94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Built Environ., 25 April 2022

Sec. Building Information Modelling (BIM)

Volume 8 - 2022 | https://doi.org/10.3389/fbuil.2022.864722

This article is part of the Research TopicCognitive Digital Twins for Facilitating Construction 4.0: Challenges and Opportunities for ImplementationView all 5 articles

Modularized construction with precast concrete elements has many advantages, such as shorter construction times, higher quality, flexibility, and lower costs. These advantages are mainly due to its potential for prefabrication and series production. However, the production processes are still craftsmanship, and automation rarely occurs. Fundamental to the automation of production is digitization. In recent years, the manufacturing industry made significant progress through the intelligent networking of components, machines, and processes in the introduction of Industry 4.0. A key concept of Industry 4.0 is the digital twin, which represents both components and machines, thus creating a dynamic network in which the participants can communicate with each other. So far, BIM and digital twins in construction have focused mainly on the structure as a whole and do not consider feedback loops from production at the component level. This paper proposes a framework for a digital twin for the industrialized production of precast concrete elements in series production based on the asset administration shell (AAS) from the context of Industry 4.0. For this purpose, relevant production processes are identified, and their information requirements are derived. Data models and corresponding AAS for precast concrete parts will be created for the identified processes. The functionalities of the presented digital twin are demonstrated using the use case of quality control for a precast concrete wall element. The result shows how data can be exchanged with the digital twin and used for decision-making.

Prefabricated components offer advantages to the construction industry, such as low development and manufacturing costs, simple repair and assembly processes, and increased flexibility by allowing the building to be adapted to new requirements through a different combination of components. Especially in metropolitan areas, construction sites often significantly impede urban dynamics. With prefabricated components, the construction site area and construction time can be significantly reduced, thus minimizing the disruptive effects. Deconstruction or reconstruction is also easier and faster with components and allows flexibility and adaptability that cannot be guaranteed with conventional construction methods. Modularized construction can also be described as serial construction in which the components of the building are manufactured in series. This makes it possible to produce buildings in shorter construction times, but also in higher quality and, due to the economies of scale, in less expensive series production. A building is “broken down” into as many identical modular units as possible during factory planning. Accordingly, the aim of “industrial construction” is to advance the mechanization and partial automation of production processes in factories. As a result, it is possible to increase productivity and component quality in weatherproofed production conditions. All in all, this leads to a high level of process reliability, predictable planning effort, and easier cost control.

This holistic view of planning, production, and operating processes has been redesigned and significantly improved in recent years through the introduction of Industry 4.0 methods. Production in Industry 4.0 is interlinked with state-of-the-art information and communication technology. Rigid and firmly defined value chains are becoming flexible and dynamic. Globally networked value creation networks are emerging in digital ecosystems that enable new forms of cooperation and at the same time contribute to a climate-friendly and resource-conserving future. Data spaces are emerging that guarantee data sovereignty, security, and integrity and create the conditions for innovative products and business models. Industry 4.0 determines the entire life cycle of a product: from the idea to development, production, use and maintenance to recycling.

The digital twin is described as a key element for Industry 4.0 applications. In the course of a product’s lifecycle, various information sources, models, and tools become relevant. However, the flow of information within or between the individual lifecycle phases is currently often interrupted. For example, information from the maintenance phase cannot easily be fed back into the engineering phase to enable better tuning of a device’s parameters. This interrupted flow of information not only leads to a dispersion or even loss of information but also makes it difficult to access the right information. A digital twin acts as a container for integrating information from different sources at different lifecycle stages. The information it contains can be in different formats, come from different tools, and need not necessarily be stored in a central location. A digital twin helps reduce the effort required to access and manage information. The information contained in the digital twin can also be used to analyze the current performance of assets and derive design data for future systems.

In civil engineering, the focus of digital twins is often on the description of entire buildings or infrastructures. The digital twin is based on digital building models using Building Information Modeling (BIM). Subsequently, these models are linked to real data obtained with, for example, sensors. Aspects of the production of individual components or elements are not currently considered. In contrast, in the context of Industry 4.0, both components and machines are mapped using individual digital twins, which in turn can communicate with each other. The digital twins can change and expand in the course of their life cycle. Ultimately, there is no single digital twin but a dynamic network of twins. Even though the focus in this paper is on the creation of AAS as digital twins for concrete elements, the Reference architecture model Industrie 4.0 (RAMI4.0) as described in (Deutsches Institut für Normung e.V., 2016) defines an “Industrie 4.0 component” as the combination of a physical asset with its AAS. Those I4.0 components are tracked over their life cycle and offer services on different layers. The definition of I4.0 components is hierarchical in the sense of granularity, meaning that from the smallest I4.0 component up to the “connected world,” there is a strict hierarchy. In the case of production in mechanical engineering, those granularity levels are Product, Field Device, Control Device, Station, Work Center, Enterprise, and Connected World. The transfer of these concepts requires adjustment to the reality of civil engineering and can utilize the previous work of Sacks et al. (2020) or Mêda et al. (2021).

This paper shows how Industry 4.0 approaches can be transferred, further developed, and used for the production of precast elements in the construction industry. The concepts will be explained and evaluated using selected examples. The following research questions are to be answered:

• How can digital twins be set up during production for individual prefabricated elements?

• How can the various information for planning, production, and quality assurance be structured and dynamically linked?

• How can the individual information on prefabricated components be easily linked to form a digital twin for a building?

• How can components and machines exchange information and thus enable production control?

Following the introduction, State of the Art section gives an overview of the current state of digital twins and their applications in construction. In addition, Industry 4.0 and the administration shell are presented as an implementation of the digital twin in Industry 4.0. Concept section introduces the concept, including an analysis of the underlying processes, a description of the submodels of the administration shell, and an introduction to the description of the interaction and communication forms of the administration shell. Implementation section uses the example of a precast concrete wall to show how to create an administration shell for a specific precast module and host it on a server. Finally, the results are discussed in Discussion section, and conclusions are made in Conclusion section.

The following chapter will give an overview of the concept of digital twins and the current state of the art in the construction industry. Furthermore, a brief introduction to Industry 4.0 and its implementation of the digital twin, the Asset Administration Shell, is given. Lastly, recent research that addresses the adaptation of the administration shell in construction is presented.

The concept of the digital twin was first described during a lecture on “Product Lifecycle Management (PLM)” by Michael Grieves (2016) at the University of Michigan. NASA adopted the concepts for its next-generation aircrafts and published the first definition of a digital twin that is still widely used today: “A digital twin is an integrated multi-physics, multi-scale, probabilistic simulation of an as-built vehicle or system that uses the best available physical models, sensor updates, fleet history, etc., to represent the life of the corresponding flying twin.” (Tuegel et al., 2011; Glaessgen and Stargel, 2012). Since then, many industries have adopted the concept to their specific requirements, and various definitions have emerged so that no common definition and understanding of the concept exists. Some works are concerned with characterizing the digital twin and distinguishing it from other concepts such as a digital shadow or a digital model (Kritzinger et al., 2018; Jones et al., 2020; Sepasgozar, 2021). Kritzinger et al. (2018) categorize existing definitions and concepts of digital twins in the literature based on their degree of integration. They define a digital twin as a virtual representation with an automated bidirectional data flow with its respective physical twin. In contrast, they define a virtual representation with automated unidirectional data flow as a digital shadow and a digital representation without any form of automated data flow as a digital model. One of the first industries to exploit the potential of this disruptive technology was the manufacturing industry. In their work, Tao et al. (2018) describe a novel approach based on the digital twin concept for product design, manufacturing, and service, which aims to create a link between physical and virtual products, ultimately leading to greater efficiency, intelligence, and sustainability. The construction industry is still in the early stages of adapting the digital twin concept. In general, a digital twin in construction is understood to be a virtual representation of buildings, bridges, and other structures in the built environment that goes beyond a pure 3D model and is similar to definitions used in other industries. Boje et al. (2020) state that Building Information Modeling (BIM) provides procedures, technologies, and data schemas, while the digital twin conveys a more holistic socio-technical and process-oriented characterization by leveraging the synchronicity of cyber-physical bidirectional data flow. Furthermore, BIM does not have sufficient integration of control systems and sensor networks for which dynamic data exchange is essential. Boje et al. (2020) describe a digital twin consisting of three main components: a physical component, a virtual representation, and a data link connecting the two. To better understand the digital twin in construction, Davila Delgado and Oyedele (2021) analyze existing implementations of the digital twin of the manufacturing industry. They compare digital twins, cyber-physical systems, and BIM and categorize the implementations based on their structural and functional descriptions. Furthermore, the paper contributes to identifying key aspects and establishes a basis for developing specific concepts and process models for the implementation of digital twins in construction. Shahzad et al. (2022) also analyze the definition and characteristics of digital twins in construction and highlight interactions with other digital technologies and their applications and challenges in their literature review. Akanmu et al. (2021) discuss the use of digital twins in cyber-physical systems and propose use cases for improving productivity, health and safety, life cycle management of building systems, and employee competence, among others. They identify key technologies and challenges for implementing cyber-physical systems of the future in construction.

Opoku et al. (2021) provide a comprehensive overview of the current state of the digital twin. The number of publications directly related to the digital twin application in the construction industry has shown significant growth since 2018. Opoku et al. (2021) argue that the contextualization of the technology for construction is completed. Most of the analyzed papers focus on single phases of the lifecycle. Few concepts in the literature consider multiple lifecycle phases. In construction, the application of digital twins can be broken down into four areas of the life cycle of a building structure: 1) planning, 2) detailed design, 3) fabrication or construction, 4) operation and maintenance.

The use of digital twins on construction sites enables the networking and flexible provision of data for construction machines, workers, and processes. Work in this area uses Internet-of-Things methods and sensor networks to provide a database for informed decision-making. In their work, Hasan et al. (2021) discuss the operation of construction machines and the automatic recording of construction progress. As part of their work, they identify augmented reality and digital twins as key technologies for implementing these systems. Turner et al. (2021) identify industrial connectivity as a key technology to take advantage of other technologies such as advanced data analytics and artificial intelligence, robotics, or sensors. In addition, Turner et al. propose phased plans to implement Industry 4.0 technologies. Liu et al. (2021) identify hoisting building components on construction sites as the primary source of hazards and propose a digital twin for safety management. Their work contributes to improving the efficiency of information integration and dissemination, which eventually leads to effective decision-making. In their work, Zhang et al. (2022) propose a framework for using digital twins to enhance the level of detail in BIM for construction site management. For this purpose, they analyze and improve the functionality of digital twins in terms of digital representation based on BIM, the Internet of Things, data storage and analysis, and interactions with the physical environment. Hou et al. (2021) analyze the current state of integrating digital twin-based technologies to improve workplace health and safety. They conclude that the construction industry has not yet fully realized the potential of digital twins.

For the operational phase, several concepts have been proposed in the literature to improve the control and monitoring of a building through the use of digital twins combined with computer vision methods, sensor networks, and intelligent algorithms, ultimately leading to a higher level of comfort and safety for the users of intelligent structures. Lu et al. (2020) show that there are still few efficient strategies to collect data from assets that can help monitor, detect, record, and communicate operation and maintenance problems. They present an approach that combines the concept of a digital twin with advanced computer vision and artificial intelligence methods to detect anomalies in asset and building monitoring. Khajavi et al. (2019) present a method for setting up a sensor network to create a digital twin of a building. Furthermore, their paper discusses the application of the digital twin to reduce costs and increase comfort. Lydon et al. (2019) present simulation methods for thermal systems integrated into lightweight roof structures using a digital twin. Their approach uses models from the design phase, among others, to support the operational phase by linking operational data with design context data. Cognitive digital twins can recognize complex behavior and dynamically develop process optimization strategies and information-based decision-making. In their work, Yitmen et al. (2021) investigate the applicability, interoperability, and integrability of an adapted model of cognitive digital twins in building life cycle management, contributing to a better understanding of the impact of integrating cognitive digital twins, machine learning, cyber-physical systems, Big Data, artificial intelligence and the Internet of Things. Antonino et al. (2019) work augments BIM models with advanced image recognition using real-time data from camera systems to capture the occupancy of buildings.

Recent work is focused on the integration of blockchain technology into digital twins. Götz et al. (2020) investigate the applicability, interoperability, and integrability of a blockchain-based digital twin over the entire lifecycle of an asset. They conduct a literature review to identify use cases of the digital twin, blockchain technology, and other technology from the Industry 4.0 context. Jiang et al. (2021) use the unified standards and protocols of blockchain technology to improve information sharing and communication to counteract the fragmentation and discontinuity of information systems in construction. They propose a blockchain-enabled cyber-physical intelligent platform for modular integrated construction. Initial results show that it improves the traceability of cyber-physical construction progress, visualization, and evaluation of KPIs in real-time, as well as reliability, immutability, and transparency. Teisserenc and Sepasgozar (2021b) present a theoretical framework for implementing an environmentally sustainable blockchain-based digital twin for the construction industry. For this, they analyze the life cycle of buildings and collect necessary key data. Furthermore, they mention key factors and non-functional requirements necessary for this kind of digital twin. In another work Teisserenc and Sepasgozar (2021a), they propose an implementation of blockchain technology for digital twins to improve trust, security, efficiency, information management, and information sharing throughout the lifecycle of projects.

In some research, the digital twin is recognized as an excellent tool for data collection and analysis for sustainability assessments of the built environment. Kaewunruen and Lian (2019) created and analyzed a 6D BIM as a digital twin for the life cycle management of railway turnout systems. The digital twin of the turnout consists of schedule, cost, and sustainability data throughout the life cycle. Their approach enables economic, management, and sustainability assessment and shows that material emissions during the manufacturing phase are the most significant contributor to the carbon footprint, and the rebuild phase is the most expensive phase of the life cycle. Tagliabue et al. (2021) propose a framework for moving from a static to a digital twin and an Internet of Things-based dynamic approach for sustainability assessment. The framework enables real-time assessment and control of various user-centric sustainability criteria. The presented methodology is the basis for supporting decision-making processes related to sustainability criteria throughout the life cycle.

Various works deal with the application of the digital twin concept for prefabrication. Current work particularly addresses accuracy in both design and fabrication of precast components. Rausch et al. (2021) identify geometric conformance as essential for the construction site’s trouble-free assembly and structural integrity of prefabricated components. They present a framework for geometric digital twins based on 3D scans to detect assembly and other potential problems that may arise. He et al. (2021) propose in their work a BIM-based approach to support the detailed design and digital fabrication. The developed tool can create more accurate geometric models for production. Simulation of the tool path in 3D printing demonstrates its applicability to digital manufacturing. The research of Tran et al. (2021) is concerned with the quality assurance of finished parts. Tran et al. developed a digital twin-based approach to capture the geometric quality of prefabricated facade elements. The framework performs automated matching between 3D as-designed and 3D as-built data based on a LIDAR point cloud. Some works address digital twin-based precast supply chain improvement. Zhong et al. (2017) present a platform that combines Internet-of-Things with BIM approaches to provide real-time visibility, traceability, and advanced decision-making throughout the process. Lee and Lee (2021) developed a digital twin framework based on building data modeling, IoT sensors, and GIS to enable real-time logistics monitoring and simulation of supply chain processes in precast construction.

Industry 4.0 is characterized by the infusion of information and communication technology innovations into the industry’s products, services, production processes, and organizational structures (Monostori et al., 2016) (Monostori, 2014). The characteristics of Smart Products (SP) were defined by committees such as the International Academy of Production Engineering (CIRP) (Abramovici and Stark, 2013), the German Electrical and Electronic Manufacturers’ Association (ZVEI - Zentralverband Elektrotechnik und Elektronikindustrie e. V., 2016), and the American Initiative IIC (Industrial Internet Consortium). Likewise, Cyber-Physical Production Systems (CPPS) open new opportunities for a paradigm shift in production towards a flexible lot size one production (Biffl et al., 2017).

International standards for interaction models and architectures also provide frameworks for standardizing the global movements of research projects in the field of digitization (Monostori, 2014). Examples include the German reference architecture model industry 4.0 (RAMI 4.0) or the American IIRA (Industrial Internet Reference Architecture).

The introduction of a uniform digital representation for each type of (smart) product is a necessity for the desired level of interoperability in Industry 4.0. This can be accomplished using the asset administration shell model from the Reference Architecture Model Industry 4.0 (RAMI 4.0) (Plattform Industrie 4.0, 2016; Deutsches Institut für Normung e.V., 2016). In RAMI 4.0, each so-called asset is developed, created, used, and disposed of, and is thus subject to a life cycle that follows industry standards. Regardless of whether it is a physical product, a software component, or a service, an asset is a tangible or intangible entity with value for the business. The data describing an asset is digitally stored in the accompanying asset administration shell (AAS) and made available for human-machine and machine-machine communication, resulting in an Industry 4.0 component as the fixed combination of an asset and its AAS (Plattform Industrie 4.0, 2016). By combining I4.0 components, a new I4.0 component is created in each case: a new asset with its AAS. This creates a recursive asset description that can reach any level of granularity, from simple semi-finished products to manufacturing plants. The concept of I4.0 components serves as the basis for introducing Industry 4.0 based on smart products (Plattform Industrie 4.0, 2017; Roth, 2016). To design smart products, current research efforts are moving towards new holistic development methods, such as smart engineering (Abramovici, 2017) or smart systems engineering (Gausemeier, 2014). The literature review by Kritzinger et al. (2018) highlights the different understandings, definitions, and concepts surrounding digital representations. The Digital Twin in the context of Industry 4.0 is a fully integrated digital depiction of a physical product, in which changes in the information world cause changes in the physical world and vice versa (Kritzinger et al., 2018). This fully integrated digital representation is referred to as the AAS in RAMI 4.0.

The structure of the AAS is based on a technology-neutral metamodel specified using the Unified Modeling Language (UML). It consists of a header in which information on identification and a designation of the asset are stored and a body in which data and information on various aspects and use cases are stored in a large number of independent submodels. As a result, the AAS is a modular structure of submodels that together comprise the digital representation of the asset rather than a single, all-encompassing model. Each submodel has its semantic description as well as a distinct identification. The separate definition of submodels offers several advantages, including the ability to generate content in parallel and to continuously grow, as well as the fact that it is reusable. A distinction is made between the type and instances of assets, submodels, or features. The data and information for a component family are stored in a type AAS. At the start of production, component-specific data is stored in an instance AAS (Boss et al., 2019; Boss et al., 2020). To ensure a standardized exchange of information throughout the lifecycle, the goal is to create a standardized template for each submodel (Plattform Industrie 4.0, 2020a).

AAS’s exist in three different implementation forms, which differ in their data exchange and communication capabilities. Type 1 is a passive AAS in file format enabling standardized information exchange across life cycle phases. Direct communication is not possible. Type 2 is a server-based AAS that provides its contents via an API. Similar to type 2, type 3 is a server-based AAS but, unlike type 2, can actively and independently initiate interactions with other I4.0 components for data and information exchange. The data exchange or communication between the components is implemented via a specific I4.0 language (Plattform Industrie 4.0, 2021b). Different data formats are required in communication protocols or information models depending on the lifecycle phase and application. In order to ensure interoperability as well as data exchange functionality over the entire life cycle, schemas for serialization in XML and JSON format exist. Mappings to standard data formats such as OPC UA, RDF, or AutomationML are also possible. For information exchange with offline AAS’s, there is also a package format that, in addition to serializing the AAS in XML or JSON format, also contains the content referenced in the AAS, such as PDF-files (Plattform Industrie 4.0, 2020a; Plattform Industrie 4.0, 2021b). Properties, element collections, or files are examples of submodel elements that describe the state or behavior of an asset. Assets can have defined capabilities, allowing for asset searches based on functions (Plattform Industrie 4.0, 2020a). Existing standards, such as ECLASS, can be referenced by a SemanticID (Plattform Industrie 4.0, 2020b).

In addition to the officical specification of the AAS, various other publications exist adressing the AAS. The terms, concepts, and the vision of the AAS and the Digital Twin are compared along a plant’s lifecycle resulting in a holistic version of a Digital Twin that equals an AAS (Wagner et al., 2017). To better understand the AAS, Ye and Hong (2019) created an AAS of a manufacturing line for demonstration purposes. The authors also describe the AAS benefits and provide implementation recommendations. The potentials of implementing the AAS with a given standard for cyber-physical systems are presented together with different possible business models and communication technologies (Tantik and Anderl, 2017).

Many publications are focusing on integrating existing standards into the AAS. Grangel-Gonzales et al. (2016) showed that structured information in the AAS based on RDF can be easily accessed with URI-based identification to achieve loss-free communication and interoperability. This simplifies the integration of existing standards like eClass. Focusing on the communication technologies, a first framework for describing interactions and exchanging information exchange between multiple AAS’s with the oneM2M standard is implemented by Willner et al. (2017). To increase the interoperability, Fuchs et al. (2019) showed how a semantic description of an asset based-on an OPC UA information model could be translated into the AAS information model without losing information. Other publications are focusing on implementations using the AAS concept. Toro et al. (2020) show how AAS’s can be implemented in mini-factories and proved their concept with a case study demonstrating the possible capabilities of Industry 4.0. A capability-based engineering methodology based on AAS was introduced by Huang et al. (2021). The methodology consists of the phases, capability checking, feasibility checking, and the final skill execution. Also, in the context of capability-based production, Motsch et al. (2021) presented a prototypical implementation of an energy-related submodel with BaSyx-Middleware.

The first research works deal with the adaptation of the administration shell in the construction industry. Wolf et al. (2021) present the first approach to applying the administration shell as a digital twin and thus extend current BIM approaches by a cyber-physical component. Their work describes requirements, contents, and interactions based on the use case of quality control for precast concrete parts. Similar to other areas of civil engineering, the information management of bridges is fragmented and discontinuous in the life phases of planning, construction supervision, and execution. Braml et al. (2022) developed a digital twin based on the AAS, which focuses on the physical engineering model. The digital twin captures the bridge structure holistically over their entire lifetime and provides a data basis for AI-based analyses.

Digital twins can fundamentally improve the design, automated production, installation, and maintenance of building components in the construction industry. Current concepts tend to follow central and not very flexible modeling, storage, and exchange of relevant information for the life cycle of a component. This paper presents a decentralized and extensible digital twin for the industrialization of precast concrete production applying Industry 4.0 approaches. If end-to-end and interlinked digital models are available, precast production can be better controlled and made more efficient. Together with other Industry 4.0 components, cyber-physical production systems (CPPS) can be built to support the automation in the industry construction. Various information is already provided via Building Information Modeling approaches. Therefore, suitable approaches for linking Industry 4.0 and Building Information Modeling must also be developed. This paper focuses on the fundamental concepts to build digital twins to introduce CPPS for the production of precast concrete elements. The following aspects are analyzed and elaborated in detail (cf. Figure 1):

• Identification of relevant production processes and associated information requirements for precast concrete elements

• Integration of existing and development of additional data models for the identified processes as well as their Industry 4.0 compliant description

• Elaboration and support of the communication between precast elements and machines for the establishment of CPPSs

For the development of digital twins for the production of precast elements, it is essential to consider the whole production system, including the machines and processes. The production of precast concrete elements generally includes forming, reinforcing, concreting, stripping and curing, and quality assurance. All relevant data and the status of the precast part must be continuously recorded, compiled, and made available for these processes.

An essential requirement for a digital twin is a connection to its physical counterpart, which enables communication to exchange data and information and access to the functions of the digital twin. Data from sensors, control commands, and machine parameters are transmitted for automatic production. For some use cases, data exchange must take place in real-time. Therefore, the data structure must be extensible to allow new data and information to be added throughout the lifecycle.

The digital twin of a precast concrete component contains information about the component (e.g., material or dimensions) as well as information about the production process or required qualities. In this way, the digital twin can, for example, initiate contact with the reinforcement bar bending and welding machine and transmit all the necessary machine parameters. During the production of the reinforcement, the machine’s digital twin transmits the status of the process step in real-time and, when the process step is completed, transmits a log back to the digital twin of the precast element as manufacturing feedback. In addition, the digital twin of the precast element knows its position in the building structure and neighboring components.

The concept of the AAS of Industry 4.0 is used to build the digital twin. General structures for identifying and describing precast concrete elements can be adopted directly. However, AAS only provides a framework that must be structured in a problemspecific manner. Therefore, the relevant submodels must be identified and specified for precast concrete elements. Furthermore, approaches for the interaction with other digital twins, respectively AAS components, must be developed. The focus of this paper lies mainly on the submodels for the support of the production processes with an emphasis on quality assurance.

For example, a submodel modeling the aspect of quality assurance would have to enable a target/actual comparison between design and measured data in the context of production. Different data structures are required for such questions. However, the submodels must be linked semantically to enable a uniform query.

This paper considers the individual steps required to produce precast concrete elements in a flow manufacturing process. Process analysis is used to identify the requirements for the digital twin in the form of the administration shell and its submodels. The starting point for the analysis is the completed detailed design of a precast concrete part. Information about the dimensions, material, and quality specification, as well as tolerances and fabrication instructions, are provided by corresponding submodels and external data sources (e.g., BIM models). In addition, all relevant data and information must be modeled for each production step, including the construction of the formwork, insertion of the reinforcement, concreting, and removal of formwork from the finished element (cf. Figure 2). In order to keep formwork times as low as possible, it is sensible in a flow manufacturing process to additionally cure elements using heat treatment. After each completed production step, quality control is carried out, for example, by visual procedures that check the position of the reinforcement and the formwork to ensure quality. At the end of the manufacturing process, the nominal and actual dimensions of the components are checked and compared with tolerances in final quality control.

For the automation of the production processes, the data and information must be made available. Furthermore, both data transmitted back from the production processes and the results of the quality controls must be stored and made available for further analyses. Submodels are defined below for essential use cases. Other submodels can be created analogously to this procedure and added to the administration shell.

Submodels have already been developed and standardized for some use cases. These include submodels for identifying an asset, providing technical data and information, and documentation. It is sensible to base administration shell developments on standards and add use case-specific submodels. The submodels described below are a sound basis for developing administration shells. They are also consistent with the concepts and principles defined in DIN EN 17412-1 (Deutsches Institut für Normung e.V., 2021a) for determining the level of information need, which is described in the sense of geometric and alphanumeric information and documentation. Different applications have different data needs reflected in the administration shell through different submodels.

Submodel Identification: The Identification submodel was developed for the unique identification of an asset and for retrieving the asset via its characteristics (Plattform Industrie 4.0, 2020b). The prerequisite for communication between two I4.0 components is the unique identification of both components. For this purpose, the submodel contains machine-readable features that serve the identification. The unique machine-readable features would first be exchanged to initiate communication before querying additional human-readable features in the intended use case.

Submodel Technical Data: The submodel Technical Data provides an interoperable asset description based on technical properties. In the intended use case, the submodel describes an asset based on technical data that other actors can clearly understand, such as market participants or operators of industrial plants (Plattform Industrie 4.0, 2020b). The submodel provides a base set of submodel elements that provide the required information for this use case. For the application in the construction industry, the submodel has general information about the manufacturer and technical data such as main dimensions, exposure classes, or reinforcement volume ratio of the component.

Submodel Documentation: The Documentation submodel developed for the process industry was developed for the interoperable provision of information from manufacturers to operators of industrial plants (Plattform Industrie 4.0, 2020b). The submodel defines standardized metadata and classification for documents. The stored documents include, for example, construction, installation, or maintenance instructions. The intended use case in construction includes technical documents such as reinforcement and formwork plans, transport and assembly instructions, and delivery bills.

The following chapters will discuss unique and new submodels of precast concrete elements, including general information of the detailed design such as dimensions, material, or BIM models. Furthermore, the submodels for production and final quality control will be addressed.

For the automation of the production process with the proposed methodology, other assets also need to be represented by digital twins or AAS, including, e.g., machines or other reusable resources such as formwork elements. The AAS of a production system is outside the scope of this paper. Crucial for realizing a cyber-physical production system is a communication among the participants. Therefore, at the end of this chapter, communication possibilities and paths relevant for precast concrete elements are described.

Domain experts can only create the concrete contents of the submodels. Submodels should be continuously reviewed, updated, and, if possible, standardized. Established norms and standards provide a sound basis for the development of submodels. For precast concrete elements, these are essentially DIN EN 206 (Deutsches Institut für Normung e.V., 2021b), which specifies requirements for concrete, DIN 488 (Deutsches Institut für Normung e.V., 2009a) (Deutsches Institut für Normung e.V., 2009b), which specifies requirements for reinforcement steel and DIN EN 13369 (Deutsches Institut für Normung e.V., 2018), which specifies general requirements for precast concrete elements, as well as various product standards that contain the specific requirements for different precast concrete element types. Furthermore, similar to submodels, ontologies represent the knowledge of a specific domain. Ontologies are therefore also an excellent basis for creating submodels for AAS.

Today, Building Information Modeling offers many advantages for the planning of precast concrete elements. Detailed models, for example, also provide added value in the bidding phase through simple quantity takeoff. Thanks to intuitive tools, any structure can be modeled with the highest level of detail and the data can be exchanged based on open standards (Industry Foundation Classes). BIM models help all parties involved understand design and planning and improve collaboration between the planning and design office, production, and the construction site.

Generally, a distinction must be made between geometric and semantic information for detailed design. For the submodel, the geometry of the entire precast concrete element, including the reinforcement, is mapped based on the Industry Foundation Classes (IFC). The Detailed Design submodel contains a link to an IFC file that includes all the information of the geometry. GUIDs (Globally Unique Identifiers) of the individual IFC objects (e.g., complete precast element, individual reinforcement elements) are used for this connection. In the Detailed Design submodel, the geometry is only stored in a simplified form by means of general dimensions (e.g. width, height, and depth). The specific geometry must be determined via the IFC file.

Semantic information, especially about the material, is already stored in IFC models. However, there is no comprehensive standardization of individual material parameters. Although there is an initial standardization through IFC4Precast, many material parameters are still not included. Therefore, storing the material parameters directly in the Detailed Design submodel is sensible. For this purpose, a separate ontology has been developed. The ontology thus includes different information besides the concrete type, such as exposure class, design class, or chloride class. Furthermore, information on the cement content includes a detailed description of the cement used.

In addition to these properties, information on the mechanical properties of the material is also stored. In the previous chapter, it was mentioned that details about the reinforcement also have to be stored in the asset administration shell. This information is also assigned to this submodel. Consequently, the submodel must include several element collections. The first collection contains the details on the composition and properties of the material and the components described above. In another collection, the reinforcement is described in detail. Mechanical properties and geometric characteristics are recorded as well as information on strength classes or reinforcement types. It is also possible to insert a reference to eClass, where many properties are precisely specified.

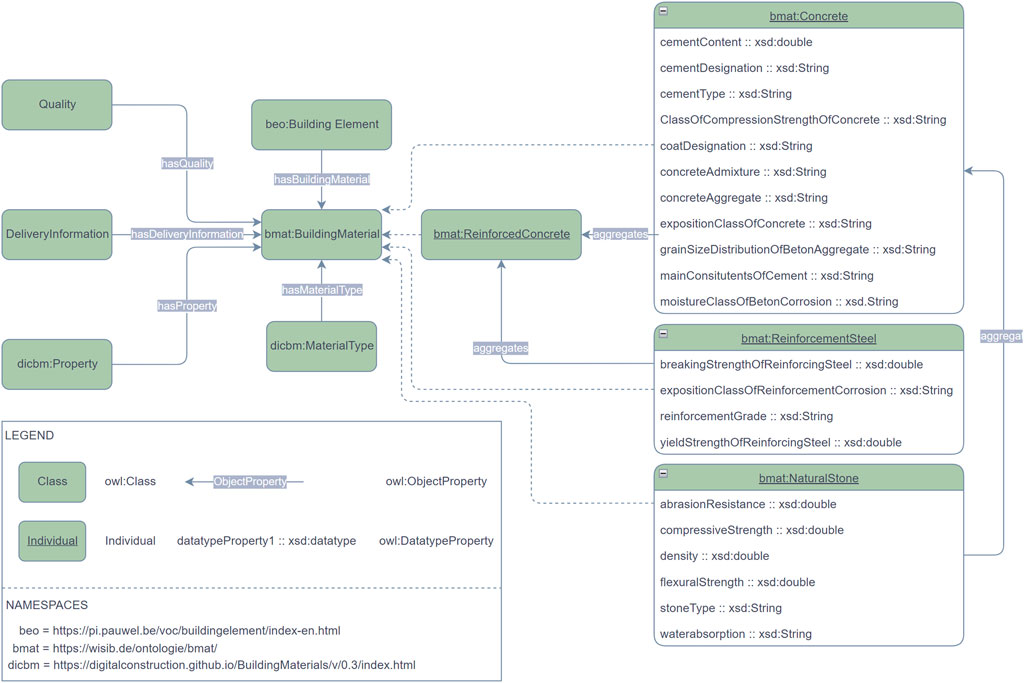

The “Digital Construction - Building Materials Ontology” (dicbm) and “The Building Material Ontology” (bmat) are suitable as a basis for the development of material information for this submodel (Karlapudi and Valluru, 2019; Hamdan, 2021). Both ontologies define the necessary relationships between components, materials, and their respective properties. Figure 3 shows the metamodel of the ontology created by combining both ontologies. The aspects of quality and delivery are not addressed by either ontology but are important for manufacturing precast elements with flow manufacturing methods and are therefore added.

FIGURE 3. Metamodel for the Ontology of the Material Submodel based on the Building Material Ontology (bmat) and Digital Construction - BuildingMaterials Ontology (dicbm).

The main class of the ontology is Building Material from the bmat ontology, which represents a building material and can be assigned to a building element via the object property has Building Material. The representation of a building element is done by the Building Element Ontology (Pauwels), which can be used to define common building elements based on the IFC class Ifc Building Element. Furthermore, the Material Type and Property classes of the dicbm ontology are children of the main class. The Material Type class allows a classification of the material into different material types, and the Property class is used to define the properties of the materials. Delivery Information and Quality classes are added to represent the aspects of delivery information and material quality.

The purpose of the Quality Control submodel is the interoperable provision of information required to ensure the quality of precast concrete elements. The focus here is particularly on the provision of

• quality requirements based on standards and regulations,

• machine parameters for quality assurance, and

• measurement and evaluation results.

The intended use case is that the quality assurance process is unambiguous and understood for the used devices and machines. In this submodel, the quality requirements for the tolerances of the produced precast element are compiled and made available for evaluation. All data for the configuration of the devices and machines can be retrieved and transferred. In addition, the results recorded during the process are stored for evaluation considering the specified tolerances. The evaluation result is documented accordingly and is the basis for further decisions.

The Construction Quality Inspection and Evaluation Ontology (CQIE) developed by Zhong et al. (2012) is suitable for developing the contents of the Quality Control submodel. The CQIE ontology was developed to define the essential concepts and relationships in construction quality inspection. In the context of this work, the ontology was extended to include the aspect of equipment and machinery used. Figure 4 shows the augmented metamodel of the CQIE ontology based on Zhong et al. (2012).

FIGURE 4. Metamodel for the Ontology of the Quality Control Submodel based on Zhong et al. (2012).

The ontology consists of the main class Inspection-Task, subordinated by the Inspection-Object, Inspection-Checking-Action, Evaluation-Task, and Regulation-Constraint classes. Through the Inspection-Object class, all entities are defined that are regulated by regulations and must undergo a quality assurance procedure. The quality data and information to be collected are compiled in the Inspection-Checking-Action class and have a Checking-Result that represents the actual inspection result. The result can be recorded, for example, in the form of length, angle, and flatness deviations. These deviations originate from the evaluation of the target/actual comparison of the component, which, in the case of a laser scan, for example, is done by superimposing the point cloud with the geometry of the component stored as a BIM-Model. To compare the inspection results with the regulations, the Inspection-Task class has the Evaluation-Task class, consisting of Evaluation-Criteria and Evaluation-Result, which model the comparison and the result of the comparison, respectively. The Regulation-Constraint class represents the regulations and standards that contain the corresponding tolerances and requirements. For example, the tolerance is shown here, analogous to the length, angle, and flatness deviations. In addition, all required parameters, such as machine or geometric parameters, are represented by the Parameters class. The devices and machines used, including laser or CT scanners, are represented by the Inspection-Device class, extending the CQIE ontology. Parameters necessary for the configuration of the devices are assigned to this class.

The purpose of the Production submodel is the interoperable provision of information required for production and interaction within the production system. The focus here is on

• the provision of parameters for the production machines,

• the logging of production processes and live data monitoring, and

• the compilation of the required equipment and resources.

The intended use case is that the process steps are described unambiguously and comprehensibly for all elements of the production system as well as the users so that the necessary process steps can be initiated, configured, and controlled through the exchange of information. Data needed to optimize production is collected in this submodel and made available for evaluation.

Although several ontologies can be found in the literature that model production systems also concerning Industry 4.0, none met the specific requirements for modeling the production of precast concrete elements. Instead, an ontology was developed for the Production submodel, whose metamodel is shown in Figure 5. The ontology presented is intended to define the general concepts and relationships associated with precast concrete products, including production steps, equipment, and machine parameters.

The main class of this ontology is the Production-Task class and represents the entire production process for which data concerning the status and date of production are collected. Subordinate to this class are other classes, Building-Element, Item-Production-Action, and Production-Process. The class Building Element originates from the Building Element Ontology (Pauwels, 2020) and defines all common building elements based on the IFC subtree Ifc Building Element. The Item-Production-Action class compiles the production steps required to produce the finished part. The Production-Result class represents the result of the production steps. The production processes are defined by the Production-Process class, which in turn consists of

• the Production-Machine class, which represents the required production machines and provides machine parameters for them,

• the Production-Equipment class, which represents the equipment and resources required for production, including formwork and reinforcement, and

• the Process-Data class, which provides all live data that can be retrieved during production.

Production processes include reinforcement, forming, concreting, and curing. Data regarding the start and end times are collected for evaluation of each of these processes.

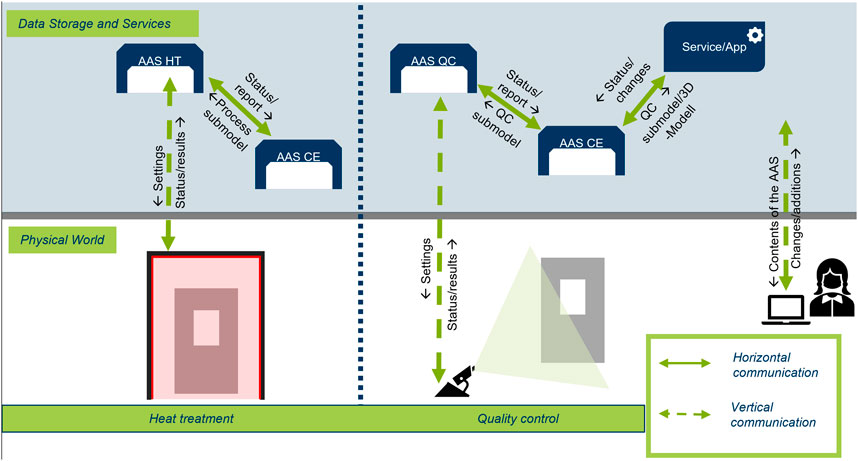

In order to enable a largely self-organized and self-controlled production, communication and interaction possibilities must be available for data exchange with humans, machines, and other precast elements represented by AAS. For this purpose, communication options should be defined to retrieve, modify and delete certain contents of the submodels. The communication possibilities can be divided into machine-to-human (m2h) and machine-to-machine (m2m) communication and further subdivided into horizontal and vertical communication. For a better understanding, the possible communication types are explained based on the production processes presented in Process Analysis section, namely curing and quality control (cf. Figure 6).

FIGURE 6. Communication scheme using the example of the heat treatment and quality control process steps.

The machine-to-machine communication takes place in the virtual world. It is the horizontal communication between two or more AAS. In the highlighted production process, several possibilities for horizontal communication exists. The AAS of the precast concrete element (AAS CE) can communicate with the AAS of the heat treatment system (AAS HT) or with the AAS of the quality control system based on laser scanning (AAS QC). The submodel Production is relevant for the communication between the AAS HT and AAS CE. In this submodel, all necessary data for the heat treatment are stored. Therefore, this information is sent from the AAS CE to the AAS HT. In the other direction, a log file is sent after completion of the heat treatment, which is then stored in the Production submodel of the AAS CE. The preceding process steps run according to the same principle. For concreting, for example, the data from the Detailed Design submodel are transmitted together with the process parameters from the Production submodel. Not all data stored in the AAS CE are transmitted, just the data required for the specific production step.

The communication between the AAS CE and the AAS QC is similar, but here several submodels are relevant in the AAS CE. First of all, the required process parameters are stored in the submodel Quality Control. These are sent to the AAS QC. After the execution, in this case, for example, a laser scan, the inspection date, and a point cloud are sent back to the AAS CE. The target and actual values must be accessed to compare measured and planned values. For this purpose, the data from the AAS CE are obtained. In particular, on the one hand, the actual data from the Quality Control submodel where the permissible tolerances that are also required are located, and, on the other hand, from detailed design. Thus, the target data in the form of a 3D file are retrieved from a service and evaluated. The results are then stored in the Quality Control submodel in the form of a status describing the module’s state. Consequently, the m2m-communication in the virtual world can be used to exchange data between two or more AAS’s, or it can be used by a service that accesses the data from AAS’s and processes them as desired.

Besides m2m-communication in the virtual world, it is also possible to communicate between the virtual and the real world. The communication can be explained here by the AAS QC and the physical quality control system. The AAS QC has received the required settings for quality control from the AAS CE. These are now transmitted to the system to perform quality control. Afterward, the AAS CQ receives the data from the quality control and can forward them to the AAS CE as described above.

The communication between the precast concrete element and its AAS is different in comparison. First of all, a simple concrete element is not able to communicate. This can change if, for example, sensors are installed in the element. These elements then provide information about specific values. Each precast element gets its own ID-Tag (e.g., barcode, RFID). The tag is linked to the AAS CE, therefore, scanning the tag will show the information stored in the element’s AAS. However, there is no direct communication between the concrete element and its AAS. All information regarding the status of the concrete element comes from systems and their AAS’s involved in the production process.

Lastly, in addition to machine-to-machine communication, human-to-machine communication is possible. To monitor production, the content of all AAS must be retrievable and essential information must be displayed (cf. Figure 6). Dashboards can be used to visualize key performance indicators (KPIs) and the production status of the concrete element. With the dashboard, the user can read data, send commands to the AAS, and overwrite process parameters stored in the AAS.

The communication possibilities shown above indicate that implementing the presented concept with the AAS would offer a lot of potential for fully digitalized and automated production.

A prerequisite for applying the proposed submodels in their domain is an appropriate source for data and information. Standards, guidelines, and other digital models are preferred sources for the needed data, whereas BIM models are particularly suitable for their semantic information about each modeled component. An extension of the approach by other sources, such as eClass, is planned for future work. As a demonstration scenario, the focus is on the quality control after production of a precast concrete wall element, depicted in Figure 7.

The example precast wall element is 5 m wide, 4 m high, and 0.2 m deep. At the height of 1.5 m and a distance of 0.9 m from the left edge of the wall, there is a 1.20 m high and 0.68 m wide window opening. The digital model of the component, which is available in IFC data format, contains semantic information regarding material, reinforcement, and geometry. The proposed steps for creating AAS consist of templating, instantiation, finalization, and deployment. After that, a web-based application can access, update, and validate the quality control data.

The authors’ general template for an AAS of a precast concrete element consists of the standard submodels used for identification and the proposed construction-specific submodels, which describe all relevant characteristics of the precast concrete elements. Although the general submodel structure is the same for all concrete elements in a precast process, the data structures, and contents of the submodels are not necessarily identical. The characteristics of the submodels vary, for example, depending on the materials used or the layout of reinforcement selected. In addition, the submodels describing the production and quality assessment process vary according to the process steps and technology used. The resulting AAS templates for specific detailed designs are stored on a server in a database or repository so that, due to the semantic searchability of the AAS’s, components can be found based on the properties and characteristics defined in the AAS. The AASX Package Explorer is used to create the AAS templates. The AASX Package Explorer is a software tool with a graphical user interface designed for modeling and manipulating AAS, with export options in XML and JSON formats and the native AASX format (Plattform Industrie 4.0, 2021a).

The templates developed in the previous step are loaded into the AASX Package Explorer to add all required components or instance-specific data. Data needed for the instantiation can be taken from external sources, which enables the automation of the instantiation process. The authors implemented a Java-based software tool for the automated instantiation of the AAS based on data and information from an IFC file and using the aforementioned templates.

In the scenario at hand, the implementation is done using off-the-shelf components of the BaSyx middleware as type 2 AAS’s with API-based access. With this server implementation, the AAS and its submodels are made available and accessible. The standard Rest-API can now be used to query, change, and add AAS, submodels, or individual properties’ values. For example, the Quality Control submodel can be queried via a GET request as depicted in Figure 8.

The content of the submodel is then returned as the response. A PUT request can then be used to add or change submodels, properties, or set values for a specific property (Ziesche, 2021). The following use cases make use of this server implementation.

The first part of the proof of concept is the instantiated submodel for the detailed design of the aforementioned concrete wall element. Figure 9 shows the Detailed Design submodel based on the requirements and content described in the concept by ontologies. The submodel essentially consists of the two areas, Dimensions and Material, represented by submodel element collections (SMC). In addition, the submodel contains a reference to an IFC file of the component.

The Dimensions section contains general dimensions of the part that define a virtual bounding box by the characteristics of width, height, and depth around the part.

The Material section contains data and information on each material used in the component. The area is subdivided into two additional SMCs representing Concrete and Reinforcement Steel in the present case. The development of further SMCs to represent new materials is the scope of future work.

The Concrete SMC contains basic information regarding the concrete type, strength class, classification into exposure, chloride, design, and consistency classes. Furthermore, information and quantities on the cement, aggregate, additives, and admixtures used can be found. Information on mechanical properties and delivery information are also included. The used cement and aggregate information are stored in one SMC each. The cement used is described by type, strength class, and information about the supplier of the cement. The information on the aggregate includes various properties for classifying the aggregate, such as grading curve or platitude index, and information on the supplier.

The Reinforcement Steel SMC has product form and standard information, ductility class, and design class. Mechanical, welding, and delivery information are listed in separate SMCs. For example, the mechanical properties include data on yield strength, modulus of elasticity, and density of the steel. The SMC relating to welding properties gives information on the proportions of carbon, phosphorus, nitrogen, sulfur, or copper, details essential for weldability. Delivery information is given analogously to the SMC already described for concrete.

The submodel shown in Figure 9 contains data and information for a C30/37 concrete and B500A rebar. All defined properties have a concept description. The right part of the figure shows an example of the feature Cube Compressive Strength, which has a unique ID and Concept Description. The concept description includes a definition and definition source of the characteristic, an indication of the physical unit, and a formula symbol. Alternatively, a reference to an external repository such as eClass could also be made here.

Figure 10 shows the submodel for quality control. It consists of Process, Requirements, and Results, each represented by an SMC. In addition, the submodel contains the Status feature, which represents the evaluation result of the quality control. The required tolerance values were taken from the DIN 18203-1 (Deutsches Institut für Normung e.V., 1997) standard, which has been withdrawn as such but still represents the current state of the art and is used in practice.

The SMC Process contains essentially all the parameters required for configuring the quality assurance system and executing the process. In the context of the presented use case, all required parameters for a laser scan are provided in another SMC Laser Scanning, which in turn is subdivided into further SMCs

• System Requirements, which lists technical requirements for the quality assurance system,

• Laser Scanner, which contains information about the selected scanner,

• Legs, which contains the position and configurations for the individual measurement runs, and

• Advanced, which enables advanced configurations of the laser scanner.

The InspectionDate feature documents the inspection date.

The SMC Requirements contain requirements placed on the component and must be verified by the quality assurance process. In this case study, a virtual laser scan is performed to verify the part’s dimensions. Included are features that represent the width, height, and depth tolerances and tolerances for flatness and angular deviations. The tolerances were taken from the relevant standards and regulations. Additional requirements can be added for other quality assurance procedures, such as CT scans.

The SMC Results contain the measurement results of the quality assurance procedure. Analogous to SMC Requirements, the collection contains measured length, width, height, flatness, and angle deviations. In addition, there is a reference to raw measurement data, such as a point cloud in the demonstrated case.

Due to the inherent characteristic of a digital model to have the exact nominal geometry, an additional model was created that has an imperfection of 0.01 m for demonstration purposes, which was evenly applied to the length dimensions of the wall. The virtual laser scan is created for the 3D model with the artificial imperfection and corresponds to the actual state of the component, which is compared with the nominal state in the form of the model without imperfection in the course of quality assurance. The Helios++ software was used to create the virtual laser scan. The framework can generate 3-D point clouds based on LiDAR (Light Detection And Ranging) simulations and includes pre-configured models for various static and dynamic platforms, such as tripod or quadrocopter, and various scanner systems. The models can be extended to implement additional platforms and systems (Bechtold and Höfle, 2016; Winiwarter et al., 2022). Figure 11 shows the point cloud for the wall element.

By superimposing the point cloud and the 3D model of the wall, which is stored in the AAS, deviations can be determined. In this case, the distance between the actual geometry determined from the 3D point cloud and the nominal geometry from the 3D model was measured.

A GUI was developed so that content can be retrieved from the AAS and values, such as the measured deviations, can be fed back into the AAS or corresponding services. The GUI is depicted in Figure 12. To explain the GUI and its functionality, the sequence diagram in Figure 13 is presented to show the process behind the GUI. The quality control process involves the user, the GUI, BaSyx with all AAS’s, the AAS of the specific wall element, the Quality Control submodel, and validation service to compare the tolerances with the measured values. If the user initializes the quality control for Concrete Element #123, BaSyx is addressed via the GUI. In BaSyx, the AAS of element #123 must then be used to transfer the tolerances for width, height, and depth stored in the Quality Control submodel back to the GUI. These are displayed under “max. tolerances.” To perform a quality check, the actual deviations must also be entered in the “new_value” field in the GUI. The entered values are then transmitted to the Quality Control submodel and stored there. In the GUI, the entered values are then displayed under the current value as soon as they are stored in the AAS. To compare deviations and tolerances, which can be triggered via the button in the GUI at quality check, a validation service accesses the GUI and compares the two values. The result, in this case, either within or out of tolerance, is then transmitted to the GUI and displayed.

The case studies show that the concept of the AAS can be implemented for both singular property collections such as material, as well as the QC process of a concrete wall element. An external application, in this case, the web-based GUI, can access the contents of the AAS. The process results can then be stored in the AAS’s concerning submodel. Even though the use case is a relatively simple scenario where only a few properties of the whole AAS are accessed, the models can be extended as needed for future applications.

Most precast concrete elements are currently produced in a handcrafted manufacturing process. The basis for the automation of these analog processes is digitization. Data that accumulates during the manufacturing process must be collected, processed, and analyzed to steer production processes and enable adaptation and optimization of the production. Therefore, the end-to-end digitalization and networking of all processes and stakeholders in production are essential for automating the production of precast concrete elements. For optimized production of precast concrete elements, which have a high degree of individualization, it is essential to implement smart capabilities, such as networking and communication, so that the components can independently find their optimal path through the factory and production processes. Current Building Information Modeling (BIM) approaches provide all necessary information and data of the elements themselves on a type-level but are not suitable to independently exchange data with other actors of the production process on an instance level. This paper presents an approach to solve this problem based on developing a digital twin for precast concrete elements, which can then be manufactured in a fully networked and digitized production process. The central aspect in the development of the digital twin was to allow the twin to carry and exchange data and information with other actors in the production system independently and in a self-organized manner, in this case, in the process step of quality control. Due to data processing, communication, and interaction capabilities, the presented approach extends existing BIM approaches after the detailed design phase. It connects the information via the digital twin to the production of precast concrete elements within cyber-physical production systems with a higher degree of automation and flexibility.

This work developed a concept for implementing digital twins based on the AAS concept developed by the German Platform Industry 4.0 consortium. In terms of content, the AAS approach comprises all the relevant data and information required by the production system for production and quality assurance of precast concrete elements. The modular structure enables the AAS to be expanded with additional data for new production machines, equipment, or sensors. The data stored in the AAS is verifiable and can be queried to check requirements enabling the decision-making capability of the digital twin, which is essential for the quality assurance process when checking dimensional tolerances, among other things. The AAS data is accessed either via OPC UA or REST query. A special Industry 4.0 language enables data exchange between AAS’s. The initial focus is put on accessing the data via REST query.

Further research will address the implementation of the Industry 4.0 language. Therefore, messages need to be defined for communication between precast concrete elements and, for example, laser scanners. The digital twin developed in our research can transmit machine parameters to production machines on the one hand and IoT data platforms, on the other hand, to apply various analysis methods of machine learning and artificial intelligence. The digital twin presented meets all data management requirements for future production systems. Future developments in the AEC sector concerning industrialized production are enabled through the flexibility and adaptability of this approach. All production steps can be optimally networked, and the data can be made available in an uncomplicated manner. In low or non-automated productions, the digital twin is also advantageous. Content can be used through handheld devices or computer vision technologies such as augmented and virtual reality to support workers in their work optimally. Production data can be stored in the digital twin by shop floor workers with little effort so that analyses of the production process and ultimately optimizations are also possible here. At the same time, the digital twin is the ideal basis for future automation efforts.

This work demonstrated a quality assurance process with a laser scanner as a first example. It was shown how a comparison of the actual geometry based on a point cloud with dimensional tolerances could be implemented for a wall element. The measurement data storage and the comparison with the tolerances were carried out manually for demonstration purposes. Automation of this adjustment is possible and is planned for further research. A prerequisite for automating the quality assurance process is providing the laser scanner with an AAS and implementing the query logic using the I4.0 language. Semantic queries can be implemented using the RDF serialization of the AAS via SPARQL or SHACL queries or by using the ontologies developed in the concept section of this paper. Via this ability to implement different logic, the precast concrete element can make intelligent decisions independently. This can include, among other things, the component disqualifying itself when specified requirements and tolerances are not met. To further verify the possibility of using the presented concept in the production of precast concrete elements, it is necessary to represent other participants of the production system through AAS’s, in particular, to show the interactions between each participant. This research shows how data and information for production and quality assurance can be structured using the digital twin concept. Implementing the digital twin based on the AAS enables advanced methods for communication with and between digital twins. The developed concept will be driven forward in further research projects to implement additional interaction possibilities to realize a flexible and adaptable production in cyber-physical production systems.

This research was set out to develop a digital twin for the production of precast concrete elements based on the implementation of the digital twin in Industry 4.0–the AAS. A key strength of the proposed approach is its flexibility and extensibility so that the digital twin can represent any precast concrete element that is either part of a production system applying the methods and principles of Industry 4.0 or is about to transform into one. Due to the various interaction possibilities of the AAS, the precast concrete element is intelligently able to participate in the production process.

The present research aimed to develop the first template for an AAS for precast concrete elements. For this purpose, requirements were derived from a use case analysis, based on which the data structure of the AAS was developed. The second aim of this study was to develop a methodology for creating AAS’s based on the BIM model of a modularized building. The functionality of the digital twin was demonstrated using a virtual precast wall element, for which quality control was performed with a virtual laser scanner. The application shows how the data can be made available uncomplicated and how the digital twin enables the precast concrete element to make intelligent decisions.

The present work has some limitations. The administration shell described in the concept/application section is a prototype that has only been applied to the use case presented. Furthermore, no communication between administration shells has been implemented yet, as the administration shell of a precast concrete element has been considered in isolation so far. The data structure of the administration shell should be extended to cover different precast element types and use cases.

Future research will address the extension of the concept to the entire manufacturing plant, creating a digital factory for precast concrete production. Modeling the interaction and data flows along the production steps will eventually enable the simulation and optimization of the entire production process. For this concept to work, the digital twin of the precast element must interact with other participants of the production system, i.e., production or transport machines, to exchange data independently. For this purpose, future research is also concerned with implementing the Industry 4.0 language for the application in the production of precast concrete elements.

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

SK, OV, MW, MK and DG contributed to the design and implementation of the research, to the analysis of the results and to the writing of the manuscript.

This research is funded under Grant No. 423963709 by the German Research Foundation as part of the priority program “SPP2187 - Adaptive modularized constructions made in flux.”

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

We acknowledge support by the Open Access Publication Funds of the Ruhr University Bochum.

Abramovici, M., and Stark, R. (2013). Smart Product Engineering. Berlin, Heidelberg: Springer Berlin Heidelberg.

Abramovici, P. D.-I. M. (2017). WiGeP-Positionspapier: “Smart Engineering”. Garbsen: Wissenschaftliche Gesellschaft für Produktentwicklung WiGeP e.V.

Akanmu, A. A., Anumba, C. J., and Ogunseiju, O. O. (2021). Towards Next Generation Cyber-Physical Systems and Digital Twins for Construction. ITcon 26, 505–525. doi:10.36680/j.itcon.2021.027

Antonino, M., Nicola, M., Claudio, D. M., Luciano, B., and Fulvio, R. C. (2019). Office Building Occupancy Monitoring Through Image Recognition Sensors. Int. J. SAFE 9, 371–380. doi:10.2495/SAFE-V9-N4-371-380

Bechtold, S., and Höfle, B. (2016). Helios: a Multi-Purpose Lidar Simulation Framework for Research, Planning and Training of Laser Scanning Operations with Airborne, Ground-Based Mobile and Stationary Platforms. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. III-3, 161–168. doi:10.5194/isprsannals-III-3-161-2016

Biffl, S., Gerhard, D., and Lüder, A. (2017). “Introduction to the Multi-Disciplinary Engineering for Cyber-Physical Production Systems,” in Multi-Disciplinary Engineering for Cyber-Physical Production Systems. Editors S. Biffl, A. Lüder, and D. Gerhard (Cham: Springer International Publishing), 1–24. doi:10.1007/978-3-319-56345-9_1

Boje, C., Guerriero, A., Kubicki, S., and Rezgui, Y. (2020). Towards a Semantic Construction Digital Twin: Directions for Future Research. Automation in Construction 114, 103179. doi:10.1016/j.autcon.2020.103179

Boss, B., Bader, S., Orzelski, A., and Hoffmeister, M. (2019). “Verwaltungsschale,” in Handbuch Industrie 4.0. Editors M. ten Hompel, B. Vogel-Heuser, and T. Bauernhansl (Berlin, Heidelberg: Springer Berlin Heidelberg), 1–27. doi:10.1007/978-3-662-45537-1_139-1

Boss, B., Malakuti, S., Lin, S., Usländer, T., Clauer, E., Hoffmeister, M., et al. (2020). Digital Twin and Asset Administration Shell Concepts and Application in the Industrial Internet and Industrie 4.0. Berlin, Heidelberg: Springer Vieweg.

Braml, T., Wimmer, J., Varabei, Y., Maack, S., Küttenbaum, S., Kuhn, T., et al. (2022). Digitaler Zwilling: Verwaltungsschale BBox als Datenablage über den Lebenszyklus einer Brücke. Bautechnik 99, 114–122. doi:10.1002/bate.202100094

Davila Delgado, J. M., and Oyedele, L. (2021). Digital Twins for the Built Environment: Learning from Conceptual and Process Models in Manufacturing. Adv. Eng. Inform. 49, 101332. doi:10.1016/j.aei.2021.101332