuildmat.2020.121456

Sun, Z., Liu, H., Huyan, J., Li, W., Guo, M., Hao, X., et al. (2021). Assessment of importance-based machine learning feature selection methods for aggregate size distribution measurement in a 3D binocular vision system. Constr. Build. Mater. 306, 124894. doi:10.1016/j.conbuildmat.2021.124894

Taffese, W. Z., and Sistonen, E. (2017). Machine learning for durability and service-life assessment of reinforced concrete structures: Recent advances and future directions. Automation Constr. 77, 1–14. doi:10.1016/j.autcon.2017.01.016

Tanyildizi, H., Şengür, A., Akbulut, Y., and Şahin, M. (2020). Deep learning model for estimating the mechanical properties of concrete containing silica fume exposed to high temperatures. Front. Struct. Civ. Eng. 14 (6), 1316–1330. doi:10.1007/s11709-020-0646-z

Thai, H.-T. (2022). Machine learning for structural engineering: A state-of-the-art review, structures. Elsevier, 448–491.

Timur Cihan, M. (2019). Prediction of concrete compressive strength and slump by machine learning methods. Adv. Civ. Eng. 2019, 1–11. doi:10.1155/2019/3069046

Unlu, R. (2020). An assessment of machine learning models for slump flow and examining redundant features. Comput. Concr. 25 (6), 565–574. doi:10.12989/cac.2020.25.6.565

Valikhani, A., Jaberi Jahromi, A., Pouyanfar, S., Mantawy, I. M., and Azizinamini, A. (2021). Machine learning and image processing approaches for estimating concrete surface roughness using basic cameras. Computer-Aided Civ. Infrastructure Eng. 36 (2), 213–226. doi:10.1111/mice.12605

Wang, H., Ma, C., and Zhou, L. (2009). “A brief review of machine learning and its application,” in Proceeding of the 2009 international conference on information engineering and computer science, Wuhan, China, December 2009 (IEEE), 1–4.

Wang, J., Zou, Y., Lei, P., Sherratt, R. S., and Wang, L. (2020). Research on recurrent neural network based crack opening prediction of concrete dam. J. Internet Technol. 21 (4), 1161–1169.

Xie, H., Shi, W., Issa, R. R., Guo, X., Shi, Y., and Liu, X. (2020). Machine learning of concrete temperature development for quality control of field curing. J. Comput. Civ. Eng. 34 (5), 04020031. doi:10.1061/(asce)cp.1943-5487.0000916

Yan, K., and Shi, C. (2010). Prediction of elastic modulus of normal and high strength concrete by support vector machine. Constr. Build. Mater. 24 (8), 1479–1485. doi:10.1016/j.conbuildmat.2010.01.006

Yeh, I.-C. (1998). Modeling of strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 28 (12), 1797–1808. doi:10.1016/s0008-8846(98)00165-3

Yinfeng, D., Yingmin, L., Ming, L., and Mingkui, X. (2008). Nonlinear structural response prediction based on support vector machines. J. Sound Vib. 311 (3-5), 886–897. doi:10.1016/j.jsv.2007.09.054

Yokoyama, S., and Matsumoto, T. (2017). Development of an automatic detector of cracks in concrete using machine learning. Procedia Eng. 171, 1250–1255. doi:10.1016/j.proeng.2017.01.418

Young, B. A., Hall, A., Pilon, L., Gupta, P., and Sant, G. (2019). Can the compressive strength of concrete be estimated from knowledge of the mixture proportions?: New insights from statistical analysis and machine learning methods. Cem. Concr. Res. 115, 379–388. doi:10.1016/j.cemconres.2018.09.006

Zhang, J., Huang, Y., Wang, Y., and Ma, G. (2020). Multi-objective optimization of concrete mixture proportions using machine learning and metaheuristic algorithms. Constr. Build. Mater. 253, 119208. doi:10.1016/j.conbuildmat.2020.119208

Zheng, J., and Hryciw, R. D. (2018). Identification and characterization of particle shapes from images of sand assemblies using pattern recognition. J. Comput. Civ. Eng. 32 (3), 04018016. doi:10.1061/(asce)cp.1943-5487.0000765

Zheng, L., Cheng, H., Huo, L., and Song, G. (2019). Monitor concrete moisture level using percussion and machine learning. Constr. Build. Mater. 229, 117077. doi:10.1016/j.conbuildmat.2019.117077

Keywords: machine learning, concrete, mix optimization, performance, data, crack detection

Citation: Gamil Y (2023) Machine learning in concrete technology: A review of current researches, trends, and applications. Front. Built Environ. 9:1145591. doi: 10.3389/fbuil.2023.1145591

Received: 16 January 2023; Accepted: 30 January 2023;

Published: 23 February 2023.

Edited by:

Matteo Pelliciari, University of Modena and Reggio Emilia, ItalyReviewed by:

Marco Martino Rosso, Polytechnic University of Turin, ItalyYuri De Santis, University of L’Aquila, Italy

Copyright © 2023 Gamil. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yaser Gamil, eWFzZXIuZ2FtaWxAbHR1LnNl

Yaser Gamil

Yaser Gamil