- 1University of Northumbria, Newcastle-upon-Tyne, United Kingtom

- 2CESI Ecole d’Ingénieurs, Nanterre, France

Building Information Modelling (BIM) can be defined as a set of tools, processes and technologies that are enabled by a digital multi-dimensional representation of the physical and functional characteristics of a built asset. The ‘fourth’ dimension (4D BIM) incorporates time-related project information in the 3D model to simulate and optimise the project construction process. To achieve this, the 3D objects within the aggregated design model must be linked with each activity in the construction schedule. However, the levels of maturity and expertise in using BIM amongst the project participants still varies considerably. This generates collaboration problems within the project and adds further obstacles to the ability to derive full benefits from BIM. Ideally, 4D BIM can be automatically generated, but in reality, because the 3D and 4D models are created separately and at different stages of the project, this is not currently possible, and the process requires considerable manual effort. The research reported in this paper was prompted by the construction of a new training and research building: the Nanterre 2 CESI building in France. It proposes an efficient approach that minimises the effort of creating 4D BIM construction schedules. The CESI four-phase process aims to help project participants to fully exploit the potential of 4D BIM and enables: 1) a clear expression of the 4D BIM objectives; 2) the identification of information requirements and relevant workflows to achieve these objectives; 3) the implementation of a project schedule; and 4) BIM model production to suit the 4D BIM use case. Although the CESI approach was developed in the context of the French contracting system, the observations and conclusions of this study are intended to be generally applicable.

1 Introduction

The construction sector has undergone many technical and regulatory developments over the last decades. Concerned about the impact of their projects on the environment and the safety of end-users and other project stakeholders, project owners have become more and more demanding when it comes to commissioning projects (Cavka et al., 2017). However, those involved in construction have, according to some commentators, changed their working methods very little (Buisman, 2018). This gap between changes in rules and standards that affect the demand-side and the relative stagnation of those on the supply-side has significant impacts on the duration, cost and quality of the works delivered. A project is an environment where stakeholders with different profiles are required to achieve specific objectives. The success or failure of a project depends on the strategy adopted to organize, coordinate and supervise all the activities and works that need to be scheduled then delivered while taking into account the various internal and external project constraints (Camacho et al., 2018).

1.1 Construction project planning

The planning and scheduling of construction projects represents an important part of the management of the construction process. It plays a crucial role in a project’s success, since it facilitates the allocation of resources (such as equipment, materials, and labour) to project activities over time, to ensure the completion of the project on time and within budget (Conlin and Retik, 1997). In addition to determining the pace of the work, good scheduling enables project stakeholders to check project feasibility, estimate the preliminary costs, maintain safety, optimise the use of resources, and allow the project team to monitor and control progress and determine if the work is proceeding efficiently and ensure that the client’s objective is achieved (Construction Engineering and Management, 2022). Furthermore, planning and scheduling deficiencies (Egwim et al., 2021) and poor communication among project participants (Chen et al., 2019) have been identified as major factors that can lead to project delays and cost overruns (Flyvbjerg, 2014) and ultimately to claims and disputes (Aravindhan et al., 2021).

Scheduling software packages, such as Primavera and Microsoft Project as well as planning techniques like bar charts, time charts, and network approaches, have been used for some time to assist and help project managers in planning construction projects (Chen et al., 2012). Further advances have been made possible with the advent of Building Information Modelling (BIM), which has the potential to assist project managers in expediting their duties more effectively than in the past.

1.2 Building information modelling

BIM can be defined as a set of tools, processes and technologies that are enabled by a digital representation of the physical and functional characteristics of a built asset (Sacks et al., 2018) expressed in data-enriched 3D models and their relationships. This digital replica constitutes a shared and central source of data about a facility, forming a reliable basis to produce information that supports insightful decision making for planning and managing a construction project during its whole life cycle (Dashti et al., 2021). Such information could include onsite spatial and topographical information, temporal and schedule information, and resources and cost information, among others (Popov et al., 2010; Moon et al., 2014; Bortolini et al., 2019). BIM models are characterised by a level of development (LoD) which varies from 100 to 500 (i.e., from least to most developed) that can describe a model and also serve to specify the appropriate amount of information required for specific uses (AIA, 2013).

1.3 4D building information modelling and project planning

Such digital representation is multi-dimensional, or “nD”, where each so-called dimension indicates information-processing capacities for various aspects of design, construction and operation (Koutamanis, 2020). The “fourth” BIM dimension (4D BIM) incorporates time-related project information in the 3D information model to simulate and optimise the project construction process (Ding et al., 2014). In practical terms, this consists in linking units of work or elements in the form of objects from the geometric 3D model to the construction scheduling activities using proprietary software, such as Navisworks or Synchro Pro (Staub-French and Khanzode, 2007), (Mazars and Francis, 2020).

This can be a solution to overcoming many deficiencies of current planning practices (Sheikhkhoshkar et al., 2019), improving the quality of the construction planning process, and enabling the development and integration of several use cases, including 1) dynamic site analysis with temporary components, such as equipment movement, resource availability, the management of congestion and other operational constraints (Huang et al., 2007; Zhou et al., 2015; Antwi-Afari et al., 2018); 2) construction health and safety management (Sloot et al., 2019; Tran et al., 2021); 3) evacuation path planning (Kim and Lee, 2019); 4) logistics management; 5) augmented vehicle tracking and transportation route planning (Chen and Nguyen, 2019); 6) construction waste management (Guerra et al., 2020); 7) spatial conflict detection and workspace congestion avoidance; and 8) the monitoring of construction progress with site layout designs (Costin et al., 2018; Hosseini et al., 2018).

Overall, 4D BIM simulation has been claimed to be potentially 40% more efficient than conventional planning procedures (Candelario-Garrido et al., 2017). Furthermore, 4D BIM based visualisations provide intuitive comprehension of the construction process which enables more effective communication and thus better collaboration between all project stakeholders (Hartmann et al., 2008; Mahalingam et al., 2010).

Although the benefits of 4D BIM are clearly and widely reported in literature (and summarised later), few studies have considered its actual implementation, and the corresponding processes, involving many actors, during the construction phase. Some of these actors have little or no experience in using BIM. Reports suggest that because of this, and the consequent time and expense involved, the use of 4D BIM is currently restricted to small projects with few activities (Boton et al., 2015; Mazars and Francis, 2020). To bridge this gap, this study presents case-based evidence of the use of 4D BIM during the construction phase of a real project to understand how this tool can be practically implemented to support and assist project participants in their mission.

1.4 Introduction to the study and its contribution

This paper extends 4D BIM literature by presenting empirical evidence on the implementation and use of 4D BIM tools during the construction phase of an educational building, and particularly, tackling two related research gaps.

First, the existing software tools of creating 4D BIM models are either: 1) relatively easy to use but not suitable for the full range of construction site planning functions. For instance, the Hardin and McCool approach, which proposes a solution around the Navisworks software and its TimeLiner module (Staub-French and Khanzode, 2007; Hardin and McCool, 2015), 4D Virtual Builder (4D Virtual Builder, 2022) as well as Vico Office software (Vico Office, 2016) are all known to be 4D BIM tools that are easy to use and enable creating 4D video animations usually used to communicate with the client, however they fail to implement advanced 4D functionalities, such as spatial conflict detection and workspace congestion avoidance; 2) reasonably suitable for such purposes but involve a laborious and time-consuming learning and manual conversion of 3D models processes as in the case of the Synchro Pro software (Mazars and Francis, 2020; Nechyporchuk and Bašková, 2020).

Second, as noted in the literature and confirmed in the case study presented here, few studies have considered the actual implementation of 4D BIM planning as a ‘collaborative process’ rather than simply the application of software, thus failing to detail the corresponding workflows and (sub) processes involving many actors, often with heterogenous and different levels of maturity and expertise in using BIM. This paper describes a process that addresses these two concerns and proposed a complete approach that includes and explains how the client should express their 4D BIM objectives. These must be SMART (Specific, Measurable, Achievable, Realistic and Time-bound) to enable a step-by-step process to detail, formalise, and collaboratively synchronise the implementation of the 4D BIM use case between all the construction project participants. This process should include the definition and selection of 4D BIM workflows and the software required. The CESI approach was prompted by, tested and implemented, although in atypical circumstances, on a real construction project - the CESI Nanterre 2 project.

The Nanterre 2 CESI project is a four-storey building, designed to increase the teaching capacity of the CESI campus in Nanterre, Paris. There were two reasons for adopting BIM for the design and delivery of the project. First, so that the deliverables produced by the project participants could be saved at each phase in order to make them available to CESI teaching teams and serve as real case studies. Secondly, so that the information contained in the deliverables allowed CESI to manage the operation and maintenance of the building using BIM-based workflows. CESI therefore produced a BIM specification document to detail their BIM-related expectations. CESI’s BIM management team subsequently translated these expectations into “BIM objectives” and then into “BIM use cases”. Contractually, the companies in charge of the design and construction of the work were required to produce information and deliverables for each BIM use case. However, faced with the limited skills of the contributors, the list of the 10 BIM use cases initially identified by CESI was ultimately reduced to only 8. To overcome this issue, researchers at CESI decided to perform one of the use cases not carried out by the contractors’ production teams, namely the 4D planning.

1.5 Structure of the paper

The remainder of the paper is organized into five parts. After a brief review of planning on construction projects in general, Section 2 reviews the literature on the use of 4D BIM, concluding in the identification of remaining barriers and problems for investigation. In Section 3, the sources of empirical data are introduced, including a background to the construction of a new building at the CESI campus in Nanterre, Paris. This project both prompted the overall study and was to provide a real case for the application of a proposed approach to the process of 4D BIM implementation. Section 4 includes a short survey of 4D BIM practice in France. The CESI 4DBIM methodology is detailed in Section 5 and its more general applicability to the construction industry is discussed in Section 6 alongside its implications for industry, its limitations, and the future work envisaged by the research team. The content of this paper is summarised in Figure 1.

2 Construction planning and the advent of 4D building information modelling

Planning a construction project involves identifying, for each stage of the project, the activities to be carried out to achieve the desired objectives. The activities must then be broken down into basic tasks; referred-to as the project’s work breakdown structure (WBS) which is then scheduled according to the technical, economic, and other specific constraints of the project. By doing so, the resulting deliverable makes it possible to view and communicate the detailed progress of the project and have milestones against which to measure progress. Sometimes this is linked to stage payments.

Several types of planning and scheduling methods have been used, including Critical Path, Line-of-Balance and Time-Location, Program Evaluation and Review Technique (PERT), and Critical Chain methods (Pellerin and Perrier, 2019). Many of these methods have been subjected to refinements in the way they are visualized (McKinney and Fischer, 1998), or, as in the case of Lean-based approach, in their overarching production philosophy (Aziz and Hafez, 2013).

2.1 The benefits of using 4D building information modelling in the management of a construction project

BIM makes it possible to design, build and operate a project over its entire life cycle (Sacks et al., 2018). It involves a collaborative process within a construction company and between project partners around a digital model. It is a technical database, made up of objects defined by their characteristics and the relationships between them. Typically, this incorporates the design work of multiple specialisms, including architecture, structural engineering, and mechanical-electrical-plumbing (MEP) systems. The whole forms a structured set of information about a built asset which is also useful for visualizing the planned project. However, on its own this 3D BIM model does not offer a clear appreciation of the implementation of the construction process and its dynamics: to achieve this, it is necessary to integrate a fourth dimension: time. This is the principle of 4D BIM.

It has been claimed that 4D BIM can be a solution to overcoming many deficiencies of traditional planning practices as linking the digital model to the construction schedule allows project managers to identify planning errors (Hardin and McCool, 2015). This is of great importance given that it has been claimed that 70% of traditional schedules produced are wrong or non-optimised (Hardin and McCool, 2015) and that non-compliance with a schedule has an additional direct effect on the cost of the work as well as possible indirect effects on its quality (Gebrehiwet and Luo, 2017). The enrichment of a 3D BIM model with scheduling data to produce a 4D model has the potential to improve the quality of the construction planning process through the development and integration of several use cases, such as:

1) analysing construction site with temporary components including equipment movement, resource availability, and congestion and other operational constraints management: Huang et al. (2007) proposed to integrate construction virtual prototyping systems with 4D models to provide realistic graphical simulations that incorporate both the layout and dynamic analysis of the construction site;

2) detecting and managing spatial conflict and workspace congestion: Chavada et al. (2012) studied conflicts detection between workspaces using 4D BIM visualization of construction schedules. Moon et al. (2014) developed an active simulation system based on 4D models and an optimisation process to minimise the simultaneous interference level of the schedule-workspace;

3) monitoring construction work progress: Tran et al. (2020) explored the use of 4D BIM and visual programming to develop a conceptual framework of camera planning that enables the monitoring of construction site progress. Braun et al. (2015) proposed an automated framework based on photogrammetric surveys and 4D BIM models to detect deviations in the construction process between the actual state of a construction and its planned state;

4) producing short-term work plans: Sriprasert and Dawood (Sriprasert and Dawood, 2022) implemented the LEWIS system; a visual multi-constraints planning framework based on the use of 4D BIM and Lean methodology principles, to enable integrating construction related information and constraints with 4D BIM;

5) managing construction health and safety: Tran et al. (2021) proposed a hazard identification approach based on 4D BIM and spatial-temporal conflicts potentially leading to accidents, to prevent construction accidents. Han et al. (2017) proposed the 3D-CES system to analyse 3D-based visualisation of mobile crane operation. This system enables the identification of safety and productivity aspects while selecting the most efficient crane operation to assist in elaborating the crane lift schedule. Tan et al. (2019) investigated the use of BIM and 4D acoustics simulation tools to mitigating the noise impact on maintenance workers of offshore platforms;

6) planning evacuation paths: Kim et al. (Kim and Lee, 2019) proposed a 4D BIM based framework that enables generating and visualising worker evacuation paths. The prototype developed considers construction activities and site constraints to enable the identification of accessible evacuation paths including customised parameters, such as workspaces, temporary structures and storage areas;

7) managing construction logistics: Golparvar-Fard et al. (2009) proposed to use 4D photographs to facilitate visualisation and analysis of construction progress and workspace logistics. Said and El-Rayes (Said and El-Rayes, 2014) developed an automated multi-objective construction logistics optimisation system to integrate and optimise material supply and site layout decisions. Chin et al. (2008) proposed a framework to support the logistics and progress management of structural steel works by using 4D with radio-frequency identification (RFID) technology;

8) tracking and planning construction transportation vehicle: Chen and Nguyen (Chen and Nguyen, 2019) investigated the use of BIM with web map service for construction material sources selection. The BIM-WMS decision making system developed enabled evaluating the final cost, materials delivery time, and location credits to help designers and project managers for the selection of material, cost and schedule planning; and

9) managing construction waste: Hewage and Porwal (Hewage, 2011) proposed a 4D BIM framework for material waste prediction and recycling strategies recommendation, while Won and Cheng (Won and Cheng, 2017) developed a 4D BIM construction waste estimation system which relies on construction waste factors for the estimation of waste generation.

2.2 Creating the 4D model: A view from the literature

The process of producing the 3D BIM model and that of the construction schedule each has its own workflow. Creating a 4D BIM model involves linking the 3D design model to the construction schedule through the medium of a 4D integration tool acting as an interface (McKinney et al., 1996). There exists a variety of such tools. The two most-commonly considered in the related academic literature are Navisworks© and Synchro Pro© (Nechyporchuk and Bašková, 2020). Detailed descriptions of this 4D-integration process are given in the literature (Staub-French and Khanzode, 2007; Boton et al., 2015; Mazars and Francis, 2020). The consensus is that the most time-consuming activity involves ensuring that the required schedule activities are linked to the appropriate objects in the 3D design model. Further examination of this issue reveals some major problems.

2.3 Barriers to the use of 4D building information modelling: A problem for investigation

The interoperability of different proprietary software tools (De Gaetani et al., 2020) is a technical issue that appears to be gradually solved (Lai and Deng, 2018). Leaving aside the enduring underlying problem is that the elements that must be incorporated into the 4D model are produced by different parties, with different priorities, and at different times in the project delivery period (Boton et al., 2015). One example of the resulting incompatibility is the difference in LoDs between the sources for the 4D BIM model. The design and construction process are notoriously fragmented. At the time that the 4D simulation is needed much of the 3D design model will be at a lower LoD than the construction schedule (Krippahl and Grilo, 2012), which is based upon a far more detailed work breakdown structure (Boton et al., 2015). The situation is further complicated by the likelihood that different parts (e.g., architectural, structural, MEP) of the 3D model will themselves be at different LoDs (Boton et al., 2015). This accounts for the labour-intensive and time-consuming matching and manipulation work reported by many commentators. According to some, this accounts for the assertion that 4D BIM adoption, in its fullest sense, has been reported to be quite low (Boton et al., 2015) and that 4D BIM is currently only used on small projects with few activities because of the time and effort involved (Mazars and Francis, 2020). In summary, the effort and skill needed to cope with the incompatibility between BIM authoring tools (e.g., Revit and ArchiCAD) and legacy scheduling tools (e.g., Primavera and MS Project) using 4D BIM management tools (e.g., Navisworks and Synchro Pro) is hindering the exploitation of the full potential of BIM (Staub-French and Khanzode, 2007; Mazars and Francis, 2020). This issue will be revisited later in this paper.

3 Research methods

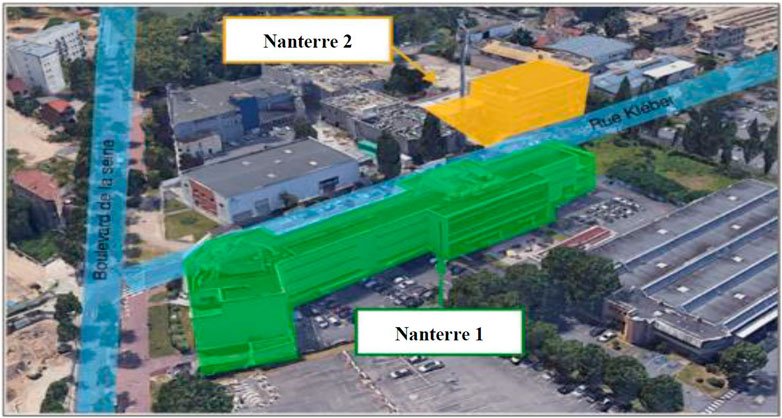

The research study reported here was prompted by the construction of a new 3,000 m2 training and research building at the CESI campus in Nanterre, Paris (the “Nanterre 2 CESI project”). The construction of the 4-storey building, which comprised teaching and research spaces and a high-tech “living lab” (for BIM, virtual reality displays, etc.) was planned for a 12-month period (between 5 May 2018, and 31 May 2019). An image of the new building (Nanterre 2) and the existing (Nanterre 1) building is shown in Figure 2. CESI, as client, specified the use of BIM for the design and construction of the Nanterre 2 building. Apart from its intrinsic commitment to the use of the latest available technologies, CESI also wanted the project as a case study that provided data for teaching and research programmes in digital construction.

3.1 The use of 4D building information modelling on the CESI Nanterre 2 project

In commissioning the Nanterre 2 building, the client, CESI, followed a similar process to that described in (the later published) ISO 19650: 2 (ISO, 2022). This involves the “appointing party” specifying, as part of its tender documents, a set of “exchange information requirements” (EIRs) which prospective appointees then reflect in their tenders, and which forms the basis (subject to pre-contract negotiation) of the appointed delivery team’s “BIM execution plan” (BEP). In this case, a BIM specification document (equivalent to an EIR) was produced that included 10 BIM use cases. These were:

• Site modelling;

• project communication;

• project review;

• analytical studies*;

• 4D BIM*;

• 5D BIM* (an application integrating the model with cost management activities);

• management of design conflicts and clashes;

• logistics support*;

• regulatory compliance checking;

• management of construction works and equipment*

Ultimately, however, for the works to proceed, it was agreed that the appointed delivery team could omit several (marked as *, above) of the BIM use cases. The main reasons for this were the deficiency of certain aspects of the requirements specification as well as the diversity in level of BIM expertise and maturity within the delivery team. One such omission was the requirement to provide 4D BIM. This being the case, and believing that it had sufficient in-house expertise, CESI decided to implement the 4D BIM planning of Nanterre 2 internally with the help of academic research teams that were familiar with digital construction. Their experience in doing so is the basis of the developmental research study reported here.

4 A preliminary survey of 4D building information modelling practice in France

The authors had obtained from the literature a general understanding of experiences in 4D BIM creation and workflows, as described above in Section 2.2. However, to establish the prevailing 4D BIM practices in France a questionnaire survey of the nation’s construction companies was conducted. The questionnaire, which was shared online, comprised three target areas of enquiry: 1) the 4D planning tools used by companies (and reasons for their choice); 2) the different use cases and applications for which these tools were employed; and 3) the strategy and methods used to implement them. The survey was conducted remotely from February to April 2020. Fifty-one BIM managers from different French construction companies completed the survey.

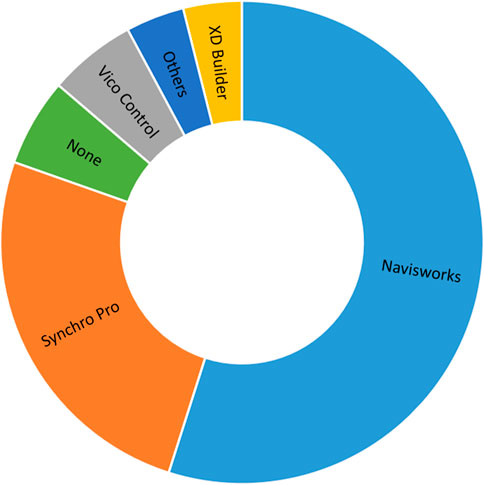

4.1 Software tools used

As illustrated in Figure 3, Navisworks (55% of respondents) and Synchro Pro (25%) were the most widely used BIM 4D products. The former was considered relatively easy to use, and functions such as operation control, conflict analysis, construction sequencing, and coordination between disciplines, were commended. However, respondents reported the need for considerable efforts in manipulating both the BIM model and the planning documents to combine their respective contents. Respondents who used Synchro Pro appreciated its functionality in integrating the planning process (with some reservations) but found the software rather difficult to learn.

4.2 Use cases and applications

The results confirmed the recent literature findings (Staub-French and Khanzode, 2007; Mazars and Francis, 2020) discussed earlier, revealing that the use of 4D planning amongst most contractors was still limited and mainly restricted to creating and simulating 4D videos for communicating internally within an individual company and/or with the client. These video animations are usually non-interactive and disconnected from the progress and control of actual onsite works. Only respondents from the larger contractors, such as Vinci Construction France or Bouygues Construction, reported reasonable familiarity with 4D planning and its use on a wider range of applications that permitted greater interaction with the site delivery team.

4.3 Implementation strategies and methods

The survey revealed two main strategies for engaging with 4D BIM for construction project planning. The first is for a company to proceed “in-house” by selecting its preferred 4D software and acquiring a license, then to build its capability through training. The second is to outsource its 4D planning to a subcontractor specializing in the process.

Irrespective of the strategy adopted, two different methodological approaches to 4D implementation were in evidence. These generally related to the choice of software tool.

The first is that described by Hardin and McCool (Hardin and McCool, 2015) and relies on the use of the Navisworks “TimeLiner” module. The linking of digital objects (in the 3D BIM model) to their corresponding project tasks (in the construction schedule) can in theory be done automatically, but only if appropriate 4D parameters have been correctly created and entered in the original digital model. In confirmation of the literature (see above, Section 2.3), if this has not been done, or if the available 3D design model(s) were incompatible in terms of their LoDs (or any other way) with the detail needed for a working 4D model, then the inevitable manual process is considerably more time-consuming.

The second method is based on the use of Synchro Pro software and was developed by the iBIM team at Vinci Construction company, France. It involves 1) remodelling and restructuring the original 3D model into elemental objects that relate to the methods of construction (this could involve “splitting” or “joining” objects); 2) creating a task for each in the schedule; and then 3) linking each elementary object to its corresponding task. This results in a 4D schedule with a very high granularity, since each object in the original 3D model can be split into multiple 4D BIM objects (or joined into composites) according to the requirements of the onsite construction schedule. For example, an object within the original BIM model that represents a concrete slab could be split into several separate sections (corresponding to concrete pours) in the 4D schedule. Although this solution allows more precise planning, its main drawback comes from the need for the detailed breakdown, which is a manual, laborious and time-consuming process. For instance, as noted by one respondent, the 3D structural BIM model for a medium-sized project (of, say, €10 million) may have more than a thousand original building objects, making its restructuring a complicated and laborious undertaking.

4.4 Summary of the identified problem, and an approach to its solution

The difficulties encountered by survey respondents corresponded closely with the observations noted in the literature, summarised in Section 2.3, above. This suggests that current methods of creating 4D tools from 3D BIM models are either 1) relatively easy but not suitable for the full range of construction site planning functions (as in the case of the Hardin and McCool approach); or 2) reasonably suitable for such purposes in terms of their granularity but involve a laborious and time-consuming learning and manual conversion process. Furthermore, few studies have considered the actual implementation of 4D BIM planning and the corresponding processes involving many actors during the construction phase. The levels of maturity and expertise in using BIM amongst the project participants still varies considerably, whereas some actors have little or no experience at all in using BIM. This generates collaboration problems within the project and adds further obstacles to the ability to derive full benefits from BIM.

The practical requirement for the CESI BIM team to undertake the implementation of 4D BIM planning on the Nanterre 2 project (as described in Section 3.1) presented an opportunity to develop a workflow that addressed these concerns. The aim was to produce an approach to 4D BIM implementation that could enable creating a construction schedule of maximum functionality with minimum extra effort expended in data exchange. From a theoretical viewpoint, this approach includes and explains how the client should express, in a SMART way, their 4D BIM objectives and enables a four-step process for an efficient and practical implementation of 4D BIM. The CESI 4DBIM process, presented in the next section, describes and formalises the implementation of the 4D BIM use case between project actors, including the definition and selection of workflows and software required to its implementation, and enables four subprocesses, namely: 1) a clear expression of the 4D BIM objectives; 2) the identification of information requirements and relevant workflows to achieve these objectives; 3) the implementation of a project schedule; and 4) BIM model production to suit the 4D BIM use case. The results, which are presented here, could help project participants more fully to exploit the potential of 4D BIM.

5 A new proposed methodology for 4D building information modelling planning: The CESI process

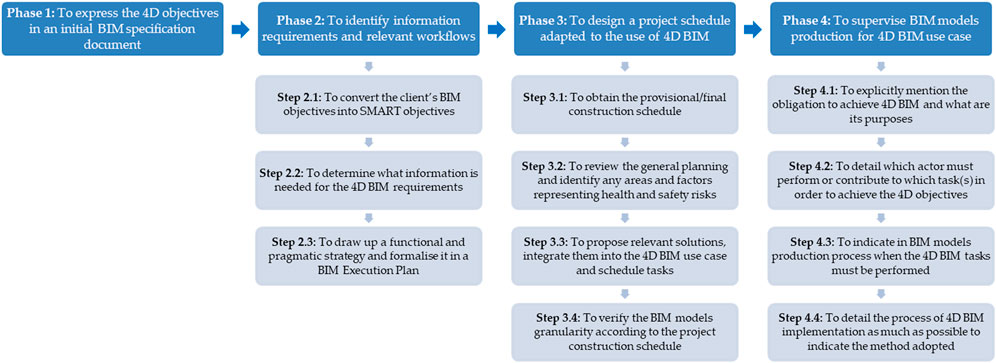

The material presented in the previous sections (findings from the literature review and from a preliminary survey) were used as a starting point for developing the approach taken to implement 4D BIM on the Nanterre 2 project. Following a four-phase process, this details the implementation of 4D BIM from its initial specification by the client through to the production and delivery of those requirements (Figure 4). This solution was intended to be simple and pragmatic. It comprises four phases, namely:

1. To express the 4D objectives in an initial BIM specification document;

2.To identify information requirements and relevant workflows;

3. To design a project schedule adapted for the use of 4D BIM;

4.To supervise BIM model production for the 4D BIM use case.

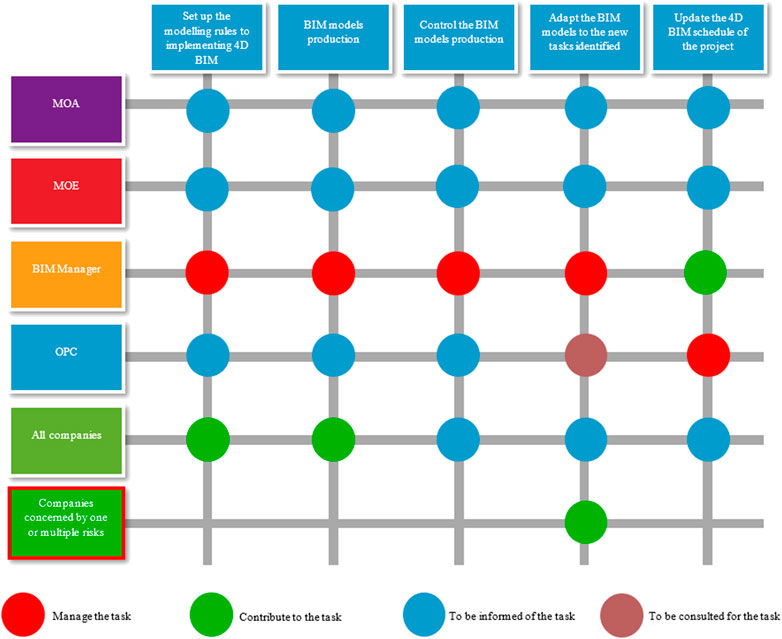

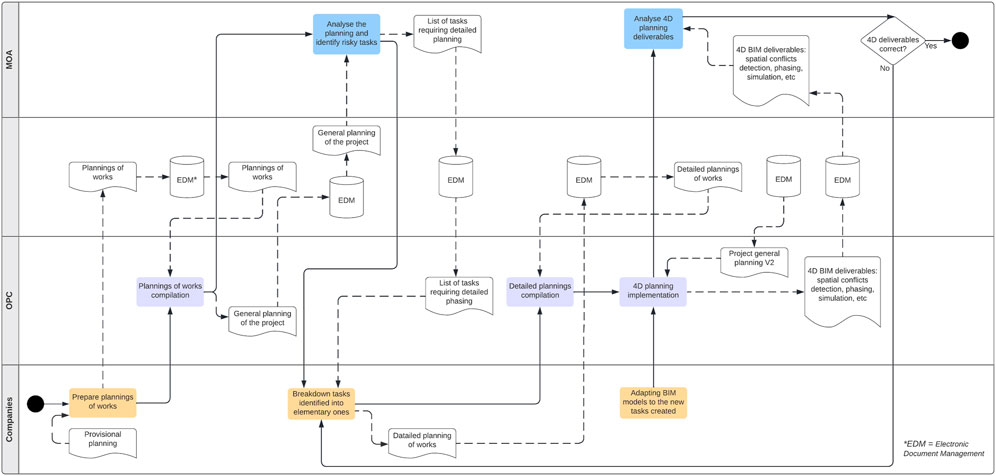

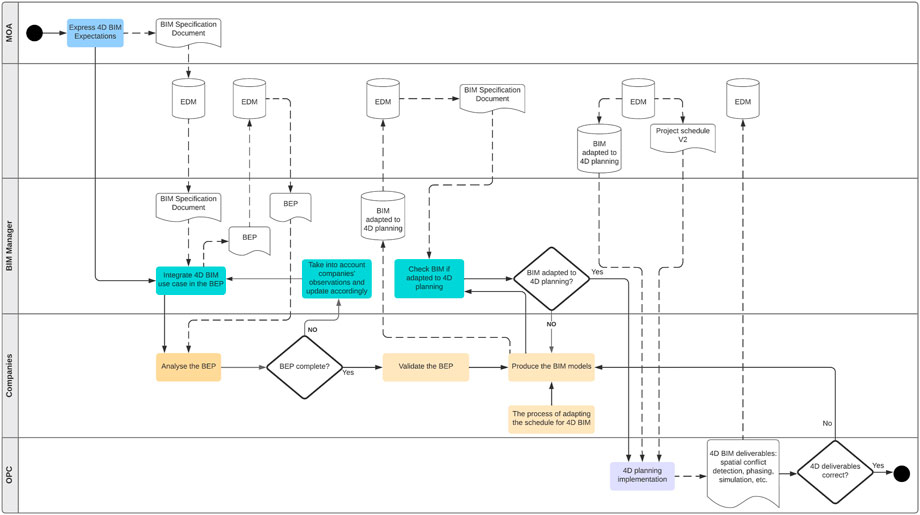

The situation under which the CESI BIM team delivered 4D BIM for its Nanterre 2 project was atypical, and the work was conducted under the circumstances described in Section 3.1. Most of the activities that follow were performed by an independent research team made up of CESI academics with more extensive knowledge and experience of BIM than that of the appointed project delivery team. Under normal circumstances this work would have had to be the subject of some form of commercial appointment. Phase 1 would be undertaken by the client or its consultant, whilst Phases 2 to 4 would be performed by member(s) of the project delivery team (for example by the lead contractor or its sub-consultant). The following subsections present these phases as they were enacted by the CESI BIM team. After this, in Section 5.2 the process is extrapolated to a normal project situation and the activities are assigned to the typical actors in a French construction project. This is illustrated (in Figures 5, 6) in the form of a “responsibility assignment matrix” or “RACI (Responsible, Accountable, Consulted, Informed) matrix” (Cleland, 2007) for each of the two processes, i.e., 1) the implementation of a project schedule to suit the 4D BIM use case (Figure 7), and 2) BIM model production to suit the 4D BIM use case (Figure 8). In Section 6, there is a discussion of the implications of this for the way construction projects are typically organised, in France and elsewhere.

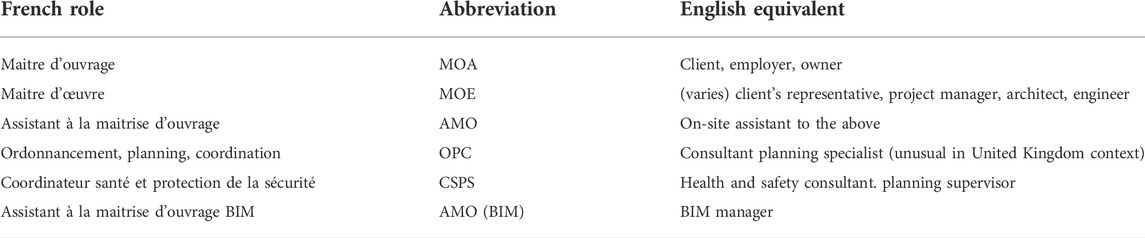

The four-phase CESI 4DBIM process is described below. It should be noted that, although generic role descriptors have been used where possible, occasionally it has been necessary to use French job titles. These, and their English equivalents (which are in some cases approximations) are provided in Appendix A.

5.1 The four-phase CESI 4D building information modelling process

5.1.1 Phase 1: To express the 4D objectives in an initial building information modelling specification document

The client’s role as appointing party is to express its BIM requirements—effectively a set of EIRs (ISO, 2022)—which should be as explicit as possible. In practice, a client may lack familiarity with construction techniques and/or BIM and so may require the support of an experienced consultant or project manager. Each of the BIM use cases required by the client were framed according to SMART (Specific, Measurable, Achievable, Realistic and Time-bound) objectives. For the 4D BIM use case, examples of such SMART objectives were:

• The contractor’s response to the invitation to tender must include 4D planning of construction methods for the works in a visual form that demonstrates its feasibility.

• The appointed Contractor’s BIM Manager is responsible for the provision of a 4D schedule for the construction phase and its submission to the client. This must allow for progress monitoring of the works at any time during their execution and include the work of all the project delivery team.

• The Contractor’s 4D planning solution must enable the identification of all co-contracting zones during the progress of the works with the objective of ensuring and optimising the safety of the site staff and operatives of the companies involved in the works.

This formulation of 4D planning objectives makes the client’s expectations explicit and should enable the Contractor’s BIM Manager to produce a set of detailed solutions—effectively a BEP (ISO, 2022)—for organising the production of BIM models (as referred-to in Phase 2, below).

5.1.2 Phase 2: To identify information requirements and relevant workflows

The next step was to determine all the parameters to be taken into account and integrated into the 4D planning. Typically, this would be done by a BIM Manager. This preliminary work is important because it helps explain to project contributors how to adapt their “traditional” deliverables (schedules and models) in order to be usable within the framework of 4D planning. To do so, the BIM Manager proceeds in three steps as follows:

Step 2.1: To convert the client’s objectives into SMART objectives if this has not been done in the specifications document. This is because non-SMART goals can be open to interpretation, unfeasible or incomplete.

Step 2.2: To determine what information is needed for the 4D BIM requirements. Where the 4D objectives require expertise that is beyond those of the BIM Manager (e.g., environmental risk management), additional experts should be appointed by the client at the request of the BIM manager.

Step 2.3: To draw up a functional and pragmatic strategy and formalise it in a BIM Execution Plan (ISO, 2022) (in French ‘la convention BIM’). This must specify: the digital tools and their capability in using the information; in which formats should the information be delivered; how the information should be produced, controlled and shared; and finally, what deliverables are expected.

5.1.3 Phase 3: To design a project schedule adapted for the use of 4D building information modelling

To ensure quality, optimal coherence and consistency between the BIM model(s) and the construction schedule, a working method is formalised (Figure 7), as follows:

Step 3.1: The provisional or final construction schedule (depending on the stage of the project) is obtained. This schedule will be the input to the design process described below.

Step 3.2: A meeting is held to review the general planning of the project and identify aspects such as complex construction methods, areas of high co-contracting, significant environmental risks, heavy traffic flow, and any factors that could represent health and safety risk for the project.

Step 3.3: Meetings are held as necessary to study in detail the scheduling of tasks. The synthesis of all this information will make it possible to propose a first solution that will then be integrated into the 4D BIM use case and using visualisation, then be validated or amended.

Step 3.4: These steps require both a knowledge of traditional planning and 4D BIM based planning tools. The appropriate parties (e.g., the contractor’s BIM Manager) is asked to verify that the BIM models have been modified according to the required granularity of the project construction schedule.

For the Nanterre 2 project, the initial schedule already included links between tasks. It therefore remained to determine a 4D parameter to be created so as to link the schedule to the BIM models to optimise its precision and facilitate the 4D process. Since the BIM model was created using Autodesk Revit software, a straightforward solution was to assign a text parameter “BIM_WBS” to all BIM model objects followed by the exact name of the individual planning task to which each must be linked.

5.1.4 Phase 4: To supervise building information modelling model production for the 4D building information modelling use case

As noted earlier, it is common for French project stakeholders to partially achieve only certain BIM use cases initially required by the client. This is partly due to the BIM maturity and expertise of some project stakeholders and partly to the disparity between LoDs required and available. A further important factor is the way the BEP was elaborated. For the use of 4D BIM, it often consists of a brief and summary description contained in a section that is less than one page length. The proposals below aim to optimise the content of the BEP to better elaborate and specify the implementation of 4D BIM.

Step 4.1: To explicitly mention the obligation to achieve 4D use, and above all what are its purposes. Thanks to the work done in Phase 1, 4D applications are easily understood using the SMART objectives identified.

Step 4.2: To detail which actor must perform or contribute to which task(s) in order to achieve the 4D BIM use objectives (Figures 5, 6). There are also two workflows whose products must be integrated, namely: 1) the implementation of a project construction schedule adaptable to the requirements of the 4D BIM use case (Figure 7), and 2) BIM model production to suit the 4D BIM use case (Figure 8).

Step 4.3: To indicate in the general process describing BIM model production when the tasks related to the 4D BIM use case must be performed. This must be done before the BIM models are checked and coordinated so that the presence of the parameters that link the BIM models to the schedule can be verified and production of specified deliverables can be monitored.

Step 4.4: The process of 4D BIM implementation needs to be very detailed to indicate to the project actors the method adopted. It should begin with a reminder of the SMART objectives envisioned; the modelling rules to comply with the rationale for model structuring and breakdown; the parameters to be created: when/who provides them; when/how the work will be controlled; the criteria for choosing 4D BIM software; when/who links the model to the schedule to produce the expected deliverables.

Figure 9 illustrates the result of 4D BIM planning using the CESI 4DBIM approach demonstrated on the Nanterre 2 CESI building.

5.2 The four-phase 4D building information modelling process: Hypothetical responsibility assignment

As noted previously the process described in Section 5.1 was a practicable solution in the circumstances but its execution was atypical. Under normal circumstances this approach would need to be implemented by the client, its consultants, or member of the construction team, often in cooperation. To illustrate this, a hypothetical responsibility assignment (‘RACI’) matrix has been produced for each of the two processes (construction schedule and BIM model creation) that need to be integrated. Responsibilities have been assigned to professional roles that are familiar in the French construction industry and are shown in Figures 5, 6. Names for these roles have been abbreviated, as is common in French construction parlance; the full titles and English equivalents are provided in Appendix A.

Clarifying and detailing the process and procedure for implementing any BIM use case (whether 4D BIM related or not) allows project participants to have a clear idea of the tasks to be performed. The more the production and control process is explained the greater the probability of achieving its objectives.

6 Discussion, conclusion, and perspectives

Traditional planning methods have been shown to be ineffective in many cases and as a result, construction project time and cost targets are rarely met. There is a consensus in the literature that BIM represents an opportunity to optimise planning methods. The effective adoption of 4D BIM can potentially reduce planning errors, promote collaboration between stakeholders, and help the project team make more effective decisions. It can facilitate the monitoring of progress to ensure that time and cost constraints are met.

However, it has also been noted in the literature (and confirmed in the case study presented here) that not all project teams are amenable to adopting BIM for project management. In the Nanterre 2 CESI case study, although the use of 4D BIM was required by the client, it could not be fully implemented by the contracted project delivery team. Instead, as described in Section 3.1, a CESI research team undertook the implementation of the 4D use case. This provided the opportunity for the CESI team to create the structured and practical approach described in Section 5.

Underlying the creation of a 4D BIM capability is the integration of a workable construction schedule with a 3D BIM model of the physical asset. However, to ensure effective integration, each element must be produced with a view to that integration.

6.1 Applicability of the proposed 4D process to normal industry practice

The context of the project, and the cooperation of the main contractor offered a rare opportunity for the academic research team to make a practical contribution to the project outcomes, whilst capturing the theoretical implications of their work through action research that informs theory. The proposed 4D method aims to enable an efficient and practical generation of 4D BIM construction schedules. It was developed and tested within a real world case study, the CESI Nanterre 2 project. It comprises a four-phase process based on: 1) a clear expression of the 4D BIM objectives; 2) the identification of information requirements and relevant workflows to achieve these objectives; 3) the implementation of a 4D BIM planning approach that permits the effective integration of the construction schedule and the BIM model; and 4) the development of BIM models suitable for 4D BIM implementation. However, as described in Section 5.2, the proposed method, if it was to be implemented in more typical circumstances, it would require certain levels of collaboration between key project actors. The two hypothetical RACI matrices (Figures 5, 6) show the required interactions between key project actors for effective integration of the two processes (construction schedule and BIM model creation). The collaboration of these key project actors is crucial.

The issue of collaboration is frequently raised when realisation of the benefits of BIM are considered. Increased collaboration is not only a prospective beneficial outcome of BIM adoption (Barlish and Sullivan, 2012); it is a prerequisite for full attainment of these potential benefits (Matthews et al., 2018). Thus, studies have suggested that the realisation of BIM’s key benefits relies upon the degree of collaboration achieved and that this is not achievable with traditional project procurement approaches (Ilozor and Kelly, 2012; Collins and Parrish, 2014; Vass and Gustavsson, 2017). Objectively, the adoption of 4D BIM provides very little added value without the necessary and timely integration of construction scheduling and BIM model creation; a process that is hardly possible in traditional project frameworks.

6.2 Overcoming the barriers to benefits realisation

The argument that the increased collaboration is not only a benefit from, but also a prerequisite for the full exploitation of BIM has prompted a reaction to traditional project procurement approaches. The procurement innovation that has been the most associated with the adoption of BIM is Integrated Project Delivery (IPD). In the United States, IPD originally emerged to address the shortcomings of the adversarial relationships associated with traditional procurement. Under IPD key actors from each discipline are present from project inception to work collaboratively and make collective decisions to ensure that the project design meets its requirements (Azhar, 2011; AIA National, 2012; Mesa et al., 2019). Such an approach would clearly address the fragmented development of BIM use cases and enable collaboration between key project actors (in this case, those responsible for the design and the creation of the construction schedule) as illustrated by the hypothetical RACI matrices in Figures 5, 6. Regrettably, it appears that the adoption of an IPD approach remains a radical and risky option for clients (Kent and Becerik-Gerber, 2010) despite the proposal of various financial devices to overcome the commercial reluctance towards the early appointment of contractors (Jung et al., 2012).

A less radical solution is the creation of a new role with the capability to cope with the effective integration of the construction schedule and the BIM model by ensuring that their respective LoDs are complementary. This resonates with a Swedish study (Vass and Gustavsson, 2017) that recognised the need for new consultant roles, such as BIM project managers and/or BIM coordinators. In the French construction context this would be the appointment of an Assistant à la maitrise d’ouvrage (AMO) with a specific mandate, i.e., an “AMO BIM” for overseeing the complete 4-phase process developed in this study.

6.3 Limitations, possible improvements, and future work

The approach to creating a 4D BIM use case described here is the product of unusual circumstances that permitted the CESI BIM research team to intervene in a project and design an idealised approach to 4D BIM adoption. To replicate this on a typical project would not be easy for reasons explained in Section 6.1, above. Possible strategies for overcoming these difficulties are proposed in Section 6.2.

Furthermore, the case study presented was set in the context of the French contracting system which differs in many respects from systems in other parts of the world. Nevertheless, the authors consider that the observations and conclusions are, mutatis mutandis, generally applicable.

The Nanterre 2 CESI building has been open to students since September 2019. Operation and maintenance management of this building is expected to be implemented using BIM technology. To do this, it is essential to implement and use a classification system such as Uniclass 2015. This system also allows the classification of physical objects using the “Entities,” “Elements,” “Systems,” and “Products” tables, as well as construction processes and activities through the “Activities” table. Consequently, it allows a simultaneous integration of PBS (Product Breakdown Structure) and WBS (AIA National, 2012) and therefore an implementation of BIM for operation phase in which the building objects are linked to their respective operation and maintenance activities. This ontological link between objects and activities should also enable standardisation and automation of 4D BIM planning and simulation for both construction and operation phases.

Sacks et al. (2010) proposed a matrix that contains 56 interactions between Lean methodology principles and BIM functionalities to clarify possible synergies between the two methodologies. Use of this matrix should be investigated as a starting point for improving the proposed method to enable better streamlined and optimised workflows proposed in this paper.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

Funding

This work was funded by the European Union’s Horizon 2020 Research and Innovation Programme through the RINNO project [https://RINNO-h2020.eu/(Doukari et al., 2021; Lynn et al., 2021)] under Grant Agreement Number 892071.

Acknowledgments

The authors would like to gratefully acknowledge the useful assistance, help and support received from Ridha Bensahaila, Lionel Poisson, and David Failly during the development of this work.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

4D Virtual Builder, 20224D Virtual Builder (2022). Project planning plugin for trimble SketchUp. Available online: http://www.4dvirtualbuilder.com/(Accessed on August 26, 2022).

AIA National (2012). IPD case studies. AIA Minnesota and School of Architecture – University of Minnesota.

Antwi-Afari, M. F., Li, H., Pärn, E. A., and Edwards, D. J. (2018). Critical success factors for implementing building information modelling (BIM): A longitudinal review. Autom. Constr. 91, 100–110. doi:10.1016/j.autcon.2018.03.010

Aravindhan, C., Santhoshkumar, R., Bonny, K., Vidhya, K., Manishankar, S., and Dhamodharam, P. (2021). Delay analysis in construction project using Primavera & SPSS. Mater. Today Proc. doi:10.1016/j.matpr.2021.07.186

Azhar, S. (2011). Building information modeling (BIM): Trends, benefits, risks, and challenges for the AEC industry. Leadersh. Manag. Eng. 11 (3), 241–252. doi:10.1061/(ASCE)LM.1943-5630.0000127

Aziz, R. F., and Hafez, S. M. (2013). Applying lean thinking in construction and performance improvement. Alexandria Eng. J. 52, 679–695. doi:10.1016/j.aej.2013.04.008

Barlish, K., and Sullivan, K. (2012). How to measure the benefits of BIM — a case study approach. Autom. Constr. 24, 149–159. doi:10.1016/j.autcon.2012.02.008

Bortolini, R., Formoso, C. T., and Viana, D. D. (2019). Site logistics planning and control for engineer-to-order prefabricated building systems using BIM 4D modeling. Autom. Constr. 98, 248–264. doi:10.1016/j.autcon.2018.11.031

Boton, C., Kubicki, S., and Halin, G. (2015). The challenge of level of development in 4D/BIM simulation across aec project lifecyle. A case study. Procedia Eng. 123, 59–67. doi:10.1016/j.proeng.2015.10.058

Braun, A., Tuttas, S., Borrmann, A., and Stilla, U. (2015). A concept for automated construction progress monitoring using BIM-based geometric constraints and photogrammetric point clouds. J. Inf. Technol. Constr. ITcon 20, 68–79.

Buisman, A. (2018). How are engineering and construction companies adapting digital to their businesses. Ernst&Young.

Camacho, A., Cañizares, P. C., Estévez, S., and Núñez, M. (2018). A tool-supported framework for work planning on construction sites based on constraint programming. Autom. Constr. 86, 190–198. doi:10.1016/j.autcon.2017.11.008

Candelario-Garrido, A., García-Sanz-Calcedo, J., and Reyes Rodríguez, A. M. (2017). A quantitative analysis on the feasibility of 4D planning graphic systems versus conventional systems in building projects. Sustain. Cities Soc. 35, 378–384. doi:10.1016/j.scs.2017.08.024

Cavka, H. B., Staub-French, S., and Poirier, E. A. (2017). Developing owner information requirements for BIM-enabled project delivery and asset management. Autom. Constr. 83, 169–183. doi:10.1016/j.autcon.2017.08.006

Chavada, R., Dawood, N., and Kassem, M. (2012). Construction workspace management: The development and application of a novel ND planning approach and tool. Electron. J. Inf. Technol. Constr. 17, 213–236.

Chen, G.-X., Shan, M., Chan, A. P. C., Liu, X., and Zhao, Y.-Q. (2019). Investigating the causes of delay in grain bin construction projects: The case of China. Int. J. Constr. Manag. 19, 1–14. doi:10.1080/15623599.2017.1354514

Chen, P.-H., and Nguyen, T. C. (2019). A BIM-WMS integrated decision support tool for supply Chain management in construction. Autom. Constr. 98, 289–301. doi:10.1016/j.autcon.2018.11.019

Chen, S.-M., Griffis, F. H., Bud, )., Chen, P.-H., and Chang, L.-M. (2012). Simulation and analytical techniques for construction resource planning and scheduling. Autom. Constr. 21, 99–113. doi:10.1016/j.autcon.2011.05.018

Chin, S., Yoon, S., Choi, C., and Cho, C. (2008). RFID+4D CAD for progress management of structural steel works in high-rise buildings. J. Comput. Civ. Eng. 22, 74–89. doi:10.1061/(asce)0887-3801(2008)22:2(74)

Cleland, D. I. (2007). Project management: Strategic design and implementation. McGraw-Hill Education.

Collins, W., and Parrish, K. (2014). The need for integrated project delivery in the public sector, 719–728. doi:10.1061/9780784413517.074

Conlin, J., and Retik, A. (1997). The applicability of project management software and advanced IT techniques in construction delays mitigation. Int. J. Proj. Manag. 15, 107–120. doi:10.1016/S0263-7863(96)00046-4

Construction Engineering and Management (2022). Importance of scheduling in construction projects. Available online: https://theconstructor.org/construction/const-management/importance-scheduling-construction-projects/1710/(Accessed on April 22, 2022).

Costin, A., Adibfar, A., Hu, H., and Chen, S. S. (2018). Building information modeling (BIM) for transportation infrastructure – literature review, applications, challenges, and recommendations. Autom. Constr. 94, 257–281. doi:10.1016/j.autcon.2018.07.001

Dashti, M. S., RezaZadeh, M., Khanzadi, M., and Taghaddos, H. (2021). Integrated BIM-based simulation for automated time-space conflict management in construction projects. Autom. Constr. 132, 103957. doi:10.1016/j.autcon.2021.103957

De Gaetani, C. I., Mert, M., and Migliaccio, F. (2020). Interoperability analyses of BIM platforms for construction management. Appl. Sci. (Basel). 10, 4437. doi:10.3390/app10134437

Ding, L., Zhou, Y., and Akinci, B. (2014). Building information modeling (BIM) application framework: The process of expanding from 3D to computable ND. Autom. Constr. 46, 82–93. doi:10.1016/j.autcon.2014.04.009

Doukari, O., Lynn, T., Rosati, P., Egli, A., Krinidis, S., Angelakoglou, K., et al. (2021). Rinno: Transforming deep renovation through an open renovation platform. Nice, France.

Egwim, C. N., Alaka, H., Toriola-Coker, L. O., Balogun, H., and Sunmola, F. (2021). Applied artificial intelligence for predicting construction projects delay. Mach. Learn. Appl. 6, 100166. doi:10.1016/j.mlwa.2021.100166

Flyvbjerg, B. (2014). What you should know about megaprojects and why: An overview. Proj. Manag. J. 45, 6–19. doi:10.1002/pmj.21409

Gebrehiwet, T., and Luo, H. (2017). Analysis of delay impact on construction project based on RII and correlation coefficient: Empirical study. Procedia Eng. 196, 366–374. doi:10.1016/j.proeng.2017.07.212

Golparvar-Fard, M., Peña-Mora, F., Arboleda, C. A., and Lee, S. (2009). Visualization of construction progress monitoring with 4D simulation model overlaid on time-lapsed photographs. J. Comput. Civ. Eng. 23, 391–404. doi:10.1061/(asce)0887-3801(2009)23:6(391)

Guerra, B. C., Leite, F., and Faust, K. M. (2020). 4D-BIM to enhance construction waste reuse and recycle planning: Case studies on concrete and drywall waste streams. Waste Manag. 116, 79–90. doi:10.1016/j.wasman.2020.07.035

Han, S., Bouferguene, A., Al-Hussein, M., and Hermann, U. (2017). 3D-Based crane evaluation system for mobile crane operation selection on modular-based heavy construction sites. J. Constr. Eng. Manag. 143, 04017060. doi:10.1061/(asce)co.1943-7862.0001360

Hardin, B., and McCool, D. BIM and construction management: Proven tools, methods, and workflows, 2nd Edition. Wiley; 2015.

Hartmann, T., Gao, J., and Fischer, M. (2008). Areas of application for 3D and 4D models on construction projects. J. Constr. Eng. Manag. 134, 776–785. doi:10.1061/(asce)0733-9364(2008)134:10(776)

Hewage, K. (2011). Sustainable construction : An information modelling approach for waste reduction.

Hosseini, M. R., Maghrebi, M., Akbarnezhad, A., Martek, I., and Arashpour, M. (2018). Analysis of citation networks in building information modeling research. J. Constr. Eng. Manag. 144, 04018064. doi:10.1061/(asce)co.1943-7862.0001492

Huang, T., Kong, C. W., Guo, H. L., Baldwin, A., and Li, H. (2007). A virtual prototyping system for simulating construction processes. Autom. Constr. 16, 576–585. doi:10.1016/j.autcon.2006.09.007

Ilozor, B., and Kelly, D. (2012). Building information modeling and integrated project delivery in the commercial construction industry: A conceptual study.

ISO (2022). ISO 19650-1:2018. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/06/80/68078.html (Accessed on April 16, 2022).

Jung, W., Ballard, G., Yong-woo, K., and Seung, H. H. (2012). Understanding of target value design for integrated project delivery with the context of game theory, 556–563.

Kent, D. C., and Becerik-Gerber, B. (2010). Understanding construction industry experience and attitudes toward integrated project delivery. J. Constr. Eng. Manag. 136, 815–825. doi:10.1061/(asce)co.1943-7862.0000188

Kim, K., and Lee, Y.-C. (2019). Automated generation of daily evacuation paths in 4D BIM. Appl. Sci. (Basel). 9, 1789. doi:10.3390/app9091789

Koutamanis, A. (2020). Dimensionality in BIM: Why BIM cannot have more than four dimensions? Autom. Constr. 114, 103153. doi:10.1016/j.autcon.2020.103153

Krippahl, M., and Grilo, A. (2012). Compatibility between design and construction building information models.

Lai, H., and Deng, X. (2018). Interoperability analysis of IFC-based data exchange between heterogeneous BIM software.

Lynn, T., Rosati, P., Egli, A., Krinidis, S., Angelakoglou, K., Sougkakis, V., et al. (2021). RINNO: Towards an open renovation platform for integrated design and delivery of deep renovation projects. Sustainability 13, 6018. doi:10.3390/su13116018

Mahalingam, A., Kashyap, R., and Mahajan, C. (2010). An evaluation of the applicability of 4D CAD on construction projects. Autom. Constr. 19, 148–159. doi:10.1016/j.autcon.2009.11.015

Matthews, J., Love, P. E. D., Mewburn, J., Stobaus, C., and Ramanayaka, C. (2018). Building information modelling in construction: Insights from collaboration and change management perspectives. Prod. Plan. Control 29, 202–216. doi:10.1080/09537287.2017.1407005

Mazars, T., and Francis, A. (2020). Chronographical spatiotemporal dynamic 4D planning. Autom. Constr. 112, 103076. doi:10.1016/j.autcon.2020.103076

McKinney, K., and Fischer, M. (1998). Generating, evaluating and visualizing construction schedules with CAD tools. Autom. Constr. 7, 433–447. doi:10.1016/S0926-5805(98)00053-3

Mesa, H. A., Molenaar, K. R., and Alarcón, L. F. (2019). Comparative analysis between integrated project delivery and lean project delivery. Int. J. Proj. Manag. 37, 395–409. doi:10.1016/j.ijproman.2019.01.012

Moon, H., Dawood, N., and Kang, L. (2014). Development of workspace conflict visualization system using 4D object of work schedule. Adv. Eng. Inf. 28, 50–65. doi:10.1016/j.aei.2013.12.001

Nechyporchuk, Y., and Bašková, R. (2020). The conformity of the tools of selected software programs for 4D building modeling. IOP Conf. Ser. Mat. Sci. Eng. 867, 012034. doi:10.1088/1757-899X/867/1/012034

Pellerin, R., and Perrier, N. (2019). A review of methods, techniques and tools for project planning and control. Int. J. Prod. Res. 57, 2160–2178. doi:10.1080/00207543.2018.1524168

Popov, V., Juocevicius, V., Migilinskas, D., Ustinovichius, L., and Mikalauskas, S. (2010). The use of a virtual building design and construction model for developing an effective project concept in 5D environment. Autom. Constr. 19, 357–367. doi:10.1016/j.autcon.2009.12.005

Sacks, R., Eastman, C., Lee, G., and Teicholz, P. BIM handbook: A guide to building information modeling for owners, designers, engineers, contractors, and facility managers, 3rd Edition | Wiley; 2018.

Sacks, R., Koskela, L., Dave, B. A., and Owen, R. (2010). Interaction of lean and building information modeling in construction. J. Constr. Eng. Manag. 136, 968–980. doi:10.1061/(asce)co.1943-7862.0000203

Said, H., and El-Rayes, K. (2014). Automated multi-objective construction logistics optimization system. Autom. Constr. 43, 110–122. doi:10.1016/j.autcon.2014.03.017

Sheikhkhoshkar, M., Pour Rahimian, F., Kaveh, M. H., Hosseini, M. R., and Edwards, D. J. (2019). Automated planning of concrete joint layouts with 4D-BIM. Autom. Constr. 107, 102943. doi:10.1016/j.autcon.2019.102943

Sloot, R. N. F., Heutink, A., and Voordijk, J. T. (2019). Assessing usefulness of 4D BIM tools in risk mitigation strategies. Autom. Constr. 106, 102881. doi:10.1016/j.autcon.2019.102881

Sriprasert, E., and Dawood, N. (2022). Next generation of construction planning and control system: The lewis approach. Available online: https://www.semanticscholar.org/paper/NEXT-GENERATION-OF-CONSTRUCTION-PLANNING-AND-SYSTEM-Sriprasert-Dawood/b34eb601bbae61605e89f563449aa3a72f6c019d (Accessed on April 20, 2022).

Staub-French, S., and Khanzode, A. (2007). 3D and 4D modeling for design and construction coordination: Issues and lessons learned. Electron. J. Inf. Technol. Constr. 12, 381–407.

Tan, Y., Fang, Y., Zhou, T., Gan, V. J. L., and Cheng, J. C. P. (2019). BIM-supported 4D acoustics simulation approach to mitigating noise impact on maintenance workers on offshore oil and gas platforms. Autom. Constr. 100, 1–10. doi:10.1016/j.autcon.2018.12.019

Tran, S., Ali, A. K., Khan, N., Lee, D., and Park, C. (2020). “A framework for camera planning in construction site using 4D BIM and VPL,” in ISARC Proc, 1404–1408.

Tran, S. V.-T., Khan, N., Lee, D., and Park, C. (2021). A hazard identification approach of integrating 4D BIM and accident case analysis of spatial–temporal exposure. Sustainability 13, 2211. doi:10.3390/su13042211

Vass, S., and Gustavsson, T. K. (2017). Challenges when implementing BIM for industry change. Constr. Manag. Econ. 35, 597–610. doi:10.1080/01446193.2017.1314519

Vico Office (2016). 4D scheduling and resource management - Vico Office. Available at: https://vicooffice.dk/en/solutions/4d-scheduling-and-resource-management/.

Won, J., and Cheng, J. C. P. (2017). Identifying potential opportunities of building information modeling for construction and demolition waste management and minimization. Autom. Constr. 79, 3–18. doi:10.1016/j.autcon.2017.02.002

Appendix A: French terminology for project actors with English equivalents.

Keywords: 4D BIM, construction scheduling, project planning, lean methodology, French BIM practice, survey, activity mapping

Citation: Doukari O, Seck B and Greenwood D (2022) The efficient generation of 4D BIM construction schedules: A case study of the Nanterre 2 CESI project in France. Front. Built Environ. 8:998309. doi: 10.3389/fbuil.2022.998309

Received: 19 July 2022; Accepted: 30 August 2022;

Published: 14 September 2022.

Edited by:

Mohammad Mayouf, Birmingham City University, United KingdomReviewed by:

Cen Ying Lee, University of Reading Malaysia, MalaysiaJinying Xu, The University of Hong Kong, Hong Kong, SAR China

Copyright © 2022 Doukari, Seck and Greenwood. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Omar Doukari, b21hci5kb3VrYXJpQG5vcnRodW1icmlhLmFjLnVr

Omar Doukari

Omar Doukari Boubacar Seck

Boubacar Seck David Greenwood1

David Greenwood1