- 1Mohamed Premier University, LME Lab, Oujda, Morocco

- 2Univ Paris Est Creteil, CERTES, Creteil, France

- 3Green Energy Park (IRESEN, UM6P), Benguerir, Morocco

Recycling plastic waste has been one of the most significant challenges in the recent decade. The reuse of one of the most produced cellular plastics (i.e. EPS) within a conventional construction binder can contribute, simultaneously, to waste elimination and improving energy performances of the building envelopes. This work investigates the recycling of expanded polystyrene (EPS) waste within a cement-based matrix. The aim is to develop a lightweight, energy-efficient composite for eco-construction. Portland cement was mixed with a small amount of gypsum (4 wt%) before adding EPS aggregates ranging from 0–0.6 wt%. The thermal properties were determined using two different non-destructive methods, the transient plane source technique (Hot Disk Method) and the Flash method. The experimental results showed a remarkable decrease of 54, 12, and 36% in thermal conductivity, thermal diffusivity, and density, respectively. These results indicate the improvement of thermal resistance of EPS-cement-gypsum- mixes. In addition, water absorption and compressive tests revealed that cement-based composites containing EPS beads have improved durability and can be used for structural and insulation purposes. Finally, Numerical results indicated that energy savings of up to 18% may be achieved by applying produced waste-based mortar, underscoring the promise of using this product for building energy efficiency benefits.

1 Introduction

Waste recycling and energy-efficient buildings are crucial challenges facing the world today, given their environmental and socio-economic impact. Incorporating waste into building envelopes can tackle both issues at once. Researchers have reported extensively on the use of industrial, bio-sourced, and municipal wastes as additives for conventional construction materials (cement, clay, etc.) (Raut et al., 2011; Zhang et al., 2018; Jami et al., 2019; Horma et al., 2022). The results indicated that waste additives can indeed improve the properties of building elements. The building and construction industry plays a critical role in the climate crisis, consuming about one-third of the world’s energy, and engendering massive amounts of CO2 emissions (IEA, 2019). Therefore, enhancing thermal properties is the most desirable outcome of waste incorporation, which will positively affect the performance of buildings and passively save considerable energy.

Expanded polystyrene (EPS) refers to a solid white foam made from pre-expanded EPS beads. The excellent thermal insulating and lightweight properties made EPS a prime material in the packaging and construction industries. It is one of the largest commodity polymers produced worldwide, with over 10 million metric tons per year (Tiseo, 2021). However, most developing countries avoid using EPS in buildings due to its consequential added cost. Moreover, EPS from packaging is designed mainly for single-use goals, which leads to enormous amounts of waste after utilization (Geyer et al., 2017). Even though EPS is recyclable, the high cost and complex logistics required by EPS compacting machinery signify that most countries cannot afford or implement this recycling technique (Waring, 2018). Nevertheless, using EPS waste as an additive in construction materials is simple, cheap, and can passively save energy throughout the life cycle of buildings (50 years).

From the literature, most research on the incorporation of EPS into different binders has shown similar properties evolution. The main impact EPS has on conventional construction binders is the decrease in the thermal conductivity, density, and compressive strength (Şahin and Karaman, 2012; Ferrándiz-Mas et al., 2014; Horma et al., 2020; Maaroufi et al., 2021). Even though the compressive strength diminishes with increasing EPS content, the composites containing high volume fraction percentages of EPS (e.g., cement/EPS ratio of 2:3) remain within the acceptable range for mortar applications. Bras et al. (Brás et al., 2013) studied the difference between EPS-mortar and cork-mortar, as they noticed that EPS does not affect the workability of the mortar paste as much as bio-based materials (cork), which is due to the water retention of the latter. Moreover, EPS-mortar showed higher compressive strength compared to cork-mortar. Whereas, both materials improve the thermal conductivity of the composite. In addition, Ferrandez et al. (Ferrández et al., 2022) discussed the application of panels made from waste EPS and gypsum as part of the interior building envelope. They found that using insulating aggregates (EPS) resulted in improved hygrothermal properties, namely thermal conductivity and water absorption capillarity, both of which decreased with the introduction of EPS. Furthermore, despite an expected decrease in flexural and compressive strength, EPS gypsum boards were still recommended for interior building composition. Besides, it is also important to mention that EPS has relatively high acoustic absorption. Patricia et al. (2022) (Bergmann Becker et al. (2022)) found that mortar incorporating EPS aggregates with dimensions similar to ours performed best acoustically out of several insulating materials (aerogel, EPS, and vermiculite) during their investigation of lightweight coating mortars.

This work presents the development and thermo-physical and mechanical characterization of a green construction composite. The investigation of the thermal properties was conducted using two methods, the Transient Plane Source (TPS) and the Flash techniques. Water absorption and compressive strength were examined to assure that the studied EPS-mortar meets the standard requirements for eventual structural or insulating applications. Lastly, to illustrate the influence of integrating this material into building envelopes, a thermal simulation was carried out using Energy-plus software. Cement/Expanded Polystyrene CEP mortar was introduced in exchange for regular mortar as a non-structural material, which depending on the numerical results, indicates how this new material affects building performances.

2 MATERIALS AND SAMPLE PREPARATION

2.1 Expanded Polystyrene

EPS used in this study was collected from electronics packaging waste (TV, home appliance, etc.). It has a density of around 20 kg/m3 which is within the normal density range of 11–32 kg/m3 (Zwiebel, 1973). The motive behind using EPS waste apart from developing a green construction material is the disposal of this non-biodegradable material which can harm the environment.

2.2 Binder

Cement C35 from HolcimLafarge™ was used in this work as the main binder. This cement is conformed with the European standards (Lafarge Holcim Maroc, 2013) and was chosen since it is the main type used for non-structural mortars, which aligned with the aim of our study.

Before studying the incorporation of EPS into a cement binder, 4 wt% of gypsum was blended into cement. This procedure helps control the setting time of cement (Li et al., 2019), which improves its workability. Moreover, this addition also enhances marginally the thermal properties, as shown in the study (Horma et al., 2020), where gypsum addition decreased the thermal conductivity and thermal diffusivity.

2.3 Preparation Process

First, EPS packaging waste was scraped manually into EPS beads with sizes ranging from 1 to 3 mm. Then, different percentages by weight of EPS aggregates (0.2, 0.4, and 0,6) were added to cement and were dry mixed to reach a uniform distribution. Afterward, 0.5 of the water to binder ratio was used to make the cementitious pastes. Finally, the different cement-EPS (CEP) mixtures were molded into cylindrical and block shapes, as listed thereafter:

- Cylindrical (d = 40 mm, h = 80 mm) for water absorption and compression tests.

- Cylindrical (d = 50 mm, h = 20 mm) for the hot disk method.

- Block (30 × 150 × 150 mm3) for the flash method.

Where d and h refer respectively to the diameter and the height of the specimens. Table 1 presents the preparation mix for each of the produced specimens, while the final products can be seen in Figure 1. Other studies have considered EPS as a volume fraction of the binder, thus for comparison purposes, both weight and volume percentages were provided in Table 1.

3 Methods

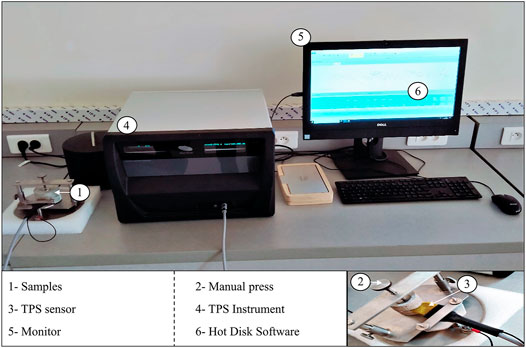

3.1 The Hot Disk Method

HDM is one of the most popular TPS (transient plane source) techniques used to determine the thermal properties of solids, liquids, and powders. This method stands out among others by the rapidity of measurement, the flexibility of the TPS sensor, and more importantly the ability to measure multiple thermal properties at the same time, mainly the thermal conductivity, thermal diffusivity, and volumetric specific heat. The hot disk sensor consists of two nickel spirals wrapped by a thin layer of Kapton as an insulator and can act as a thermal probe and a heating source simultaneously. The theoretical framework, as well as the governing equations, of the hot disk method are detailed in (Gustafsson (1991), Mihiretie et al. (2017)) (Gustafsson; Mihiretie et al.).

The measurement process follows these simple steps:

• Sandwiching the 6.403 mm Kapton sensor between two plane identical samples, while applying pressure to avoid air gaps, as seen on the bottom left of Figure 2.

• The power and heating time used in this work ranges from 50 to 100 mW and 40–80 s, respectively.

• Starting the tests with 7–12 min interval between each measurement to allow for thermal stability.

Figure 2 presents the different elements of this method. The concept by which this technique operates relies on recording the time-dependent thermal response of the samples via the double spiral sensor after heating them through a direct electrical current. Then, the thermal transport properties are determined based on the recorded temperature increase. Finally, the hot disk thermal analyzer v 7.3 software interprets the numerical results and displays the thermal properties.

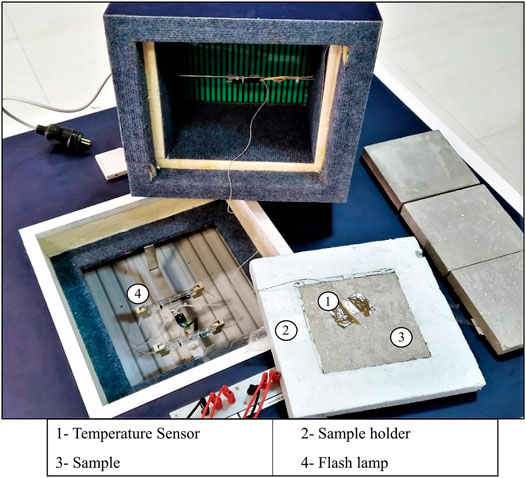

3.2 Flash Method

The reason behind using this method along the HDM is to observe the thermal reaction of the studied material under intense short-term temperature excitement as well as the comparison between the results of both methods.

This test was performed using the second box of the EI702 cell, which was developed by Menguy et al. (Menguy et al. (1986)) as a thermal characterization method allowing the measurement of the thermal conductivity in the first box and the thermal diffusivity in the second one, as shown in Figure 3. The flash technique relies on recording the temperature increase of the upper side of the sample as a function of time over a period of time (25–30 min) after heating the underside using a 1000 W incandescent lamp for 8 s. Three estimated values of thermal diffusivity are calculated using the following equations, according to Degiovanni et al. (Degiovanni and Laurent (1986)):

Where ti (i: 1/3; 1/2; 2/3; 5/6) is the ith characteristic time when the temperature reaches i of the maximum temperature and e is the thickness of the sample. The thermal diffusivity of the studied sample is then obtained by averaging the three found values.

3.3 Water Absorption

Water absorption (WA) is a decisive property in determining the durability and viability of building materials. This study examined the water absorption of CEP samples using the total immersion method. The cylindrical specimens are immersed in water for 24 h to record their wet mass mwet then their dry mass mdry is noted after another 24 h in the oven at 70 C°. Based on the wet and dry mass values of the samples, the water absorption can directly be calculated through the following equation:

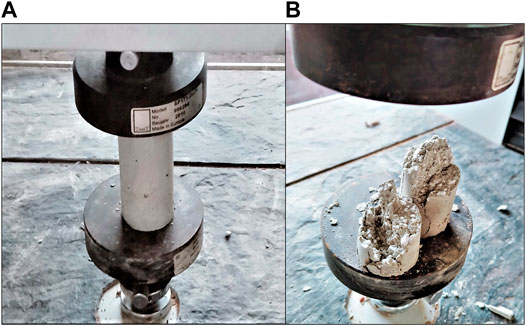

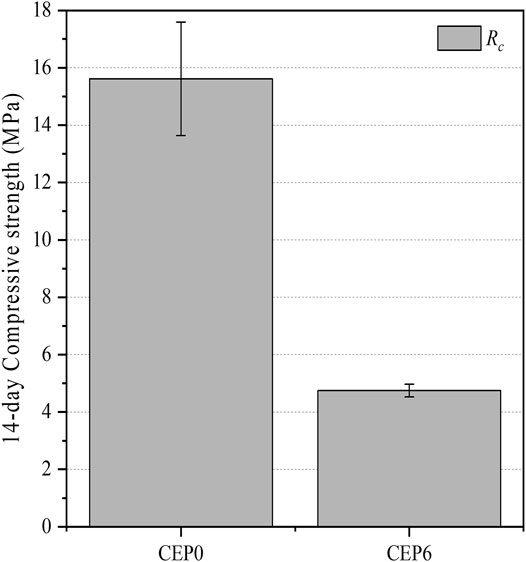

3.4 Compressive Strength

The most relevant mechanical property for building materials is the compressive resistance (Rc), as it assesses the possible engineering applications of the investigated material. Therefore, compressive strength tests on the best performing specimen (CEP6) and the reference (CEP0) were conducted using the Testwell device. The machine operates the compaction automatically at a speed of 0.5 mm/min with a maximum capacity of 20 kN. The test consists of applying an increasing vertical force on the plane surface of the cylindrical specimens until failure, as displayed in Figure 4. This test aims to determine how suitable is CEP6 composite as a mortar, while also examining its potential use in structural applications.

4 Results and Discussion

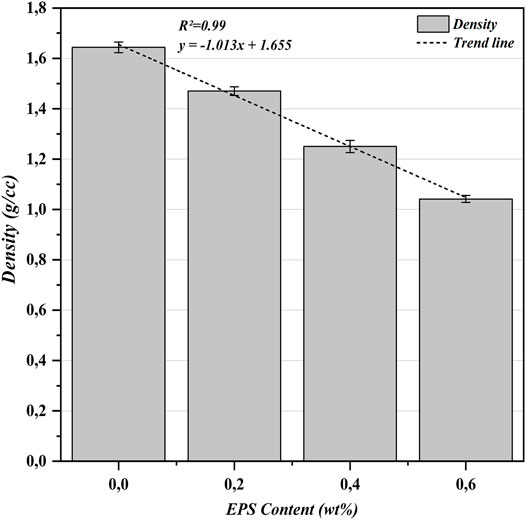

4.1 Density

Lightweight construction materials have significant economic and environmental advantages over the heavier alternative, as they reduce labor, raw material use, transportation fuel consumption, and related GHG emissions. The density of our CEP mortar is presented in Figure 5. It can be observed that increasing EPS additives lead to a decrease in density, due to the low mass of EPS in comparison with the binder. The diminishing of the composite’s density is uniformly linear with an almost perfect correlation (R2 = 0.99). The overall decrease in density for the addition of 0.6 wt% of EPS represents more than a third (36%) of the original sample’s (CEP0) density.

These results are in line with the literature, as higher EPS content leads to lower density composites. Previous works involving EPS have mainly studied very high EPS (>80 vol%) content incorporation, which explains the low range of density that was found (600–200 kg/m3) (Zhang et al., 2019; Maaroufi et al., 2021). However, in this study a relatively small percentage of EPS additives is investigated, thus, the density of our last specimen is higher in comparison (1,030 kg/m3). This also implies that our CEP composites are stronger due to lower EPS addition and higher density.

4.2 Thermal Properties

This work primarily focuses on the energy-efficient aspects of the developed CEP material. Thus, the thermal transport properties constitute the most important characteristics. Moreover, two different methods were used in the thermal characterization of CEP to verify the accuracy of the thermal test’s results. The Hot Disk method was used to measure the thermal conductivity, the thermal diffusivity, and specific volumetric heat, while the specific heat was deduced using the following equation:

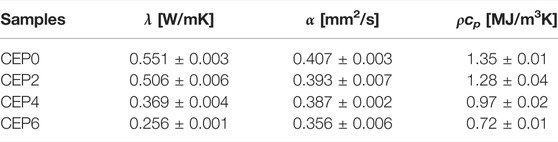

Table 2 shows the thermal properties of CEP composites resulting from averaging three HDM measurements along with their respective standard deviations.

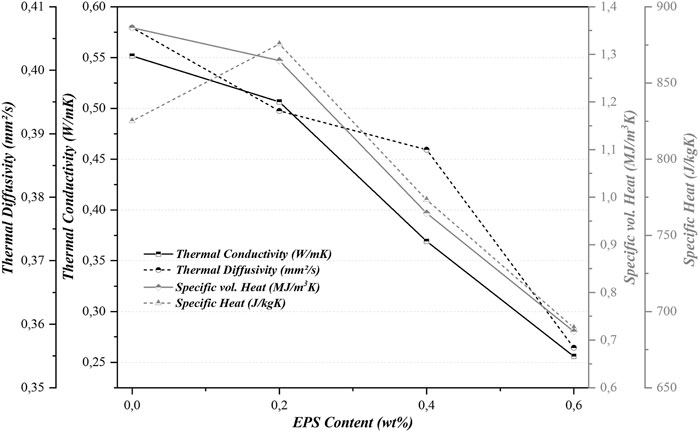

The experimental results showed that EPS additives improve remarkably the overall thermal performance of the CEP composites, as seen in Figure 6. The most significant impact noticed is the enhancement of the thermal insulating capacity of the material, as the thermal conductivity saw a 54% reduction for CEP6 compared to CEP0. The thermal diffusivity decreases by 13% which may lead to an increase in the time lag of the CEP composites. Whereas for the specific heat the result indicates an increase for the first EPS addition of 0.2 wt%, then a linear decrease is observed for higher EPS content. This type of variation can be seen in other studies, where after the first introduction of an insulating material (hemp) the specific heat increases before decreasing with higher additive content (Charai et al., 2021).

The thermal properties of CEP composites are in agreement with previous studies. Maaroufi et al. (Maaroufi et al. (2021)) studied EPS beads incorporation of about 170% of the binder’s volume, which resulted in a 60% of thermal conductivity decrease. Ferrandiz et al. (Ferrándiz-Mas et al. (2014)) worked on the addition of EPS waste as ground and powder and found that adding 60 vol% of EPS content into a cement-based matrix also depends on the morphology, as the thermal conductivity diminished by 60% for ground EPS while only a 47% reduction is seen for powder EPS.

The results of both the density and thermal conductivity indicate strongly that the addition of EPS beads into cement matrices can lead to the development of lightweight energy-efficient building components.

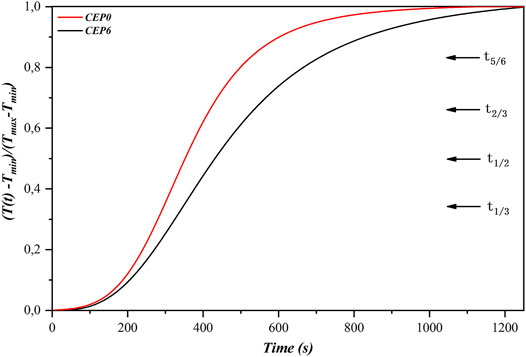

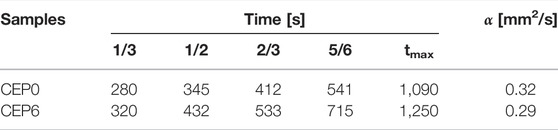

The thermograph in Figure 7 presents the temperature increase of the upper face of the CEP6 and the reference sample (CEP0). This shows clearly that introducing EPS into mortar lowers the thermal diffusivity, as the time to reach the maximum temperature from the incandescent lamp excitation significantly decreases for CEP6 (1,250 s) in comparison with CEP0 (1,090 s). This also indicates an improvement in the thermal inertia of the CEP6 composite. These results suggest that incorporating CEP6 into building envelopes may improve the thermal comfort of the occupants, not only as a thermally insulating material but also during hot weather by increasing the thermal time lag. Based on the equations (Zhang et al., 2018) and (Raut et al., 2011), the thermal diffusivity values for both the reference and CEP6 samples were deduced from the times needed to reach 1/3, 1/2, 2/3, and 5/6 of the maximum temperature increase displayed in Table 3 which showed a slight decrease from CEP0 to CEP6 which is in agreement with the Hot Disk Method results. It should be noted that the gypsum addition in the binder also affects the thermal properties, as seen in previous work (Horma et al., 2020). As cement-plaster mixtures presented 17 and 14% lower thermal conductivity and thermal diffusivity, respectively, when compared to plain ordinary Portland cement.

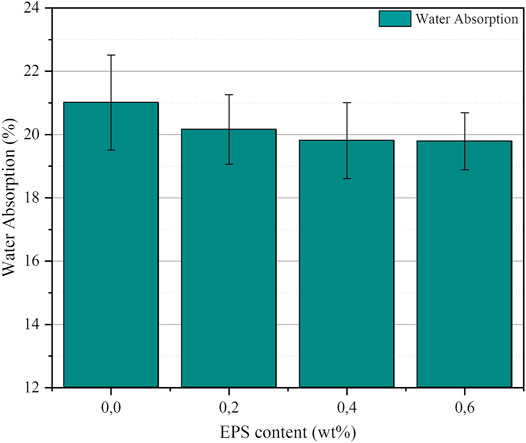

4.3 Water Absorption

The water absorption property is a key factor that indicates the durability of construction materials as well as its insulating capacity, knowing that water absorbed affect negatively the thermal insulating properties of the composite. The experimental results displayed in Figure 8 indicate that increasing EPS content up to 0.4 wt% leads to a decrease of around 1.2% in water absorption. However, insignificant variation can be observed from adding 0.4 to 0.6 wt% EPS. Overall, the addition of about 60 vol% EPS resulted in a decrease in water absorption, which can be explained by the hydrophobic nature of expanded polystyrene. Moreover, these results strongly support the previous findings, as Zhang et al. (Zhang et al. (2019)) showed that the water absorption decreases for increasing EPS beads incorporation, then increases for 82 vol% and higher EPS additions. Furthermore, Tittarelli et al. (Tittarelli et al. (2016)) have also demonstrated that increasing EPS dosage in mortar leads to a decrease in capillary water absorption. Nevertheless, rigorous physical tests should be conducted for CEP mortar to be considered for industry-level applications.

4.4 Compressive Strength

From the literature, it is shown that higher EPS content leads to mechanically weaker composites, which is evidently due to the low compressive strength of the EPS beads (Maaroufi et al., 2021). However, most studies on EPS incorporation into cement matrixes used high volume ratios of the additive, not far from a 2: 1 ratio for EPS/cement mix portions. Therefore, indicating that CEP composites in this work should have significantly better strength, as the volume ratio used for EPS/cement does not exceed 2: 3. In order to confirm this initial assumption, compressive tests were carried out for CEP6 and CEP0 as described in the method section. The experimental results are presented in Figure 9, showing an expected decrease of Rc due to the addition of 0.6 wt% EPS. Nonetheless, the compression of 14-day old specimens, where the mortar is at 80–90% of its full strength, was enough to achieve satisfying strengths. The compressive strength went from 15.61 to 4.74 MPa due to 0.6 wt% EPS content, representing a decrease of 69%. In addition, it is noteworthy to mention that the standard error is remarkably lower for CEP6, which suggests a higher accuracy of the yielded property. Consequently, from the measured mechanical and thermal characteristics, CEP6 can definitely be used for structural and insulating applications according to RILEM’s classifications (Rc > 3.5 MPa; λ < 0.3 W/mK) (Rilem, 1978). Moreover, Liu et al. (Liu and Chen (2014)) have shown that EPS addition produces crack-resistant composites with a slow failure mode under high loads as the higher EPS content, the better the plastic deformation. During the experiment process, similar behavior was noticed as the CEP6 composite took almost double the time of CEP0 to reach failure.

5 Thermal Performance Simulation

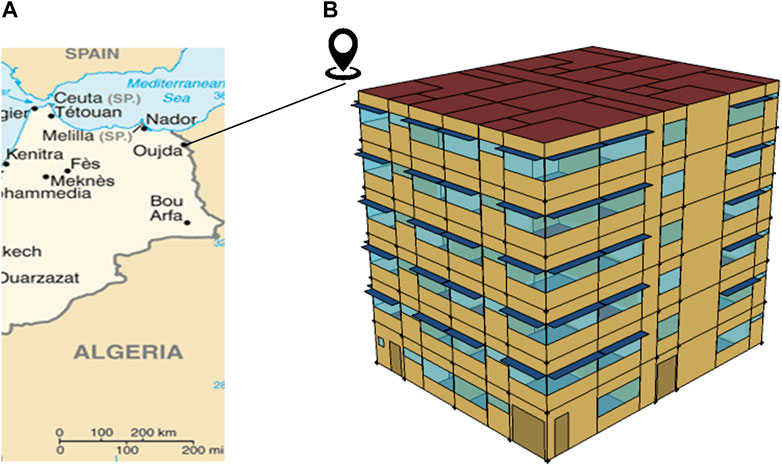

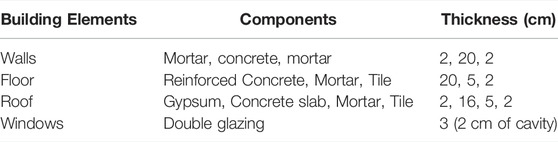

This section aims at determining the potential energetic impact of CEP6 composite as a regular mortar replacement in conventional building envelopes. Thus, in this simulation, our composite acts, similarly to mortar, as a non-structural element of the building envelope.

5.1 Simulation Process

Three dynamic thermal simulations were conducted on a virtual 6-story residential building in Oujda City, Morocco. The simulation software used is Energy-plus, one of the most reliable software for building’s thermal performance assessments, while Sketch-up was used to design the building model presented in Figure 10. The composition of the building can be seen in Table 4, and their properties are listed in the study (Horma et al., 2020). The first simulation concerns the reference building containing traditional mortar, whereas for the second and third simulations, the CEP0 and CEP6 mortars, respectively, substitute the regular mortar.

The main parameters used for these simulations are the following:

• Typical meteorological year (TMY) for Oujda City.

• Multifamily (R+5) building with a total floor area of 320 m2.

• Window to wall ratio of 26%.

• Infiltration 0.6 air change per hour.

• Heating/cooling set-points 20/26°C.

• Unoccupied building to assess the direct impact of building materials on annual thermal loads of buildings.

5.2 Numerical Results

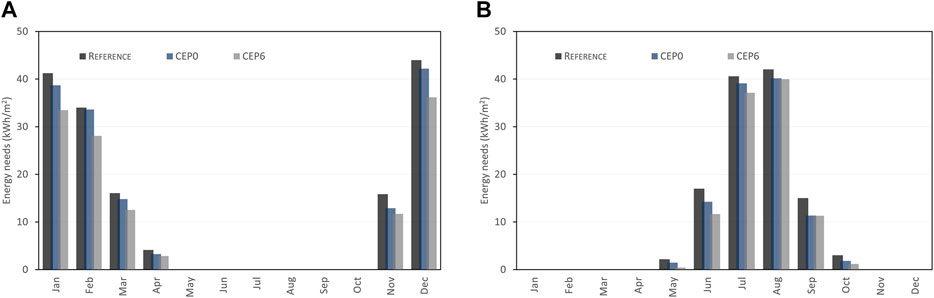

The monthly energy load per m2 to maintain the building constantly within the comfort zone (20–26°C) is given in Figure 11. As expected, CEP6 has shown a significant decrease in heating energy demand due to the remarkable improvement in the insulating capacity. The coldest months showed the biggest energy needs decrease (Dec, Jan, and Feb), which shows the effectiveness of CEP6 against cold weather. The annual heating loads decreased by about 20 and 15% when compared with the reference and CEP0 buildings, respectively. Whereas the decrease is slightly lower for cooling energy needs, as CEP6 contributes to lowering the energy demand by 15 and 6% in comparison with the reference and CEP0, respectively. The overall annual energy savings per m2 per year observed when substituting regular mortar (Reference) and CEP0 by CEP6 reaches a decrease of 18 and 11%, accordingly.

It should be noted that the comparison of CEP0 and CEP6, identify precisely the impact of incorporating EPS waste (0.6 wt%) into a relatively small, non-structural component (Mortar) of the building envelope.

6 Conclusion

This work presents a low-cost and comprehensive way to recycle EPS waste while tackling the excessive building energy consumption, by incorporating EPS beads into cementitious matrices. After discussing the literature and analyzing the results of experimental tests, the following conclusions can be drawn:

• EPS beads decrease remarkably both the density and the thermal conductivity.

• The density decreases uniformly with each EPS addition (12% per 0.2 wt%), up to 0.6 wt%.

• Adding 0.6% of EPS content by weight leads to a 36% decrease in density.

• The thermal conductivity decreased by 54% for CEP6 compared to CEP0.

• A slight decrease in the thermal diffusivity representing (10–12%) is measured by both the hot disk method and the flash technique as an effect of adding 0.6 wt% of EPS beads.

• The water absorption decrease indicates an improvement in the durability of CEP composites.

• The compressive strength of CEP6 (4.7 MPa) is within the acceptable range for both structural and insulating engineering applications.

• The thermal performance simulation confirmed the experimental results as CEP6 has shown a significant improvement in the thermal insulating capacity by decreasing the heating demand by 20% in comparison with typical mortar.

• The cooling needs decreased by 15% which can be explained mainly by the decrease in thermal diffusivity and the increase in the time lag found through the flash method.

Even though rigorous industry scale tests are still needed, all these results support the conclusion that EPS waste can definitely be used in the development of lightweight energy-efficient composites, thus contributing simultaneously to reducing the non-biodegradable plastic waste and saving energy passively throughout the building lifetime.

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author Contributions

OH: Conceptualization, Methodology, Laboratory tests, Sample preparation, Formal analysis, Investigation, Resources, Writing—original draft, Writing—review and editing. MC: Conceptualization, Sample preparation, Formal analysis, Laboratory tests, Writing—review and editing. SE: Writing—review and editing. AE: Writing—review and editing. MM: revision, writing, review, and editing. AM: Investigation, Writing—review and editing, Supervision.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Patricia, F B. B., Effting, C., and Schackow, A. (2022). Lightweight Thermal Insulating Coating Mortars with Aerogel, EPS, and Vermiculite for Energy Conservation in Buildings. Cem. Concr. Compos. 125 (October 2021), 104283. Available from: https://doi.org/10.1016/j.cemconcomp.2021.104283. doi:10.1016/j.cemconcomp.2021.104283

Brás, A., Leal, M., and Faria, P. (2013). Cement-cork Mortars for Thermal Bridges Correction. Comparison with Cement-EPS Mortars Performance. Constr. Build. Mater 49, 315–327. doi:10.1016/j.conbuildmat.2013.08.006

Charai, M., Sghiouri, H., Mezrhab, A., and Karkri, M. (2021). Thermal Insulation Potential of Non-industrial Hemp (Moroccan Cannabis Sativa L.) Fibers for Green Plaster-Based Building Materials. J. Clean. Prod. 292, 126064. [Internet]. Available from: https://www.sciencedirect.com/science/article/pii/S0959652621002845. doi:10.1016/j.jclepro.2021.126064

Degiovanni, A., and Laurent, M. (1986). Une nouvelle technique d'identification de la diffusivité thermique pour la méthode " flash ». Rev. Phys. Appl. Paris. 21 (3), 229–237. [Internet]. Available from: https://doi.org/10.1051/rphysap:01986002103022900. doi:10.1051/rphysap:01986002103022900

Ferrández, D., Álvarez, M., Saiz, P., and Zaragoza, A. (2022). Experimental Study with Plaster Mortars Made with Recycled Aggregate and Thermal Insulation Residues for Application in Building. Sustain 14 (4), 2386. doi:10.3390/su14042386

Ferrándiz-Mas, V., Bond, T., García-Alcocel, E., and Cheeseman, C. R. (2014). Lightweight Mortars Containing Expanded Polystyrene and Paper Sludge Ash. Constr. Build. Mater 61, 285–292. doi:10.1016/j.conbuildmat.2014.03.028

Geyer, R., Jambeck, J. R., and Law, K. L. (2017). Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 3 (7), e1700782–8. doi:10.1126/sciadv.1700782

Gustafsson, S. E. (1991). Transient Plane Source Techniques for Thermal Conductivity and Thermal Diffusivity Measurements of Solid Materials. Rev. Sci. Instrum. 62 (3), 797–804. doi:10.1063/1.1142087

Horma, O., Charai, M., Mezrhab, A., and Karkri, M. (2020). “Thermal Characterization of Cement-Plaster-Expanded Polystyrene Composites,” in 2020 5th International Conference on Renewable Energies for Developing Countries (REDEC). Ben Guerir: IEEE Xplore, 1–6. doi:10.1109/redec49234.2020.9163883

Horma, O., Charai, M., and Mezrhab, A. (2022). “Improving the Thermal Insulation of Cement-Based Composites Using Tea Waste Aggregates,” in Improving the Thermal Insulation of Cement-Based Composites Using Tea Waste Aggregates BT - the 15th International Conference Interdisciplinarity in Engineering. Editors L. Moldovan, and A. Gligor (Cham: Springer International Publishing), 466–476. doi:10.1007/978-3-030-93817-8_43

IEA (2019). Buildings a Source of Enormous Untapped Efficiency Potential. [Internet]. Available from: https://www.iea.org/topics/buildings (Accessed December 2021).

Jami, T., Karade, S. R., and Singh, L. P. (2019). A Review of the Properties of Hemp Concrete for Green Building Applications. J. Clean. Prod. 239, 117852. Available from: https://www.sciencedirect.com/science/article/pii/S0959652619327222. doi:10.1016/j.jclepro.2019.117852

Lafarge Holcim Maroc (2013). Information Note, Holcim (Morocco). [Internet]. Available from: https://www.lafargeholcim.ma/sites/morocco/files/atoms/files/note_dinformation_holcim_maroc-_decembre_2013.pdf (Accessed February 2022).

Li, P., Ma, Z., Zhang, Z., Li, X., Lu, X., Hou, P., et al. (2019). Effect of Gypsum on Hydration and Hardening Properties of Alite Modified Calcium Sulfoaluminate Cement. Materials 12, 3131. [Internet]. Available from: https://pubmed.ncbi.nlm.nih.gov/31557933. doi:10.3390/ma12193131

Liu, N., and Chen, B. (2014). Experimental Study of the Influence of EPS Particle Size on the Mechanical Properties of EPS Lightweight Concrete. Constr. Build. Mater. 68, 227–232. Available from: http://dx.doi.org/10.1016/j.conbuildmat.2014.06.062. doi:10.1016/j.conbuildmat.2014.06.062

Maaroufi, M., Belarbi, R., Abahri, K., and Benmahiddine, F. (2021). Full Characterization of Hygrothermal, Mechanical and Morphological Properties of a Recycled Expanded Polystyrene-Based Mortar. Constr. Build. Mater. 301 (July), 124310. Available from: https://doi.org/10.1016/j.conbuildmat.2021.124310. doi:10.1016/j.conbuildmat.2021.124310

Menguy, G., Laurent, M., Moutarda, A., and Leveau, J. (1986). Cellule de mesure des caractéristiques thermophysiques des matériaux E1700. Société Weber Broutin. Bull. Tech. Deltalab Carcassonne, Fr.

Mihiretie, B. M., Cederkrantz, D., Rosén, A., Otterberg, H., Sundin, M., Gustafsson, S. E., et al. (2017). Finite Element Modeling of the Hot Disc Method. Int. J. Heat Mass Transf. 115, 216–223. Available from: http://dx.doi.org/10.1016/j.ijheatmasstransfer.2017.08.036. doi:10.1016/j.ijheatmasstransfer.2017.08.036

Raut, S. P., Ralegaonkar, R. V., and Mandavgane, S. A. (2011). Development of Sustainable Construction Material Using Industrial and Agricultural Solid Waste: A Review of Waste-Create Bricks. Constr. Build. Mater. 25 (10), 4037–4042. Available from: http://dx.doi.org/10.1016/j.conbuildmat.2011.04.038. doi:10.1016/j.conbuildmat.2011.04.038

Şahin, S., and Karaman, S. (2012). The Properties of Expanded Polystyrene - Pumice - Gypsum Blocks as a Building Material. J. Tekirdag Agric. Fac. 9, 51–56.

Tiseo, I. (2021). Production Capacity of Expandable Polystyrene Worldwide from 2018 to 2024. [Internet]. Statista Research Department. Available from: https://www.statista.com/statistics/1063653/expandable-polystyrene-production-capacity-globally/ (Accessed February 2022).

Tittarelli, F., Giosuè, C., Mobili, A., Di Perna, C., and Monosi, S. (2016). Effect of Using Recycled Instead of Virgin EPS in Lightweight Mortars. Procedia Eng. 161, 660–665. doi:10.1016/j.proeng.2016.08.728

Waring, O. (2018). Can You Recycle Polystyrene? Here’s what You Should Do with it. [Internet]. Metro News. Available from: https://metro.co.uk/2018/04/18/can-recycle-polystyrene-7478185/#metro-comments-container (Accessed January 2022).

Zhang, J., Chen, B., and Yu, F. (2019). Preparation of EPS-Based Thermal Insulation Mortar with Improved Thermal and Mechanical Properties. J. Mater. Civ. Eng. 31 (9), 04019183. doi:10.1061/(asce)mt.1943-5533.0002825

Zhang, Z., Wong, Y. C., Arulrajah, A., and Horpibulsuk, S. (2018). Review of Studies on Bricks Using Alternative Materials and Approaches. Constr. Build. Mater. 188, 1101–1118. Available from: http://www.sciencedirect.com/science/article/pii/S0950061818320920. doi:10.1016/j.conbuildmat.2018.08.152

Keywords: green building material, waste recycling, expanded polystyrene, passive energy savings, thermal insulation

Citation: Horma O, Charai M, El Hassani S, El Hammouti A, Moussaoui MA and Mezrhab A (2022) Thermal Performance Study of a Cement-Based Mortar Incorporating EPS Beads. Front. Built Environ. 8:882942. doi: 10.3389/fbuil.2022.882942

Received: 24 February 2022; Accepted: 13 May 2022;

Published: 31 May 2022.

Edited by:

Foo Wei Lee, Universiti Tunku Abdul Rahman, MalaysiaReviewed by:

Syed Minhaj Saleem Kazmi, RMIT University, AustraliaKwong Kok Zee, Tunku Abdul Rahman University, Malaysia

Copyright © 2022 Horma, Charai, El Hassani, El Hammouti, Moussaoui and Mezrhab. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Othmane Horma, aG9ybWEub3RobWFuZUB1bXAuYWMubWE=

Othmane Horma

Othmane Horma Mouatassim Charai

Mouatassim Charai Sara El Hassani

Sara El Hassani Aboubakr El Hammouti1,2

Aboubakr El Hammouti1,2 Ahmed Mezrhab

Ahmed Mezrhab