94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Built Environ., 24 November 2022

Sec. Construction Management

Volume 8 - 2022 | https://doi.org/10.3389/fbuil.2022.1046954

This article is part of the Research TopicSociotechnical Challenges in Construction ManagementView all 4 articles

Using wood in multistory apartment construction (WMC) has a climate-positive advantage with buildings acting as long-term carbon storage. Business ecosystem (BE) development around WMC is needed to accelerate the adoption of wooden materials in the conservative construction industry. As the business actors around WMC are essentially different from those using other building materials, new knowledge must be built from the project level. This study uses a qualitative interview approach among actors from three pioneering urban building projects to address their perceptions of building with wood regarding a project-based BE. Based on the thematic analysis, sources of both tangible and intangible value creation were found to arise from building with wood. A higher degree of prefabrication associated with WMC was seen in all projects to influence the reorganization of logistics, enabling faster building processes and lean material use. No strong sustainability-driven culture could be identified in any of the projects. Results further flag the sensitivity and importance of management and coordination skills in targeting improvements of the construction business based on WMC. In the bigger picture, there is still room for further research at regional and global level on business model changes in building with this renewable and recyclable material.

Socio-technical transitions (e.g., Markard et al., 2016) include the emergence of novel products, services, business models, organizations, regulations, norms and user practices, which are complementing or substituting existing ones. According to Lehman (2013), choosing less emission intensive materials and materials that can store carbon offers a potential avenue towards sustainability transition in the construction sector (see also O’Neill and Gibbs 2014). The construction industry is globally responsible for producing a significant share of carbon emissions while concurrently having a significant potential to reduce these emissions with improved energy efficiency and by choosing new materials to substitute carbon-intensive concrete and steel (Churkina et al., 2020). The demand for urban housing is generally on the rise, even in markets where total population growth is modest such as in the Nordic countries. Future building material demand and related emissions can be reduced through more intensive use of buildings (reducing per capita floor area), building lifetime extensions, using lighter constructions and less carbon-intensive building materials (e.g., wood-based construction instead of steel and concrete), or by reducing construction waste (Hertwich et al., 2019). Amiri et al. (2020) further suggest that long-term carbon storages are achieved especially in cities with a great need for new buildings and residential housing.

According to a review by Xia et al. (2018), environmental aspects of corporate responsibility practices in the construction industry incorporate resource-efficient materials and the management of carbon emissions. Reuse, remanufacturing, material recycling, appropriate material choice, or the use of off-site construction (i.e. prefabrication) to reduce construction waste are avenues for improving corporate responsibility, as materials contribute to over 50% of the carbon footprint of buildings and infrastructure and material efficiency improves strategies such as the light-weighting of and lifetime extension for products (Hertwich et al., 2019). In addition, the request to enhance corporate responsibility practices in the construction industry relates Xue et al. (2018) to demand factors in housing markets, where consumer consciousness for sustainability also reaches the materials used in their homes (Harju and Lähtinen 2022).

While the European Union has a target of carbon neutrality by 2050, one of its member states, Finland, aims to reach carbon neutrality as early as 2035. An estimated ∼30% of Finland’s greenhouse gas emissions are caused by construction and energy use in buildings, and 40% of the total energy consumption is used in buildings (Rakennusteollisuus 2020). Hence, the built environment has great potential and a need for reducing emissions while increasing carbon capture and storage. Especially in urban areas, apartment buildings show strong potential in reducing emissions due to resource-efficiency gains (Wiedenhofer et al., 2018), emphasizing the special need to study the material choices made in multistory construction processes (see also Himes and Busby 2020; Kinnunen et al., 2022). In a recent review, Hill (2019) concluded that timber derived from sustainably managed forests can be used in long-life products in the built environment to meet climate change challenges.

Previous literature suggests that wood use in urban construction and multistory apartment building (WMC) has an advantage over other materials with buildings functioning as long-term carbon storage (for a recent review, see Kinnunen et al., 2022). When wooden elements are used in buildings, the buildings function as carbon storage for decades, until they reach the end of their life cycle and the materials are disposed of, reused, or utilized as a raw material for new products. Influencing the amount of carbon in buildings is possible in the construction industry by preferring wood as a structural material, for example by using cross-laminated timber (CLT) or wooden frames. Various options affect the amount of wood used and thus the carbon storage (Hafner and Schäfer 2018), with the volume of wood used playing a key role (Amiri et al., 2020). For example, Viljakainen and Lahtela (2019) compared the carbon footprint of construction by studying a timber frame, concrete frame, CLT, and a hybrid frame with concrete, steel, and stiffening parts manufactured of CLT, and argued that the carbon handprint plays a major role in wood structures and describes the environmental impacts more broadly. Also according to Švajlenka and Kozlovská (2020), the use of panel wood-based systems, which are an example of off-site technology, is considerably more efficient than using on-site technology. Slowly but steadily, WMC business has gained higher impetus as an emerging alternative to replacing the concrete-based construction regime in the Nordic area (Franzini et al., 2021; Jussila et al., 2022).

As a parallel trend, increasing material circularity is suggested to be essential for improving the sustainability performance of the building sector, generating both environmental and economic gains (Koutamanis et al., 2018; Nussholz et al., 2020). According to a review by Gallego-Schmid et al. (2020), analysis of the linkages between circular economy solutions and climate change mitigation actions in the built environment has been scarce in the literature so far. In addition to pure material flow aspects, a circular economy in the built environment often involves partnerships and collaboration in building projects (new and existing). This calls for wider engagement with involved stakeholders in the networks for resource sharing and reuse (Pomponi and Moncaster 2017). According to Piroozfar and Piller (2013), integrating residents in industrialized building design processes may bring both sustainability gains and increase in customer value creation, but this is rarely focused on (e.g., Viholainen et al., 2020).

Breaking free from a highly subcontracting-based, cost-efficiency-driven, and low-innovation industry (Gann and Salter 2000) is possible at the niche level, with WMC offering an example of this (Hemström et al., 2017; Vihemäki et al., 2020). The most important factor behind the growth of WMC is the prevailing path dependence in the construction industry (Hemström et al., 2017). However, the business networks around WMC are essentially different from those using other building materials, and WMC business networks severely lack research. For example, Gosselin et al. (2018) found that WMC projects involve value-added stakeholder relationships rather than linear relationships, which also appear to be closer, more frequent, and involve active knowledge and information sharing. In light of this, it is relevant to understand how diverse ecosystem actors in wooden multistory construction projects could collaborate to find new innovative solutions in the construction sector, contributing to both internal corporate responsibility-driven pressures and external pressures toward lower environmental impacts in the built environment. Scientific understanding of such aspects is still missing, although Toppinen et al. (2019) and Viholainen et al. (2021) are exceptions because they provide information on project-level implementation of WMC through the lens of a business ecosystem (BE). Both studies underlined the importance of communication, establishing cooperation, and knowledge accumulation processes over a longer time. In addition, especially the role of material suppliers in WMC projects was only vaguely understood, although suppliers are generally acknowledged to be elementary for the success of WMC projects.

To contribute to filling this gap, we address questions regarding the emergence of a WMC project-based BE with a qualitative interview approach. Our overall aim was to answer the following research questions:

Conceptually, we draw our background from Moore (1993), Thomas and Autio (2014), and Pulkka (2016), who define BE actors to have the following aims: cooperating in the development of new products to create value and satisfy customer needs, and thriving to create new innovations. Moore (1993) also distinguishes two inner layers of the BE as an extended enterprise and core business, which may include divergent functions depending on the actors. According to Aarikka-Stenroos and Ritala (2017), the BE concept emphasizes co-evolution, increased interdependency, and developing complementary capabilities among participating actors. They also note that the term ecosystem is used in various ways, ranging from a synonym for a business network to an analogy for interconnected business environments, and we also follow this rather open formulation.

Accordingly, the participant network develops in the ecosystem because there is an interdependence between the participants, which also shows the direction of the network (Thomas and Autio 2014), and an ecosystem must therefore prepare for continuous renewal (Williamsson and de Meyer 2012). This leads to the need to create a stronger link between companies and possibly to organizational integration among certain actors. This further increases the interdependence of business relationships.

Various roles exist within ecosystems. Keystone actors (sometimes called hubs) play a role in enabling the whole network, creating, and sharing value among others involved in the ecosystem. Instead, niche actors develop their own special expertise and may be responsible for most innovation and value creation (Thomas and Autio 2014). The third group of actors, dominators, tend to either control many network functions or have only limited direct control over the network and do little to add value to the whole network.

Ecosystems are characterized by the creation of collective value, i.e., the goal of those involved in the ecosystem is to jointly find customer-oriented solutions that make value creation possible. Every participant within the ecosystem is interdependent in creating value, and this also applies to the external environment outside of the ecosystem (Thomas and Autio 2014). In certain situations the ecosystem is more likely to be successful in value creation. These situations include the effective joint learning and development of participants or situations in which participants clearly specialize or strongly complement each other.

An important aspect of our study is acknowledging the project-level nature of the highly subcontracted and fragmented construction business, which calls for a good fit and coordination between complex, interdependent, and non-simultaneous tasks implemented within strict project timelines (Gann and Salter 2000). However, the nature of the construction industry remains strongly rooted in traditional concrete-based building methods and approaches (Hemström et al., 2017; Martek et al., 2019). This may slow down a transition toward a more sustainability-driven culture (Mahapatra and Gustavsson 2008), and limits the focus more on tangible supply chain processes instead of business development.

Furthermore, the risk-averse nature of the construction value chain (Gosselin et al., 2018), resisting the uptake of new practices, appears to be a hindrance for the future market potential of WMC (Hurmekoski et al., 2015). Better recognition of patterns, interactions, and the interplay among a diverse set of not only project but also non-project stakeholders (such as municipal planners, local residents) is called for to efficiently manage this BE transformation. According to Gosselin et al. (2018), a higher degree of prefabrication enables smoother relationships by limiting the number of stakeholders while promoting innovative thinking, which is another structural benefit of a WMC ecosystem.

Familiarity and trust in discontinuous inter-organizational settings, such as building projects, play important roles when collaborating and sharing new knowledge (Maurer 2010). In their review, Mokhlesian and Holmen (2012) state that capability development, partner networks, and value configuration are the most important elements facilitating change towards more sustainable construction practices. Deep et al. (2021) also underline the importance of trust, commitment, and reliability as enablers of deepening the collaboration in construction. Instead, failure of the main contractor when transferring risks to subcontractors tends to lead to vicious development and to the growth of opportunism, regionalism, and favoritism.

Pulkka et al. (2016) were the first to apply the BE concept in the construction industry setting, and they found positive impacts on value creation, which could be achieved through collaboration extending beyond traditional project-based subcontracting. At the practical level, a functioning BE associated with a particular project is connected to smooth information sharing practices via shared knowledge platforms and information systems, and mutual team building efforts, despite the temporal structures of a construction project (Viholainen et al., 2021). The project manager’s role is often emphasized in promoting the effectiveness of communication, but various networked organizational structures and the use of more informal practices may also influence how information flows (Chen et al., 2021).

When many actors are involved in developing integrated solutions, strong links must be established between the actors. Identifying these important actors becomes easier with the help of an extensive network (Windahl and Lakemond 2006). According to Matinaro and Liu (2017), stronger collaboration and more active communication are key elements of organizational innovativeness and in improving sustainability in the construction field. Hence, to materialize sustainability transformation in the construction industry, BE development around WMC, and the establishment of cooperation and knowledge accumulation processes over a longer time across different projects are of importance. Collaboration and shared logic are primary elements around a well-functioning BE over other ecosystem-related aspects, such as network governance and network participant selection.

When becoming involved with new types of construction materials (such as CLT) and building processes (increased prefabrication and off-site construction), construction companies must develop new capabilities and cooperational relationships (Mokhlesian and Holmén 2012). Intensifying business cooperation to break free from niche-level WMC would essentially comprise changing both the construction industry mindset by increasing collaboration with suppliers, on-site contractors, and engineered wood product manufacturers to develop off-site construction methods (Gosselin et al., 2018). Advancing broader research and development efforts with intermediating organizations and associations developing technical standards that are affecting the WMC business are also needed (Vihemäki et al., 2020). Mutual awareness of the cooperating network of partners, their shared goals in cooperation, and understanding of how the value is created and shared in the network are related key elements, as also identified in the WMC case (Toppinen et al., 2019).

Following an established approach in construction management research (see e.g., Pulkka et al., 2016; Hemström et al., 2017; Martek et al., 2019; Toppinen et al., 2019), the qualitative semi-structured interviews were chosen as a method in data gathering. This encourages project actors to describe their experiences and actions in their own wording (Edwards and Holland, 2013), which was considered important for deepening our understanding of the phenomena behind novel WMC projects, with no intention or possibility to quantify the meanings. The key benefit from using semi-structured interviews is that this approach enables increased interaction between the interviewer and interviewee. It also facilitates exploring topics wider than the ones originally intended, which is an important aspect in studying this emerging business ecosystem around wood material. In order to address the research questions, the project participant interviews were used to collect original data to study the business ecosystem from the specific project management context (< href="statement-Research_question_1">Research question 1). Instead, more free form elaboration on the perceived sustainability gains and other benefits accruing from the project level collaboration (< href="statement-Research_question_2">Research question 2) was allowed since this topic invites reflections from more general business level.

Empirical data were collected from project actors involved in owner-occupied residential construction projects. Project 1 was a four-story residential building with 36 apartments, Project 2 was a five-story building with 57 apartments, and Project 3 was an apartment complex of three houses ranging from two to five stories with 46 apartments in total. In all three projects, wood was used as the construction material for the bearing structures of the buildings (herewith “structural material”), and it is also visible in external applications such as the facades. Although the projects were already completed by 2019 (and were chosen for the sake of comparability), an overwhelming majority of the contacted organizations still wanted to become involved (only two contacted experts declined) and expressed enthusiasm about the interview opportunity.

As the timing of material suppliers entering building projects has been acknowledged as crucial for WMC projects success, project actor interviews were complemented with key informant interviews with a national pool of wooden element suppliers, which helped to gain a wider perspective on this novel material-driven ecosystem. In the text, the interviewees are referred to using codes given in Table 1, describing each interviewee’s background and expertise.

TABLE 1. Companies and individuals involved in the interviews during October 2021–March 2022, and interview duration.

The interview guide was based on a literature review and on the theoretical framework from the business ecosystem, drawing from Thomas and Autio (2014), Pulkka et al. (2016), and the various ecosystem levels suggested by Moore (2006). The interview guide was divided into several themes (see Appendix): the construction project as a larger BE, cooperation and communication practices, new ways of collaborating, along with environmental awareness and the role of buildings as a carbon storage. As the general COVID-19 situation was still active, all 15 interviews were conducted remotely on the Microsoft Teams platform and recorded for transcription.

Using a qualitative interview study, the thematic analysis used a theory-based content analysis method, as the theory already guided the formulation of the questions (Braun and Clarke 2006). The material was therefore grouped according to topics, after which the aim was to find views in the material that emerge in connection with a specific theme (Tuomi and Sarajärvi 2018). Most of the topics and themes discussed during the interviews were recurring, which indicates that, taken together, the data were quite well saturated and can be considered sufficient for the purpose of addressing the two research questions.

The reliability and validity of our study was ensured by carefully documenting the research process and through transparent communication of the data-gathering process with the use of authentic data excerpts in the results section. During the analysis process, we also concluded that the interview data were sufficient for analyzing the research questions, as recurring themes were observed, and only marginal new information was obtained during the final stages of the interview process. As a limitation, because the data were compiled in three locations (large-sized Finnish cities), the contextual background may also have some differences. Further, the tasks of the interviewed actors were completed by 2019, which decreased the depth of the interview discussions and may end up blending the interiewees’ experiences from the case projects with other projects they had worked on since. However, our choice was dictated by our wish to establish some degree of comparability between WMC projects targeted at the owner-occupied segment, and the selected three similar-sized projects were at that time—and still are—the very few completed projects in Finland that belong to this field of construction business.

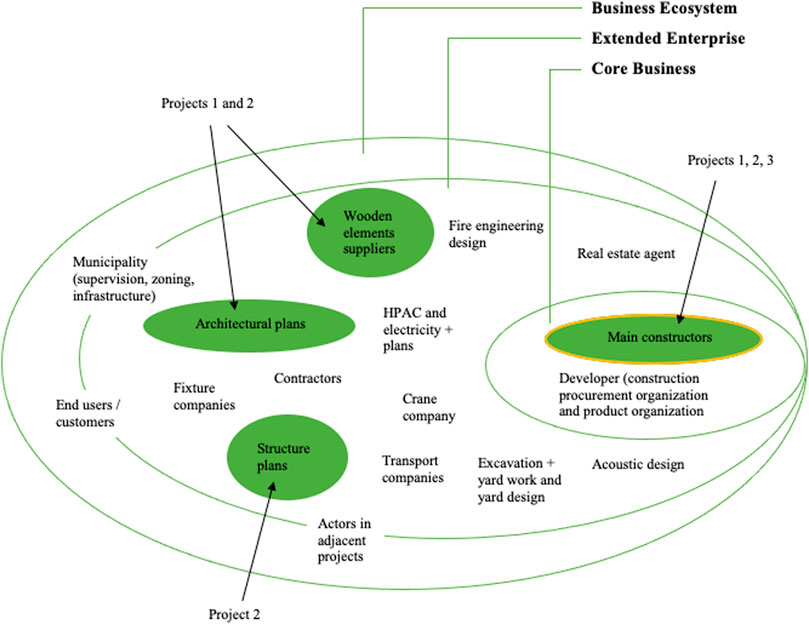

The whole range of WMC ecosystem participants identified in the interviews are depicted in Figure 1. According to it, there is the core business embedded in main developer or constructor having a keystone role. Structural planners, designers, architects, and wooden element suppliers also have varying degrees of influence within the extended enterprise during the project span. Smaller-scale, more specialized subcontracting organizations were merely mentioned when respondents were asked to list all involved project participants.

FIGURE 1. Identified project-based business ecosystem structure (participants included in direct interviews marked in green, the rest of participants were mentioned in interviews).

The three projects were the first WMC projects for many participating actors, which is also reflected to some extent in how respondents expressed that more clarity is required in project leadership, as the following quote demonstrates:

“Before that [project], our organization had not built a wooden multistory building. Now we at least know how challenging it is.”—Project 2, interviewee 4.

The projects had common goals of producing high-quality and environmentally friendly construction, which contributes to increasing carbon storages in harvested wood products. The interviewees acknowledged that open discussion, high motivation, and the effectiveness of cooperation were factors that led to successful project execution in both projects 1 and 2. Based on interviews from project 3, superior customer knowledge and product development based on it are the key foundations for project success. The following quote describes one interviewee´s feelings concerning the new way of collaborating:

“It certainly brings complementary know-how that would otherwise not be gained unless useful additional know-how is obtained from the outside, which is believed to be beneficial.”—Project 1, interview 11.

Interestingly, the third project differed from the other two because it used a clearer partnership model. Construction participants worked together to form a more integrated collaborative building concept with an integrated delivery system, but we were unable to uncover the extent to which the team would have a joint management structure under multiparty contractual arrangements of project partnering.

Especially in project 1, many of the actors knew each other beforehand. Because of the close collaboration, the ecosystem could also expand beyond a single project, as shown by the following quote:

“Such everyday cooperation in the project is almost like being part of the same organization, we constantly deal with many people across organizational boundaries.” - Project 1, interviewee 1.

According to the interviewees, project 1 did not manifest any major challenges, although the higher-than-expected living costs of the material came as a surprise, which was explained to be caused by the WMC project being the first of its kind for the company. On the other hand, limited communication and personal chemistry issues were identified as potential contributors to challenges experienced in project 2:

“In that sense, it was for the existing construction companies, which of course come with the old processes and the good ones, I think it was, perhaps, more challenging for them to understand that things are done in a different order when [a building is] made of wood and not concrete.”—Project 2, interviewee 8.

According to the interviewees, challenges are likely to arise if there are communication problems or changes to scheduling due to delays in other work phases. The expressed challenges also stemmed from the actors having different ways of working or being unfamiliar with a particular construction style. Based on project 3 interviews, project actors perceived new things emerging as only natural, but these were not considered to be challenges as such. The general challenge in project management was not understanding the specificities of WMC as a building method already at the design stage, which was most clearly observed in project 2.

Meetings with other actors were considered important and the most effective channels of communication. These provided opportunities to obtain first-hand information from the other actors and allowed open discussion and problem resolution in advance. This was highly needed because the WMC protocol had no clear common practices, as illustrated by the following quote:

“It all depends on the project and how much [communication] has been put into it. Now I notice that during remote working there are a lot of different practices, and some are much more organized and of course rise to a bigger value. [It depends on] how much time has been put into, the meaning of communication and what channels are used.”—Project 3, interviewee 10.

The prospects for continued project collaboration in the future varied not only between but also within the projects.

The interviewed project experts identified the potential of buildings as carbon storage and recognized the high environmental potential of wooden multistory projects. However, they felt that two issues were needed to increase the number of wooden multistory buildings: a change in resident attitudes toward wood and a change in the construction industry’s mindset. An interviewee from project 3 elaborated:

“More and more people are looking for properties that are built responsibly and have the right environmental values. But I can’t say that [project 3] would have been significantly more visible just because someone who bought the apartment for being in a wooden apartment building”—Project 3, interviewee 7.

Lean material use, associated with increased prefabrication in WMC projects, can be seen as the key approach to increasing the efficient use of the (virgin) material. In addition, more consistent calculation methods were commonly desired for demonstrating the carbon footprint and handprint, to increase the comparability of various building methods. Interviewees critically self-reflected on whether the companies have embraced environmental thinking holistically enough and whether the manifested carbon neutrality goals will be achieved both within the companies themselves and globally. Nonetheless, the increase in WMC construction was seen as a positive development, providing the opportunity to take an incremental step forwards. These positive views were shadowed by WMC still being perceived as more expensive in Finland, which does not lower the threshold for mainstreaming projects. This is also visible in the pessimistic tone of the next quote:

“But maybe just because we’re in a low-margin business, this world of construction, the fact that wood construction costs so much, it’s [therefore] a rather high threshold to promote such projects on a larger scale.”—Project 1, interviewee 3.

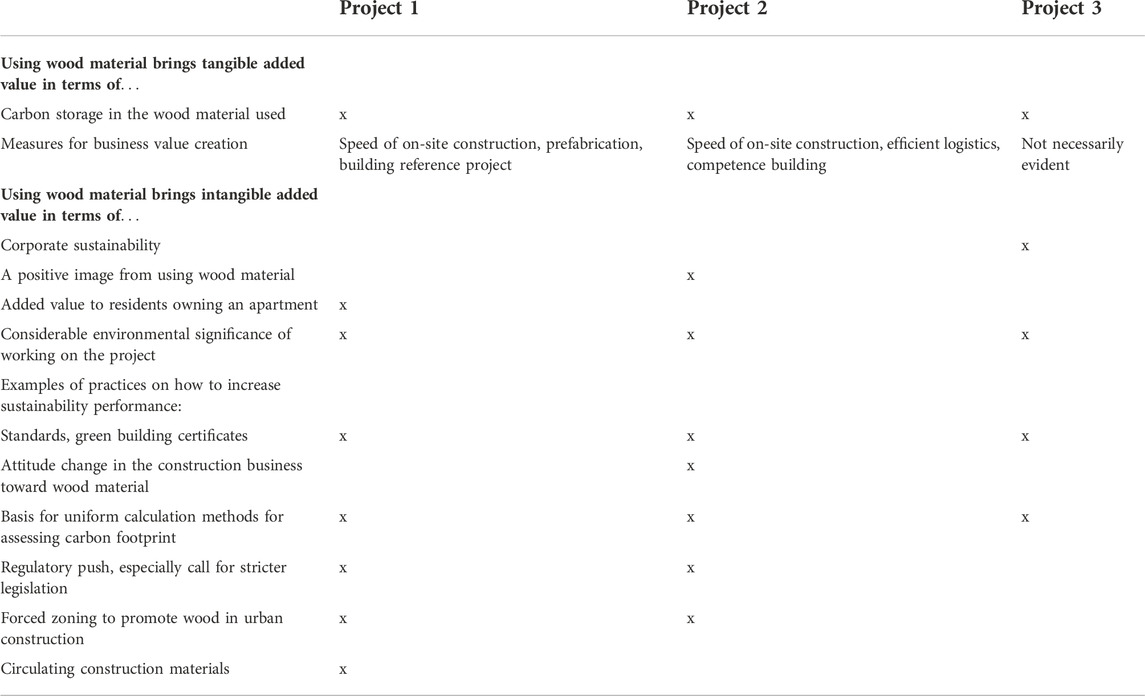

Based on project-level comparisons, summarized in Table 2, both tangible and intangible values were seen to be created from wood construction. The higher degree of prefabrication associated with WMC was uniformly considered to influence revenue distribution and logistics reorganization, the latter which enabled a higher speed of building process and lean material use. Interestingly, while the environmental significance of working with WMC was voiced in all the projects, only one project advocated a deeper attitude change in the construction business towards utilizing more environmentally friendly practices. Instead, a more instrumental approach through standards, green building certificates, and the need for uniform carbon footprint calculation methods were mentioned. The use of stricter regulation and even forced zoning in urban land use to promote WMC was suggested in projects 1 and 2.

TABLE 2. Perceptions of environmental and other benefits from building with wood arising from three multistory apartment construction (WMC) projects.

The strategic importance of wood element suppliers that enabled a successful project outcome were a common factor to projects 1–3. Vice versa, the actors’ limited awareness in how to measure carbon footprint and handprint was a critical deficit in the value creation process of all the projects. Interestingly, the contribution of WMC projects to the circular economy was only brought up by interviewees from one of the three projects.

After finishing up the interviews, we felt it necessary to focus more on the wooden element suppliers, as their involvement was frequently brought up as a key issue in all the projects. Additional wood material-based insights were provided by the follow-up interviews with four experts (I., J., K., and L. in Table 1), which constitute a major share of the wood element (including CLT) supplier organizations in the domestic niche market.

Insights concerning the benefits arising from wood use by material suppliers mostly aligned with insights coming from the project actors. Coordinating project plans and communicating with non-project stakeholders and with parties involved in the project was mentioned on several occasions to influence project outcome. Furthermore, responses emphasized that the novelty of the technical solutions and the design criteria that exist in residential WMC must be made transparent, as WMC has differing practices compared with the traditional, highly standardized, yet still dominant concrete construction. A more demanding project management issue was also acknowledged, as the following quote shows:

“[Building with] wood includes a high quality of work, a shortening of project lead times, the functionality of moisture technology, a low number of errors. …. Project management is more demanding, and it incurs costs that the traditional concrete sector does not incur during construction.”- Company K, interviewee 14.

Based on the follow-up interviews, it became evident that element manufacturing companies did not believe they are involved sufficiently early in the project planning phase to contribute to a successful outcome. This was elaborated in an interview in the following manner:

“Our aim is to be involved as early as possible. If any earlier, then we are talking about [land] zoning, and I would see that there too [we] can bring some benefits through our standards, but we have insufficient resources. We are in certain development projects in operation in [city N], for example, which will enable us to influence the zoning and so on, to bring our insights.” - Company L, interviewee 15.

The reason for the late involvement could be related to the high level of prefabrication, which is not necessarily recognized at the project design phase. Prefabrication may also be seen as a threat to established revenue distribution in the ecosystem, which still mimics the distribution of roles and responsibilities in the mainstream concrete construction business. However, as the revenue issue was elaborated more deeply in the wood element supplier interviews, we have no possibility of authenticating this finding with the participants of the three projects. Hence, a focused follow up-study on the changing revenue structures can only be recommended.

The study focused on project-level analysis of qualitative interview data concerning perceived business- and sustainability-related benefits in urban residential wooden multistory construction. We note that the objective of this qualitative interview study is not to present generalizable results of the Finnish WMC case or beyond it, but to understand the BE from the value creation perspective in the context of actual projects. Rationale for this study is given by the need to enhance the efficiency and sustainability of the construction sector, and acknowledging the increasing expectations towards the businesses to make changes in the dominating construction practices (O’Neill and Gibbs 2014; Jussila et al., 2022). Due to the limited temporal data and qualitative approach used in the study, it is, however, difficult to assess in any absolute terms the significance of the various business ecosystem participants and their mutual influencing in regard to the development and market diffusion of WMC.1

Based on results from these pioneering owner-occupied housing projects in Finland, the higher degree of prefabrication associated with WMC was seen to influence revenue distribution and the reorganization of logistics and to enable a higher building speed. Learning to work with wood in the multistory applications was seen as the greatest benefit for actors participating in the emerging BE along with gaining access to new partner networks. Based on this analysis, we were able to create a network map (Figure 1). This illustrates the roles of companies and other stakeholders, such as the keystone company/hub, and its relation to core business companies and additionally adds to the visibility of other, more occasional, partners. Smoother collaboration may be facilitated by allowing more flexibility in how tasks are performed among the project partners. Results support previous research findings that project delivery and consequent design collaboration should be seen concurrent rather than linear, in order to support smoother flow of information and project performance (Gosselin et al., 2018; Riggio et al., 2020).

A common factor in all three projects was the perceived strategic importance of the wood element supplier, which was seen to enable a successful project outcome. Gosselin et al. (2019) also advocate that wooden element suppliers are in a key role when actively establishing relationships with all members of the WMC ecosystem and they must familiarize other actors with their products to mainstream their use. Similarly, Brege et al. (2014) highlight the prefabrication mode as the starting point for business model design in which other elements are adapted to. According to our results depicting the functioning of this collaboration, a healthy proportion of members in the project-level ecosystems perceived preconditions for communication and cooperation to be fluent, but less positive views also emerged.

Views concerning the prospects for future collaboration continuation between project partners were interestingly found to diverge not only between but also within the three projects. This suggests that the nature of collaboration still depends on the commitment of individual project partners, and the processes in coordinating and managing a complex network of participating organizations need to be further developed to ensure successful execution. This finding suggests great sensitivity to change management skills in development of the WMC BE. The findings thus contribute to understanding the critical role of business collaboration in enabling innovation within WMC market development as noted in existing literature (e.g., Nordin et al., 2010; Gosselin et al., 2018; Toppinen et al., 2019; Riggio et al., 2020; Jussila et al., 2022).

In Finnish housing markets, the three WMC projects were the first of their kind for many participating actors. This is, to some extent, visible as a lack of clarity in leadership and management of the whole construction process. Hence, how well the learning opportunities from this novel building method are being facilitated in the WMC BE remains project dependent. This observation is in line with Viholainen et al. (2021), who found vagueness in the shared goals and a lack of stronger coordination by the project manager to be hindering factors in the execution of WMC projects. Regarding our first Research question on how aligned are the perceived business and sustainability-related benefits, the results provided a positive view with multiple both tangible and intangible benefits arising from building with wood. However, the views were found diverge across WMC ecosystem members and between projects on the longevity of collaboration.

One critical deficit was evident in the value creation process of each project regarding the actors’ limited awareness and the need for a tool to measure sustainability and, more specifically, carbon handprint and footprint. Based on data from our three analyzed projects, views on sustainability perspective and carbon neutrality also differed greatly even within the same company when examining the BE and the actors within it. This suggests an ongoing need to create business models that are able to capture sustainability-based value. This also confirms the earlier findings from a comparative project-level case study by Toppinen et al. (2019). Achieving sustainability-related benefits requires learning and collaboration between actors in the BE (Martek et al., 2019) and more effective communication to make all actors aware of issues affecting the improvement of environmental performance in the construction industry (Lin et al., 2018).

Acknowledging sustainability as a driving force among project stakeholders in construction can further create a momentum for further behavioral change among stakeholders in construction projects, and the results of this study show that there is progress, but also work to be done. As an example, a contribution by WMC projects to the circular economy was only seldom brought up in the interviews and in only one of the three projects. However, the broader implications of adopting circular economy principles in the construction industry include, not only using more renewable materials by sourcing, but also promoting the material efficiency by recycling and reusing and by avoiding demolition and waste (Hossein et al., 2020). Based on this, our findings seem to indicate that the connection with the circular economy is still rather weak in the case of new residential WMC projects using virgin materials. Regarding Research question 2, low carbon material-related sustainability aspects is found to bring added value to the BE members. Instead, there, is limited awareness about new solutions toward increased material efficiency and circularity.

Future research should analyze the mainstreaming of WMC business in a more global scale. Better understanding is still needed in unraveling the benefits of inter-company co-operation and co-learning. Identifying potential means to overcome challenges in knowledge accumulation related to the one-off project-based nature would be valuable in order to renew the highly subcontracted, efficiency-driven construction business culture. Methodologically, focusing on co-evolutionary aspects of the project partners with the use of longitudinal and observational data of ongoing projects would be an interesting element for deepening BE research in the future. As also pointed out by a review by Chen et al. (2020), longitudinal research could offer further insights into the development stages where some coordination needs at construction supply chain interfaces are not recognizable through other research designs.

A logical continuum would be also conducting similar research for more complex building projects such as higher-rise wooden building. Moreover, there is limited knowledge about the involvement of end-users in a business ecosystem, and their needs should be understood more explicitly (see, however, for example Švajlenka and Kozlovská 2020 or Kylkilahti et al., 2020). Finally, with this study being focused on the ecosystem participants in new residential building projects, a follow-up study is recommended to reach also participants in renovation and retrofit construction. This could possibly contain interesting features from the sustainability perspective and include a wider set of ecosystem members such as housing companies and residents in owner-occupied houses. If such an analysis were targeted, the rate of material recycling and the related circular economy aspects would also likely have more weight in the core of sustainable construction than was the case in this study on new residential housing (Hossain et al., 2020).

The study identified both tangible (e.g., carbon storage in the wood material used in buildings and faster on-site construction) and intangible (e.g., perceived environmental significance of working on the project) value creation opportunities to arise from building with wood. A more active communication culture and accruing benefits from learning by doing can foster better functioning of this emerging business ecosystem. A higher degree of prefabrication associated with WMC in these projects influences the reorganization of logistics, enabling faster building processes and leaner material use. On the other hand, actors’ limited awareness and the need for a tool to measure sustainability especially in terms of carbon handprint and footprint of the building were identified as critical deficit for the value creation processes. Involving wood element-manufacturing companies early in the project was seen important to enable a successful project outcome. Results of the study further flag the sensitivity and importance of management and coordination skills in targeting improvements of the construction business based on WMC. While the study contributes to understanding potential changes in the business models of actors involved in the emerging wood construction business ecosystem, there is still room for further research at regional and global level on business model changes in building with this renewable and recyclable material.

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Original idea of the article (TA), planning and design of data gathering (TA, AA, and JJ), selection of the theoretical framework and design of the analysis (TA, AA, and LK), implementation of the analysis (AA and TA), interpretation of data and the results (AA, TA, and LK), scientific writing of the manuscript (TA, JJ, and TR), funding (TA, LK, and TR).

We are grateful to comments received from the two reviewers and funding by the Tandem Forest Values II project “Building up wood construction markets with consumer knowledge, industrial and municipal strategies” (KnockOnWood) ongoing in 2020–2023, the Strategic Research Council affiliated with Academy of Finland funding (grants number 335241 and 335245), and the Puumiesten ammattikasvatussäätiö foundation.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

1We thank an anonymous reviewer for raising concern on this aspect.

Aarikka-Stenroos, L., and Ritala, P. (2017). Network management in the era of ecosystems: Systematic review and management framework. Ind. Mark. Manag. 67, 23–36. doi:10.1016/j.indmarman.2017.08.010

Amiri, A., Emami, N., Ottelin, J., Sorvari, J., Marteinsson, B., Heinonen, J., et al. (2021). Embodied emissions of buildings - a forgotten factor in green building certificates. Energy Build. 241, 110962. doi:10.1016/j.enbuild.2021.110962

Amiri, A., Ottelin, J., Sorvari, J., and Junnila, S. (2020). Cities as carbon sinks–classification of wooden buildings. Environ. Res. Lett. 15 (9), 094076. doi:10.1088/1748-9326/aba134

Braun, V., and Clarke, V. (2006). Using thematic analysis in psychology. Qual. Res. Psychol. 3 (2), 77–101. doi:10.1191/1478088706qp063oa

Brege, S., Stehn, L., and Nord, T. (2014). Business models in industrialized building of multi-storey houses. Constr. Manag. Econ. 32 (1-2), 208–226. doi:10.1080/01446193.2013.840734

Chen, Q., Hall, D. M., Adey, B. T., and Haas, C. T. (2021). Identifying enablers for coordination across construction supply chain processes: A systematic literature review. Eng. Constr. Archit. Manag. 28 (4), 1083–1113. doi:10.1108/ECAM-05-2020-0299

Churkina, G., Organschi, A., Reyer, C., Ruff, A., Vinke, K., Liu, Z., et al. (2020). Buildings as a global carbon sink. Nat. Sustain. 3 (4), 269–276. doi:10.1038/s41893-019-0462-4

Deep, S., Gajendran, T., and Jefferies, M. (2021). A systematic review of ‘enablers of collaboration’ among the participants in construction projects. Int. J. Constr. Manag. 21 (9), 919–931. doi:10.1080/15623599.2019.1596624

Edwards, R., and Holland, J. (2013). What is qualitative interviewing?. Bloomsbury, London, United Kingdom, ISBN 10:9781780938523

Franzini, F., Berghäll, S., Toppinen, A., and Toivonen, R. (2021). Comparing wood versus concrete: An explorative study of municipal Civil servants' beliefs about multistory building materials in Finland. For. Prod. J. 71 (1), 65–67.

Gallego-Schmid, A., Chen, H., Sharmina, M., and Mendoza, J. (2020). Links between circular economy and climate change mitigation in the built environment. J. Clean. Prod. 260, 121115. doi:10.1016/j.jclepro.2020.121115

Gann, D. M., and Salter, A. J. (2000). Innovation in project-based, service-enhanced firms: The construction of complex products and systems. Res. policy 29 (7-8), 955–972. doi:10.1016/S0048-7333(00)00114-1

Gosselin, A., Blanchet, P., Lehoux, N., and Cim, Y. 2018. Collaboration enables innovative timber structure adoption in construction. Buildings 8: 183. doi:10.3390/buildings8120183

Hafner, A., and Schäfer, S. (2018). Environmental aspects of material efficiency versus carbon storage in timber buildings. Eur. J. Wood Prod. 76 (3), 1045–1059. doi:10.1007/s00107-017-1273-9

Harju, C., and Lähtinen, K. (2022). Consumers’ consciousness for sustainable consumption and their perceptions of wooden building product quality. For. Prod. J. 72 (3), 155–169. doi:10.13073/fpj-d-22-00014

Hemström, K., Gustavsson, L., and Mahapatra, K. (2017). The sociotechnical regime and Swedish contractor perceptions of structural frames. Constr. Manag. Econ. 35 (4), 184–195. doi:10.1080/01446193.2016.1245428

Hertwich, E., Ali, S., Ciacci, L., Fishman, T., Heeren, N., Masanet, E., et al. (2019). Material efficiency strategies to reducing greenhouse gas emissions associated with buildings, vehicles, and electronics—A review. Environ. Res. Lett. 14 (4), 043004. doi:10.1088/1748-9326/ab0fe3

Hill, C. (2019). The environmental consequences concerning the use of timber in the built environment. Front. Built Environ. 5, 129. doi:10.3389/fbuil.2019.00129

Himes, A., and Busby, G. (2020). Wood buildings as a climate solution. Dev. Built Environ. 4, 100030. doi:10.1016/j.dibe.2020.100030

Hossain, U., Ng, S., Antwi-Afari, P., and Amor, B. (2020). Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 130, 109948. doi:10.1016/j.rser.2020.109948

Hurmekoski, E., Jonsson, R., and Nord, T. (2015). Context, drivers, and future potential for wood-frame multi-story construction in Europe. Technol. Forecast. Soc. Change 99, 181–196. doi:10.1016/j.techfore.2015.07.002

Jussila, J., Nagy, E., Häyrinen, L., Hurmekoski, E., Lähtinen, K., Mark-Herbert, C., et al. (2022). Wooden multi-storey construction market development – systematic literature review within a global scope with insights on the Nordic region. Silva Fenn. Hels. 56 (1), 10609. doi:10.14214/sf.10609

Kinnunen, A., Talvitie, I., Ottelin, J., Heinonen, J., and Junnila, S. (2022). Carbon sequestration and storage potential of urban residential environment – a review. Sustainable Cities and Society. 88, 10402, doi:10.1016/j.scs.2022.104027

Koutamanis, A., van Reijn, B., and van Bueren, E. (2018). Urban mining and buildings: A review of possibilities and limitations. Resour. Conservation Recycl. 138, 32–39. doi:10.1016/j.resconrec.2018.06.024

Kylkilahti, E., Berghäll, S., Autio, M., Nurminen, J., Toivonen, R., Lähtinen, K., et al. (2020). A consumer-driven bioeconomy in housing? Combining consumption style with students' perceptions of the use of wood in multi-storey buildings. AMBIO 49 (12), 1943–1957. doi:10.1007/s13280-020-01397-7

Lehmann, S. (2013). Low carbon construction systems using prefabricated engineered solid wood panels for urban infill to significantly reduce greenhouse gas emissions. Sustain. Cities Soc. 6, 57–67. doi:10.1016/j.scs.2012.08.004

Mahapatra, K., and Gustavsson, L. (2008). Multi-storey timber buildings: Breaking industry path dependency. Build. Res. Inf. 36 (6), 638–648. doi:10.1080/09613210802386123

Markad, J., Suter, M., and Ingold, K. (2016). Socio-technical transitions and policy change – advocacy Coalitions in Swiss energy policy. Environ. Innov. Soc. Transit. 18, 215–237. doi:10.1016/j.eist.2015.05.003

Martek, I., Hosseini, M. R., Shrestha, A., Edwards, D. J., and Durdyev, S. (2019). Barriers inhibiting the transition to sustainability within the Australian construction industry: An investigation of technical and social interactions. J. Clean. Prod. 211, 281–292. doi:10.1016/j.jclepro.2018.11.166

Matinaro, V., and Liu, Y. (2017). Towards increased innovativeness and sustainability through organizational culture: A case study of a Finnish construction business. J. Clean. Prod. 142, 3184–3193. doi:10.1016/j.jclepro.2016.10.151

Maurer, I. (2010). How to build trust in inter-organizational projects: The impact of project staffing and project rewards on the formation of trust, knowledge acquisition and product innovation. Int. J. Proj. Manag. 28 (7), 629–637. doi:10.1016/j.ijproman.2009.11.006

Mokhlesian, S., and Holmén, M. (2012). Business model changes and green construction processes. Constr. Manag. Econ. 30 (9), 761–775. doi:10.1080/01446193.2012.694457

Nordin, F., Öberg, C., Kollberg, B., and Nord, T. (2010). Building a new supply chain position: An exploratory study of companies in the timber housing industry. Constr. Manag. Econ. 28 (10), 1071–1083. doi:10.1080/01446193.2010.494680

Nussholz, J. L. K., Rasmussen, F. N., Whalen, K., and Plepys, A. (2020). Material reuse in buildings: Implications of a circular business model for sustainable value creation. J. Clean. Prod. 245, 118546. doi:10.1016/j.jclepro.2019.118546

O’Neill, K. J., and Gibbs, D. C. (2014). Towards a sustainable economy? Socio-technical transitions in the green building sector. Local Environ. 19 (6), 572–590. doi:10.1080/13549839.2013.818954

Piroozfar, P., and Piller, F. T. (2013). “Principles of mass customization,” in Mass customization and personalization in architecture and construction: An introduction. Editors P. A. E. Piroozfar, and F. T. Piller (New York: Routledge), 15–64.

Pomponi, F., and Moncaster, A. (2017). Circular economy for the built environment: A research framework. J. Clean. Prod. 143, 710–718. doi:10.1016/j.jclepro.2016.12.055

Pulkka, L., Ristimäki, M., Rajakallio, K., and Junnila, S. (2016). Applicability and benefits of the ecosystem concept in the construction industry. Constr. Manag. Econ. 34 (2), 129–144. doi:10.1080/01446193.2016.1179773

Rakennusteollisuus, (2020). Vähähiilinen rakennusteollisuus 2035. Osa 4. Rakennusteollisuuden ja rakennetun ympäristön vähähiilisyyden tiekartta 2020–2035–2050. Gaia Consulting Oy. Tykistökatu, (in Finnish).

Riggio, M., Alhariri, N., and Hansen, E. (2020). Paths of innovation and knowledge management in timber construction in north America: A focus on water control design strategies in CLT building enclosures. Archit. Eng. Des. Manag. 16 (1), 58–83. doi:10.1080/17452007.2019.1617672

Švajlenka, J., and Kozlovská, M. (2020). Evaluation of the efficiency and sustainability of timber-based construction. J. Clean. Prod. 59, 120835. doi:10.1016/j.jclepro.2020.120835

Thomas, L. D. W., and Autio, E. (2014). The fifth facet: The ecosystem as an organizational field. Copenhagen, Denmark: DRUID Society Conference. https://conference.druid.dk/acc_papers/qpja8vqx0vto0qkn5vg3uiqafb24.pdf.

Toppinen, A., Miilumäki, N., Vihemäki, H., Toivonen, R., and Lähtinen, K. (2019). Collaboration and shared logic for creating value-added in three Finnish wooden multi-storey building projects. Wood Material Sci. Eng. 14 (5), 269–279. doi:10.1080/17480272.2019.1653365

Vihemäki, H., Toivonen, R., and Toppinen, A. (2020). Intermediaries to accelerate the diffusion of wooden multi-storey construction in Finland. Environ. Innov. Soc. Transit. 36, 433–448. doi:10.1016/j.eist.2020.04.002

Viholainen, N., Kylkilahti, E., Autio, M., Pöyhönen, J., and Toppinen, A. (2021). Bringing ecosystem thinking to sustainability-driven wooden construction business. J. Clean. Prod. 292, 126029. doi:10.1016/j.jclepro.2021.126029

Viholainen, N., Kylkilahti, E., Autio, M., and Toppinen, A. (2020). A home made of wood: Consumer experiences of wooden building materials. Int. J. Consum. Stud. 44, 542–551. doi:10.1111/ijcs.12586

Xia, B., Olanipekun, A., Chen, Q., Xie, L., and Liu, Y. (2018). Conceptualising the state of the art of corporate social responsibility (CSR) in the construction industry and its nexus to sustainable development. J. Clean. Prod. 195, 340–353. doi:10.1016/j.jclepro.2018.05.157

- What are the roles and tasks of the company you represent for project XYZ? How did the company you represent become involved in the project?

- What other actors do you remember being involved in the project? What companies have been important/less important cooperating partners or customers for the company you represent in this project?

- What kind of cooperation has typically occurred between these actors in the project?

- What new and complementary knowledge do you think company collaboration brought to the project?

- How was this cooperation administered in the project? Which organization was most central in terms of project coordination? What communication channels were used during the project? How did communication work during the project?

- What matters were essential for project success and for cooperation smoothness? What challenges emerged during the collaboration?

- At point in a WMC construction project is your company involved in?* Would you see any benefits if you became involved slightly earlier in similar projects? *

- What opportunities do you see for deepening cooperation in future building projects? What about obstacles?

- How do you see the role of a city in the local wood construction ecosystem?

* question addressed only in the interviews 12–15

- What added value was obtained from using wood material in the building project? What benefits could using wood material have for your future business?

- Do any characteristics in the construction industry influence the perception of a building as a carbon storage?

- Which actors emphasized the importance of carbon storage the most?

- What was the significance of environmental impacts for project operation? If environmental impacts are to be increased in such projects, what would you see as the options?

- What new modes of operation, solutions, products, or ideas emerged for wood construction during the planning or building phases of the project? How did they come into existence?

- How can environmentally friendly practices be better integrated into the building culture in Finland?

Keywords: project management, construction, wood, carbon storage, circular economy, business ecosystem

Citation: Toppinen A, Aaltio A, Lähtinen K, Jussila J and Toivonen R (2022) “It all depends on the project”—A business ecosystem in residential wooden multistory construction in Finland. Front. Built Environ. 8:1046954. doi: 10.3389/fbuil.2022.1046954

Received: 17 September 2022; Accepted: 14 November 2022;

Published: 24 November 2022.

Edited by:

Che Khairil Izam Che Ibrahim, MARA University of Technology, MalaysiaReviewed by:

John Tookey, Auckland University of Technology, New ZealandCopyright © 2022 Toppinen, Aaltio, Lähtinen, Jussila and Toivonen. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Anne Toppinen, YW5uZS50b3BwaW5lbkBoZWxzaW5raS5maQ==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.