94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

HYPOTHESIS AND THEORY article

Front. Built Environ., 10 January 2023

Sec. Sustainable Design and Construction

Volume 8 - 2022 | https://doi.org/10.3389/fbuil.2022.1098389

This article is part of the Research TopicCircularity by Design: Opportunities for Systemic Change in the Built EnvironmentView all 7 articles

Persistent fiscal and political mismanagement, together with the financial pressures of the COVID-19 pandemic, have driven Sri Lanka into a social and economic crisis triggering a decrease in national foreign exchange reserves, an inability to purchase vital imports, and an unprecedented rise in internal inflation rates. Within the correspondingly distressed construction sector, the idea of ‘design circularity’ gains natural impetus beyond eco-system protection and responsible consumption views, as a critical strategy for responding to the material and fiscal scarcity of the country’s by-now relatively closed economy. This is also in light of the fact that the post-independence history of industrial policy in the island has produced an urban landscape characterised by large underused and increasingly derelict building stock with a significant potential - and need - to be programmatically reorganised, technically recycled, and spatially and culturally re-designed. This paper moves from the proposition that, for ‘circularity’ to be of use at the scale required, its design application must expand beyond conventional interpretations of material recycling, to acknowledge the overall building fabric as a critical, transformative resource available to be renewed or reborn, with varying degrees of reforms as called by the existing opportunities, underlying programmatic needs, and/or industrial constraints. In facilitating this function, architectural design has an important role to play, as particular sets of design strategies must be employed to handle the inevitable complexities between structure and form, material and content, and product and process, against a reflective understanding of local building logic, challenges and potential. To that end, professional design can help foster design approaches to resolve the technical intricacies of building fabric transformations, to strategise actions concerning work procurement and economic planning, and to provide the leading agency in setting up future-industry configurations. How this approach could inform and affect broad market notions of design circularity for Sri Lanka is evaluated through the review of three projects that focus on different programmatic transformations (residential-to-residential, residential-to-recreational, and commercial-to-recreational), are set within different geographical locales (city, periphery and in-between), and situated in and around Kandy, Sri Lanka’s second largest city. The projects illustrate possible tactics for intervening on the existing fabric whilst considering the benefits of each and articulating the structural challenges for the practices involved.

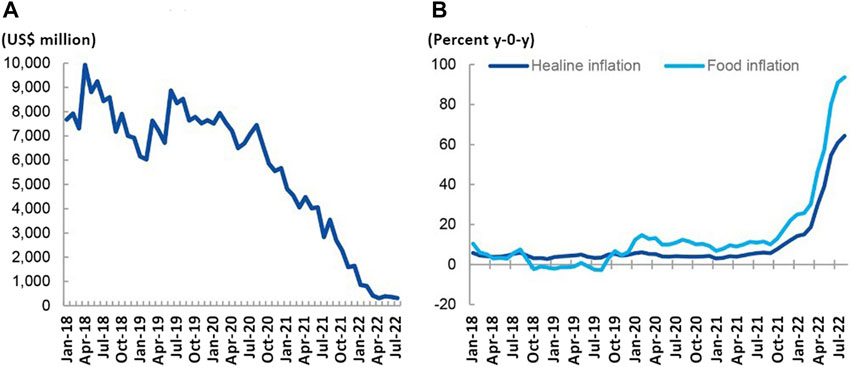

Sri Lanka is currently facing an epic economic and social crisis due to long-running political and fiscal mismanagement escalated by the COVID-19 pandemic (World Bank, 2022). Having undergone its first sovereign debt default since gaining independence from Britain, in 1948, and nearly empty of its foreign currency reserves, the South Asian nation is losing its ability to purchase imports and resist the rise in domestic prices for goods (Figure 1). Indeed, budget and current account deficits, a devalued currency, and hyperinflation do complicate efforts to keep Sri Lanka’s economy flowing (Koswanage, 2022).

FIGURE 1. (A) Gross official reserves of Sri Lanka from January 2018 to July 2022 (This excludes a currency swap that transpired between the Sri Lankan government and the People’s Bank of China in early 2022) (B) Inflation (Colombo Consumer Price Index) from January 2018 to July 2022 (World Bank, 2022).

The reasons are before everyone’s eyes. If achieving a closed economy is an almost impossible feat to complete for any country in this age of globalisation and international trade, it is particularly so for places such as Sri Lanka, which does not produce essential energy resources such as coal and oil domestically, and must thus rely on foreign suppliers to satisfy its internal demand (ADB, 2019). And yet, today, the island nation’s limited capital account has combined with the strongly deteriorating current account to generate a massive balance of payment crisis, which makes it extremely difficult for the country to pay for its essential commodities (World Bank, 2022). As a result, the national government has introduced strong measures - such as selective credit controls for non-essential goods and imposing high duties on selected products - to reduce imports and ease pressure on exchange rates. At the same time, exports have also slowed down due to multiple reasons, from unwarranted agricultural reforms to foreign exchange scarcity (Bhowmick, 2022).

Construction is among the sectors most significantly hit by this national boundaries-closing economic climate, with drastic losses of work and jobs in light of the restrictions on imported goods and the subsequent rise in material costs (Razeek, 2022). The 3 months between January and March 2022 have seen steel and cement prices increase, respectively, threefold and fourfold, while the importation of essential building goods has halted due to the dollar shortage (CIDA, 2022). The World Bank, however, has recognised Sri Lanka as only the first among many developing countries expected to buckle under the economic pressures of the post-pandemic world (Elliot, 2022). Conversely, the UN has indicated 69 countries facing rising food and energy prices, tighter financial conditions and collapse of socio-industrial action (ibid).

While the current predicaments of Sri Lanka’s economy are largely due to specific historical contingencies at global and national level (i.e., COVID pandemic and the then sitting government’s policy decisions), they are not new in the history of the country (and by-and-large in that of most transition economies in Asia, Africa and South America). Specifically, they can be connected to two past political mediations with opposite intentions: the decision, in the 1950s, to experiment with quasi-closed industrial policies to strengthen local production and spark social development (Athukoralage, 1981); and another decision, in the late 1970s, of opening the national economy to foreign direct investments (FDIs) as a catalyst for growth (Karunatilake, 1987). Given the marks left by these two events on Sri Lanka’s physical and cultural landscape as well as their possible parallels with today’s environment, it is worth bringing them into the discussion about the country’s present, eventually by using construction as a filter of their material effect. Let us start from the opening of the economy.

Towards the end of the 1970s, many developing economies took the decision to open their markets to direct foreign investments, with the conviction that this would set a scaffold for growth whilst introducing new technologies and skills, and providing infrastructure and services to the local built environment (UNCTAD, 1999). The allure of FDIs, with all the benefits these would bring to local economies, led regional governments to compete against one another to secure international capital and leading businesses. To attract them, barriers to the mobility of trade and capital would be dismantled, incentives such as tax benefits and special economic zones would be introduced, and infrastructure within ‘business districts’ would be expanded. Sri Lanka aggressively embraced an open economy model in 1978, and since then the local construction sector has been an indirect beneficiary of the worldwide capital flows instigated by transnational corporations (Karunatilake, 1987).

Yet, according to critics, countries like Sri Lanka have been participating in these global flows by compromising their own industrialisation prospects and the ability to address local social and economic problems (Dierckxsens, 2000). In doing so, they may have undermined their ‘national democratic system of accountability’, making both the state and the country’s internal social movements powerless to withstand global market pressure (ibid).

It may be limiting, however, to look at the opening of trade borders in historic isolation and without considering the move towards closed industrial systems that preceded it. This emanated, in the 1950s, from the perceived need at political and industrial levels of developing production processes capable to bring in social change and economic development through technological innovation (Gunaratna, 2001). The state-led industrialisation programs initiated by many post-colonial governments following independence sought to pursue this objective by reorganising the economy for manufacturing purposes and the achievement of self-sufficiency through local production of previously imported goods (Athukoralage, 1981). The urgency to respond to the growing building demand for urbanisation was also closely associated with the above objectives. However, mainly due to socio-economic and socio-cultural deficiencies in their application, the industrialisation attempts of the East had to be aborted by the end of the 1970s, leaving many of the countries involved with massive debts to Western countries (Dierckxsens, 2000).

In fact, as someone has claimed, the design of a viable industrial sector was never the objective of the closed economic policies but rather a by-product of them, as substitution policies were in reality geared toward reducing the large current account deficits that many post-colonial governments had to deal with (Held, 2004). As a result, heavy protection was given to local industries, leading to an inefficient industrial sector with domestic product prices much higher than world prices. Such a disparity naturally lowered the purchasing power of wages and imposed a heavy burden on local consumers (ibid).

The configuration of the current construction industry in Sri Lanka reflects the two policies outlined—i.e., the closed industrialisation and the open economy.

Steel and cement, for example, played a significant role in Sri Lanka’s industrialisation drive of the 1960s, where attempts were made to develop experimental systems and construction typologies that could respond to the expected increasing demand for buildings and infrastructure (Kulasinghe, 2001). These included the first use of pre-stressed concrete as an alternative to reinforced concrete in the late 1950s and series of cylindrical shells, pre-cast panelling and slabs, trusses and purlins (Upasena, 2001). Pre-cast pre-stressed concrete, in particular, came to be increasingly seen as an economically viable alternative to timber products during the 1960s and 1970s (Kulasinghe, 2001). This was helped by the fact that the environmental impact of prevailing traditional practices was disastrous on many levels. For example, the extraction of coral as source material for building blocks and decorations destroyed coral reefs protecting the coastline, while “firewood was used as fuel when burning lime” (Pieris, 2007). The kiln-burnt brick industry had an equally detrimental effect on the environment since the lack of reforestation programs had placed a heavy burden on timber use (de Zoysa, 2001). In addition, using concrete was seen as an effort to move the industry away from labour-intensive construction methods (Pieris, 2007).

Yet, except for the eventual adoption of some of these components in the country’s standard construction practices—e.g., concrete bricks and cement-earth stabilised blocks, concrete floor purlins and door/window frames, ferrocement ceiling panels and lightweight pre-stressed concrete columns—the use of industrialised building techniques was essentially abandoned in the mid-1970s (Mendis, 2001). In hindsight, high capital investment, failure to adapt to familiar ways of building (and thus failure to build an industrial workforce), and eventually the departure from inward-oriented economic policies, were essential reasons behind the demise of this large-scale production model (Pathiraja, 2010).

Be that as it may, the absence of a closed industrialised system enabling mass production, coupled with the limitations imposed by prevailing traditional or quasi-industrial technologies, pushed urbanising economies such as Sri Lanka towards increasing dependence on imported building products and materials. This was indeed facilitated by the free-market-based open economic policies and the subsequent participation of foreign and private sectors in domestic building and infrastructural projects. In fact, by the late 1990s, around 60% of construction materials in Sri Lanka were imported, compared with about 30% in the 1960s (Raftery et al., 1998).

With the government lifting more trade barriers in search of external investments and businesses, the demand for imported technologies increased drastically in subsequent years. A case in point is Alucobond, a composite cladding material manufactured in Germany, which started to be imported into Sri Lanka in 1997. In 2000, within 3 years from its introduction, Alucobond’s local agents recorded the highest sales growth in the Asian region, pushing past countries such as Singapore, Malaysia, Thailand, Philippines, China, Indonesia, Australia and New Zealand (Dissanayake 2001). As per advertising, the ‘modern sleek finish’ for exteriors and interiors, applicable to new buildings as well as old ones in need of refurbishment, had quickly become the building cosmetic of choice for corporate stock and new construction in Colombo, particularly within new commercial corridors (Pathiraja, 2010; Ranaweera and Pathiraja, 2013).

But besides the product acceptance reflected by the numbers, Sri Lanka’s progressive dependence on imported construction systems always presented risks. One was that of hurting local system suppliers, and therefore viability and growth of domestic construction-related sectors. Another was the risk of increasing technological failures without proper labour knowledge-transfer programs and protocols. A third was the probability that the proliferation of imported technologies created or reinforced patterns of socio-economic and socio-cultural separation within construction markets. A fourth was the cultural and environmental inappropriateness of the systems in use. The situation of the industry in pre-COVID times would essentially confirm these fears, with the bulk use of foreign materials and components applied to local building activities, particularly in urban areas, almost irrespective of their fitness for use and the capacity to age, thus compromising the building’s design life.

It should be noted that the nominal design life of a contemporary building in Sri Lanka is acknowledged to be around 60 years (Dias, 2013). However, such length depends on a variety of factors, such as the quality of the original construction, the environment in which the building is located, and the quality and degree of maintenance carried out, in addition to the selection of construction materials (ibid). Based on historical data on Sri Lankan building stock, Dias (2013) estimates a range of design life from 30 years, for reinforced concrete buildings in a wet, aggressive environment, to 100 years, for masonry and timber buildings in a dry, non-aggressive environment. Given that most buildings today in Sri Lanka are constructed of reinforced concrete skeletons in a challenging—and as such ‘aggressive’—socio-economic and socio-technical context, it is no surprise that the largely free-market propelled urban building stock from the 1980s proliferates with poorly performing buildings, either on the verge of failing or already critically deteriorated in spite of their continuous use.

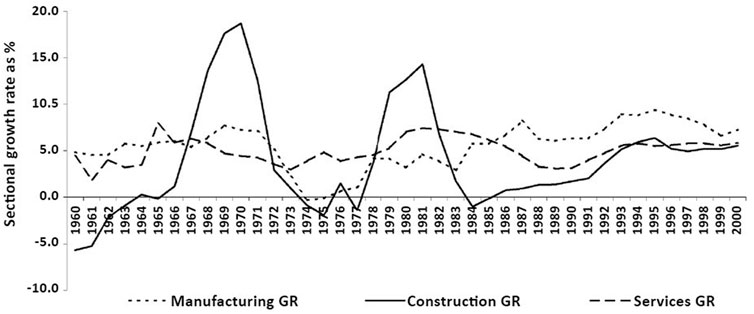

Yet, as pointed out, their buildings’ eventual liabilities notwithstanding, the two eras of closed and open economic policies saw Sri Lanka’s construction output heavily responding to their input, in fact recording the highest percentage growth within economic activities in the country. As illustrated in Figure 2, construction output in Sri Lanka rose in the mid-1960s with the introduction of inward-looking industrial growth strategies. By the early 1970s, a cusp was reached due to the domestic economy’s unfavourable responses to industrialisation efforts, poor industrial linkages and lack of internal demand; the growth rate started to drop drastically (Rameezdeen et al., 2006). The subsequent decline of trade, difficulties in accessing foreign loans, and poor returns on investment all generated a period of economic stagnation, eventually leading to Sri Lanka swapping import-substitution strategies for export-oriented ones in 1977, with an almost immediate increase in growth rate and per capita income. In the 1980s, however, the unstable political and security situation caused by the civil war and the hike in oil prices combined with the general international economic slowdown affected construction growth drastically (Karunatilake, 1987). The cessation of war hostilities in mid-2009 and the post-war building construction/reconstruction demand generated by the conditions of the building fabric across parts of the country triggered another rise in construction output. Nevertheless, this upward momentum was propped up by the large-scale infrastructure projects the then government initiated at the expense of substantial foreign debts, thus leading to the present economic crisis, propelling the country’s industrial action into another long-term slump (Bhowmick, 2022).

FIGURE 2. The trend of sectoral growth rate in Sri Lanka from 1960 to 2000 (Rameezdeen et al., 2006).

Against such background, Sri Lanka’s current multidimensional crisis can be cast under a different, propositional light, by interpreting it as an opportunity to rethink the terms of the country’s construction activity and the role of professional practice within it, vis-à-vis alternatives that are already part of its industry’s history and thus open to comparisons with or adjustments from the past.

There is no doubt, in fact, that in the current situation, the country has limited, if non-existent, ability to lure foreign investment, capital works and imported goods for the construction field—the relative bonanza of which in the years after the end of the civil war (2009–2015), incidentally, was never conducive to the fulfilment of local social building production needs or the bearing out of broad ecological concerns. Thus, in the vacuum left by the macroeconomic and market failures of the last 3 years there could be space for alternative models of industrial organization in building that, while taking stock of the economic situation could also respond to persisting challenges and pressures of urban space supply.

For example, the closure of foreign capital and material trading markets could be responded to by enacting a model of production and consumption that relied on internal dynamics of restructuring, sharing, leasing, reusing, recycling, repairing and remanufacturing existing resources and goods. A model, in other words, based on a closed loop of industrial actions, yet very different from the closed industrialisation efforts of the 1950s. This model, in fact, would be much more akin to that of a national building stock “reconditioning” enterprise, which would help counteract resource scarcity, rising prices and over-dependence on (imported) raw materials and processed components, whilst reducing uncertainty about future resource availability and affordability. Labour-wise, the recycling of available stock would (for the same reasons) be done through existing technical know-how and practices, a datum that would permit unskilled workers to enter the construction workforce as apprentices, particularly if strategies could be set up for on-the-job upskilling and labour market cross pathways (Pathiraja and Tombesi, 2009; Pathiraja, 2014). Such “reconditioning” path would also appear to be more sustainable than commonplace “new building” in terms of conserving resources, reducing waste, decreasing environmental pollution and lessening operational risks, all delineating significant contributions to the tackling of climate change and biodiversity loss.

If given the right connotation, the expression ‘circularity’ could well be used to describe the strategic intentions of such plan as well as its eventual results. While perhaps different in scale and scope of application compared to conventional interpretations, the industrial strategy of reconditioning the building stock in times of capital scarcity and trade shutdowns responds to both the definition of circularity—i.e., a value retention loop where actions occur in a circle—and its fundamental goals in construction—1) consideration of end-of-life aspects in product development; and 2) pursuit of material flows aimed at eliminating waste and pollution by enacting strategies of refunctionalisation (Geissdoerfer et al., 2017). The economy underlying these goals (through focus on regeneration and the circulation of products and systems within narrowed material and energy loops) would as well be present, although at a large urban scale. In fact, its concentration on the ‘building industry as a whole’ permits circular economy’s many definitions and themes—e.g., product durability, repairability, upcycling, modularity, demountability, circular manufacturing and flexible supply chains—all to be subsumed within it.

This process also enables either the metabolisation or the dilution of many of the critiques to circularity, for example the idea that the recycling of waste may increase the demand for it (Greer et al., 2021), or that circular economy is an opportunity for business rebranding (Stockhammer, 2021). Both would be a bonus in this case. It would also counter critiques about scale, and circularity’s ability to address the true sustainability challenges of our times given that it revolves around a relatively small fraction of global materials (Akerman et al., 2020). Here we are talking potentially about the urban fabric of a nation. Not only this. Engaging in large scale building retrofitting would respond to those who maintain that conceiving and organizing hybrid assembly processes combining ‘new’ and ‘old’ has practical difficulties, and that substituting secondary goods for primary goods constitutes a major technical challenge.

More in general, and perhaps more importantly, taking circularity to mean “reconstitution of the building stock” would answer those critics who have accentuated the somewhat techno-centric de-politicisation of the industrial potential of the circularity discourse. According to Niskanen et al. (2020), this de-politicisation occurs when circular economy is “presented as [a] managerial and technocratic, matter-of-fact issue”, which excludes potential solutions that could challenge the current capitalist order. The techno-centric approach fails to recognize underlying connections in labour practices, working conditions, social interdependencies, and political and economic constraints. Consideration is required not only for assessing how different labour profiles are linked and upskilled for a circular economy but also for the types of jobs created and the role people perform (see also Gregson et al., 2015; Cullen, 2017; Corvellec et al., 2021; Hart and Pomponi, 2021). This is exactly what a look at urban fabric upcycling as a set of circular opportunities would require and underlie.

There are, of course, inherent challenges in the enactment of this vision, which have to do with perceptions of the problem as well as cultural preferences in its resolution.

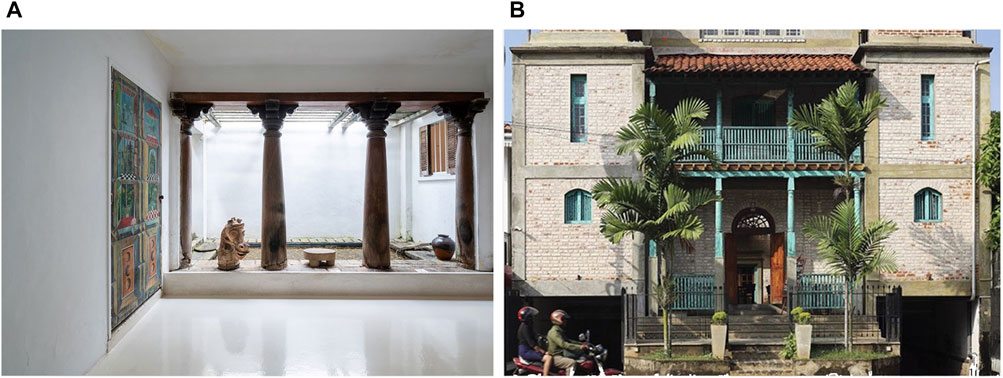

Firstly, there is the issue of “waste” (or functional end of life) in construction and what it denotes. Waste is not an absolute fact, and depends on social mores and perceptions. The same for building degradation or sub-standard performance. These depend on the context and the ability of users to draw experiental comparisons. A high-income community is likely to be much more sensitive to fabric degradation than a low-income one. Besides, in many societies, the idea of recycling has an explicit class connotation and thus a stigma associated with the reuse of materials (or building spaces perceived as sub-standard or old). Irrespective of resource restrictions and limited spending capacities, ‘newness’ still constitutes a value, however induced, for the vast majority of building consumers, particularly within urbanizing societies. Thus, by-and-large, in economies such as Sri Lanka, the ecosystem protection argument alone is not likely to drive people to embrace circular concepts based on material recyclability and waste reduction. In fact, the only sector aggressively pursuing forms of recycling is the one scavenging treasured artefacts from heritage-listed buildings to cater for cultivated tourism’s interest in history and sections of the local architectural profession’ fascination with “re-using” as an aesthetic expression. Indeed, there have been attempts to reuse leftover materials and retrofit old buildings within high architectural practice. Some of this work uses recycling to prop particular forms of social elitism that rely on the adoption of elements and components of a past lofty culture; others find inspiration in a picturesque paradigm that displays commitment to reviving vernacular practices (Figure 3). Here, however, the issue of scale and its limitations is clear, as such discreet, privileged and isolated attempts of circularity happen outside the broader cultural and technical processes that deliver solutions to social building production needs. They are, therefore, unable to impact effectively on restructuring the standard modes of economic production or the cultural conditions of urban space. With urbanisation pressures and population increases demanding a larger supply of spatial infrastructure, even in time of crisis, selective focus on recycling is not enough to solve macro challenges.

FIGURE 3. (A) Reused timber-carved columns in the renowned architect Geoffrey Bawa’s own house in Colombo (B) located in one of Colombo’s most affluent neighbourhoods - and selected as one of the eight finalists in the fifth cycle (2019/2020) of Geoffrey Bawa Awards for Excellence in Architecture - this commercial building uses wooden columns, windows and doors acquired from a house originally built in the 17th century (Senerath Yapa, 2020).

On the other hand, it is the situation of the building stock itself and its foreseeable cycles of industrial activity that may force a change of thinking and support for the kind of circularity being discussed in these pages. Based on what indicated in a previous section, the building structures produced during the first two construction booms in the history of the independent country (1965-71 and 1977-82) are reaching their probable life spans. Today, 60 years after the introduction of the industrialisation program, most of the reinforced concrete fabric that resulted out of it is either abandoned or on the verge of becoming obsolete. The wave of construction triggered in the late 1970s and characterizing the second boom has not fared much better. The introduction of open economic policies may have been politically plotted in advance, but the building industry was not planned well enough to absorb the construction demand it generated. This led to the proliferation of a commercial building fabric that relied heavily on imported materials such as steel, cement, glass, aluminium and composite systems built within a job market characterised by informal work culture, low wage structures, low-skill definitions, lack of protection, the dominance of self-employment, easy entry, and low productivity (Ofori, 1990; Jayawardane and Gunawardena, 1998). The result was the propagation of badly-built commercial ribbons along the island’s urban and regional arteries, still visually defining the cityscape but now nearing the end of the 30-year design life assigned to them by construction scholars (Figure 4).

FIGURE 4. (A) A factory building constructed during the 1960s closed industrialisation but is now in a derelict state; (B) a typical commercial ribbon development in urban Sri Lanka.

Hence, regardless of any possible cultural readings of the situation, Sri Lanka has a large building stock that negatively affects form and structure of the city, and is currently underutilised, underperforming and increasingly dilapidated. To it, one must add the large percentage of urban and rural buildings damaged and left over to decay during the long-running civil war that beset the country from 1983 to 2009.

But here is the transforming point: what would certainly appear as an urban system encumbrance to dispose of under conditions of growth can be seen as an opportunity for strategic recovery under conditions of crisis such as the current one. In fact, the comparatively low-cost reconditioning of this pervasive stock may be the only program to provide granular work opportunities to major cross sections of the building industry—from professionals to contractors, materials distributors to construction workers. The process could offer significant advantages for the definition of the future country. In particular, it would allow for discrete (e.g., small scale) interventions on the fabric, which could assist in the re-functionalisation of city sections and the replacement of obsolete functions. In doing so, it would: a) provide a testing ground for environmentally efficient typological alternatives to the until now prevalent and hardly sustainable use of imported, energy-intensive mechanical technologies; b) offer industry actors a chance to reflect on the prevailing technological frameworks of the past and their maintenance needs, eventually to define product substitution policies more in tune with the times and their inhabiting ethos; and c) facilitate experimentation with building and material solutions that, in light of their cross-industrial and cross-sectorial application, could contribute to delineate a truly contemporary language of construction emancipation and cultural autonomy.

By considering constructed fabric as a collection of assets naturally open to transformation, the argument put forth in the preceding section connects with building at both individual and collective levels. If the building stock were considered on the whole as matter on which to intervene then its entire footprint could be seen as open to forms of circular regeneration. Yet, as with anything in construction, the theoretical value in reusing and recycling existing stock must be verified and validated against actual practice, the alliances it requires, and the hurdles it conceals.

Herein may lie the challenge. Opening the idea of circularity as regional planning and design practice to the whole city fabric, with its wide contextual and technical variance, raises the issue of consistency - of approaches, means, results, assessments - in that very ‘practice’. Does the circularity paradigm at its base call for a reflective method of work that relies on the application of flexible operative categories to unique situations, or does it rest on the development and adoption of predetermined protocols that requires adherence to precise sets of actions?

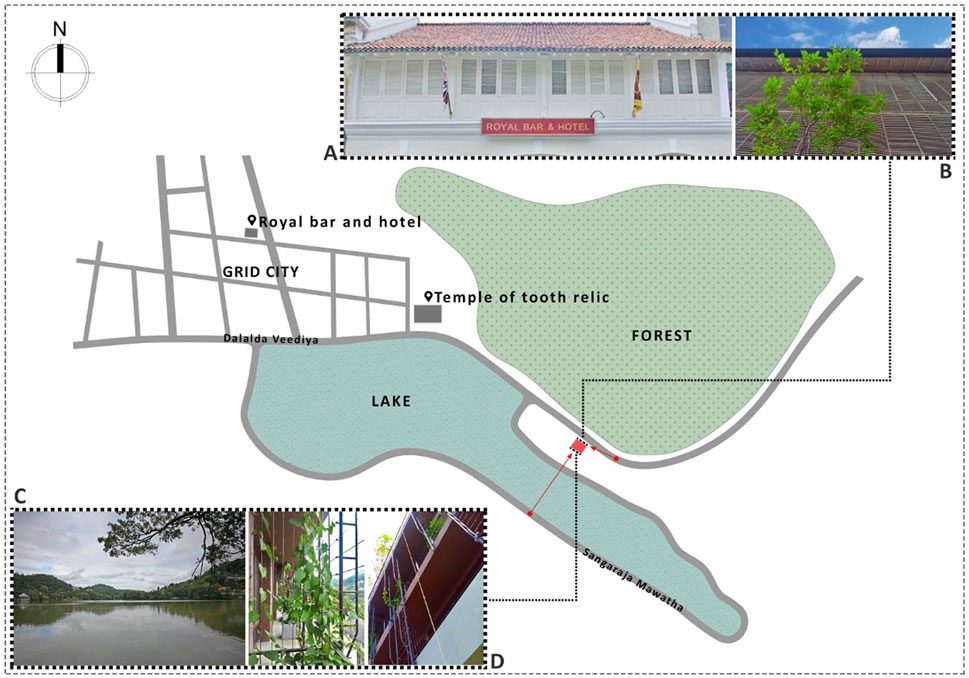

Help in answering this question can be provided by the analysis of three ongoing projects of adaptive reuse developed by Robust Architecture Workshop (RAW), an architectural firm in Colombo founded by one of the authors. The three projects are to be used as a complementary set, meaningful in light of their diversity. Indeed, the three building interventions are the reflection of different but all important programmatic transformations (from commercial to recreational, residential to recreational and residential to residential), belonging in different urban settings (city, in-between, and periphery) situated in and around Kandy, a major town centre located in the central hills of the country and a place of cultural and historical significance1.

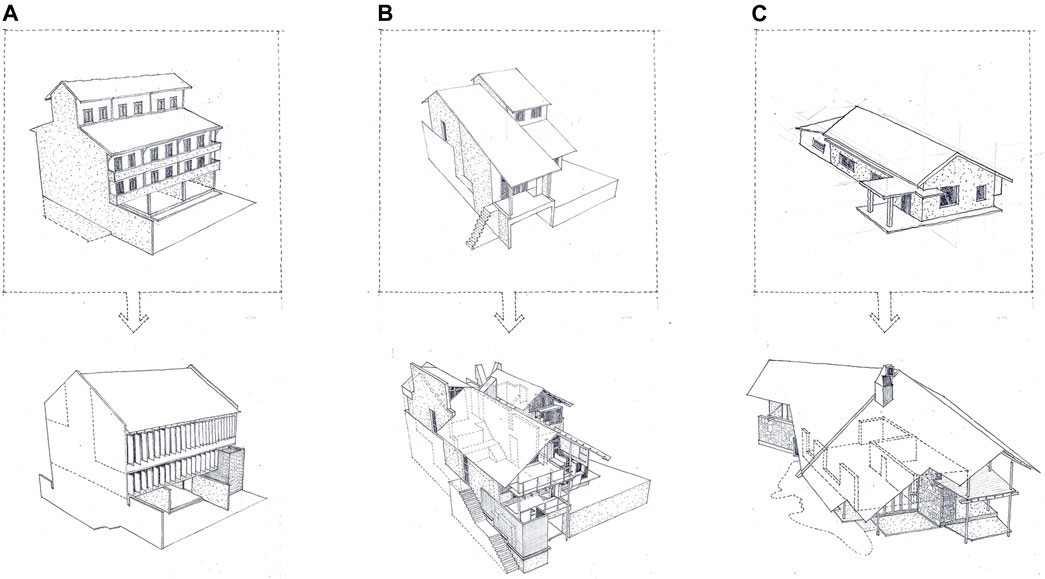

All three projects had existing structures on site, either slated for demolition and ready to pave the way for new construction, or planned to be salvaged in ways that would not have considered the circularity of resources here proposed by the authors as a critical, value-adding approach. Out of the three projects, the city project concerned the retrofitting into serviced apartments of an anonymously designed but structurally still usable commercial warehouse located along one of the city’s most important thoroughfares. The second project, by contrast, turns into a boutique hotel an environmentally and technically run-down two-bedroom house located in one of the residential suburbs circling the city centre (thus, ‘in-between’ the city and its periphery). The third project upcycles a dilapidated residential structure already condemned to be demolished into a spatially generous and environmentally sound three-bedroom house in the mountains off the city’s periphery (Figure 5).

FIGURE 5. Formal transformation of the three projects from the old to the new. (A) City project replacing a commercial warehouse with serviced apartments; (B) Suburban house adapted to a future hotel; (C) Mountain house in the periphery.

In addition to flagging technical and environmental performances, the existing fabrics providing the physical base for the three spatial transformations had unremarkable architectural features, run-of-the-mill spatial conditions, and undervalued cultural forms. As a consequence, the interventions about to be described were not built on the glory of their existing structures or upon the desire to conserve any archaeological credentials. On the contrary, they are humble attempts at non-destructive adaptive reuse, which seek to add new (architectural, historical, cultural, technical) values, to make the ‘new’ perform better than the ‘old’ while tapping into the economic and ecological gains of such an approach.

With the last sentence of the previous section providing the compass for the work, the rest of the paper will endeavour to address the issues of method brought up as a theoretical challenge when contemplating the practice of circularity, by considering the lessons one can gather by reflecting on the processes underlying the three projects introduced above.

The first lesson is the impossibility, even within the same office, of normalizing work responses to the adaptive reuse challenge. The three projects offer solutions that are almost entirely determined by their specific contextual, technical and programmatic circumstances, both spatially and technologically (Figure 6).

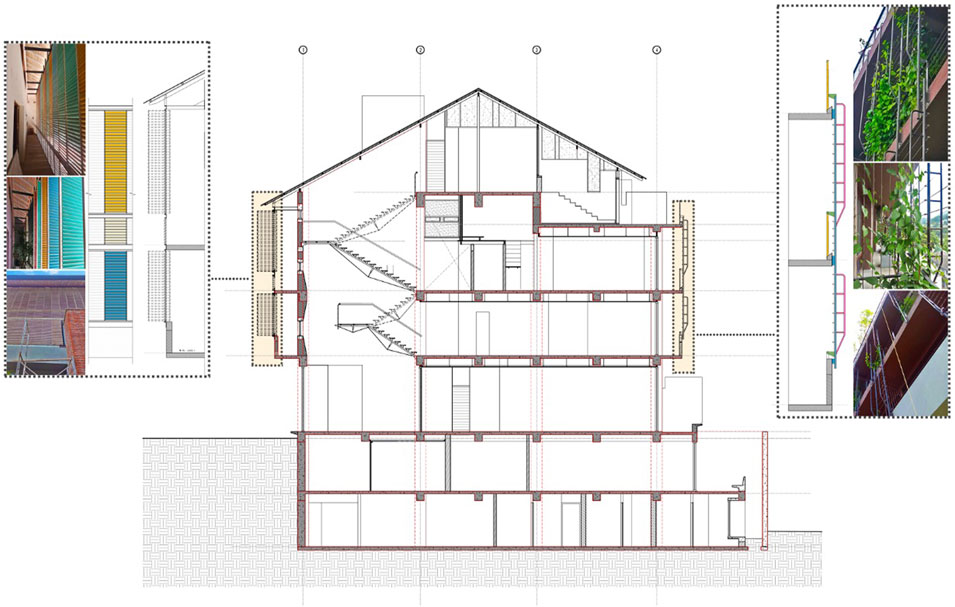

The city project retains the load-bearing structural skeleton of the old building in its entirety—for both economy and practicality—thus eliminating the need for a new superstructure. Indeed, it pursues a relatively simple strategy of enwrapping the old structure with new skins, so as to screen the existing, spatially underutilized balconies, and transform them into loggias with privacy, shade and protection against tropical rain. Such an ‘enwrapping the existing’ approach takes into consideration the budgetary limitations that are typical of commercial constructions, the need for improved performance of the building façade with its associated spatial uses, and the possibility of enhancing urban iconography.

In the suburban house, where a stable existing structure seeks to amplify the building’s height and volume, a technological “merging” of the “new” and “old” was chosen as a preferable option. To this end, a critical juxtapositioning of the old and new structures was sought to take economic and technical advantage of reuse while letting the “new” emerge from and take over the “old” by creating additional volumes, enriching spatial experiences and value-added performances.

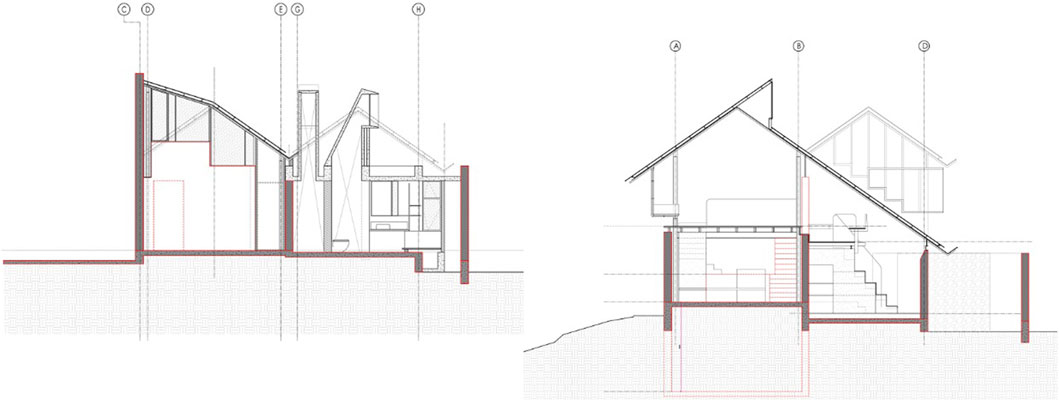

The project in the mountain resorts to a third typology where old and new structures are conceptually separated from each other, and the latter is used to shelter the former. This dual approach—structural separation and ‘new protecting the old’—contributes to overcoming the deficiencies inherent in retaining and reusing the existing fabric by responding to: a) its technical instability to perform critical load-bearing functions; b) the need for protection against elements; c) insufficient exposure to environmental amenities.

The differences just outlined, in turn, called for distinctive design strategies in each project, the definition of which was necessary to resolve the inevitable complexities between structure and form, material and content, and product and processes of the ‘existing’ and the ‘transformed’ (Figure 7).

In the city project, for example, the critical requirement was that of augmenting formal and functional value through minimal means, and without interfering with the existing structure of the building. Hence the strategy was that of introducing a series of “installations” within the internal and external volumes of the original artifact. Externally, two skins of different technical, environmental and experiential configurations modify its form: a screen of timber-louvered openable panels on one side, and vertical creepers running on reused scaffolding frames on the other side (Figure 8). The timber-louvered façade fronts the main access road while the vegetated curtain—built in absolute economy—screens the rear façade that opens to a panoramic view of a lake and beyond. By enclosing previously exposed balconies, the two vertical elevation filters generate new usable spaces whilst improving the building’s environmental performance and enhancing the urban presence of its volume. On the other hand, leftover spaces within the building’s interior are colonized by autonomous building “happenings”—staircases, partitions, floor decks, joinery units, fenestrations, etcetera, which are strategically introduced to add value to the building’s functional and cultural use. For example, the “new” main staircase “floats” in a volume “left over” by a previous circulation system, touching the existing fabric lightly through carefully planned joints; such an insertion corrects the orientation and efficiency of internal circulation to suit the new spatial program.

FIGURE 8. City project: section showing the two facade screens “wrapping” the fabric to form the habitable loggias.

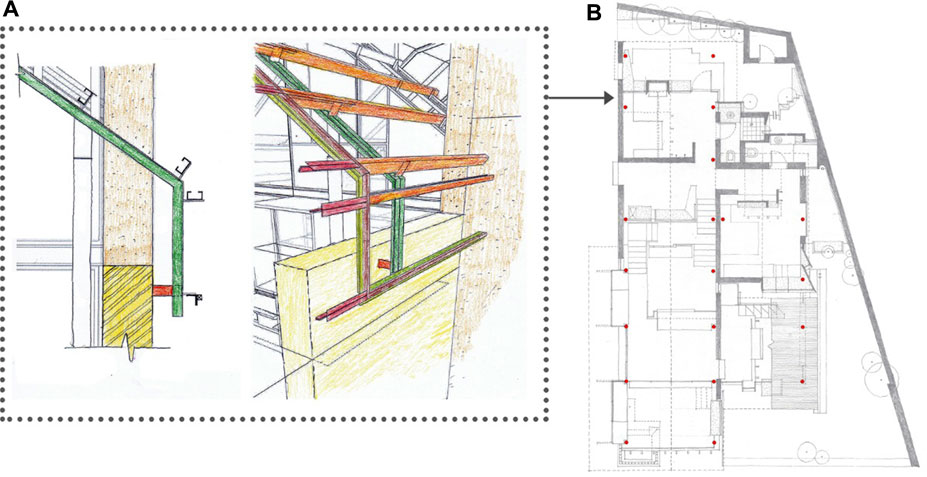

In the suburban house, on the other hand, the leading programmatic challenge was twofold. On the one hand, it was necessary to respond to the need of expanding the internal volume without infringing upon the footprint of the existing fabric, a condition imposed by the physical confinement of its suburban plot. The second challenge was technical, and involved the replacement of the existing roof structure, parts of which had tumbled down due to its state of dereliction, allowing water to infiltrate even during intermittent rains. However, the removal of the existing roof could only be done after the placing of the new one, lest to have the entire internal fabric drenched in water during Kandy’s frequent rainfalls. To add complication to an already challenging situation, the existing fabric rested on an inclined terrain, with its floor levels—cut into the land and sited at different heights—supported by a series of retaining walls. The solution required a new roof system supported by a structural skeleton that could pass through the existing roof in preparation for the new build. The new structure had to negotiate form and conditions of the existing fabric as well as confinement within the building’s original footprint without intruding upon or altering the existing retaining walls. As a result, part of the new structure had to rest on the existing fabric, whereas another part had to stand independently on strategically-placed pocket footings.

By contrast, and as often the case with peripheral properties, the mountain house could insist on a larger free site that did not require the project to stay within the boundaries of the existing footprint. In spite of the hilly landscape surrounding it, the terrain was flat, and this made the placement of a new structural arrangement easier. However, the fabric to be retained was far smaller than the spatial extent required by the new program; it was structurally unfit to support volume growth, and environmentally inferior to sustain re-birth as it were. As such, it had to be sheltered within a larger independent envelope.

The second lesson concerns the importance of considering how to connect ‘new’ and ‘existing’.

In the city project, this was done on the exterior by enwrapping the old fabric with two new screens. Internally, connections are partly spatial and partly tectonic. A system of inhabitable volumes has been introduced within the fabric of the old building, which connects the new and old via a continuum of functional and experiential uses. The loggias created through the enwrapping of the façade are part of this larger spatial system, and form the most direct connection between outside and inside. Conversely, the building ‘happenings’ mentioned earlier, e.g., staircases, floor decks, joinery units and fenestration, act as elements connecting couples of spatial components of the internal volume. Tectonically, negative joints are used to establish visual separation between the retained old structure and the new building componentry surrounding it.

In contrast to the enwrapping strategy at play in the city project, the suburban house project conceptually and technically integrates old and new structures, although the extent of their true technical collaboration is subject to the load-bearing needs and capacities of the combined systems. In certain situations, the new structure rests on the old walls to support load transfer; in other cases, it runs independently of it, using the latter only as reference system and a flexible working guideline.

By combining new and old where necessary, the hybrid system avoids any dimensional incongruities of the existing frame, which could be imprecise depending on how well it had been constructed in the first place, and what forces it had been subjected to during its ageing process. More often than not, the ‘new’ does not rely on the ‘old’ for overall structural fitness or components’ dimensional accuracy. This performance autonomy is then rendered constructively through connection joints, which provide the tolerances necessary to prevent failure chains from transferring from the old to the new and vice versa (Figure 9).

FIGURE 9. Suburban house. (A) The new roof system is connected to the existing masonry walls using a third element to tolerate the dimensional irregularities of the fabric; (B) the new structural columns are placed independently of the existing fabric using the latter as a working guideline.

Yet jointing cannot remain limited to its mechanical control functions. Making an informed connection between material and content also becomes vital in the type of work described, particularly when in search of an architectural language supporting the circularity described. To this end, the third project offers useful opportunities for reflection. As a monolithic rectangle of tight spaces, dark rooms, flat ceilings and dilapidated building portions, the original structure occupying the site of the mountain house was inevitably condemned for demolition: it made no acknowledgement of the stunning views on offer, nor presented its users with any interiors conducive enough to any form of spatial comfort or enjoyment. Peeling the plaster off its existing walls, however, revealed random-placed and irregular-shaped stonework held together by mud mortar, a technique common to building activities practised in the nearby mountain villages. It was then decided to express the textural formation of the old stone walls and organise a new spatial system of volumes, uses, experiences and journeys around it. The idea responded to multiple logics, such as the environmental and economic gains of an adaptive reuse approach, the experiential rewards of acknowledging the local material practices inhabiting the memory of the place, and the constructional benefits of following a building language that supported the use of local craft. Overall, the building language adopted for the mountain house is very episodic and almost bricolage-like (Figure 10). The strategy has been that of bringing in materials and systems of the varied kind, both new and found, in a manner that would suggest a sense of randomness and spontaneity. For example, a small quantity of Kabok (laterite) blocks found on the site has gained a new lease on life in the final building form as a part of an external wall that defines the entry sequence to the house. The flexibility afforded by the particular language of building pursued by the project made such seemingly random material insertions both feasible and advantageous to the function of circularity.

FIGURE 10. Mountain house. (A) The old house on site; (B) the new structure and roof ‘sheltering’ the retained fabric; (C) kabok bricks ‘found’ on site; (D) the new, reused kabok brick wall defining the entrance to the house; (E) the bricolage-like formal language accommodates a seemingly-random mix of new and ‘found’ material: stone, clay bricks, kabok bricks, timber, lath and plaster, steel structural skeleton, metal roofing, etc.

The third lesson further qualifies the first and resides in the importance of connecting with the local culture of building. Such a connection is and proved important not only to facilitate development and execution of the details (by taking advantage of the industry supply chains on hand and the factors of production available) but also to amplify the base of potential contractors for the job and allow the planted industrial seeds to grow.

For example, in the city project, the vegetated screen on the back façade uses commonplace steel welding techniques to connect reused scaffolding frames to a steel-framed balustrade. The timber-louvered façade, by contrast, was put together by a team of local carpenters with additional skills gathered during the production process. Efforts were made at the level of component detailing to provide the tolerances necessary to accommodate diverse labour skills. As a result, construction has been conceived and managed by standard commercial builders, whom in principle had the opportunity to learn project development strategies associable with adaptive reuse, and subsequent work tenets as and when they proceeded with the work.

The suburban house, by contrast, is being built by a coalition of small-scale contractors who had a previous but limited working relationship with the building designers; the masonry and timber gangs had worked with the architect once before, and the steel fabricator is collaborating with them for the third time. The particular selection of the workforce becomes instrumental to multiple and reciprocal objectives. Firstly, the pursuit of precision: in fact, the typology of reuse pursued in this work—‘integration’ as opposed to ‘enwrapping’ and ‘sheltering’—requires a comparatively higher degree of precision due to the underlying structural and technical interdependency between new and old construction elements. Secondly, the integration of trade work: engaging a building team previously trained by the architect—i.e., whose skills and capacities are known to them - allows project decision-making to extend beyond narrow fields of knowledge. Thirdly, the economic pre-definition of assembly tolerances: employing a workforce previously trained ‘in-house’ on specific detailing and jointing of building systems permits their qualitative use as opposed to externally skilled traders and artisans naturally sitting on higher industry scale wages (thereby reaping the economic advantages of such an approach). Fourthly, upscaling: introducing small-scale contractors to retrofitting work through on-the-job training opens them to new career paths while strengthening the culture of building that values and scaffolds fabric circularity. For example, with most of the steel used in the project recycled and bought from material salvaging yards in and around Kandy, all ironmongery work required for the project—door/window handles, hinges and locks, etc.—was manufactured on-site using the offcuts from structural steel. The labour for making these ‘crafted’ objects was supplied by the welding team commissioned to put up the steel structural frame, who worked closely with the architects to acquire the necessary skills to accomplish the task. In doing so, the project simultaneously achieved an economy of scope and an upskilling of the workforce.

In the mountain house, it was decided to continue with the old stone masonry system revealed during demolition, immediately bringing the local vernacular to the fore. Such a choice created a technical motive to use the local craft for construction, and opened up a cultural platform to bring in other craft practices such as carpentry and lath and plaster walling to the building act. This was facilitated by the bricolage-like compositional language adopted, which enabled significant levels of freedom and tolerance in pulling in a diverse mix of craft- and industry-based knowledge forms. The constructional benefits of this approach were significant, in that evidence of new adaptive reuse strategies could be produced that related to the ‘place’ tectonically and culturally, thus supporting continuity and up-skilling of local knowledge practices.

As it were, the three projects use fundamentally different strategies for labour structuring, depending on their specific cultural and technical contexts of production—i.e., commercial mainstream for the city project, cultivated small-scale contractors for the suburban house, and local craft in the mountains. This process of tapping into the conventional workforce, at times through internal upskilling and the establishment of knowledge-sharing targets across labour structures, was deemed instrumental to building, essentially via progressive contamination, the common culture required for circularity to be successful at a broad industrial level. Cultivating a culture of building responsive to adaptive reuse would, in fact, shape and provide the tangible and intangible resources needed for the transformation of the building fabric along the direction outlined, by permeating the standard processes and knowledge that determine what and how to build in and around the city.

The fourth lesson concerns the importance of establishing a clear connection between retrofitting and the improvement of buildings’ environmental performance and/or control needs, which can strengthen the rationale of the work.

In the city project, the façade systems ‘wrapping’ the existing fabric respond to two different sets of aspirations concerning urban iconography (Figure 11). The screen of timber-louvred panels fronts the western end of the celebrated Dalada Veediya, which, as its name alludes to, is the street that leads to the Temple of the Tooth Relic of Buddha (or Dalada Maligawa in Sinhalese, where ‘Dalada’ means the tooth). Dalada Veediya and the Temple, respectively, define the Southern and Western edges of Kandy’s historical grid city, which had a unique building character until the commercial developments of recent times colonised its visual and cultural dimension. In contrast to the genericity of the original elevation, the full-height timber shuttering explicitly connects to the façades of surviving historical buildings of the grid city, as a way of revisiting past vernacular and demonstrating the possibility for the city to emerge anew, by acknowledging past values within the needs and capacities of the present times.

FIGURE 11. City project: location map. (A) Façade of a historical building in the grid city; timber shutters have traditionally been used to screen balconies and loggias; (B) the new timber-shutter screen fronting the street leading to the grid city (C) panoramic view of greenery across the Kandy lake; (D) creepers running on the façade system facing the lake.

The vegetated façade on the opposite side, by contrast, is seen across the ecological habitat encircling Kandy Lake with the famed Udawatte Kele forest as its backdrop. Over the years, the hilly landscape fronting the lake has been subjected to an ill-conceived sprawl of badly-built glass and concrete structures, annihilating the ecological fabric once the pride of the city. The economical façade made of creepers running on cables fixed to reused scaffolding frames is expected to meld with the other green layers in the foreground and background, thereby showing how fabric circularity can cocoon up irreversible mistakes from the past while adding weight to the city’s identity, culture and visual form. To this end, circularity is not pursued primarily as a moral crusade in support of sustainability but as an opportunity to nurture the city back to its lost values, and cultivate a new sense of habitability.

Upgrading the environmental credentials of the suburban house took a different dual approach determined by the physical arrangement and orientation of the old house on the site. Along the existing fabric’s North- and East-facing envelope, a bare wall and a sloping roof cut off the possibility of accessing the morning light, surging breeze and expansive views. On the other hand, the site’s South and West boundaries run alongside a typical, tightly-built suburban block, which also hinders the building’s ability to access environmental amenities. In the ‘transformed’ building, the north-eastern façade uses the physical gap created by the raising of the roof over the old masonry walls as an opportunity to place a three-dimensional environmental filter consisting of a range of spatial componentry such as fenestrations, day beds, joinery units, and thresholds protected by roof eaves. For the southwestern side of the building, where the façade cannot draw in sufficient light and ventilation due to the built-up site edges, a new system of roof lights and wind scoops penetrates the horizontal envelope to improve the overall environmental performance of the internal volume (Figure 12).

FIGURE 12. Suburban house: sectional drawings showing skylights, wind scoops and the three-dimensional spatial/environmental filter occupying the space left by lifting the roof over the fabric (denoted by a day bed with openable windows in the right hand side section).

In the mountain house, the transformation of the fabric into an idiosyncratic material whole also reflected an environmental idea that could only be realised through ad hoc interventions breaking the regularity of the parti. Voids that support better circulation of internal air, elevations that bring in natural light and breeze while capturing views of the outdoors, and textures that inform both comfort and memory, are all positive values acquired through the strategic de-morphing the fabric.

The fifth lesson concerns the importance of conceiving the building as a protector of the site during the construction process.

In all three projects, the phasing of construction at the site followed a strategy that reversed the typical, bottom-up building progression. Instead, the roof system with the supporting structural skeleton was the first to get built, even before demolishing the parts of the fabric that needed removal. This included the city project, where a new structural intervention was not required due to the retention and reuse of the existing skeleton, but where the roof system was the first to be rearranged and completed. Here, specifically, the old roof had a form split into three parts, all positioned at different heights. During the retrofitting, it was considered prudent to shift the lower parts of the old roof to match its topmost section so that the new roof would have one continuous fall (for formal reasons) and acquire more volume for habitable use. Modifying the roof was thus planned and carried out as the first task of the construction process, before demolition work commenced at lower levels, to protect the building fabric rearranged underneath. Parallel to demolition, the building componentry required to make the spatial ‘happenings’ (mentioned earlier) happen, was brought in and assembled within the internal volumes, following a sequential progression from top to bottom. The building process was eventually capped off by placing the two façade screens on the outer fabric.

In the suburban house, the new GI tube structural skeleton was set in place before removing the old roof and carrying out any demolition on the fabric. This required some strategic planning, as the GI tubes had to negotiate the physical form of the retained fabric and the task of penetrating the old roof. The new roof—with its primary and secondary framing, heat insulation and corrugated sheeting—was then fixed onto the structural system, floating above the old roof and protecting the mass beneath. The removal of the old roof took place at this point, revealing the internal volumes and paving the way for the introduction of new partitions and installations into the fabric.

The mountain house, too, pursued a similar top-down construction sequence. The only difference was that, in this instance, the existing roof and the dilapidated building components were removed before the placement of the new roof and the supporting two-storey-high steel structural frame. The structural columns, in turn, were made to stand up on pad footings and placed independently of the retained stone walls, thus allowing working tolerances for demolition and assembly tasks. This was followed by placing the upper-level timber floor decks between the old walls and the new steel columns. New stone walls on strip foundations - using the same techniques practised in the old building - were then introduced at ground level to define new spatial geometries that complemented the position of the old walls.

If all three projects conformed to a top-to-bottom progression, aimed at using the emerging new building as a protector of the surviving fabric, the differences in their building sequences found their logic in the specific constructional circumstances. For example, in the mountain house, there was no compelling need to protect the retained fabric against short-term environmental exposure because the stone walls were to be strengthened later in the building process. Hence, it was seen as logical to follow the more straightforward sequence of removing the old roof before placing the new one. The same was not the case in the suburban project, where the old roof had to be kept intact until the new roof was built to protect a feeble fabric against water infiltration during the construction in rainy months.

The sixth, critical lesson concerns the variance of economic benefit accruing to project stakeholders when pursuing fabric circularity strategies in comparison to standard new build supply in the same market, particularly by taking into consideration Sri Lanka’s current economic situation and price hikes.

Quick pro-forma analyses conducted for the three projects show that they all entail lower financial investments than their new build counterparts. Differences between them, though, are significant, and it is useful to bring them out (Figure 13).

The city project (2180 sqm), which retains approximately 80% of the original fabric without significantly changing its envelope, and has roughly 60% of the remaining construction employing imported materials, generates the largest savings in the current climate. In fact, compared to the amount of materials that should be used for its ‘new build’ option (i.e., the same building program constructed from scratch), the proposal under construction uses one-fifth (both in terms of overall amounts and imported materials). Even when considering the higher incidence of bespoke solutions and associated labour resources in the development of the retrofitting scheme, which command a marginal increase of 40%, the overall cost comes at about 30% of the likely standard new build alternative for the type at current prices.

The suburban house (215 sqm), by contrast, keeps a smaller percentage of the existing fabric, around 50% of the eventual volume, essentially investing the same amount in new materials, 60% of which come from outside the country. In this case, the cost surplus produced by the geography of materials procurement in times of crisis is higher than the city project, and narrows the expenditure comparison between retrofit and new build, with retrofit coming at 65%, including cost increments due to the ad hoc craft solutions necessarily required (which are however lower than in the city project).

Last but not least, the mountain house (320 sqm) presents the lowest retaining proportion of the original fabric, roughly 35% in relation to the final volume of the project as built, with one-quarter of imported materials, and 40% of local resources1. In this case, the reduced percentage of fabric reuse, even in work conditions that are otherwise not too different from the suburban house, brings the expenditure for the circular project at 75% of its standard counterpart.

This is, however, only one part of the picture, in that it does not consider the amount of work and the professional remuneration attached to the projects, which, in Sri Lanka, is measured by construction costs. This means that the differences in fees between retrofit and new build work privilege the more expensive option, which, in this case, is standard new build. For example, the retrofitted city project (which would save its investors 70%) would procure the architect approximately 60% of the fees brought in by standard construction, even when taking into account the higher percentage fee used in retrofit work. If one then considered such amount against the additional labour time required for the circular design option to be developed and monitored—here estimated through logbooks at 2.5 times the normal work—then professional remuneration for the scope of services carried out would be four times lower than for new build.

In the suburban house, the staggering compensation difference produced for the city project would be reduced, in that circular design fees, inclusive of marginal labour increments, would arrive at 70% of new build. With the mountain house, fee parity would finally be achieved, even when considering marginal increases in labour requirements.

As suggested, more than the detailed numbers of each project, it is their comparison that calls for attention. Even with the degree of approximation utilised, data indicate that retrofitting would pay off particularly for commercial buildings (i.e., the city project), which can be refunctionalised whilst preserving the majority of their original fabric, thus reducing required investment in the purchase of new materials. From an urban design point of view, this constitutes an element of great strategic interest given the strong presence of these buildings and their position in the city. At the same time, they are the ones providing the design profession with the least economic advantages: not only construction savings normally translate in lower fees; fabric adaptive solutions also require more time to develop than standard new build ones. In other words, the value generated for the construction market or city-making by stock circularity-practicing architects does not translate into economic benefits for the architectural firms themselves.

This double-market contradiction, in a sense, highlights the importance of the current crisis in developing a culture of stock circularity: what would not be rationally defendable under normal economic conditions becomes a business opportunity for everyone in times of industrial autarchy and market decline. If building investors need reduced construction costs, professional designers need commissions. This may be the type of convergence required to reconsider the nature of professional services and the financial quantification of their value.

The seventh lesson concerns the importance of conceiving and treating building systems as distinct physical layers. As outlined, the different programmatic intentions and development conditions of the three projects called for case-specific social and technical solutions concerning their typological approach, labour organisation and building results. Yet, all three projects were developed as layered combinations of five building systems: existing fabric, new structural skeleton, partitions, installations, and finishes (Figure 14). Designing through systemisation and layering of components was seen as a way of normalising operations when tackling disparate fabric retrofitting realities or ambitions.

By and large, the advantages of this approach have been twofold. Firstly, it has enabled the creation of a conceptual platform where building systems could be brought sequentially into their fabric-transformative action and with specific procedural roles. For example, the existing fabric provides the physical base around which the behaviour of ‘new’ systems is conceptualised and designed. On the other hand, the structural system—usually the first to be introduced to the fabric - provides the element that technically connects the fabric with other building systems, and offers the socio-technical ‘means’ of organising the overall ‘end’. Correspondingly, the other ‘new’ systems—notably partitions and installations—can function anatomically independently of the structure and fabric. Secondly, such an autonomous integration of building systems and components provides technical flexibility to draw in different labour pools and material practices—for both economy and practicality reasons—and to make sure that the eventual failure of one system will not lead to a chain of failures. In other words, it brings the necessary level of design tolerance to the work. It must be stressed, however, that the technical independency mentioned here refers to the socio-technical assembly of the building systems and components. The same must indeed be dependent upon and connected by a common formal language of composition and experience. Caveat notwithstanding, developing systematic design approaches to retrofitting could establish continuity—and circularity - of practice, where reuse becomes both an intellectual position and an explicitly methodical procedure.

Whether or not exhaustive of all the possible challenges connected with the redesign of existing building structures, the seven lessons empirically brought up from the work of RAW serve to indicate the distance between the theoretical value of urban fabric renovation (with the circularity of building stock it entails) and the cultural/economic feasibility of the work processes required to make it happen but seldom discussed.

In principle, the design choices and building solutions introduced in these pages foresee fabric retainment and manipulation as ideal means for the generation of new urban environment languages apt to respond to the significant construction industry pathologies currently connoting former transition economies—in the specific case the city and the central Sri Lankan region of Kandy. This whilst providing the intellectual base for a self-reflective practice that thrives for complexity through historical continuity. As Benedikt (2007) has claimed in a never sufficiently cited essay, “historical continuity in design—having to incorporate the old—is a prime strategy in increasing the degree of balanced complexity and organisation in architecture and subsequent ascendance in value".

The stakes are neither trivial nor, historically, out of reach. As discussed in the first part of this essay, Sri Lanka’s construction sector—armed by modes of production subservient to an economy open to the world and by a largely inactive regulatory apparatus—has lent itself to forms of urban expansion that have shown a tendency to propagate inferior building fabric with little or no relevance to settlements’ historical meaning, spatial quality or environmental context (Figure 15). Admittedly, the imperfect technological applications that characterise such fabric are also a by-product of the country’s diminishing (or by now prevailing) building culture, which is burdened by substandard building systems and processes, insufficient skills of its construction workforce, and unimaginative practices of many building professionals. The consequence for urban space has been the proliferation of many underperforming building structures.

FIGURE 15. Kandy: (A) The Temple of the Tooth Relic of Buddha with the lake in the foreground and Udawatte Kele forest in the background; (B) the adhoc commercial constructions in the city centre.

At the same time, and almost by default in the current geopolitical climate, these very structures offer the possibility of being programmatically reorganised, technically recycled, and spatially and culturally re-designed. Indeed, such a strategy can provide the necessary technological base and the programmatic focus for the country’s urban building industry to overcome the resource scarcity and the shortage of work triggered by Sri Lanka’s ongoing political and economic crisis.

But while the merit of such a plan may be apparent from both an urban identity and a trade balance perspective, the analysis of the type of practices that must be activated in order to respond to the associated design mandate makes the incorporation of the ‘old’ in the economically and technically challenged urban conglomerations of Sri Lanka less straightforward.

To start with, because of the industrial sector that it must depend on. In a place like Sri Lanka, intervention on the existing building stock must forcedly engage small-scale architectural practices, currently about 90% of the country’s profession in terms of numbers and commissions, and count on their ability to cultivate the intellectual and pragmatic base necessary to demonstrate the feasibility of adding value to existing building stock through fabric-transformative design actions. In fact, if one must change general perceptions and convince the community that adaptive reuse is doable beyond boutique projects and at an extensive building scale, the role of small-scale practices in defining form and meaning of this ‘building fabric architecture’ becomes critical, as they would most likely be the first ones to become involved in such fine-grained activity.

As noted, however, any practice valuing a design approach based on the ideas of circularity outlined in these pages will have to overcome several methodological and operational hurdles to achieve efficiency and productivity with respect to the building process and its outcomes. Firstly, projects of this type present idiosyncratic paths of development wrought by case-specific spatial and technical challenges, coupled with the possibility of cropping up unforeseeable facts, situations and occurrences during the assembly process. For this reason, the architectural practice’s design methodology must follow a structure that can adapt to different—and often dynamic—production environments to yield diverse but equally effective solutions. This tends to run counter to a general tendency in the architectural services industry to standardise procedures in order to gain in work efficiency.

Secondly, more often than not, retrofitting work demands greater input than new build from the architectural team, especially during on-site construction. It requires, for example, that the architect ‘designs’ both the building product and the construction process with equal rigour, since retaining the fabric is likely to draw out critical - and often unanticipated - decision-making during the production phase. By-and-large, the marginal costs of design work as a service to on-site production are not quantified in conventional architectural practice, especially in urbanising economies. To this end, for circularity to be brought to the fore in mainstream practice, there is a need to redefine the operational boundaries of such practice and the critical objectives of the design function as professionally understood.

Thirdly, the information communicating the process of intervening on existing fabric is likely to require variations in its structure and contents, as determined by the technical environment and the social constituents of the particular building intervention. Thereupon, the practices engaged in this type of circular design will have to cultivate multiple forms, rules and techniques of project documentation, where ad-hocness and spontaneity must coexist with information meticulousness.

Fourthly, and in terms of practice recognition, recycling existing buildings with no recognised preservation value per se is conventionally seen as attracting little money and prestige whilst generating more risks and posing greater constraints to the creative process. Thus, on the one hand, it is up to architectural practitioners to develop new ideas and design approaches for seeking and finding the ‘new’ within the existing, and to build a new culture on the transformative potential of the existing fabric. On the other hand, and in relation to the important aspect of remuneration, the standard practice (for Sri Lanka) of construction percentage-based architectural fees may require critical scrutiny. As pointed out in the examples brought up, recycling existing fabric can be economically advantageous with respect to building from scratch. The cost-saving factor, obviously, depends on the scale of the intervention, the articulation of the details, and the percentage of the fabric retained. Nevertheless, lesser construction costs by no means imply reduction of the architect’s workload. On the contrary, fabric retrofitting design demands great investments of technical planning and intellectual energy on the part of the design professional, to a point where increases in design efforts produce gains in resource savings and project performance refinement. This does not necessarily follow predictable linear paths, as the production process of retrofitting buildings may call for unforeseen design work at later stages, the development of which takes up paramount importance vis-à-vis the control of building costs. All things considered, the identification of alternative and more appropriate fee methods is crucial to safeguard the quality of design labour and the value of the architect’s work, thus building incentives for design professionals to enter the market in question.

Be that as it may, for design circularity to trigger a city- and industry-wide response in a country like Sri Lanka, small-scale architectural practitioners will have to shoulder the role of public intellectuals and show the way for others by example. Ultimately, the goal should be that of arriving at practical responses to the challenges and benefits of design circularity, without being sidetracked by false perceptions about the need for decoration and opulence (that have otherwise occupied the activities of internationally published and thus culturally conditioning successful practices). Put differently, the need at this stage is to cultivate responses that are not simply embedded in the current traditions of city building but are bound to set out new traditions of circularity in the city. It is only through the facilitation of a critical yet rational approach to building retrofit that the full potential of circularity can be extended across restructuring economies such as Sri Lanka’s physical and cultural extremes.

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The handling editor PS declared a past co-authorship with the author PT.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

1Kandy is the second-largest city in Sri Lanka, the capital of the Central province and a buzzing commercial agglomeration. It was the last capital of the Sri Lankan monarchy and presently houses the former royal palace, the Temple of the Tooth Relic of Buddha (one of the most sacred places of worship in the Buddhist world), and the country’s first university built in 1942. Juxtaposed with this history and sacrality is Kandy’s picturesque landscape derived from the hill-top setting, wooded mountains and a spectacular lake at the city’s heart. Kandy’s main streets are built as a grid city following the cosmic planning principles of the Mandala concept: a geometric configuration of symbols and patterns used in Eastern cultures.

ADB (2019). Sri Lanka energy sector assessment, strategy and road map. Manila: Asian Development Bank.

Akerman, M., Humalisto, N., and Pitzen, S. (2020). Material politics in the circular economy: The complicated journey from manure surplus to resource. Geoforum 116, 73–80. doi:10.1016/j.geoforum.2020.07.013

Athukoralage, P. (1981). Import substitution, structural transformation, and import dependence: A case study of Sri Lanka. Dev. Econ. 24, 119–142. doi:10.1111/j.1746-1049.1981.tb00428.x

Benedikt, M. (2007). “Eighteen proposals for revaluing architecture,” in Take 5: Looking ahead: Defining the terms of a sustainable architectural profession. Editors P. Tombesi, B. Gardiner, and T. Mussen (Melbourne: The Royal Australian Institute of Architects), 301.

Bhowmick, S. (2022). Understanding the economic issues in Sri Lanka’s current debacle. Available at: https://www.orfonline.org/research/understanding-the-economic-issues-in-sri-lankas/(Accessed August 21, 2022).

Corvellec, H., Stowell, A. F., and Johansson, N. (2021). Critiques of the circular economy: Journal of industrial ecology. Available at: https://onlinelibrary.wiley.com/doi/pdf/10.1111/jiec.13187.

Cullen, J. M. (2017). Circular economy: Theoretical benchmark or perpetual motion machine? J. Industrial Ecol. 21 (3), 483–486. doi:10.1111/jiec.12599

de Zoysa, M. (2001). A review of forest policy trends in Sri Lanka, policy trend report 2001. (Kanagawa: Institute of Global Environmental Strategies IGES). 57.