- 1Department of Civil and Environmental Engineering, Faculty of Science and Technology, Tokushima University, Tokushima, Japan

- 2New Business Planning Department Business Creation Division, Sumitomo Mitsui Construction CO., LTD., Tokyo, Japan

In Japan, much infrastructure has been constructed over the past 50 years, and maintenance of such infrastructure is important. Repairing and retrofitting of deteriorated concrete members has become a common place. Meanwhile, re-deterioration of repaired concrete members has become of concern. To prevent re-deterioration of the repaired concrete members, it is important to evaluate the quality and condition of repair, in addition to the use of NDE. Therefore, to evaluate the condition of replacing repaired concrete specimens, an ultrasonic test, impact-echo test, and impact test for measuring mechanical impedance were applied. In addition, data of these NDT are integrated by the Mahalanobis–Taguchi system (MT system). The MT system is an information processing system for pattern recognition advocated by quality engineering. From the results, it is clarified that the Mahalanobis distance calculated by the MT method could successfully evaluate the conditions of replacing repaired specimens.

1 Introduction

At the present time, maintenance of many concrete structures is an important social issue in developed countries. In Japan, the maintenance of concrete structures proceeds and the number of structures being repaired or reinforced has been increasing. European concrete repair standard EN 1504 is entitled, and ACI562-16 is corded (BS EN 1504 -1, 1504); (ACI CODE-562-16). In the Laboratory, the pull-off test for evaluation of adhesion of repair material is widely used (EN 1542, 1542).

On the other hand, non-destructive test methods for evaluating the performance repair have not yet been established for the onsite tests, visual inspection and confirmation being the main method. In order to address these issues, TC 269-IAM: Damage Assessment in Consideration of Repair/Retrofit-Recovery in Concrete and Masonry Structures by Means of Innovative NDT has been established in RILEM (RILEM TC 269-IAM, 2016), and studies on the effective use of non-destructive tests are presently underway. The NDT methods for the assessment of concrete structures and masonry structures were reviewed (McCann and Forde, 2001); (Rehman et al., 2016), and the strategic use of NDT was presented (Alani et al., 2014). Elastic wave methods were applied to evaluate bond condition of repair (Lin and Sansalone, 1996); (Lin et al., 1996); (Santos et al., 2010); (Garbacz, 2015); (Garbacz et al., 2017) and repair evaluation of cracks (Aggelis and Shiotani, 2007); (Zoidis et al., 2013).

As there are various techniques required for repair, it is important to evaluate these using the results of multiple non-destructive tests to evaluate the quality repair. Therefore, in this study, we focused on the MT system, which is one of the pattern recognition methods. This MT system was a method proposed by Dr. Genichi Taguchi, and the basic theory was shown by Taguchi and Jugulum (Taguchi and Jugulum, 2000). It has been shown that this method provides a high accuracy of discrimination with small amounts of data (Hong et al., 2007). In the civil engineering field, it has been reported to be applicable for the judgment of reinforcing bar corrosion (Fukuyama et al., 2012), evaluation of road quality (Wang et al., 2018), evaluation of performance deterioration of concrete beams (Habib et al., 2020), and robustness monitoring for bridges (Kim et al., 2013).

In this study, the authors decided to evaluate the quality of the replaced repair method and to conduct experiments carried out on specimens. Integrity, surface denseness, and strength of repaired specimens were estimated by the impact-echo method, ultrasonic method, and mechanical impedance method, respectively. Then, using the MT method, which is one of the basic methods of the MT system, the repair effect was evaluated by the Mahalanobis distance, which is a scale that integrates multiple items. The practicality of applying the MT method to the evaluation of repair effects was investigated.

2 Experimental specimens

2.1 Specimens

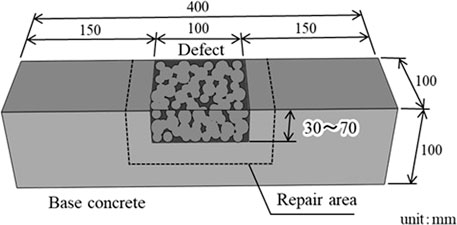

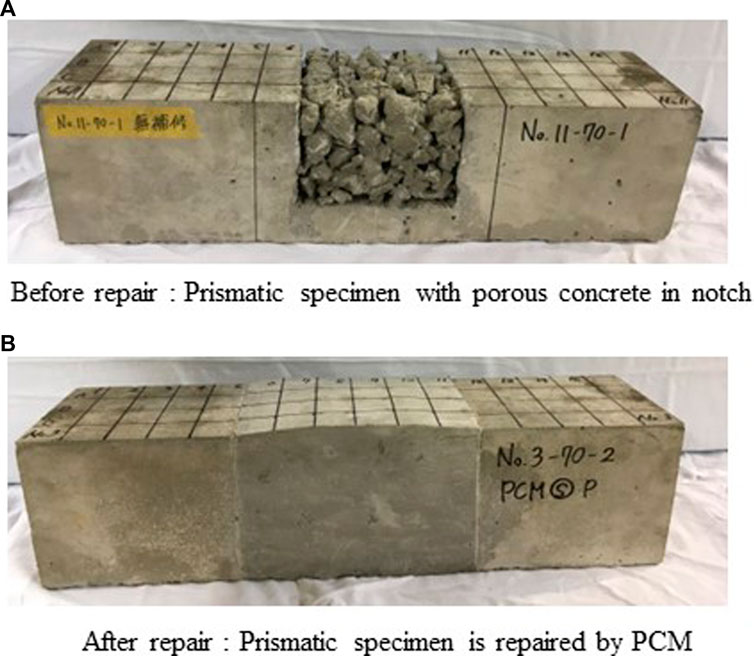

Eleven types of prismatic specimens measuring 100 mm × 100 mm × 400 mm were used. A notch with a width of 100 mm, a length of 100 mm, and a depth of 30–70 mm was made in the center of the test piece. Porous concrete was driven into the notch to simulate defects due to construction defects. The porous concrete was made after 3 days of aging of the base prismatic concrete. Figure 1 shows the procedure of making specimens. Figure 2 shows a specimen, and Table 1 shows the type of specimen and defect characteristics. Figure 3 shows the photos of specimens.

FIGURE 3. Photos of one of the prismatic specimens with the porous concert in notch and after repair by PCM.

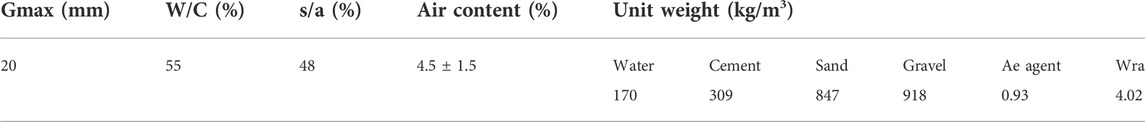

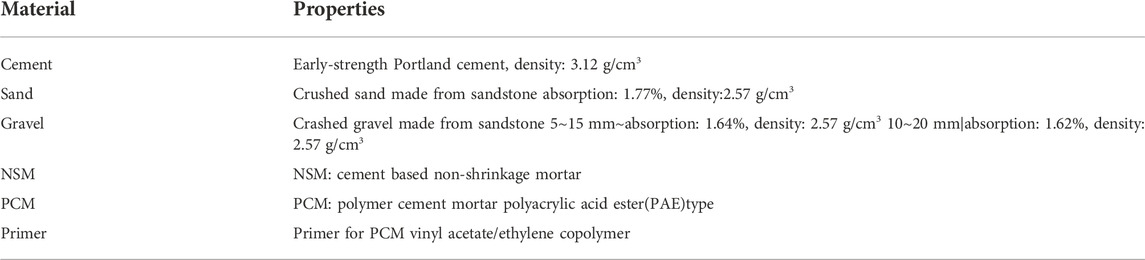

The base concrete and porous concrete with defects were made using the same mix-proportion concrete. The porous concrete was prepared by wet screening the base concrete. To clarify the difference in response from the intact concrete part, design porosity of the porous concrete was set to be about 20%. The curing method of the test piece was water cured at 20°C, and the base concrete was cured up to an age of 14 days, and then air-cured in a room at 20°C was performed. The mix proportion of the concrete is shown in Table 2, and physical properties of materials used are shown in Table 3.

2.2 Repair method for specimens

For repair of the defective part, the plastering and replacing repair method was adopted. As the cross-section restoration material, cements of non-shrink mortar (NSM) and polymer cement mortar (PCM) were used. Non-shrinking mortar contains expansion agents and water-reducing agents and does not shrink when cured. Polymer cement mortar is a mortar made by mixing cement, fine aggregate with polymer dispersion, or re-emulsified powdered resin.

Specifications of materials are shown in Table 3. When repairing using PCM, the case of primer treatment and the case of pre-wetting were examined.

The three repair methods are as follows: the case where only the surface is repaired without removing the defective part, the case where the defective part is scraped off and the inside and the surface are repaired, and the case where there is no repair. Surface repair was performed 25 mm wider than the defective part. After repair, the test piece was cured by moist sealing.

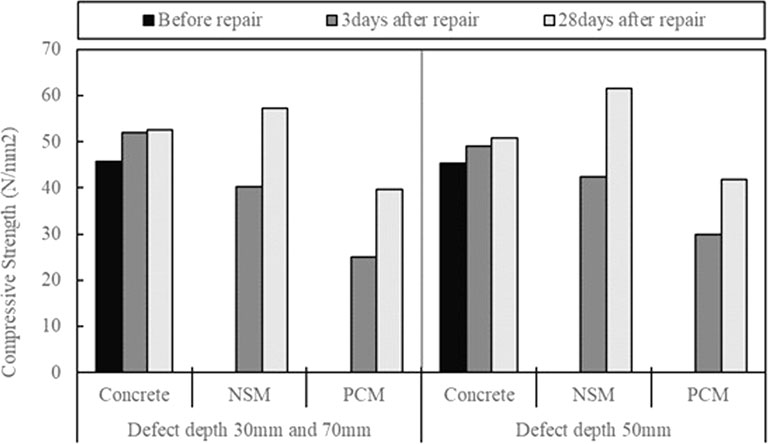

2.3 Compressive strength test and bending test

2.3.1 Compressive test for the base concrete

The compressive strength test was carried out in accordance with JIS A 1108 using a cylindrical test piece of φ100 mm × 200 mm. The test piece was prepared when the base concrete was placed, and the curing method was the same as that of the prismatic specimen. The compression test was carried out three times using specimens from the same concrete mixture. The first test was carried out before repair. The second and third were carried out on the 3rd and 28th day after repair materials had been prepared and cured.

2.3.2 Compressive test for repair materials

The compressive strength test was carried out in accordance with JIS A 1171 using a prismatic test piece of 40 × 40 × 160 mm. The test piece was prepared at the time of repairing the partially defective test piece. The curing method is sealing curing in a wet state. The strength test was carried out on the 3rd and 28th day after repair materials have been prepared and cured.

3 Non-destructive test for the evaluation of repair effects

3.1 Impact-echo method

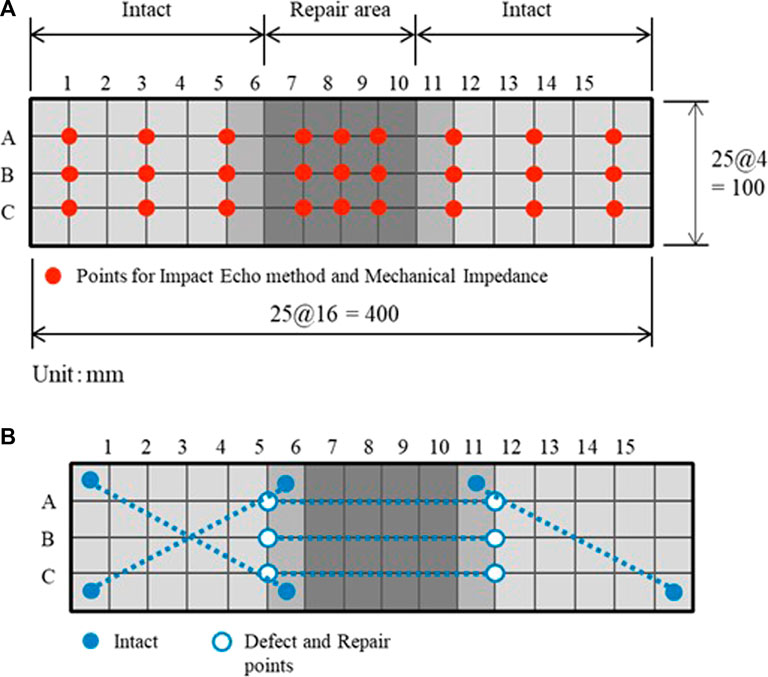

The impact-echo method was conducted by the multiple reflection method to evaluate the filling of inside of the specimen. Impact points were the intersections of the meshes at 25 mm intervals as shown in Figure 4A, and nine points each for the left and right intact parts and the defective and repaired parts. A steel ball with a diameter of 8 mm was used for excitation of the elastic waves. A small accelerometer (measurement frequency range: 4 Hz–20 kHz) was used to acquire the response signal generated by the impact. The sampling time in the measurement was 20 μ seconds, the number of samplings was 4,096, and the time history response by five hits was recorded on a personal computer. The recorded time history response waveform was FFT transformed, and the frequency spectrum was acquired. The elastic wave velocity was calculated from

Here, Vp is the elastic wave velocity (m/s), f0 is the dominant frequency (Hz), and L is the specimen height (m).

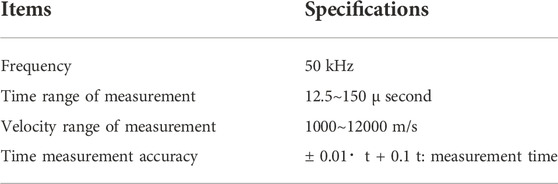

3.2 Ultrasonic test method

In order to evaluate integrity of the repaired surface, ultrasonic velocity was measured using a handheld ultrasonic measuring instrument. This device does not require a contact medium for bringing the transmitter/receiver into a close contact during measurement and does not require an external power supply. Therefore, ultrasonic velocity can be easily measured.

Table 4 shows specifications of the measuring equipment. The distance between the transmission and receiving probes was 150 mm, and the measured ultrasonic waves were longitudinal waves propagation. Ultrasonic velocity measurement lines are as shown in Figure 4B. The intact part, defective part, and repaired part were tested. A measurement was performed with each of the three survey lines in consideration of the variation in ultrasonic velocity due to the surface texture of the test piece, and the average value of the three survey lines was used as the measured value.

3.3 Mechanical impedance method

The mechanical impedance method is a test method in which a hammer with an attached accelerometer hits a concrete surface and measures mechanical impedance from the obtained hitting waveform. Measurement of mechanical impedance is standardized by the Japanese Society for Non-destructive Inspection as NDIS 3434–3 (Standard of the Japanese Society for Non-destructive Inspection NDIS 3434-3, 2017). Mechanical impedance is an index showing the elastic properties of concrete. In this study, a commercially available measuring instrument was used to estimate the strength and integrity by the instrument. This device has a calibration formula obtained from the relationship between mechanical impedance and compressive strength of concrete and can estimate the compressive strength of concrete. Strength index value (STR value) and surface deterioration index (INDX value) were calculated using the striking force waveform. The STR value is the compressive strength (N/mm2) estimated from the index of the spring constant per unit area of the concrete surface. The INDX value is a value that represents the ratio of initial velocity when the hammer make contact with the concrete and the initial velocity when it is repelled. If it is a completely elastic body, the INDEX value becomes one, and if the surface is deteriorated, the INDX value will be large. The hammering point was the same as the multiple reflection method of the impact elastic wave method. The test was conducted once for each point. Measured values were the average values of nine points for each of the left and right healthy parts and nine points for the defective and repaired parts.

3.4 Moisture content measurement method for concrete

The moisture content of concrete affects elastic waves propagating in concrete. Therefore, the surface moisture content was measured using a high-frequency capacitance type concrete/mortar moisture meter. The measurement was carried out in the intact part and the repaired part in consideration of the difference in materials used, and the average value of the two measurements was taken as the measured value.

4 Results and discussion

4.1 Results of compressive strength

The compression test results of each material are shown in Figure 5. It was confirmed that the strength tends to increase with age.

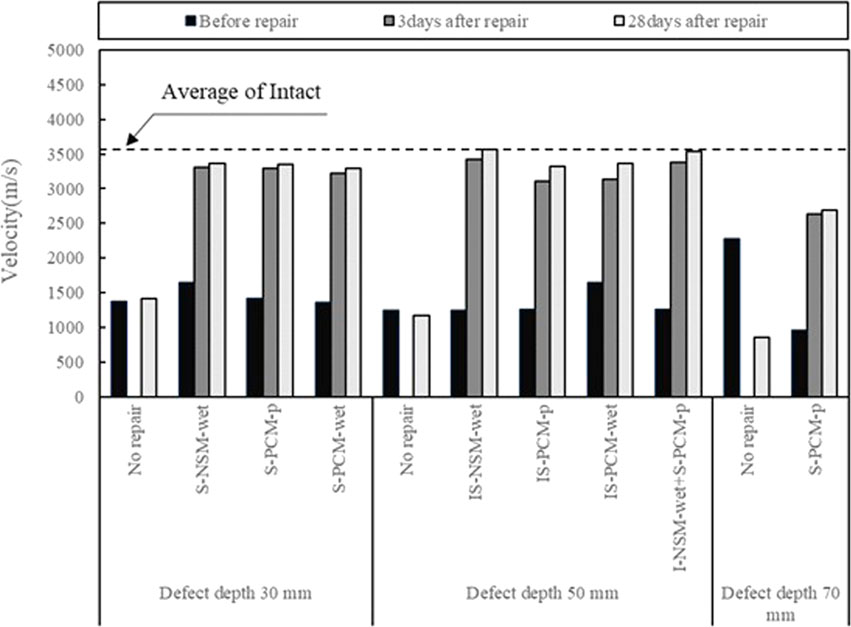

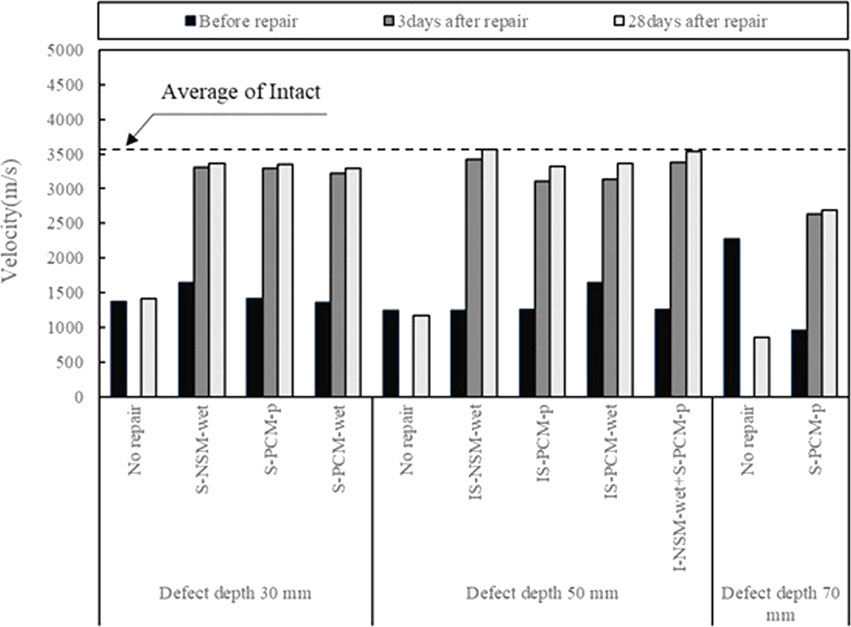

4.2 Results of impact-echo

Elastic wave velocities of defective and repaired parts are shown in Figure 6. The figure also shows the average value of elastic wave velocities at the age of 28 days for intact parts. Focusing on the changes in elastic wave velocities before and after repair, it is evident that the elastic wave velocities of the repaired part of the repaired specimen increased in the repaired specimen. Focusing on the difference in the repair method and defect depth, it was confirmed that specimens repaired by removing the defects tended to have a higher overall elastic wave velocity than specimens repaired without removing the defects.

In the test piece repaired without removing the defect, recovery amount of elastic wave velocity after repair was smaller in the test piece with a defect depth of 70 mm than in the test piece with a defect depth of 30 mm. This is because, in the case of the multiple reflection method, it shows the average velocity in the propagation direction of the elastic wave. Therefore, it can be said that the test piece with a defect depth of 70 mm is affected by the remaining defects.

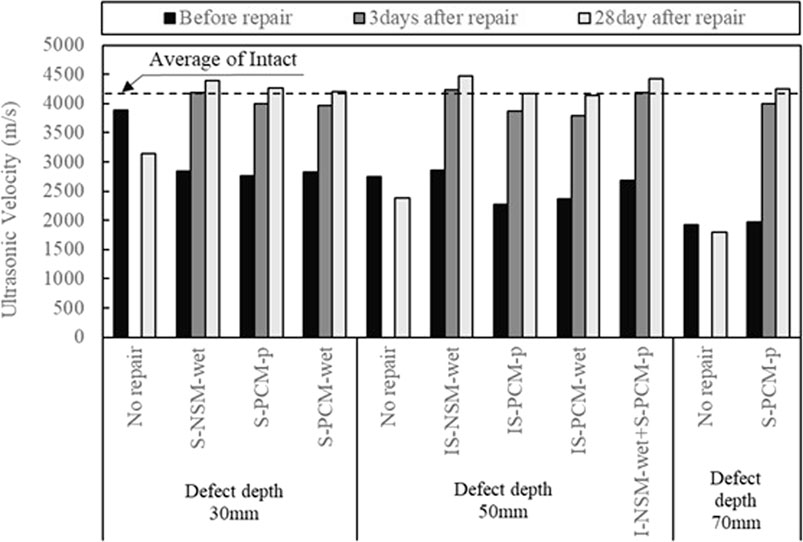

4.3 Results of the ultrasonic test

Figure 7 shows the ultrasonic velocity at the cross section of the repair (defect). The figure also shows the average value of ultrasonic velocity of intact part. Focusing on the ultrasonic velocity before and after repair, the ultrasonic velocity after repair increased in the repaired specimen. It was confirmed that the ultrasonic velocity of all the repaired specimens recovered to a level higher than that of the healthy part at the age of 28 days of the repair material. On the other hand, in the test piece that was repaired without removing the defect, the velocity difference could not be confirmed, unlike the elastic wave velocity by the impact elastic wave method. It was difficult to confirm the influence of internal defects by ultrasonic velocity. This is because the ultrasonic method measures the p-wave velocity near the concrete surface.

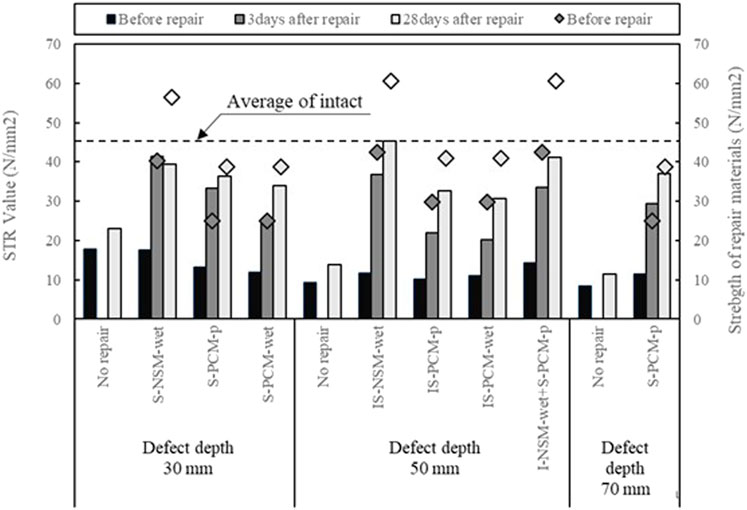

4.4 Results of the mechanical impedance method

Figure 8 shows the STR value of the repair section. The left axis and bar graph show the STR value, and the right axis and plot form show the compressive strength of each material. The figure also shows the average compressive strength of the repair material and the STR value of the intact part. It was confirmed that the STR value, which is an index of strength, increased in the repaired test piece, and that it tended to increase further with age. Comparing the STR value and compressive strength of the repair material, it can be said that the strength was estimated when the repair material is repaired without removing the defective part at the age of 3 days.

5 Evaluation of condition and quality of repair by the Mahalanobis–Taguchi method

5.1 Mahalanobis–Taguchi system and MT method

The Mahalanobis–Taguchi (MT) system is a method for pattern recognition and prediction devised by Dr. Genichi Taguch. In the MT system, the normal state is set as a reference, and the difference in pattern from this reference is quantified by the Mahalanobis distance (Taguchi and Jugulum, 2000). The main purpose of the MT system is to develop and optimize a diagnostic system with a measurement scale to classify multivariate data (Mota-GutiérrezGuadalupe et al., 2018). In the MT system, we need only a group of observations called a “normal” or “healthy” group to obtain correlation structure and to define the reference point to the measurement scale (Taguchi and Jugulum, 2000).

The relationship between the MT system and evaluation of repair condition is shown in Figure 9. In Figure 9, the left figure is an image of discrimination using the Mahalanobis distance in the MT system, and the right figure is an image of the repair effect evaluation in this study. The purpose of repairing is to repair the deterioration and restore the performance of sound members. Therefore, here, a normal group is created from the data obtained at the sound member part, and the state of the defective part is evaluated by the Mahalanobis distance. Subsequently, when the repaired part is evaluated, it is considered that it returns to a healthy state as a result of repair. In this study, we assumed that the degree of recovery could be evaluated by the Mahalanobis distance.

Based on the Mahalanobis distance, multidimensional data are converted and evaluated one-dimensionally. Here, a normal-state data group composed of samples whose results are stable is called “unit space”, and an unknown data group for calculating the Mahalanobis distances and their estimates is called “target data.”

The MD is calculated by the MT method from Eq. 2 using the inverse matrix of the correlation coefficient.

Here, D is the Mahalanobis distance (MD), where; k is the number of items, x is the value of each item, m is the mean value for each item, σ is the standard deviation for each item, and aij is a component of the inverse matrix of the correlation matrix. MD is a measure that can express how similar it is to the normal state that constitutes unit space by considering the correlation between measurement items in the Euclidean distance.

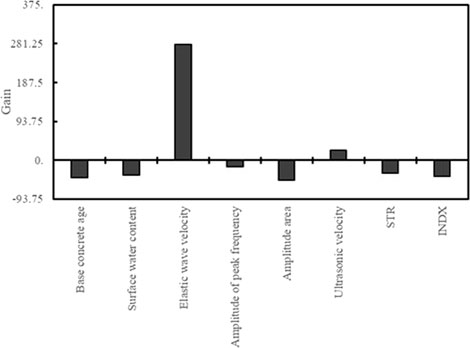

The degree of influence of each item on the evaluation by the MT method was judged by the gain from the creation of the factor effect diagram, which was examined at two levels, with and without using the item using an orthogonal array. Here, the gain is a value obtained by subtracting the SN ratio when each item is not used from the SN ratio when each item is used, and if the gain is high, it can be said that the item is important for making a judgment.

5.2 Items used for evaluation by the MT method

JUSE-Stat Works/V5 was used for the evaluation of the Mahalanobis distance based on the MT method. JUSE-Stat Works was developed in Japan by the Institute of JUSE (Japanese Union of Scientists and Engineers). Characteristic items used for the evaluation were the following eight items: 1) base concrete age (day), 2) surface water content (%), 3) elastic wave velocity (m/s), 4) amplitude of peak frequency (mV), 5) amplitude area, 6) ultrasonic velocity (m/s), 7) STR value, and 8) INDX value. In this study, to comprehensively evaluate the effect of repair methods, average values obtained in the intact part and defective (repaired) part were used for 2)–8). The unit space was created from all 49 data of the intact parts before and after repair of each test piece. For target data, 30 data values of the repaired and defect part before and after the repair were used.

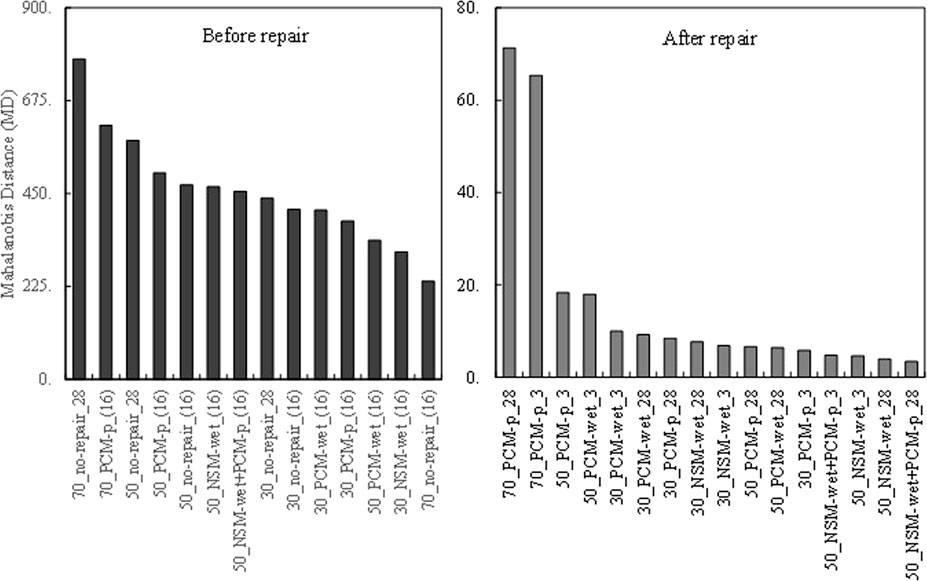

5.3 Results of evaluation by the MT method

Evaluation results obtained by the MT method are shown in Figure 10. In the graph legend in the figure, for example, “70_no-repair_28” means that the defect dept, repair method and material age in the NDT test.

Focusing on the size of MD before and without repair, it is observed that MD is extremely large and clearly different from the normal state of unit space. In addition, the MDs are arranged according to the depth of the defect. It is implied that MDs are gradually different depending on the properties of the test piece.

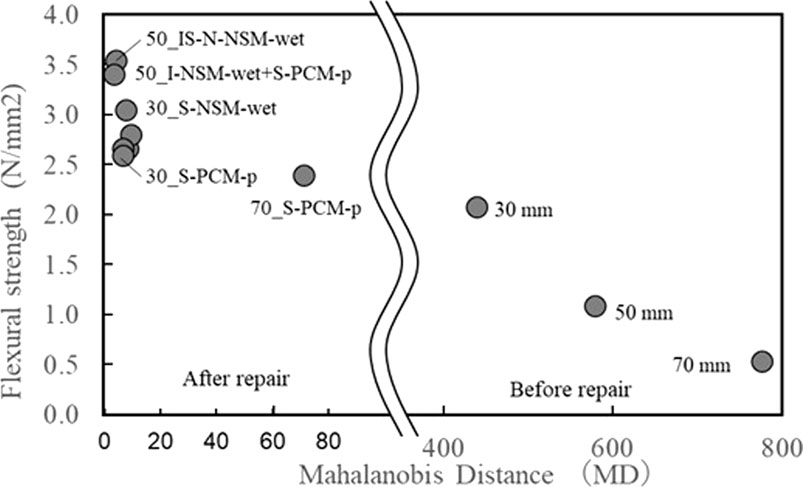

Next, focusing on the MD of the repaired part after repair, the 70_PCM-p test piece repaired without removing the defect has a larger MD than the test piece that has been repaired. From this, it is recognized that the repair is not sufficient. The MD of the repaired specimen was about 5–20, and the MD was significantly smaller than that before repair. This indicates that the repaired part is nearing a healthy state. Regarding the data of the intact part, all MD showed a value of less than 4. These results show that MD is an effective method for expressing the repair effect.

Figure 11 shows the degree of influence of each item on the evaluation by the MT method. Within the scope of this study, the gain of elastic wave velocity was the largest. In the replacing repair method, the influence of integrity and filling in the depth direction is large and elastic waves acquired by the multiple reflection method of the impact-echo method. It is presumed that the wave velocity calculated by the impact-echo method was able to capture effects in the depth direction. Assuming the application of the MT method to other defects and repair methods, the tendency of useful parameters may change. In the future, there are plans to study more useful items by NDT and how to create a unit space with the evaluation of actual structures.

6 Conclusion

The results obtained in this study are summarized as follows.

1) It was confirmed that relative evaluation of the repair effect before and after the repair is possible by IE, UT, and the mechanical impedance method.

2) From applying the test data obtained by various non-destructive tests to the MT method, the repair effect of the replacing repair method could be expressed as the distance from the normal state. It was possible to evaluate the quality of the repair effect from the difference in the repair method by MD.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material; further inquiries can be directed to the corresponding author.

Author contributions

TW, AN, and SN conceived the idea of the study. TW and AN developed the experiment and analysis plan and conducted. SN and CH contributed to the interpretation of the results. TW and AN drafted the original manuscript. All authors reviewed the manuscript draft and revised it critically on intellectual content. All authors approved the final version of the manuscript to be published.

Conflict of interest

AN was empolyed by Sumitomo Mitsui Construction CO., LTD.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

ACI CODE-562-16 Code requirements for assessment, repair, and rehabilitation of existing concrete structures and commentary. Harrisburg, PA, USA, Department of Labor and Industry

Aggelis, D. G., and Shiotani, T. (2007). Repair evaluation of concrete cracks using surface and through-transmission wave measurements. Cem. Concr. Compos. 29 (9), 700–711. doi:10.1016/j.cemconcomp.2007.05.001

Alani, A. M., Aboutalebi, M., and Kilic, G. (2014). Integrated health assessment strategy using NDT for reinforced concrete bridges. NDT e Int. 61, 80–94. doi:10.1016/j.ndteint.2013.10.001

BS EN 1504 -1 Products and systems for the protection and repair of concrete structures. Definitions, requirements, quality control and evaluation of conformity. Bruxelles, Belgium: CEN.

EN 1542 Products and systems for the protection and repair of concrete structures - test methods - measurement of bond strength by pull-off. Bruxelles, Belgium: CEN.

Fukuyama, Tomoko, Nagai, Hironori, and Noguchi, Takafumi (2012). Quantitative corrosion detection analysis of reinforcing bars by mahalanobis-taguchi system: 4th ACF International Conference on Concrete for Sustainable Engineering. Taipei, Taiwan.

Garbacz, A. (2015).Application of stress based NDT methods for concrete repair bond quality control, Bulletin of the Polish Academy of Sciences, Technical Sciences, 63, 77–85.doi:10.1515/bpasts-2015-0009

Garbacz, A., Piotrowski, T., Courard, L., and Kwaśniewski, L. (2017). On the evaluation of interface quality in concrete repair system by means of impact-echo signal analysis. Constr. Build. Mater. 134, 311–323. doi:10.1016/j.conbuildmat.2016.12.064

Habib, M. A., Rai, A., and Kim, J. M. (2020). Performance degradation assessment of concrete beams based on acoustic emission burst features and mahalanobis—taguchi system. Sensors 20 (12), 3402. doi:10.3390/s20123402

Hong, J., Jugulum, R., Paryani, K., Ragsdell, K. M., Taguchi, G., and Cuney, E. A. (2007). An evaluation of Mahalanobis-Taguchi system and neural network for multivariate pattern recognition. Int. J. Industrial Syst. Eng. 1.

Kim, C. W., Isemoto, R., Sugiura, K., and Kawatani, M. (2013). Structural fault detection of bridges based on linear system parameter and MTS method. J. JSCE 1 (1), 32–43. doi:10.2208/journalofjsce.1.1_32

Lin, J. M., and Sansalone, M. (1996). Impact-echo studies of interfacial bond quality in concrete: Part l-effects of unbonded fraction of area. Mater. J. 93 (3), 223–232.

Lin, J. M., Sansalone, M., and Poston, R. (1996). Impact-echo studies of interfacial bond quality in concrete: Part II-Effects of bond tensile strength. Mater. J. 93 (4), 318–326.

McCann, D. M., and Forde, M. C. (2001). Review of NDT methods in the assessment of concrete and masonry structures. Ndt E Int. 34 (2), 71–84. doi:10.1016/s0963-8695(00)00032-3

Mota-Gutiérrez, C. G., Reséndiz-Flores, E. O., and Reyes-Carlos, Y. I. (2018). Mahalanobis-Taguchi system: State of the art. Int. J. Qual. Reliab. Manag. 353, 596–613. doi:10.1108/ijqrm-10-2016-0174

Rehman, S. K. U., Ibrahim, Z., Memon, S. A., and Jameel, M. (2016). Nondestructive test methods for concrete bridges: A review. Constr. Build. Mater. 107, 58–86. doi:10.1016/j.conbuildmat.2015.12.011

RILEM TC 269-IAM (2016). Damage assessment in consideration of repair/retrofit-recovery in concrete and masonry structures by means of innovative NDT. Availble At: https://www.rilem.net/groupe/269-iam-damage-assessment-in-consideration-of-repair-retrofit-recovery-in-concrete-and-masonry-structures-by-means-of-innovative-ndt-347 (Accessed May 15, 2022).

Santos, P., Júlio, E. N. B. S., and Santos, J. (2010). Towards the development of an in situ non-destructive method to control the quality of concrete-to-concrete interfaces. Eng. Struct. 32 (1), 207–217. doi:10.1016/j.engstruct.2009.09.007

Standard of the Japanese Society for Non-destructive Inspection NDIS 3434-3 (2017). Non-destructive testing of concrete – impact testing method Part3: Test method for measuring the mechanical impedance, Tokyo, Standard of the Japanese Society for Non-destructive Inspection, 1–18.

Taguchi, G., and Jugulum, R. (2000). New trends in multivariate diagnosis. Indian J. Stat. 62B (2), 233–248.

Wang, H., Huo, N., Li, J., Wang, K., and Wang, Z. (2018). A road quality detection method based on the mahalanobis-taguchi system. IEEE Access 6, 29078–29087. doi:10.1109/access.2018.2839765

Keywords: non-destructive test, repair, Mahalanobis–Taguchi system, impact-echo, ultrasonic test, mechanical impedance

Citation: Watanabe T, Nouchi A, Namerikawa S and Hashimoto C (2023) Evaluation of condition on replacing repaired concrete based on NDT and the Mahalanobis–Taguchi system. Front. Built Environ. 8:956684. doi: 10.3389/fbuil.2022.956684

Received: 30 May 2022; Accepted: 27 October 2022;

Published: 05 January 2023.

Edited by:

Ninel Alver, Ege University, TurkeyReviewed by:

Hwa Kian Chai, University of Edinburgh, United KingdomChia-Chi Cheng, Chaoyang University of Technology, Taiwan

Copyright © 2023 Watanabe, Nouchi, Namerikawa and Hashimoto. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Takeshi Watanabe, dF93YXRhbmFiZUB0b2t1c2hpbWEtdS5hYy5qcA==

Takeshi Watanabe

Takeshi Watanabe Ayaka Nouchi2

Ayaka Nouchi2