94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Built Environ., 10 October 2022

Sec. Construction Materials

Volume 8 - 2022 | https://doi.org/10.3389/fbuil.2022.992552

This article is part of the Research TopicSustainable and Eco-friendly Building MaterialsView all 5 articles

Kennedy C. Onyelowe1

Kennedy C. Onyelowe1 Ahmed M. Ebid2*

Ahmed M. Ebid2* Ariel Riofrio3,4

Ariel Riofrio3,4 Atefeh Soleymani5

Atefeh Soleymani5 Haci Baykara3,4

Haci Baykara3,4 Denise-Penelope N. Kontoni6,7

Denise-Penelope N. Kontoni6,7 Hisham A. Mahdi8

Hisham A. Mahdi8 Hashem Jahangir9

Hashem Jahangir9In this research study, extensive literature searches on the compressive strength of concrete produced from the addition of fly ash (FA) and silica fume (SF) as extra constituents to the conventional concrete mixes, which gave rise to 330 mix points of concrete database. Due to the worrisome environmental impact of concrete production and usage in concrete activities, it has been pertinent to conduct the life cycle impact assessment of this procedure. Secondly, due to the over dependence of concrete production experts on laboratory exercise, there is also an urgent need to propose equations that reduce this dependence, that can be used in design, construction and performance evaluation of concrete infrastructure, hence the multi-objective nature of this research work. The results of the global warming potential (GWP) based on cement dosage show that Portland cement contributes about 90% of the total score. This is followed by the use of coarse aggregate contributing 6%, superplasticizer, 3% and fine aggregates, 2%. These show the functions of CO2 emissions and other greenhouses gas emissions in the entire system. Also, the result of the terrestrial acidification potential (TAP) for the concrete mixes in this study show that the lowest cement mix “C340-FAg658-FA0-SF15ˮ has a human toxicity, both carcinogenic and non-carcinogenic that showed an added impact of about 14 kg of 1, 4 equivalents of dichlorobenzene (DCB eq.). This result is 428% less impact than other studies found in the literature that used FA. Finally, it was found that the addition of FA and SF in concrete has a lowering effect on the environmental impact indicators due to reduced cement dosage. Furthermore, the results of the model predictions show that ANN with a performance index of 0.986 (4.8%) showed decisive superiority to predict the compressive strength of the FA-SF concrete over EPR, 0.951 (8.7%), GP, 0.94 (9.5%) and GEP, 0.93 (10%).

The construction activity is being increased day by day to provide shelter to population growth and also to enhance the quality of life (Soleymani and Esfahani mohammad, 2019; Jahangir and Eidgahee, 2021). As a result, there are some environmental costs involved. The construction industry is producing a considerable amount of carbon emissions and ranks third among carbon emissions contributors. The main carbon emissions contributor to the construction industry is cement. Many researchers throughout the world-wide putting efforts to reduce carbon emissions by utilizing the alternative material to the cement (Salesa et al., 2017). The amount of one ton of ordinary Portland cement (OPC) produces near about one ton of CO2, resulting in global warming, ozone depletion and climate change (Samad and Shah, 2017). Concrete’s global warming potential in terms of CO2-eq may be calculated using Equation (1) (Ma et al., 2016):

The utilization of the industrial by-products to partially replace the cement has taken place in recent years (Liew et al., 2017; Ting et al., 2021). The use of many forms of industrial waste as pozzolanic or binder material in concrete has been thoroughly researched from various aspects, including strength, corrosion resistance, durability, and permeability (Alyousef et al., 2022a; Wang et al., 2022a; Alyousef et al., 2022b; Alyousef et al., 2022c; Min et al., 2022). Ground Granulated Blast-Furnace Slag (GGBFS), Silica Fume (SF), and Fly Ash (FA) are the most commonly used industrial wastes that are being used as a partial replacement for cement.

By decreasing the requirement for cement, using supplemental cement ingredients like SF and FA has a favorable impact on energy, economical, and environmental considerations in the concrete industry (Dong et al., 2015; Hossain et al., 2016; Liu et al., 2017; de Matos et al., 2020; Kumar et al., 2021a; Alaloul et al., 2021; Çelik et al., 2022). Optimizing concrete mixes using supplementary content is another important consideration in literature (AlShareedah and Nassiri, 2021; Bhuva and Bhogayata, 2022; Wang et al., 2022b; Chen et al., 2022; Rezazadeh Eidgahee et al., 2022; Siamardi, 2022; Solouki et al., 2022; Sun et al., 2022; Warda et al., 2022). As an example, the mechanical characteristics of FA-SF plain concrete (FA-SPC) and FA SF coconut fiber reinforced concrete (FA-SCFRC) are examined in Khan and Ali’s study (Khan and Ali, 2019). In addition to the 0, 5, 10, and 15 percent FA content applied to the cement mass, the SF percentage equals 15 by cement mass. It turns out that FA-SCFRC has typically better qualities than the corresponding FA-SPC. In summary, FA-SCFRC exhibits overall optimal mechanical characteristics compared to FA-SPC due to its 10% FA content.

In parallel with the recommendation of an optimized mixture, Life-cycle assessment (LCA) is typically used as the basis for the sustainability evaluation criteria. LCA is one of the environmental management tools to assess the effects and loadings of goods and services by assessing energy and material consumption and waste discharge into the ecosystem throughout a product’s lifetime. Although it starts with an environmental perspective and often does not cover the social or economic implications, its life cycle methodology and approach are adaptable to be applied to other areas (Xing et al., 2022).

LCA evaluates a mixture’s GWP (global warming potential). The structure outlined in ISO 14,040 (ISO 14040, 2006) and ISO 14,044 (SO 14044, 2006) standards served as the foundation for this LCA analysis. Goal and scope definition, life cycle inventory (LCI) analysis, life cycle impact assessment (LCIA) computation, and outcome interpreting are the four primary elements of the iterative framework for conducting LCA study as defined by the guidelines (Xing et al., 2022).

FA is a thin grey powder made up primarily of spherical, glassy particles that is a waste product of coal-fired thermal power plants. FA contains pozzolanic properties; when it comes in contact with water, it forms cementitious material and is also called supplementary cementitious material. Partial replacement of cement by using FA material increases the concrete’s strength and improves segregation (Che Amat et al., 2020; Kumar et al., 2021b). FA offers several advantages as presented in Figure 1, including being cost-effective, environmentally friendly, and reducing carbon emissions (Sandanayake et al., 2020; Tayeh et al., 2020). In comparison to OPC, FA has low embedded energy. The characteristics of cement pastes heavily influence the behaviour of cement-based composites. Controlling the cement hydration products can therefore result in significant improvements, particularly in the strength qualities of cement pastes.

In concrete, SF is used as a pozzolanic material that is very fine in nature (Bhanja and Sengupta, 2005). The use of SF in concrete increases the durability as well as the compressive strength of the concrete (Mazloom et al., 2004; Nochaiya et al., 2010). Mazloom et al. (2004) used SF in the concrete mixes and found that the consistency of a concrete mix may be enhanced by adding the SF material. The use of SF improves the mechanical qualities of concrete and reduces shrinkage. Bhanja and Sengupta (Bhanja and Sengupta, 2005) also studied the behaviour of SF in the concrete mixes. They observed that adding SF to concrete increases its durability. Based on an investigation of the heterogeneity in LCA conclusions, Seto et al. (2017) research analyzed approaches for assigning the environmental effect of FA generation in a LCA study of concrete. LCA models of concrete with 10%, 25%, and 50% FA as cement substitute were developed. A sensitivity analysis was also carried out. The results revealed that as the proportion of FA in the concrete increases, the environmental effect decreases.

Three previous concrete mixtures—pervious concrete with regular Portland cement (PC-Regular), pervious concrete with FA (PC-FA), and pervious concrete with BFS (PC-BFS)—were examined by Chen et al. (2019) for their technical characteristics, costs, and energy and environmental effects. The energy usage and greenhouse gas (GHG) emissions of pervious concrete mixes with various material combinations were measured using the life-cycle assessment (LCA) method. According to tests performed, pervious concrete mixes, including slag or FA, exhibited equal freeze-thaw resistance to conventional pervious concrete but reduced mechanical strength, particularly in tensile or flexural strength. Compared to the sample with PC, results demonstrate a 6%–9% lower energy savings and 11%–19% lower GHG emission. The previous concrete with FA had the most remarkable overall performance when several engineering characteristics, cost savings, energy savings, and GHG decrease were balanced.

Silica fume (SF) is produced during the burning operations used in the silicon and ferrosilicon industries. The colour of SF is either excellent white or grey. It has particles 100 times smaller than those found in ordinary cement. SF is a highly effective pozzolanic material because of its silica concentration and fineness. SF is used to improve the characteristics of concrete as presented in Figure 2. It has been demonstrated that SF enhances the compressive strength, bond strength, and abrasion resistance, lowers permeability, and aids in preventing corrosion in steel bars (Khan and Siddique, 2011).

The influence of the quantity of SF and the supply of FA on the washout resistance of high-volume fly ash concrete (HVFAC) mixtures was examined by Kumar et al. (Ganesh Kumar et al., 2022). When the underwater concrete (UWC) admixtures were made utilizing FA with a higher surface area, slump and washout resistance improved by up to 19 and 11%, respectively. Increases in SF proportion were accompanied by increases in the strength and workability of the UWC. Additionally, these combinations’ wash out resistance and durability improved. This demonstrates how adding SF to the HVFAC increased the amount of free water their surfaces could absorb, stabilizing them against water conditions. The HVFAC’s stability was additionally boosted by the pozzolanic activity and the microstructure densification processes. They also claimed that employing HVFAC mixes stabilized with SF while developing UWC seems to be environmentally beneficial and that using such concretes in underwater conditions is both easy and affordable.

The study provided by Ashraf et al. (2022) examined how bentonite clay (BC) affected the strength, durability, and microstructure of concrete by working in tandem with SF. While SF was held constant at 10 percent, five distinct mixes were produced, each of which contained 0 percent, 7.5 percent, 15 percent, and 22.5 percent (by weight) of BC as a substitute for cement. According to the research observations, the inclusion of SF improved compressive strength as curing time increased. The BC and SF greatly enhanced the pore architectures and resistance to sulfate attack and chloride infiltration, according to durability tests. According to the environmental assessment research, using BC and SF can cut carbon emissions by around 23% compared to control mix. The suggested concrete combinations were considered economically, technically, and environmentally feasible for use in the building industry.

The use of FA and SF together might improve the characteristics of fresh and hardened concrete in a synergistic way, and this impact was examined by Thomas et al. (1999). They discovered that adding SF to concrete improves early-age characteristics and that adding FA to concrete improves long-term qualities. As a result, concrete properties can be improved at an early-age and gives long-term qualities with the combined effect of FA and SF. When compared to Portland cement mixtures, Nochaiya et al. (2010) found that the use of FA and SF results in a more significant water requirement. They also confirmed that adding FA and SF to concrete boosts its compressive strength at an early stage. Nezerka et al. (2019) looked at how adding SF and FA to concrete affected the interfacial transition zone (ITZ). Authors discovered that SF and FA-modified concrete had superior ITZ characteristics to reference concrete. SF is the critical substance that helps fill the voids and pozzolanic activity of the mix. According to environmental and financial research, substituting cement with the simultaneous addition of a significant amount of FA and SF results in a greater decrease of the embodied CO2 emission (Ganesh Kumar et al., 2022).

The goal of Ting et al. (2021) research was to improve silico-manganese slag concrete by adding SF and FA. The interaction of SF and FA on concrete workability, durability and compressive strength was explored by statistically assessing the experimental results. A polynomial function prediction model was created by utilizing the Response Surface Method (RSM) for the optimization of SF and FA contents. The models were statistically noteworthy and had minimal residual errors, according to an analysis of variance using a p-value at a significance level of 0.05. The fitness of all models was good, with R2 values ranging from 0.999 to 0.853. The impact of SF and FA on the drying shrinkage, compressive strength, abrasion resistance and cracking of concrete was investigated by Wang et al. (2021). The connections between concrete porosity and abrasion resistance were analyzed. The findings revealed that SF greatly enhances drying shrinkage, particularly at an early age, while combining SF and FA can reduce the probability of the final shrinkage and of early plastic shrinkage induced cracks to some extent. Furthermore, using 20 wt% FA and 5 wt% SF combined enhanced the mechanical property and abrasion resistance by roughly 4%–9% at various ages. Additionally, the concrete porosity is directly connected to the concrete compressive strength and abrasion resistance. Both SF and FA may reduce the concrete porosity and raise Ds (pore surface fractal dimensions). In terms of mechanical properties, abrasion resistance, and cracking, a combination of 20% FA and 5% SF is adequate for concretes used for wearing surfaces.

In another research, Ghalehnovi et al. (2022) tested ten mixes to investigate the effects of simultaneously using red mud (RM) and SF as cement substitutes (5 and 7.5 percent and 5 percent, respectively) on concrete properties. They claimed that increasing RM inclusion decreased mechanical characteristics but that utilizing 20% RM and 5% SF as a replacement for cement achieved the same compressive strength as the benchmark. Additionally, a simplified cost analysis was performed on all mixes, along with assessments of the environmental effects of using water and the possibility of global warming. The mix with 10% RM and 7.5% SF obtained the highest overall aggregated performance grade.

In this paper, multiple data for the compressive strength of concrete produced from the addition of fly ash (FA) and silica fume (SF) in addition to the traditional concrete constituents was collected, life cycle assessment based on global warming potential (CO2 emissions potential) of the FA-SF-based concrete was also carried out and artificial intelligent predictions of the compressive strength of the FA-SF-concrete was proposed considering four machine learning techniques.

The data collection and preparation approach adopted in this present research work was purely the literature search method where multiple data points of the compressive strength of concrete made from the addition of fly ash and silica fume. During the extensive literature search, 330 records were curated from previous results (Khan and Ali, 2019; Che Amat et al., 2020; Tayeh et al., 2020; Kumar et al., 2021b; Ashraf et al., 2022). Figure 3 shows the theoretical framework of the methodology applied in the research paper. The whole database was analyzed on the basis of the environmental impact of FA-SF addition in concrete production in terms of CO2 emissions contribution to the global warming potential and also on the basis of intelligent prediction of the compressive strength of the FA-SF-based concrete considering the concrete’s life cycle assessment evaluation.

330 records were collected for experimental tested concrete mixtures with different components’ ratios including the Fly Ash (FA) and Silica Fume (SF). Each record contains the following data: cement content (C) ton/m3, ine aggregates content (FAg) ton/m3, coarse aggregate content (CAg), ton/m3, water content (W), ton/m3, fly ash content (FA), ton/m3, silica fume content (SF), ton/m3, superplasticizer content (PL), ton/m3, relative curing age (A), (concrete age/28 days) and cylinder compressive strength of concrete (Fc), MPa.

The collected records were divided into training set (270 records-80%) and validation set (60 records-20%). Tables 1, 2 summarize their statistical characteristics and the Pearson correlation matrix. Finally, Figure 4 shows the histograms for both inputs and outputs.

The environmental assessment is based on the international norms ISO 14040 (The International Standards Organisation, 2006). It provides the evaluation of the environmental impacts of the life of the analyzed structure. The goal of this study is to analyze and compare different environmental indicators for concrete that contain fly ash or silica fume. For this purpose, a life cycle assessment (LCA) has been carried out for the concrete samples described in the 330 data points. The functional unit for LCA has been defined as 1 m3 of concrete production. The scope of this study covers the extraction of the different materials used in the different mixes such as cement, fly ash, fine aggregate, coarse aggregate silica sand, and superplasticizer (PL). The details of each mix design show the statistics of FA-SF-C proportions, the important of which is the amount of cement utilized in each mix.

Figure 5 represents the system boundary which shows each component considered in the LCA. The LCA shows the environmental burden of concrete samples based on cement or partially replaced cement with recycled/value-added components like fly ash. Moreover, it considers the use of fine and coarse aggregate, and depending on the concrete mix design, the addition of silica fume. Besides, as seen in system boundary, the use of a superplasticizer (PL) as water reducing agent was also taken into account.

The mixes for the LCA were classified based on the amount (kg) of cement, fly ash and silica fume required. If a mix has a repeating code, then, the amount of fine aggregates was included. For instance, a concrete mix with 400 kg of cement and no silica fume or fly ash has the code C400-FA0-SF0. However, there is another mix with the same mass of cement but a variation in the fine aggregate (677 kg). Thus, the code for that mix is C400-FAg677-FA0-SF0 (FA-SF-400).

The inventory accounts for the inputs of the different materials needed for the production of the concrete mix following the functional unit. The EcoInvent Database 3.2 (Wernet et al., 2016) was used to evaluate the impact of each material used for the production of 1 m3 of concrete production. Ordinary Portland cement (OPC), cement with fly ash 5%–15%, silica sand, fine aggregate, and coarse aggregate considered in a global market approach and consequential unit perspective was applied in the LCA to give a broader range of results that could be applied globally.

The LCA software requires the inclusion of a methodology that is capable of transforming input data into environmental impacts. For this study, ReCiPe Midpoint H (Huijbregts et al., 2017) was used to assess the impacts of the different concrete mixes from the 330 data points. This method allows for a global approach on the environmental impacts while maintaining a conservative but balanced approach on those impacts.

Four different Artificial Intelligent (AI) techniques were used to predict the characteristic strengths and the slump of concrete using the collected database. These techniques are genetic programming (GP), gene expression programming (GEP), artificial neural network (ANN) and polynomial regression optimized using genetic algorithm which is known as evolutionary polynomial regression (EPR). All the three developed models were used to predict the characteristic compressive strength (Fc) using cement content (C), fine aggregates content (FAg), coarse aggregates content (CAg), water content (W), Fly Ash content (FA), silica fume content (SF), super-plasticizer content (PL) and relative age (A) (concrete age/28 days). Each model on the four developed models was based on different approach (evolutionary approach for GP& GEP, mimicking biological neurons for ANN and optimized mathematical regression technique for EPR). However, for all developed models, prediction accuracy was evaluated in terms of sum of squared errors (SSE). The following section discusses the results of each model. The accuracies of developed models were evaluated by comparing the (SSE) between predicted and calculated shear strength parameters values.

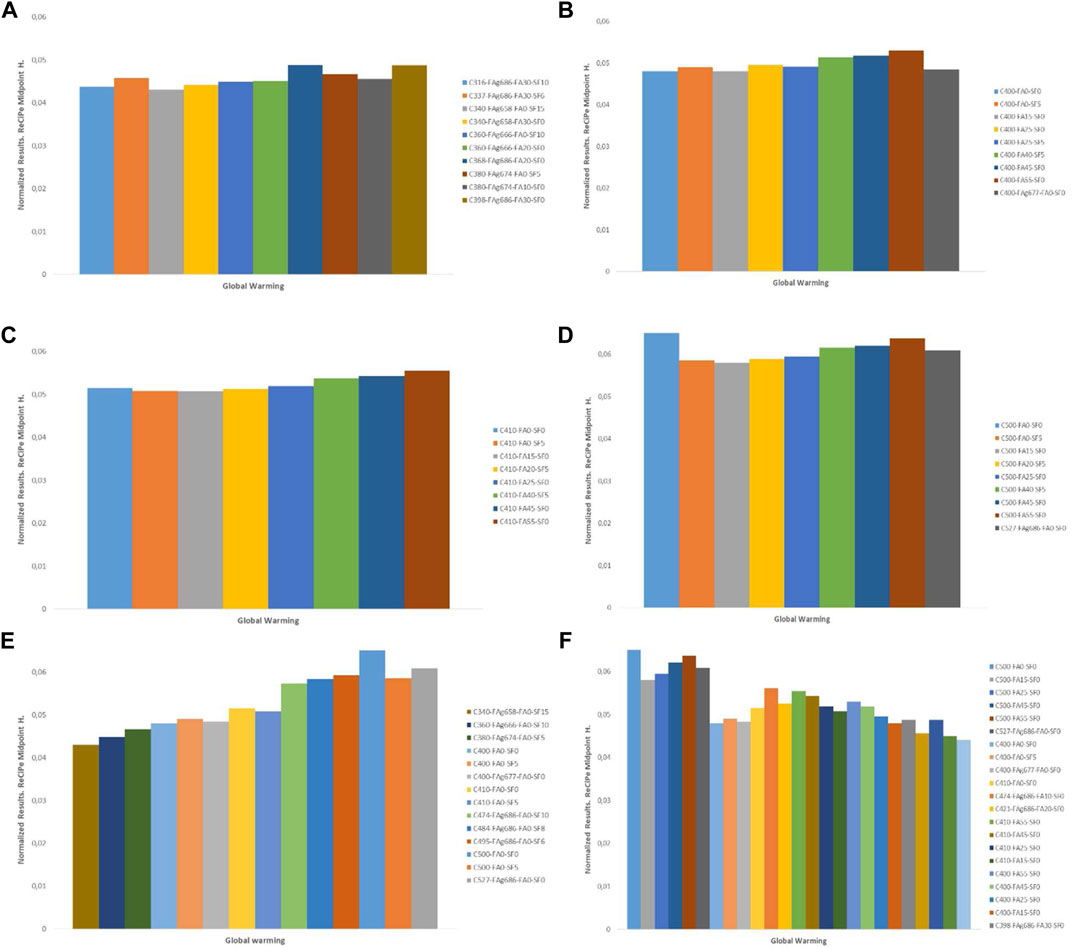

The life cycle impact assessment analyzed in first place the effect of cement on the environmental indicators. Cement is the main contributor to global warming potential in any concrete mix (Garcia-Troncoso et al., 2022). Therefore, its impact on the environment is the first step in a life cycle assessment. Figures 6A–D shows the impact score of the mixes based on the amount of cement that they contain. Results showed that lower percentages of cement have direct effect on environmental impact. Figure 6A) has the mixes with the lowest burdens which is related directly to the use of cement. The bottom part of the Figures 6E,F, the influence of fly ash and silica fume was assessed. Figure 6E) shows variations in the amount of silica fume while maintaining fly ash at zero. The same was conducted for fly ash in Figure 6F). Once again, the tendency is to be more affected by the cement than any of the two other variables because of the small amounts used when compared to OPC. However, it can be noticed that the addition of silica fume and fly ash have slight effect on the indicator because it adds impact. Fly ash contributes more to the impact than silica sand.

FIGURE 6. Global warming potential depending on the dosage of cement (A-D), silica fume (E), and fly ash (F).

The mean score for global warming potential for all the mixes was 418.15 kg of CO2 per m3 with a standard deviation of 49.80 kg of CO2 per m3. The lowest result was achieved by the mix design that uses 340 of cement, 658 kg of fine aggregates, no fly ash, and 15 kg of silica fume. In this sense, one study that assessed the inclusion of fly ash and copper tailings obtained a global warming potential that was in the range of approximately 290 kg–460 kg of CO2 (Dandautiya and Singh, 2019). Another study had results for variations of fly ash in the ranges of 413 kg–662 kg of CO2 per m3 and about 780 kg of CO2 per m3 of conventional concrete (Teixeira et al., 2016). This study has results in the ranges presented by literature. For instance, the mean score is half of the impact of conventional concrete.

The mix with the better environmental profile was analyzed in further detail. The process contribution of the mix can be seen in Figure 7. For this impact category, Portland cement contributes about 90% of the total impact score, followed by the use of coarse aggregate (6%), superplasticizer (PL) (3%), and fine aggregates (2%). Literature showed for one research that had a functional unit of 100 years of operation for the concrete mix that the inclusion of fly ash had a positive repercussion on the impact, lowering the different impact categories (Panesar et al., 2019). In the same way, for this study when fly ash was considered in the mix, impacts were reduced.

The environmental burden rises when the amount of cement is increased in the mix as aforementioned. However, in this category, the first mix which has the lower percentage of cement has also the lowest environmental impact score. This shows a stronger relation between the impact indicator and the OPC. For this category, Teixeira et al. (2016) reported values for acidification potential with a mean value of 3.3 kg of SO2 per m3 of concrete mix. Meanwhile, the lowest mix in this study has a score of 0.6 kg of SO2 per m3; this is ∼82% less impact for this category. Figure 8 shows that the increase of cement in the mixture directly increases the impact indicator. Further analysis while maintaining the cement proportion is needed to establish the correlation between the impacts of the fly ash or silica fume with this indicator.

Additionally, the lowest cement mix stated before has a human toxicity, both carcinogenic and non-carcinogenic, that have an added result of ∼14 kg of 1,4 DCB eq. This result is 428% less impact than one study found in literature that used fly ash as well (Dandautiya and Singh, 2019). In addition, literature showed that the eutrophication potential when varying fly ash showed 10 times more impact that the mixes presented for this research (Teixeira et al., 2016).

A GP model with five complexity levels was developed to predict (Fc) values. The population size, survivor size and number of generations were 100,000, 30,000 and 100 respectively. Eq. 1 presented the output formula for (Fc). Both average error % of total dataset and (R2) value are 9.5% and 0.941% respectively. The closed-form equations are used in consideration of the environmental impact of the Portland cement dosage in concrete to predict both manually and intelligently the compressive strength of concrete based healthy considerations at reduced CO2 emissions which will conform to previous results (Teixeira et al., 2016; Dandautiya and Singh, 2019; Panesar et al., 2019).

The developed GEP model has 50 lines of code. The population size, survivor size and number of generations were 10,000, 3,000, and 1,000 respectively. Eq. 2 presented the output formula for Fc. The average error % of total dataset is 10.0% while the R2 value is 0.935.

The developed EPR model was limited to cubic level, for 8 inputs; there are 165 possible terms (120 + 36+8 + 1 = 165) as follows:

GA technique was applied on these 165 terms to select the most effective 10 terms to predict the values of (Fc). The outputs are illustrated in Eq. 3. The average error in % is 8.7% and R2 value is 0.951) for the total datasets.

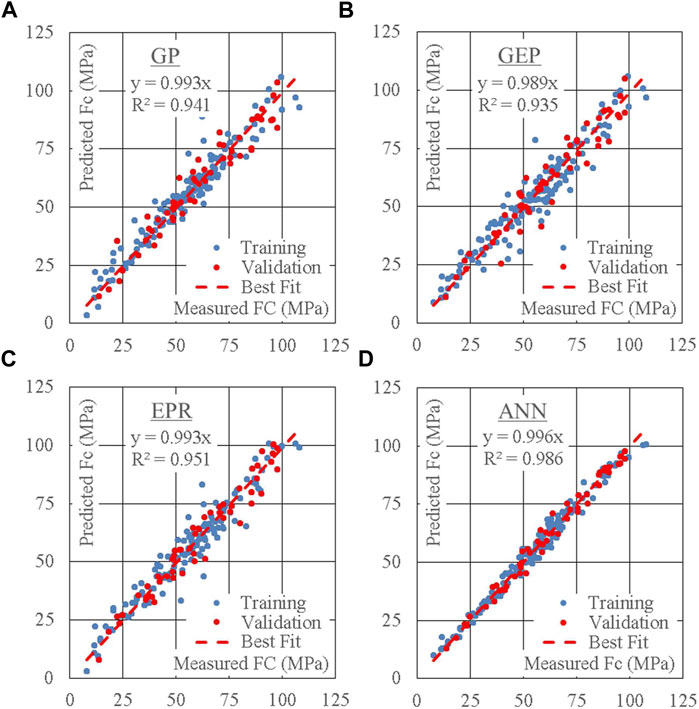

The developed model layout is (8:5:1), normalization method (-1.0 to 1.0), activation function (Hyper Tan) and “Back Propagation (BP)” traditional algorithm. The developed model was used to predict (Fc). The used network layout is illustrated in Figure 9 while its weight matrix is showed in Table 3. The average errors % of total dataset is 4.8% and the R2 value is 0.986. The relative importance values for each input parameter are illustrated in Figure 10, which showed that water, fine aggregates, fly ash contents and relative age are the most important inputs. Coarse aggregates, silica fume, and cement contents came in second place and lastly the super-plasticizer content. The relations between calculated and predicted values for the models are shown in Figure 11. Figures 12–14 shows the Taylor diagram, variances and the relative error (%) between predicted and measured/average values for the model exercise. As presented in Figure 12, the correlation coefficient, root mean squared error and standard deviation of the studied parameters of the models are graphically shown. The summation of the absolute weights of each neuron in the input layer of the developed (ANN) model indicated that water, fine aggregates, fly ash content sand relative age are the most important inputs which presents about 63% of the total influence with almost equal shares. Coarse aggregates, silica fume, and cement contents came in second place with about 30% of the influence with almost equal shares. Lastly the super-plasticizer content presented the rest 7% of the influence. Table 4 summarized the accuracies of the four developed predictive models.

FIGURE 11. Relation between predicted and calculated (Fc) values using the developed models. (A) using GP, (B) using GEP, (C) using EPR and (D) using ANN.

This research presents four models using three (AI) techniques (GP, GEP, EPR and ANN) to predict the cylinder compressive strength (Fc) in MPa considering the relative age (A) (concrete age/28 days) besides cement content (C), fine aggregate content (FAg), coarse aggregate content (CAg), water content (W), fly ash content (FA), silica fume content (SF) and super-plasticizer content (PL) as inputs. First, an environmental impact of the fly ash-silica fume was conducted by evaluating the life cycle impact assessment (LCIA) of all the collected mix points. It was found that the addition of fly ash and silica sand (fume) has a lowering effect on the impact indicators analyzed because the main contributor in the environmental profile of the mixes is ordinary Portland cement (OPC). The tendency of the impacts rises while increasing the proportion of cement. The environmental effect of fly ash and silica fume in the mixes have less negative impact when compared to OPC for the quantities replaced in this study. Generally, the use of FA-SF in concrete production is achieved by proportional replacement of cement, which indicates the reduction of cement proportion. Having established through research that cement usage is the primary contributor to the environmental impact of concrete production, it follows that its replacement by FA-SF credits the admixture for its role in the reduction of the effect of cement usage impact. The impact on water index, water is heavily consumed by concrete during its production and it takes energy to either transport water or pump it for usage during the production of concrete and this is where it is applied as impacting on the environment.

Furthermore, from the following artificial intelligence predictive models for the Fc, it can be concluded as follows:

- (GP), (GEP) and (EPR) models shared almost the same level of accuracy (90.5%, 90.0% and 91.3%) respectively. They all generated closed form equations with almost the same level of complexity. Hence, these modes are equivalent and could be applied manually.

- The (ANN) model presented a slightly higher levels of accuracy (95.2%), complexity, and lower scattering than (GP), (GRP) and (EPR). Although, it has a better accuracy, but the generated model can’t be applied manually.

- Taylor chart showed that the correlation coefficients exceeded 99% for (ANN) models, 95% for (GP), (GEP) and (EPR) models.

- For all developed models, the characteristic compressive strength after 28 days could be computed by substituting (A = 1.0).

- None of the developed models used the all eight inputs except the (ANN). (GP) used six inputs and neglected (W, PL). (GEP) also used six inputs and neglected (CAg, W). Finally, the (EPR) model used only four inputs and neglected (CAg, PL, FA, SF). These results give the advantage to the (GP) model because it is the model that used the all admixture components (where water and super-plasticizer contents could be roughly estimated assuming the total volume = 1.0 m3 and total weight = 2,350 kg–2,400 kg for normal weight aggregates).

- GA technique successfully reduced the 165 terms of conventional polynomial regression quadrilateral formula to only 10 terms without significant impact on its accuracy.

- Like any other regression technique, the generated formulas are valid within the considered range of parameter values, beyond this range; the prediction accuracy should be verified.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

KO: Conception AE: AI modeling AR: literature review AS: Statistical analysis HB: Editing DK: visualization HM: Supervision HJ: Software.

We would like to thank Pré Consultants B.V. for providing the SimaPro software license for academic and research use.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Alaloul, W. S., Musarat, M. A., Haruna, S., Law, K., Tayeh, B. A., Rafiq, W., et al. (2021). Mechanical properties of silica fume modified high-volume fly ash rubberized self-compacting concrete. Sustainability 13, 5571. doi:10.3390/su13105571

AlShareedah, O., and Nassiri, S. (2021). Pervious concrete mixture optimization, physical, and mechanical properties and pavement design: A review. J. Clean. Prod. 288, 125095. doi:10.1016/j.jclepro.2020.125095

Alyousef, R., Mohammadhosseini, H., Ebid, A. A. K., and Alabduljabbar, H. (2022). An integrated approach to using sheep wool as a fibrous material for enhancing strength and transport properties of concrete composites. Materials 15, 1638. doi:10.3390/ma15051638

Alyousef, R., Mohammadhosseini, H., Ebid, A. A. K., Alabduljabbar, H., Poi Ngian, S., Huseien, G. F., et al. (2022). Enhanced acoustic properties of a novel prepacked aggregates concrete reinforced with waste polypropylene fibers. Materials 15 (3), 1173. doi:10.3390/ma15031173

Alyousef, R., Mohammadhosseini, H., Ebid, A. A. K., Alabduljabbar, H., Ngian, S. P., and Mohamed, A. M. (2022). Durability enhancement of sustainable concrete composites comprising waste metalized film food packaging fibers and palm oil fuel ash. Sustainability 14, 5253. doi:10.3390/su14095253

Ashraf, M., Iqbal, M. F., Rauf, M., Ashraf, M. U., Ulhaq, A., Muhammad, H., et al. (2022). Developing a sustainable concrete incorporating bentonite clay and silica fume: Mechanical and durability performance. J. Clean. Prod. 337, 130315. doi:10.1016/j.jclepro.2021.130315

Bhanja, S., and Sengupta, B. (2005). Influence of silica fume on the tensile strength of concrete. Cem. Concr. Res. 35, 743–747. doi:10.1016/j.cemconres.2004.05.024

Bhuva, P., and Bhogayata, A. (2022). A review on the application of artificial intelligence in the mix design optimization and development of self-compacting concrete. Mater. Today Proc. 65, 603–608. doi:10.1016/j.matpr.2022.03.194

Çelik, Z., Bingöl, A. F., and Ağsu, A. S. (2022). Fresh, mechanical, sorptivity and rapid chloride permeability properties of self-compacting concrete with silica fume and fly ash. Iran. J. Sci. Technol. Trans. Civ. Eng. 46, 789–799. doi:10.1007/s40996-021-00676-x

Che Amat, R., Ismail, K. N., Ahmad, K. R., and Ibrahim, N. M. (2020). Effects of metakoalin on municipal solid waste incineration (MSWI) bottom ash-cement composite. Mater Sci. Forum 1010, 653–658. doi:10.4028/www.scientific.net/msf.1010.653

Chen, H., Deng, T., Du, T., Chen, B., Skibniewski, M. J., and Zhang, L. (2022). An RF and LSSVM–NSGA-II method for the multi-objective optimization of high-performance concrete durability. Cem. Concr. Compos. 129, 104446. doi:10.1016/j.cemconcomp.2022.104446

Chen, X., Wang, H., Najm, H., Venkiteela, G., and Hencken, J. (2019). Evaluating engineering properties and environmental impact of pervious concrete with fly ash and slag. J. Clean. Prod. 237, 117714. doi:10.1016/j.jclepro.2019.117714

Dandautiya, R., and Singh, A. P. (2019). Utilization potential of fly ash and copper tailings in concrete as partial replacement of cement along with life cycle assessment. Waste Manag. 99, 90–101. doi:10.1016/j.wasman.2019.08.036

de Matos, P. R., Oliveira, J. C. P., Medina, T. M., Magalhães, D. C., Gleize, P. J. P., Schankoski, R. A., et al. (2020). Use of air-cooled blast furnace slag as supplementary cementitious material for self-compacting concrete production. Constr. Build. Mat. 262, 120102. doi:10.1016/j.conbuildmat.2020.120102

Dong, B., Qiu, Q., Xiang, J., Huang, C., Sun, H., Xing, F., et al. (2015). Electrochemical impedance interpretation of the carbonation behavior for fly ash–slag–cement materials. Constr. Build. Mat. 93, 933–942. doi:10.1016/j.conbuildmat.2015.05.066

Ganesh Kumar, B., Muthu, M., Chajec, A., Sadowski, Ł., and Govindaraj, V. (2022). The effect of silica fume on the washout resistance of environmentally friendly underwater concrete with a high-volume of siliceous fly ash. Constr. Build. Mat. 327, 127058. doi:10.1016/j.conbuildmat.2022.127058

Garcia-Troncoso, N., Baykara, H., Cornejo, M. H., Riofrio, A., Tinoco-Hidalgo, M., and Flores-Rada, J. (2022). Comparative mechanical properties of conventional concrete mixture and concrete incorporating mining tailings sands. Case Stud. Constr. Mater. 16, e01031. doi:10.1016/J.CSCM.2022.E01031

Ghalehnovi, M., Roshan, N., Taghizadeh, A., Asadi Shamsabadi, E., Ali Hadigheh, S., and de Brito, J. (2022). Production of environmentally friendly concrete incorporating bauxite residue and silica fume. J. Mat. Civ. Eng. 34. doi:10.1061/(ASCE)MT.1943-5533.0004060

Hossain, M. M., Karim, M. R., Hasan, M., Hossain, M. K., and Zain, M. F. M. (2016). Durability of mortar and concrete made up of pozzolans as a partial replacement of cement: A review. Constr. Build. Mat. 116, 128–140. doi:10.1016/j.conbuildmat.2016.04.147

Huijbregts, M. A. J., Steinmann, Z. J. N., Elshout, P. M. F., Stam, G., Verones, F., Vieira, M., et al. (2017). ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 22, 138–147. doi:10.1007/s11367-016-1246-y

ISO 14040 (2006). Environmental management: Life cycle assessment; principles and framework. Int. Organ Stand.

Jahangir, H., and Eidgahee, D. R. (2021). A new and robust hybrid artificial bee colony algorithm–ANN model for FRP-concrete bond strength evaluation. Compos. Struct. 257, 113160. doi:10.1016/j.compstruct.2020.113160

Khan, M., and Ali, M. (2019). Improvement in concrete behavior with fly ash, silica-fume and coconut fibres. Constr. Build. Mat. 203, 174–187. doi:10.1016/j.conbuildmat.2019.01.103

Khan, M. I., and Siddique, R. (2011). Utilization of silica fume in concrete: Review of durability properties. Resour. Conserv. Recycl. 57, 30–35. doi:10.1016/j.resconrec.2011.09.016

Kumar, K. R., Shyamala, G., Awoyera, P. O., Vedhasakthi, K., and Olalusi, O. B. (2021). Cleaner production of self-compacting concrete with selected industrial rejects-an overview. Silicon 13, 2809–2820. doi:10.1007/s12633-020-00636-6

Kumar, M., Sinha, A. K., and Kujur, J. (2021). Mechanical and durability studies on high-volume fly-ash concrete. Struct. Concr., 22. doi:10.1002/suco.202000020

Liew, K. M., Sojobi, A. O., and Zhang, L. W. (2017). Green concrete: Prospects and challenges. Constr. Build. Mat. 156, 1063–1095. doi:10.1016/j.conbuildmat.2017.09.008

Liu, J., Wang, X., Qiu, Q., Ou, G., and Xing, F. (2017). Understanding the effect of curing age on the chloride resistance of fly ash blended concrete by rapid chloride migration test. Mat. Chem. Phys. 196, 315–323. doi:10.1016/j.matchemphys.2017.05.011

Ma, F., Sha, A., Yang, P., and Huang, Y. (2016). The greenhouse gas emission from Portland cement concrete pavement construction in China. Int. J. Environ. Res. Public Health 13, 632. doi:10.3390/ijerph13070632

Mazloom, M., Ramezanianpour, A. A., and Brooks, J. J. (2004). Effect of silica fume on mechanical properties of high-strength concrete. Cem. Concr. Compos. 26, 347–357. doi:10.1016/S0958-9465(03)00017-9

Min, J., Zandi, Y., Agdas, A. S., Majdi, A., Ali, H. E., JanSalameh, A. A. A., et al. (2022). The numerical analysis of replenishment of hydrogel void space concrete using hydrogels containing nano-silica particles through ELM-ANFIS. Gels 8, 299. doi:10.3390/gels8050299

Nežerka, V., Bílý, P., Hrbek, V., and Fládr, J. (2019). Impact of silica fume, fly ash, and metakaolin on the thickness and strength of the ITZ in concrete. Cem. Concr. Compos. 103, 252–262. doi:10.1016/j.cemconcomp.2019.05.012

Nochaiya, T., Wongkeo, W., and Chaipanich, A. (2010). Utilization of fly ash with silica fume and properties of Portland cement–fly ash–silica fume concrete. Fuel 89, 768–774. doi:10.1016/j.fuel.2009.10.003

Panesar, D. K., Kanraj, D., and Abualrous, Y. (2019). Effect of transportation of fly ash: Life cycle assessment and life cycle cost analysis of concrete. Cem. Concr. Compos. 99, 214–224. doi:10.1016/j.cemconcomp.2019.03.019

Rezazadeh Eidgahee, D., Jahangir, H., Solatifar, N., Fakharian, P., and Rezaeemanesh, M. (2022). Data-driven estimation models of asphalt mixtures dynamic modulus using ANN, GP and combinatorial GMDH approaches. Neural comput. Appl. doi:10.1007/s00521-022-07382-3

Salesa, Á., Pérez-Benedicto, J. Á, Esteban, L. M., Vicente-Vas, R., and Orna-Carmona, M. (2017). Physico-mechanical properties of multi-recycled self-compacting concrete prepared with precast concrete rejects. Constr. Build. Mat. 153, 364–373. doi:10.1016/j.conbuildmat.2017.07.087

Samad, S., and Shah, A. (2017). Role of binary cement including supplementary cementitious material (scm), in production of environmentally sustainable concrete: A critical review. Int. J. Sustain. Built Environ. 6, 663–674. doi:10.1016/j.ijsbe.2017.07.003

Sandanayake, M., Gunasekara, C., Law, D., Zhang, G., Setunge, S., and Wanijuru, D. (2020). Sustainable criterion selection framework for green building materials – an optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 25, e00178. doi:10.1016/j.susmat.2020.e00178

Seto, K. E., Churchill, C. J., and Panesar, D. K. (2017). Influence of fly ash allocation approaches on the life cycle assessment of cement-based materials. J. Clean. Prod. 157, 65–75. doi:10.1016/j.jclepro.2017.04.093

Siamardi, K. (2022). Optimization of fresh and hardened properties of structural light weight self-compacting concrete mix design using response surface methodology. Constr. Build. Mat. 317, 125928. doi:10.1016/j.conbuildmat.2021.125928

SO 14044 (2006). Environmental management: Life cycle assessment; principles and framework. Int. Organ Stand.

Soleymani, A., and Esfahani mohammad, R. (2019). Effect of concrete strength and thickness of flat slab on preventing of progressive collapse caused by elimination of an internal column. J. Struct. Constr. Eng. 6, 24–40. doi:10.22065/jsce.2017.98444.1335

Solouki, A., Tataranni, P., and Sangiorgi, C. (2022). Mixture optimization of concrete paving blocks containing waste silt. Sustainability 14, 451. doi:10.3390/su14010451

Sun, Z., Yang, S., Hang, M., Wang, J., and Yang, T. (2022). Optimization design of ultrahigh-performance concrete based on interaction analysis of multiple factors. Case Stud. Constr. Mater. 16, e00858. doi:10.1016/j.cscm.2021.e00858

Tayeh, B. A., Ibrahim, O., and Mohamed, O. (2020). Combined effect of lightweight fine aggregate and micro rubber ash on the properties of cement mortar. Adv. Concr. Constr. 10.

Teixeira, E. R., Mateus, R., Camões, A. F., Bragança, L., and Branco, F. G. (2016). Comparative environmental life-cycle analysis of concretes using biomass and coal fly ashes as partial cement replacement material. J. Clean. Prod. 112, 2221–2230. doi:10.1016/j.jclepro.2015.09.124

The International Standards Organisation (2006). Environmental management — life cycle assessment — principles and framework, 1–47. (Standard No. 14040).

Thomas, M. D. A., Shehata, M. H., Shashiprakash, S. G., Hopkins, D. S., and Cail, K. (1999). Use of ternary cementitious systems containing silica fume and fly ash in concrete. Cem. Concr. Res. 29, 1207–1214. doi:10.1016/S0008-8846(99)00096-4

Ting, M. Z. Y., Wong, K. S., Rahman, M. E., and Selowarajoo, M. (2021). Prediction model for hardened state properties of silica fume and fly ash based seawater concrete incorporating silicomanganese slag. J. Build. Eng. 41, 102356. doi:10.1016/j.jobe.2021.102356

Wang, A., Huang, M., Chu, Y., Zhu, Y., Liu, K., Guo, L., et al. (2022). Optimization of mix proportion of basic magnesium sulfate cement-based high-strength coral concrete. Constr. Build. Mat. 341, 127709. doi:10.1016/j.conbuildmat.2022.127709

Wang, H., Habibi, M., Marzouki, R., Majdi, A., Shariati, M., Denic, N., et al. (2022). Improving the self-healing of cementitious materials with a hydrogel system. Gels 8, 278. doi:10.3390/gels8050278

Wang, L., Jin, M., Guo, F., Wang, Y., and Tang, S. (2021). Pore structural and fractal analysis of the influence of fly ash and silica fume on the mechanical property and abrasion resistance of concrete. Fractals 29, 2140003. doi:10.1142/S0218348X2140003X

Warda, M. A., Ahmad, S. S. E., Mahdi, I. M., Sallam, H. E-D. M., and Khalil, H. S. (2022). The applicability of TOPSIS- and fuzzy TOPSIS-based taguchi optimization approaches in obtaining optimal fiber-reinforced concrete mix proportions. Buildings 12, 796. doi:10.3390/buildings12060796

Wernet, G., Bauer, C., Steubing, B., Reinhard, J., Moreno-Ruiz, E., and Weidema, B. (2016). The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 21, 1218–1230. doi:10.1007/s11367-016-1087-8

Keywords: silica fume, fly ash, environmental impact, life cycle assessment, sustainable concrete, CO2 emission, global warming potential

Citation: Onyelowe KC, Ebid AM, Riofrio A, Soleymani A, Baykara H, Kontoni D-PN, Mahdi HA and Jahangir H (2022) Global warming potential-based life cycle assessment and optimization of the compressive strength of fly ash-silica fume concrete; environmental impact consideration. Front. Built Environ. 8:992552. doi: 10.3389/fbuil.2022.992552

Received: 12 July 2022; Accepted: 20 September 2022;

Published: 10 October 2022.

Edited by:

Hosam Saleh, Egyptian Atomic Energy Authority, EgyptReviewed by:

Ramakanta Panigrahi, Veer Surendra Sai University of Technology, IndiaCopyright © 2022 Onyelowe, Ebid, Riofrio, Soleymani, Baykara, Kontoni, Mahdi and Jahangir. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ahmed M. Ebid, YWhtZWQuYWJkZWxraGFsZXFAZnVlLmVkdS5lZw==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.