- Construction Engineering Department, École de Technologie Supérieure, Montreal, QC, Canada

Recently, new methods and technologies, including building information modeling (BIM) and lean management, have been introduced to the construction industry. Their objectives are to increase collaboration, ensure smooth flows of information, improve productivity, reduce different types of waste, and stabilize production. These constraints have forced the industry to gradually change by applying more adapted operational processes and contractual models that focus on value and by integrating the design, construction, and operation phases. Traditional scheduling methods based on activities modeling have become less adapted to this new reality. As a result, complementary concepts have emerged, particularly the Last Planner system, takt time, space planning, and spatiotemporal scheduling. This paper presents an extensive review and an assessment of the state of the art of the spatiotemporal planning of construction projects. The paper categorizes the research efforts, presents a timeline of the most significant scientific developments in this domain, and addresses their possible impacts on the construction industry.

Introduction

Since the early 1990s, a new range of planning techniques specific to the construction field has begun to emerge based on the management of construction site spaces. The first method proposed optimal use of workspaces and better management of the circulation and movement of teams and materials on site (Tommelein, 1989; Riley, 1994; Thabet and Beliveau, 1994).

The availability of space represents a significant constraint for the planning of construction projects and dictates the duration of projects. Rodriguez-Ramos (1982) proposed a model that allocates space to objects for conflict detection to solve static layout planning problems in construction. Thus, workspaces are considered a resource similar to labor and materials (Tommelein and Zouein, 1993). Labor cannot be used beyond the capacity of workplaces. Otherwise, congestion of workspaces will negatively affect circulation and reduce productivity at construction sites (Francis, 2019). Traditional scheduling methods focus on tasks and constraints and do not convey workspace occupation or space availability (Akinci et al., 1998). That aspect of the management of workspaces on construction sites is often neglected.

The construction industry is traditionally considered a fragmented industry with low productivity that is reluctant to take full advantage of opportunities (Riddell, 2017; U.S. Bureau of Labor Statistics, 2019). However, recent technical and technological developments, notably building information modeling (BIM) and its 4D to 7D dimensions, have started to gradually change this tradition and the means of collaborating among different actors. Whether for risk management, quality assurance, or site monitoring, the methods and techniques are constantly evolving. For example, lean methods for project planning have been introduced to optimize work processes and eliminate waste in the operating chain. Thus, methods such as the last planner system (Ballard, 2000), takt-time planning (Frandson and Tommelein, 2014), and spatiotemporal modeling (Francis, 2019) may replace traditional methods in the near future.

To our knowledge, no research has been published in the past demonstrating a literature review and an assessment of the state of the art of space planning for construction projects. The main goal of this paper is to synthesize scientific research in the field of spatiotemporal planning of construction projects. The aim is to summarize the different methods applied and knowledge developed in this field. This paper contributes to the existing body of knowledge by synthesizing the state and evolution of these processes to guide future research as well as promoting such knowledge in the construction industry.

The principal strength of the research method applied is related to the scope of research and the extensive literature review of scientific publications through a methodical approach with rigorous screening and assessment of the state of the art. The authors’ excellent knowledge of this field ensures the validity of the obtained results.

The literature review is based on a pragmatist approach. The review includes two steps: (1) a systematic review and (2) a conceptual and critical review. A timeline and an analysis of the state of the art of research on construction project space planning are also presented. The next sections demonstrate these steps.

Systematic Research

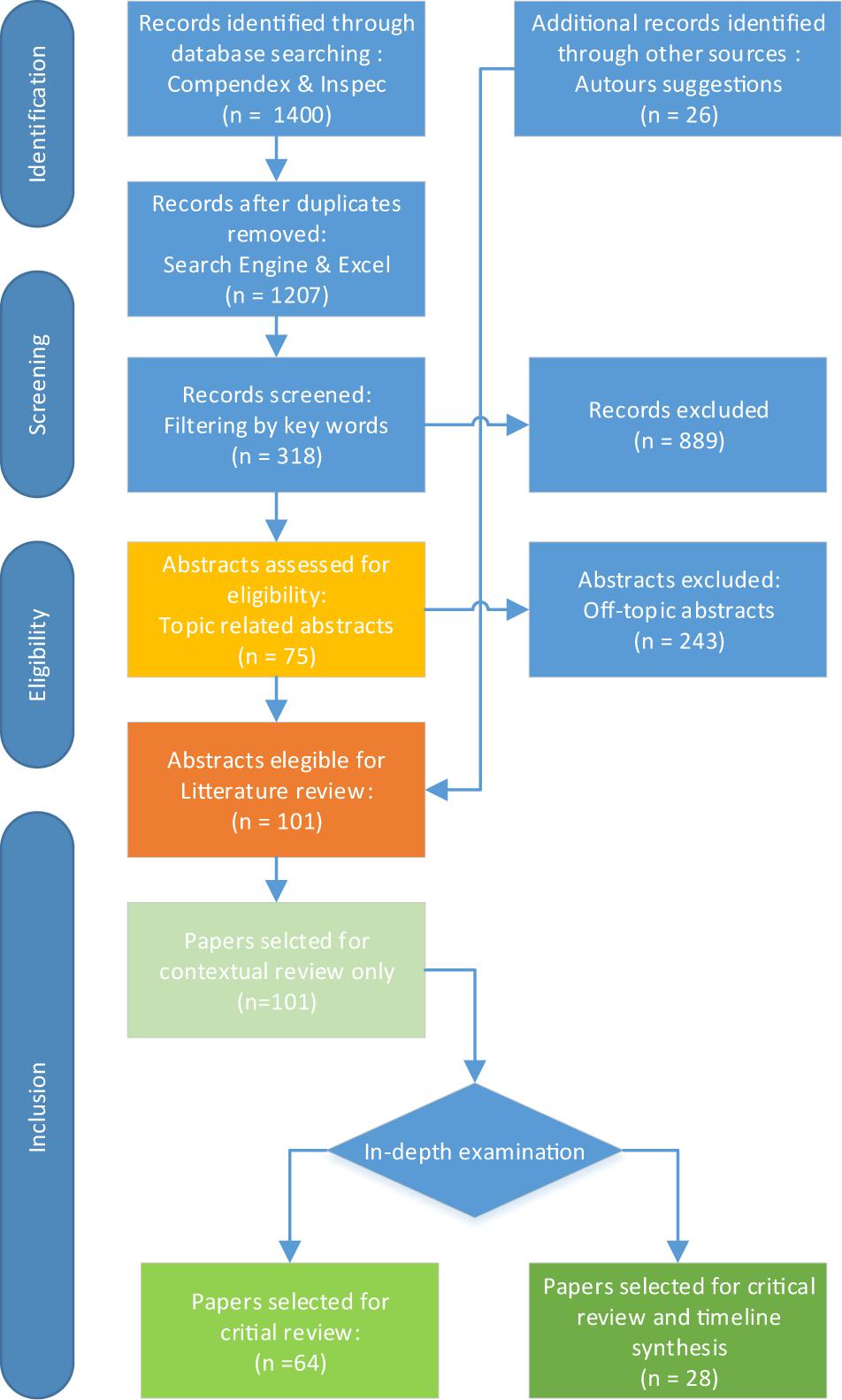

The systematic research used followed the PRISMA process (Moher et al., 2009). Figure 1 presents the proposed process diagram that was adapted to this literature review and the number of articles found at each stage of this process.

Figure 1. Systematic review flowchart (adapted from Moher et al., 2009).

Identification

During the identification stage, the search was limited to journal papers contained in the specialized engineering databases Compendex and Inspec. Keywords were selected to include all relevant research on the planning of construction projects while taking into consideration location and space planning. The search criteria used corresponded to the following formulation:

(((({construction industry} OR {construction projects}) AND ((location AND (planning OR scheduling)) OR (space AND (planning OR scheduling))) WN ALL))) AND ({ja} WN DT))

Screening

At the time of writing, 1207 scientific publications, dating from 1929 to 2020, have been found within the databases consulted. Given this very large number, the initial search results were exported for processing in Excel. A second validation was carried out to remove duplicates undetected by the search engine. In addition, papers that did not contain specific keywords in the abstract were ignored. The filtering applied met the following criteria:

(planning OR scheduling) AND (space OR location)

At the end of the filtering process, 318 scientific journal papers, dating from 1989 to 2020, were screened.

Eligibility

The publications identified during the screening process were studied to validate their direct links with the spatiotemporal planning of construction projects. Although 318 abstracts passed through the filtering process conducted in the previous stage, only 75 publications were relevant to this literature review. The other 243 papers were off-topic and research was principally centered on other construction projects planning issues or even other disciplines such as architecture and urbanism. Subsequently, few conference papers or doctoral theses that demonstrate significant scientific advances have been added.

Inclusion

The analysis of selected publications was carried out at three levels of detail: (1) a contextual review, (2) a critical review, and (3) a timeline synthesis. The conceptual review identified and grouped research according to concepts, or categories, or themes. The critical review involved a more detailed examination to compare and evaluate a number of perspectives (Grant and Booth, 2009).

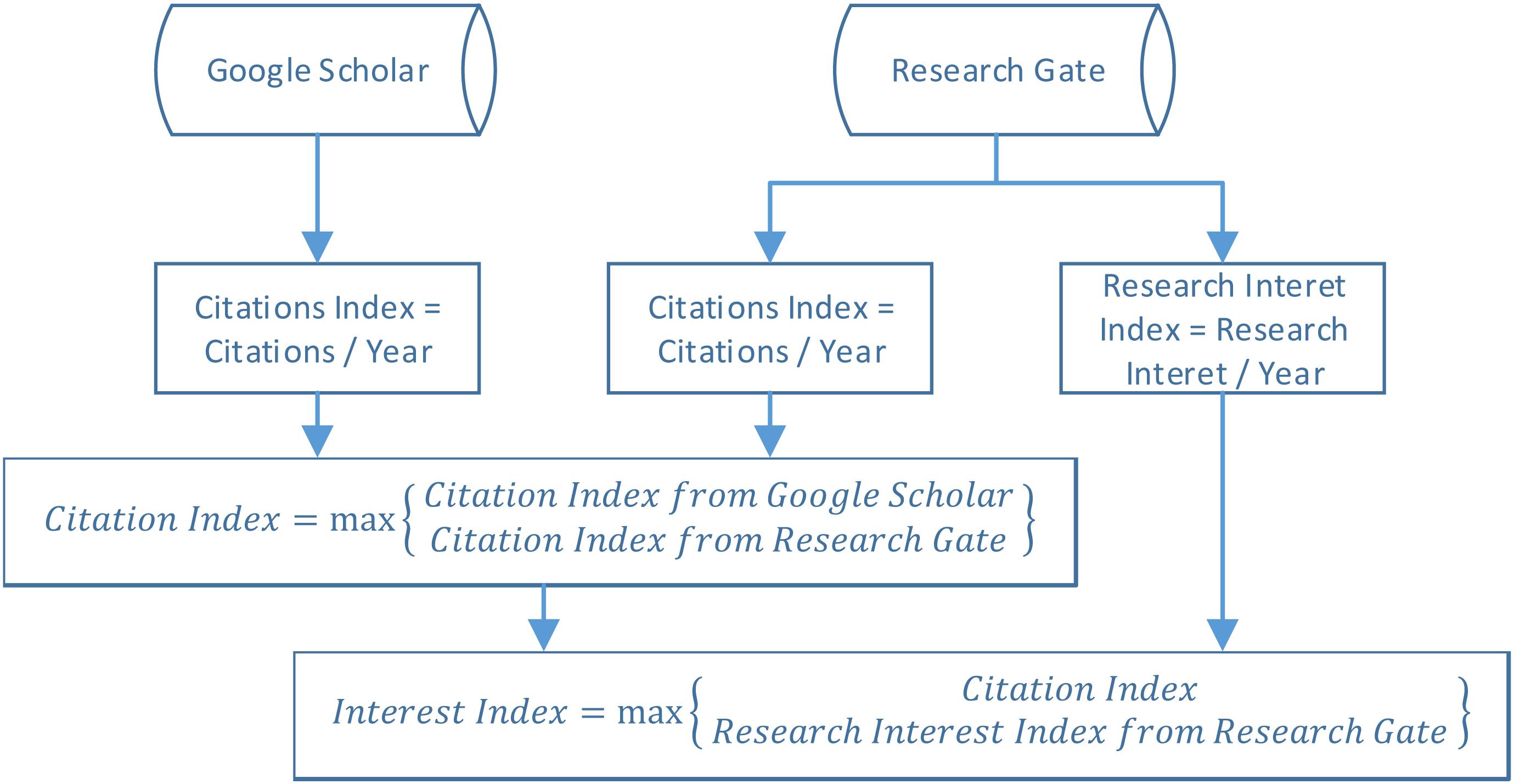

The contextual review was for all inclusions. A second, more in-depth examination was to select publications to be included in the critical review and timeline synthesis. The content of the papers was reviewed to determine if the research was innovative, original, and relevant to the research subject. This more in-depth validation was conducted considering an interest index and the authors’ knowledge of the field. The interest index was based on the citation number compiled by Google Scholar and Research Gate, as well as the Research Interest Index proposed by Research Gate. Figure 2 presents the proposed interest index model.

Conceptual Review

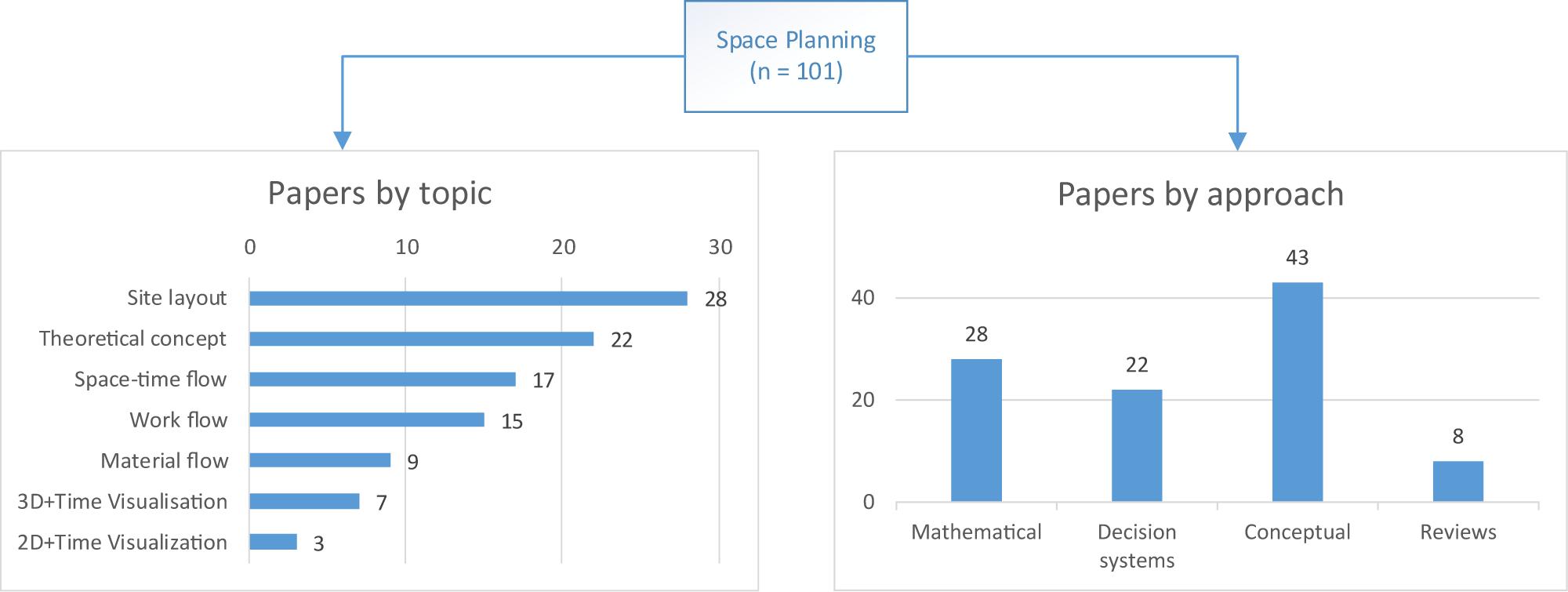

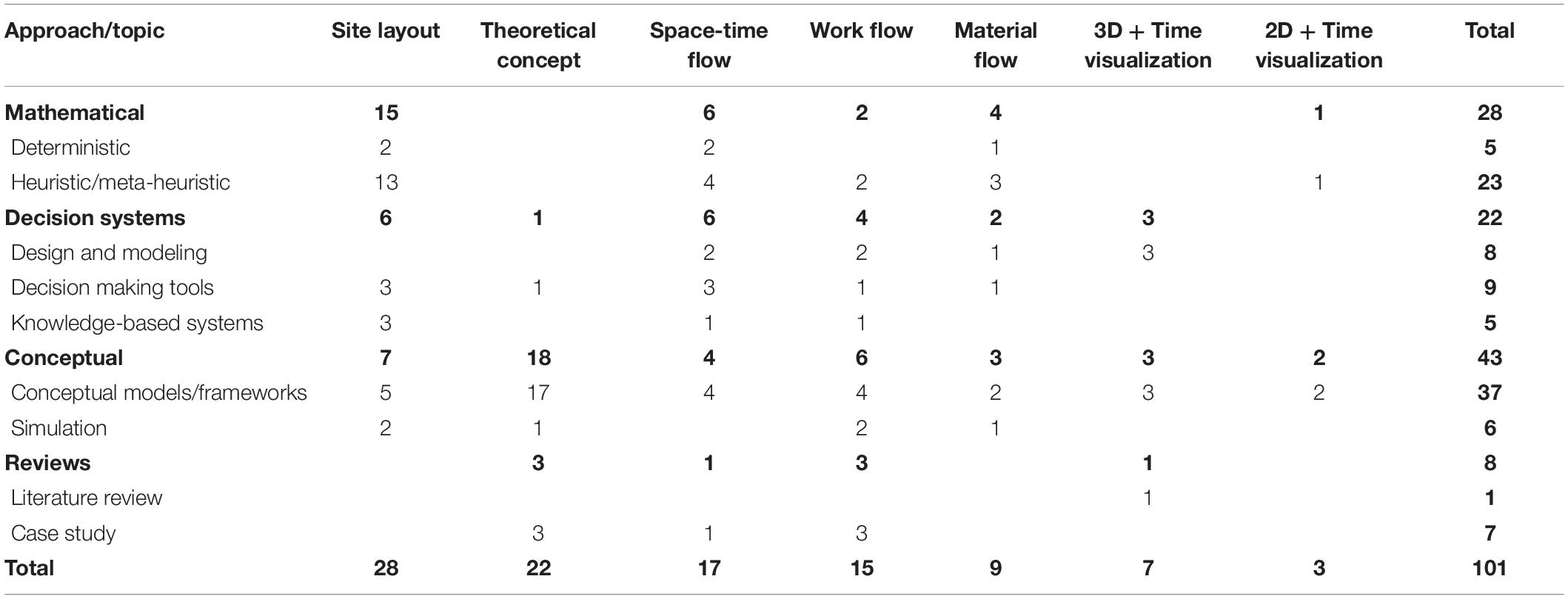

The conceptual review and a detailed analysis of the 101 publications selected led to the identification of two classification categories:

1) Research topics: site layout, theoretical concepts, space-time flow, workflow, material flow, and 3D + time and 2D + time visualization.

2) Research scheduling and optimization approaches: (i) mathematical (deterministic or heuristic/metaheuristic), (ii) decision systems (design and modeling, decision-making tools, knowledge-based systems), (iii) conceptual (conceptual models/frameworks or simulations), and (iv) reviews (case studies and literature reviews). Figure 3 presents the number of publications associated with each grouping criterion.

Table 1 presents the number of publications identified in matrix form, which demonstrates the link between these two classification types (topics and approaches).

Critical Review

This section demonstrates a more detailed examination of the selected publications. The paper content is presented in accordance with the research scheduling and optimization approaches described in the contextual review, and different perspectives were identified.

Mathematical Approaches

Among mathematical approaches, different deterministic and heuristic/metaheuristic methods were used. Approximately half of the research works (15 publications) were conducted on site layout planning. The flow of space-time, work, and materials were also studied (13 publications). Only one paper studied the 2D + time visualization. These approaches were divided into four subcategories, as follows.

Objective Functions

Some authors utilized linear programming techniques and objective functions for site layout and material flow planning. Easa and Hossain (2008) proposed a model that, according to the type of facility (temporary or permanent), considers two types of areas: available and unavailable. Temporary facilities are located in available areas, whereas permanent facilities are located in unavailable areas. The model analyzes constraints such as region, non-overlapping, adjacency, facility proximity, object region, visibility, and flexible orientation. The locations of the objects are then determined by an objective function. Huang and Wong (2015) developed a mathematical formulation in order to model and optimize the site facilities location during the different stages of construction projects. The authors used a binary-mixed-integer-linear program to formulate the site layout problem that was solved by a standard branch-and-bound algorithm. The mathematical objective function established aims to minimize the cost of material transportation, facility setup, and relocation in each construction stage. The authors also took into account safety design considerations.

Singularity Functions

Space-time flow was analyzed by Lucko et al. (2014) and Isaac et al. (2017) who used singularity functions to represent the progression of activities over time and through space. Lucko et al. (2014) categorized how activities might behave within a 3D spatial–temporal environment, the 2D of the floor plan area plus time. Their model seeks to minimize total project duration by using a conflict-avoiding heuristic scheduling algorithm. Isaac et al. (2017) created a mathematical model that supports the allocation of time and workspace with concurrent activities and under safety constraints. Temporal and spatial buffers are also considered and maintained between work paths.

Genetic Algorithm

Among mathematical approaches, genetic algorithms (GAs) are the most favored optimization technique within the selected publications. More than half of publications of this category utilized GAs for site layout planning, the space-time, and the material flow optimization. 2D + time visualization is also considered.

Regarding space-time flow, Moon et al. (2014) proposed an optimized algorithm based on a location-constraint GA. This algorithm looks for an alternative schedule that minimizes the interference of workspaces. The optimized schedule is compared to the initial plan integrated to a 4D model. An active simulation system based on BIM is realized. Tao et al. (2018) considered the space-time project-scheduling problem and formulated it as a multi-objective mixed-integer programming problem. To solve this problem, and to minimize resource reallocation and congestion, they developed a non-dominated sorting genetic algorithm II (NSGA-II) and then modified by it integrating an electromagnetism-like mechanism (NSGA-II-EM).

Workflow was considered by Dong et al. (2012). The authors proposed a GA-based method for look-ahead scheduling that focuses on the finishing phase of construction projects. To optimize project duration and/or cost, this method takes into account three main aspects: the engineering priorities of each individual sub-project, the zone, and blocking constraints.

Genetic algorithms are also common in research that focuses on site layout planning. Osman et al. (2003) and Kumar and Cheng (2015) sought to automate the process of site layout planning. For that, Osman et al. (2003) used a CAD environment and GAs to automate space detection of the site layout while satisfying geometrical constraints dictated by the facility assignment problem. The optimization goal is to minimize total transportation costs. Geometrical constraints are modeled using CAD and not through traditional mathematical formulations. This fact adds flexibility to the constraint representation. This approach can provide the planner with an initial layout that can be adjusted according to secondary objectives. Kumar and Cheng (2015) presented a framework to create dynamic site layout models automatically by utilizing BIM. In conjunction with a GA, the authors used the A∗ algorithm to develop an optimization framework. The framework considers the actual travel paths of on-site labor and equipment. The model optimizes the dimensions of facilities to address the space limitation on site. The interior storage within buildings under construction is also considered. Papadaki and Chassiakos (2016) and Farmakis and Chassiakos (2018) proposed multi-objective optimization models. The models integrate the optimization capabilities of GAs to solve the problem of dynamic construction site layout planning. The model developed by Papadaki and Chassiakos (2016) takes into account facility locations, transportation, and safety. It aims to minimize a generalized cost function. The model developed by Farmakis and Chassiakos (2018) considers multiple aspects, such as construction and relocation costs of facilities, transportation costs of resources, and safety and environmental considerations that result from the operation and interconnection of facilities.

Other Heuristic/Metaheuristic Methods

In addition to the methods mentioned above, various heuristic/metaheuristic methods are used for solving the site layout-planning problem and analyzing space-time, work, and material flow. Yeh (1995) formulated the problem of construction site layout as a combinatorial optimization problem by using the annealed neural network model and the Hopfield neuronal network. The annealed neural network model merges many features of simulated annealing, while the Hopfield neuronal network is employed to solve the problem. Zouein and Tommelein (1999) presented a dynamic layout construction procedure using a hybrid incremental solution method. The objective of the procedure is to allocate site space to resources while avoiding spatial conflicts and minimizing distance-based adjacency and relocation costs. The optimal position for each resource is defined by solving a linear program. The algorithm allows exploring better alternative solutions. Xu and Li (2012) and Li et al. (2015) proposed a multi-objective decision-making model for the planning of construction site layout. To reduce the possibility of safety or environmental accidents, Xu and Li (2012) considers two objectives: minimizing the total cost of site layout and maximizing the distance between high-risk and “high-protection” facilities. A multi-objective particle swarm optimization (MOPSO) algorithm with permutation-based representation is used to solve this problem. Years later, Li et al. (2015) integrated the security-planning problem and proposed a bi-level multi-objective model for the dynamic construction site layout. They defined two programing levels: the upper level (project manager actions) and the lower level (attacker reactions). A multi-objective bi-level particle swarm optimization (MOBLPSO) algorithm was designed to solve this model. Al Hawarneh et al. (2019) proposed a grid layout model with safety as a design parameter beside cost. The model is based on the safety level between the facilities that uses the Site Blocks Algorithm. A MATLAB computer code developed to account for travel distances of laborers and equipment. The authors developed a Binary Integer Linear Programming Model to optimize the site layout while considering parameter such as availability, overlapping, setup, dismantling, prohibited regions and relocation constraints. Güden and Süral (2019) presented a mixed integer programming formulation of the dynamic p-median problem. The authors used discretization of distances as criteria to control locational decision variables such as facility locations, opening/closing times of facilities, routes of mobile facilities, and demand allocations to open facilities. To solve the problem, a branch and price algorithm and constructive heuristics were developed.

Space-time and work flow were considered by Zouein and Tommelein (2001) and Lee (2012). Zouein and Tommelein (2001) presented a time-space tradeoff algorithm to solve the problem termed “space scheduling.” This algorithm describes alternative methods for performing an activity by using resource levels. Each level represents another demand for space over an activity duration. The algorithm minimizes the increase in project duration by varying resource levels of activities or delaying their start date. This is to vary the demand for space on-site over congested lapse of time. Lee (2012) proposed an integrated model that uses ant colony optimization to calculate the amount of pedestrian walk time through simulation and search for the near-optimal schedule. The model is applied to planning a renovation project for building that remains in operation. The proposed model reduces the pedestrian walk time when compared to the schedule obtained with planning techniques based on the location of work zones.

Decision Systems

Different decision systems focus principally on the theoretical concept of space planning and the work and material flow management (13 publications). Site layout planning and 4D modeling are also considered (nine publications). Decision systems are divided into three subcategories, as follows.

Design and Modeling

Space-time flow was considered by Chavada et al. (2012) and Kassem et al. (2015). Both works focus on 4D and 5D planning. Chavada et al. (2012) presented an interactive decision support system that integrates workspace planning into 5D planning. The decision support system consists of a process framework that identifies schedule conflicts, workspace conflicts and their severity, allowing solving spatial conflicts prior to construction. Kassem et al. (2015) developed a methodology for workspace management. The methodology provides a holistic solution for workspace management through the allocation of workspaces to activities, as well as the detection of congestion and spatial and temporal conflicts. A 4D tool based in the Industry Foundation Class (IFC) was also developed.

Wang et al. (2004) and Bakchan et al. (2019) presented decision systems that focus on the flow of work and materials. Wang et al. (2004) presented the 4D Site Management Model + (4DSMM +), a model that integrates 4D technology to resource management and site space utilization. The authors also developed 4D Management for Construction Planning and Resource Utilization (4D-MCPRU), an information system platform that allows to implement the 4DSMM +. This platform integrates dynamic resource management at the project level and decision-making support. Bakchan et al. (2019) sought to outline the conceptual interactions that define the integration of construction waste management (CWM) and BIM with construction management. The authors proposed a multi-dimensional framework that provides guidance on CWM applications such as CW disposal scheduling, disposal cost estimation, on-site reuse, and allocation of waste bins. The framework presents interactions between CWM and construction management fields, such as scheduling, estimation, sustainability, and site planning.

Finally, Akinci et al. (2002) and Chau et al. (2005) developed tools for 3D + time visualization. Akinci et al. (2002) presented mechanisms that automatically generate project-specific workspaces based on a generic workspace ontology and a 4D production model. Workspaces attributes corresponds to when, where and how long they exist, and how much volume they occupy. Chau et al. (2005) proposed a 4D graphics for construction planning and site utilization (4D-GU) model that integrates the 4D model with other computer-based techniques for site management. The model performs a variety of site management functions over spatial and temporal parameters. It incorporates construction planning, resource analysis for individual activity, site layout generation, material allocation and cost breakdown.

Decision-Making Tools

Tommelein and Zouein (1993) focused on site layout planning, whereas Ma et al. (2005) looked for 4D building models and 4D site model integration. Tommelein and Zouein (1993) developed MovePlan, a model that integrates data needed to construction layouts into an activity schedule. The augmented schedule aims to facilitate layout planning, including the positioning of temporary facilities on-site and the movement of materials and equipment. Through a graphical interactive interface, the MovePlan prototype system allows to model approximate site space needs during project scheduling and to create layouts for different stages of construction. Ma et al. (2005) introduced the 4D Integrated Site Planning System (4D-ISPS), addressing both 4D building models and 4D site models. The proposed system provide 4D graphical visualization capability for construction site planning by integrating schedules, 3D models, resources, and site spaces.

Regarding 3D modeling, Kim and Cho (2015) proposed a geometric reasoning system called Construction Spatial Information Reasoner (CSIR). This system analyzes geometric information in building designs to derive construction-specific spatial information and assist in construction planning. Adjacency relationships, acquired by means of relationship acquisition algorithms, are transformed into a set of graphs that represent work packages. The algorithms are embedded into the BIM platform by using a commercially available BIM platform.

Some decision-making tools also target the flow of space-time and work. Winch and North (2006) presented a decision support tool that helps to address the space-scheduling problem. The authors also presented the concept of critical space analysis. The concept involves optimizing the available space, allocating tasks to spaces, and analyzing and space loading in relation to the critical path, which Winch and North call “space-time broking.” Dawood and Mallasi (2006) presented a decision support tool for critical space-time analysis. The tool organizes the product’s coordinates according to the required execution sequence and assigns workspaces using layering within the AutoCAD model. Then activities are linked to workspaces to provide a 4D construction simulation of processes. Chen et al. (2012) presented an intelligent scheduling system (ISS) that looks for the near-optimum schedule plan in the function of project objectives and constraints. To find the near-optimal solution, the ISS uses simulation techniques to distribute resources and assign different levels of priority to different activities. The ISS considers and integrates in a unified environment the most important construction factors, such as schedule, cost, space, labor, equipment, and materials.

Knowledge-Based Systems

Tommelein et al. (1991) developed SightPlan, a knowledge-based system that addresses the problem of temporary facilities on construction sites. SightPlan use two strategies to propose a solution the expert strategy, which emulates the strategic decisions and steps taken by experts in the field, and the artificial intelligence (AI) strategy. Using these two strategies, the system explores the architecture of an interactive design-support system that allows users to exploit the strengths of humans and machines to plan better designs. Jin et al. (2017) presented an optimization model based on the spatial relationship between work envelope and scaffolding placement requirements to improve scaffolding availability while maximizing piping crew productivity. The model involves two elements: the simulation-based optimization model and a multi-attribute utility (MAU) based alternative selection model. The MAU allows handling the uncertainty of the assessment weights on the attributes.

Other knowledge-based systems are interested in space-time and work flow. Jongeling et al. (2008) sought to take advantage of the quantitative data contained in 4D models. They illustrates how different types of 4D content can be extracted from 4D models to support 4D content-based analyses and novel presentation of construction planning information. The 4D content extracted corresponds to workspace areas, work locations, and distances between concurrent activities. Bansal (2011) proposed integrating geographic information systems (GISs) into a 4D model to facilitate the identification and resolution of space conflict systems. According to Bansal, this approach facilitates topographic modeling, different types of geospatial analyses, and database management. A feature attribute table (FAT) was also proposed and associated with each space. This to describe when, where, and how long that space will be required on the jobsite.

Conceptual Approaches

Research using conceptual approaches principally contributes to the development of space planning theory (18 publications). We found other contributions regarding the flow of space-time, work, and materials (13 publications). Site layout planning (seven publications) and 2D/3D + time visualization (5 publications) are also considered. This section distinguishes between the conceptual model/frameworks and simulation systems.

Conceptual Models/Frameworks

Conceptual modes and frameworks are broken down into five subcategories: (1) workspace parameters, (2) space planning techniques, (3) graphical modeling, (4) site layout planning techniques, and (5) space-time floats.

Workspace Parameters

Various models and criteria are proposed to classify workspaces. Thabet and Beliveau (1994) developed a model to define and quantify workspace demand and availability parameters for repetitive floors in multistory buildings. They proposed an activity classification that is space demand-oriented. The space demand classification is resource-oriented. Work continuity and variable crew productivity rates are also considered. Riley and Sanvido (1995) presented a construction-space model that defines the descriptive space types and typical patterns of space use in multistory building construction. The model identifies 12 construction-activity space uses and patterns. It also characterizes space needs to predict space demand and support the logical planning of productive work sequences. Choi et al. (2014) categorized a workspace by its function and movability and proposed a framework for the workspace planning process. The proposed framework involves five phases: 4D BIM generation, workspace requirement identification, workspace occupation representation, workspace problem identification, and workspace problem resolution.

Other research targets the spatial requirements and graphical representation of construction operations. Akinci and Fischer (2000) developed and formalized a mechanism through space templates to capture spatial requirements of different trades. They described the integration of these space templates within construction method models. Francis (2016) proposed the Chronographic protocol for modeling of construction projects. This protocol involves a conceptual framework that details all the elements required for the planning of construction operations: processes, logical constraints, and association and organizational models. Visual parameters and their associated values were studied to define a standard graphical presentation composed by shapes, sketches, codes, text, textures, and colors.

Space Planning Techniques

New planning techniques, based on space and resource requirements, started to develop in the 1990s. Thabet and Beliveau (1997) proposed a space-constrained and resource-constrained knowledge-based system (SCaRC) for scheduling repetitive floors in multistory projects. The proposed system recognizes the space requirements of activities as a scheduling constraint by integrating space-based and resource-based techniques. It also includes procedures that define and verify the construction logic constraints associated with the linear scheduling of vertical construction. Riley and Sanvido (1997) presented a space planning method for multistory building construction. The proposed method provides a logical order and priority for space-planning decisions. It allows identifying the specific spaces required for activities, defining their locations on building floors, developing a work sequence that defines the occupation sequence of spaces, and identifying potential spatial conflicts. Akinci et al. (1998) formalized and automated a time-space conflict analysis method to assist construction managers, in proactively managing spatial conflicts between activities at their sites. The proposed time-space model prevents conflicts before they occur at a construction site and eliminates non-value-adding activities when a time-space conflict is identified.

The chronographic method for the planning of construction projects was presented by Francis (2004) and Francis and Miresco (2006). This method includes a theoretical concept, a graphical approach, a mathematical model, and a prototype program. The proposed modeling method is based on two generic entities: the principle entity, which symbolizes the production tools, and the dependent entity, which determines the decisional functions and relational constraints. Other constraints not specifically identified by entities are represented as attributes or as external or internal measures of the principal entities. Years later, Francis (2019) proposed a hybrid solution based on spatiotemporal techniques that combine graphical, procedural, and algorithmic aspects. This solution integrates spaces and operations to ensure the continuous use of spaces and teams, as well as linear production. The approach prioritizes the critical space on the critical path of activities.

Kenley and Seppänen (2009) presented guidelines for defining a location-based management system (LBMS). To optimize the schedule, the model uses a layered logic and a critical path method (CPM) network calculation, a critical planning decision that affects the quantity takeoff, the number of logic relationships required to schedule a project, and the variation of quantities between locations. The use of the LBMS to plan and control production in construction projects was evaluated by Seppänen et al. (2014). The system uses control actions that realign the schedule forecast with the approved plan. This to respond effectively to deviations in production instead of continuously updating the plan with actualized completion dates.

Other planning techniques are also proposed using 3D + time visualization, computational algorithms, and adapting planning techniques used in other industries. Jongeling and Olofsson (2007) presented a process method for workflow planning by using location-based scheduling and 4D CAD. Said and El-Rayes (2013) developed a congested construction logistics planning model (C2LP). The proposed model uses computational algorithms to model interior space allocation, complex space constraints, and the impact of interior space utilization on activity scheduling. Four types of decision variables are considered: material procurement, material storage, facility layout, and scheduling of non-critical activities. Lucko et al. (2016) proposed extending the modeling and analytical capabilities of the slip chart, a scheduling technique from the aerospace industry, to improve linear schedules. For that, the authors developed a conversion algorithm for linear schedules. In addition, they introduced new buffers, criticality and float for a comprehensive approach.

Graphical Modeling

Interest in graphical modeling of space planning started to appear in the 2000s. Mallasi (2006) established a concept for visualizing workspace competition between construction activities. He developed a critical space-time analysis (CSA) approach, in order to model and quantify the site workspace congestion. The severity of workspace congestion was measured using a multicriteria function embedding spatial and schedule-related criteria. A dynamic 4D simulation environment was developed using three workspace-planning features: execution patterns, work rate distributions, and a time-based simulation of the progressing quantities of work. Su and Cai (2016) presented a generic construction 4D topology framework. The framework formalizes the spatial-temporal relationships between construction activities. In addition, it offers a topology categorization method that formats the 4D topological representations into task templates. The analysis is conducted through mathematical method. Mirzaei et al. (2018) proposed a dynamic conflict detection and quantification system that uses 4D-BIM to identify time–space conflicts and quantify their impacts on project performance. The system identifies the conflict between different activities’ workspaces by considering the labor crew movement in the assigned workspace during different time intervals.

Based on the chronographical method, Francis (2013) presented the chronographical approach for planning and monitoring construction projects. The predefined modeling approach helps improve visual communication through layering, sheeting, juxtaposition, alterations, and permutations. This allows for groupings, hierarchies, and classification of project information. Francis et al. (2019) proposed a spatiotemporal model that promotes efficient site use by defining optimal site occupancy and workforce rotation rates, minimizing intermediate stocks, and ensuring a suitable procurement process. The authors studied the material flow on the site while considering horizontal and vertical paths, traffic flows, and means of transportation to ensure fluidity and safety. A comparison of the performance and procurement processes when using the chronographic model versus the Gantt precedence diagram is also given.

Frandson and Tommelein (2014) described the implementation of Takt-time planning in a case study on a retrofit project in an operating healthcare facility. They illustrated the Takt-time planning process and situated it in the context of the different levels of the Last Planner system using the steps of master scheduling, reverse phase scheduling, make-ready planning, and commitment planning.

Site Layout Planning Techniques

Li and Love (1998) used a GA system to allocate a set of predetermined facilities into a set of predetermined places, with the goal of optimizing the construction site-level facility layout while satisfying layout constraints and requirements. Elbeltagi et al. (2004) presented a layout planning approach that considers both safety and productivity. This approach involves a procedure to determine optimum layout of temporary facilities while considering four aspects: safety-related temporary facilities requirements, proper safety zones around construction spaces, safety in determining the optimum placement of temporary facilities, and use of the constructed space as temporary facilities to relieve congestion.

Other site layout planning techniques that use 2D and 3D modeling have also been proposed. Sadeghpour et al. (2006) developed an interactive CAD site layout model to support site planning. The model performs on two levels: site representation, and site space analysis and allocation. The site representation uses an open architecture supported by object-based concepts. The model introduces a geometric reasoning approach to analyze site space and find an optimum or near-optimum location for facilities. Dagan and Isaac (2015) used a matrix-based method to define minimum safe distances between workers. 3D time-space diagrams were used to represent and analyze the dynamic movements of workers on site.

Space-Time Floats

Said and Lucko (2016) compiled the different types of floats that can exist in a spatial schedule and defined three activity float metrics: shift, rate, and combined floats. The space float contours for a construction site are generated by means of an algorithm. According to the authors, activity float metrics contribute to expand the capabilities of spatial scheduling models when assessing the criticality of activities. The space float concept enables a direct integration between scheduling and other project management tasks. Francis and Morin-Pepin (2017) introduced the concept of margin calculation based on site occupation using chronographical modeling. The site occupation rate considers the category of locations and the activity types. This method involves five levels of layers according to the stage of construction: creation of spaces, systems, division of spaces, finishing and closing of spaces. Depending on the choices made by the user, the method establishes a level of risk for the completion of the project according to the criticality of activities, as well as location occupation rates.

Simulation

Cho et al. (2013) proposed a space zoning concept-based scheduling model (SCHEME) for repetitive construction processes. The proposed model adopts simulation techniques and can reflect space-zoning characteristics to maximize productivity and achieve schedule reduction of a construction project. Razavialavi and Abourizk (2015) presented a simulation-based approach that combines discrete and continuous simulation for modeling the size of facilities that temporarily contain materials in construction projects. The impact of facility size is analyzed quantitatively and corrective actions are proposed to optimize the space shortage in facilities. A hybrid discrete-continuous simulation technique is adopted to enhance accuracy and model the project focusing on operational level (i.e., activity level) and strategic level (i.e., summary activity level).

Timeline and Discussion

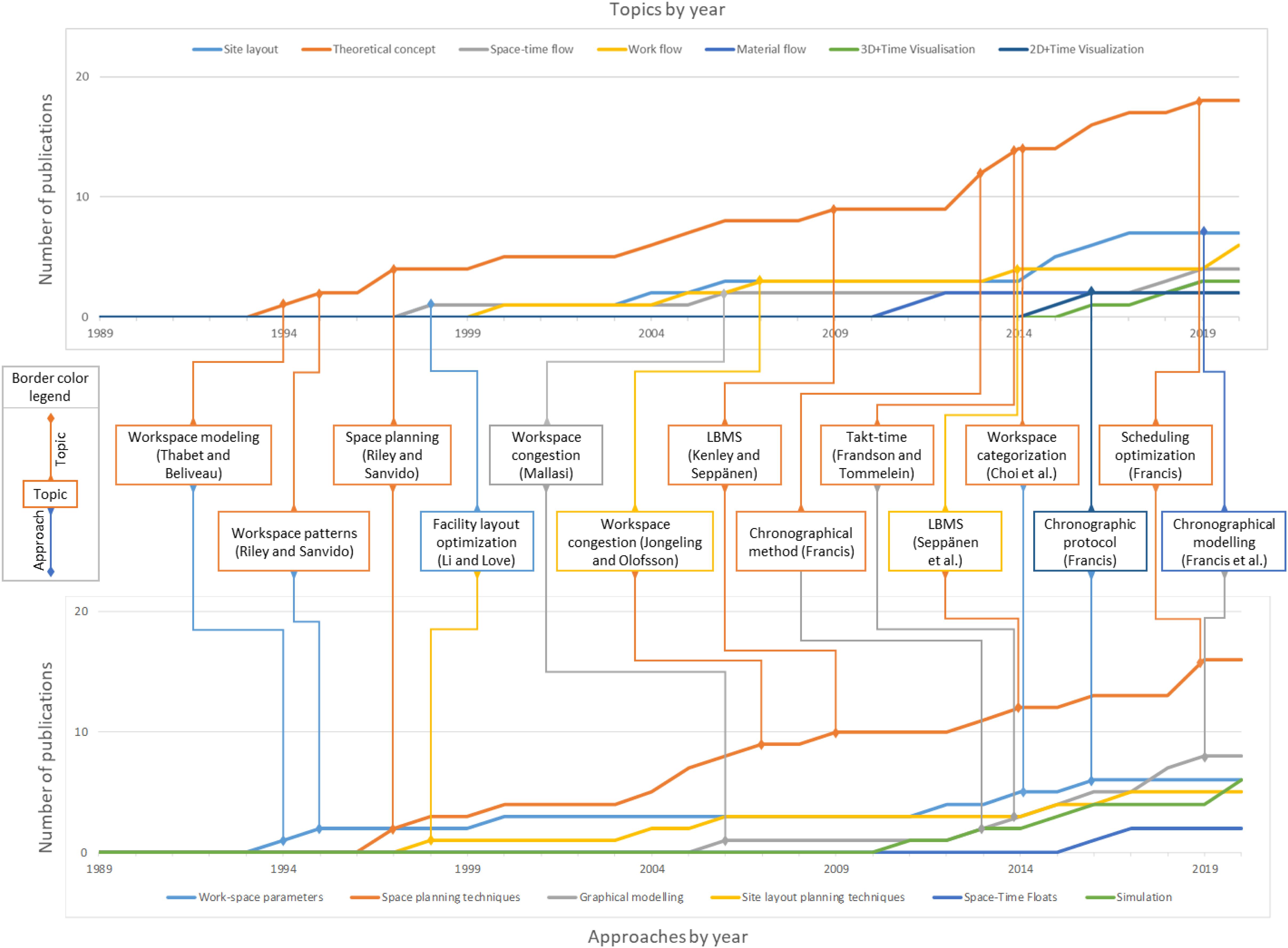

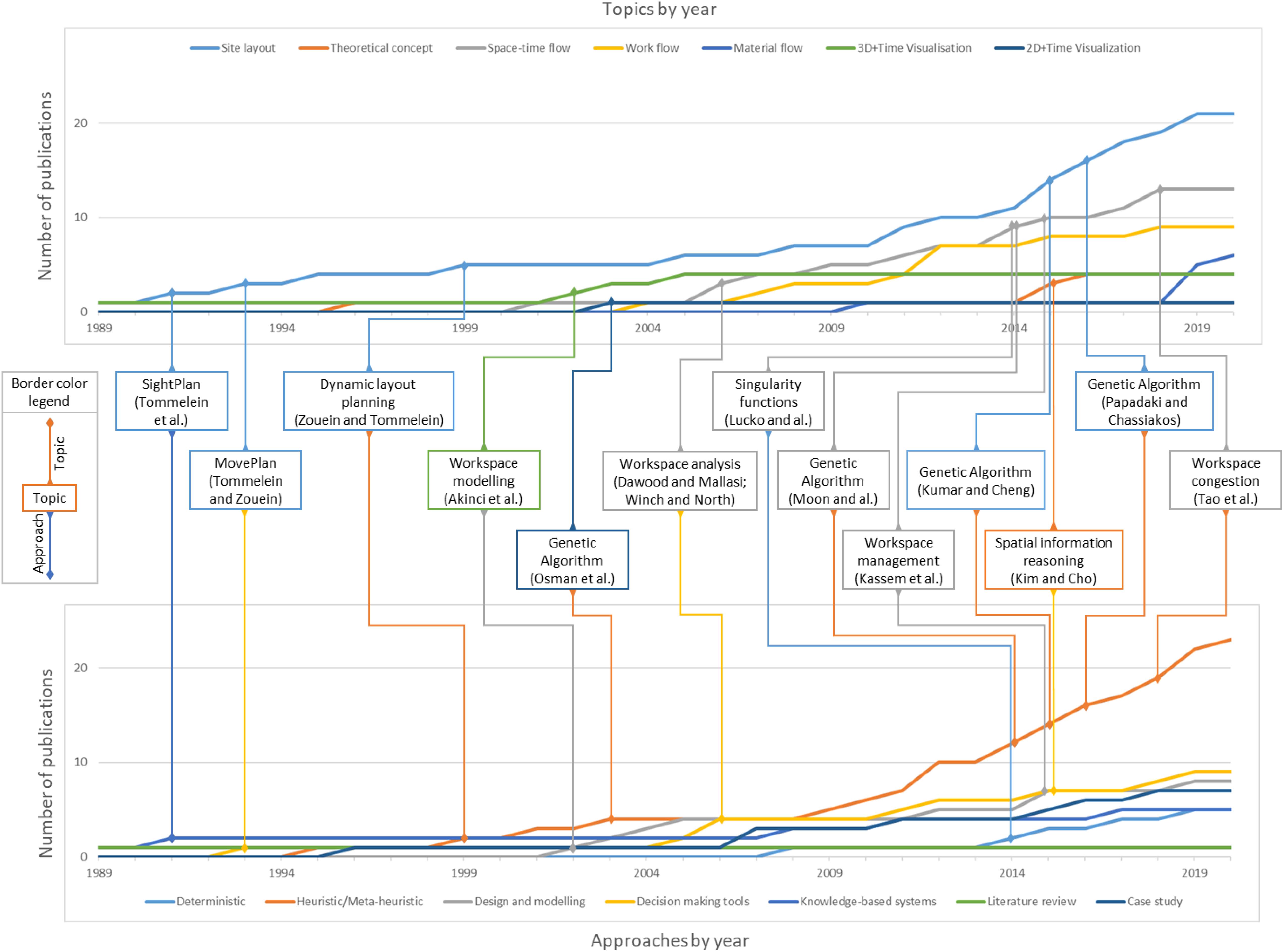

The ultimate goal of this paper is to present a synthesis of the most important scientific developments in spatiotemporal planning for building projects. The aim is to summarize the different methods applied and knowledge developed in this field. This paper contributes to the existing body of knowledge by synthesizing the scientific evolution from 1989 to date and by presenting a timeline that categorizes the scientific contributions in the field of space-time planning of building construction projects. The timeline uses the same classification explained in section 3: (i) the research topics: site layout, theoretical concepts, space-time flow, workflow, material flow, and 3D + time and 2D + time visualization; and (ii) the research approaches: mathematical, decision systems, conceptual, and reviews.

To lighten the timeline, given the large number of scientific contributions to date, the timeline is represented in two separate figures, Figures 4,5 according to the research approach used in the paper. The explanation of the evolution of the curves presented in these two figures is as follows:

Figure 4. Timeline of research on spatiotemporal planning—Mathematical, decision systems and empirical approaches.

- Figure 4 shows the research timeline of spatiotemporal planning based on mathematical, decision systems and empirical approaches. This figure demonstrates that the heuristic and metaheuristic methods mostly use GAs as optimizing approaches. The other methods mainly target site layout, followed by space-time flow and workflow.

- Figure 5 demonstrates the research timeline of spatiotemporal planning based on conceptual approaches. This figure demonstrates that most of these works contribute to the development of the theoretical concept and site layout, as well as workflow and the flow of materials.

Regarding scientific evolution, the 1990s saw a strong evolution of research and knowledge in this area. During these years, the dynamic layout planning was introduced, as well as the 4D modeling and simulation of construction operations (Figure 4). The workspace modeling and the space planning theory were also developed during this period (Figure 5).

Despite a short stagnation in research in the 2000s, some developments have been observed in the analysis of the workspace (Figure 4) and the spatial requirements (Figure 5). Finally, there has been a good resumption of work since 2010, notably for the LBMS (Figure 4), the chronographical method, and the takt time method (Figure 5).

Based on this review, this paper makes three conclusions:

1. Most of the existing methods are based on the critical path logic that primarily relies on scheduling the activities sequences to calculate the project duration. These methods hardly take into account the impact of circulation and the site occupancy by operations and intermediate storage. Only some researchers applied a 4D simulation based on the critical-space for optimizing the site occupancy rate. The development of more critical-space based methods should be encouraged.

2. Several methods are based on purely mathematical approaches. These approaches consider some parameters and neglect several others. Considering the increased complexity of projects and the multiplication of actors, these approaches fail to provide practical solutions applicable to the construction industry. Approaches that promote the involvement of real construction players, based on collaborative techniques, such as the Last Planner, must be encouraged. The lack of interoperability between systems and maturity and adaptability of the 4D simulation should be considered, at least in the short term.

3. Emphasis must be placed on the development of new spatiotemporal methods and techniques for monitoring work progress based on information technology. The digital revolution, the arrival of new technologies and the development of new construction techniques offer the construction industry a unique opportunity to grow. The application of the concept of industry 4.0 to the construction industry should result in massive use of digital data in real-time and in the automation of tasks by the application of AI and machine learning. It is an opportunity for more innovation in the construction industry, a traditionally conservative industry.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors without undue reservation.

Author Contributions

FA contributed to the research and analysis of the results obtained. AF contributed to the validation and optimization of the theses results. FA wrote the first draft of the manuscript. AF wrote the sections of the manuscript. Both authors contributed to manuscript revision, and read and approved the submitted version.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

Akinci, B., and Fischer, M. (2000). “An automated approach for accounting for spaces required by construction activities,” in Proceedings of the Construction Congress IV Building Together for a Better Tomorrow in an Increasingly Complex World, ed. K. D. Walsh (Orlando, FL: ASCE).

Akinci, B., Fischer, M., and Kunz, J. (2002). Automated generation of work spaces required by construction activities. J. Constr. Eng. Manage. 128, 306–315. doi: 10.1061/(ASCE)0733-93642002128:4(306)

Akinci, B., Fischer, M., and Zabelle, T. (1998). “Proactive approach for reducing non-value adding activities due to time-space conflicts,” in Proceedings of the 6th Annual Conference of the International Group for Lean Construction, (Guaruja: IGLC).

Al Hawarneh, A., Bendak, S., and Ghanim, F. (2019). Dynamic facilities planning model for large scale construction projects. Autom. Constr. 98, 72–89. doi: 10.1016/j.autcon.2018.11.021

Bakchan, A., Faust, K. M., and Leite, F. (2019). Seven-dimensional automated construction waste quantification and management framework: Integration with project and site planning. Resour. Conserv. Recycl. 146, 462–474. doi: 10.1016/j.resconrec.2019.02.020

Ballard, H. G. (2000). The Last Planner System of Production Control. Dissertation thesis, University of Birmingham, Birmingham.

Bansal, V. K. (2011). Use of GIS and topology in the identification and resolution of space conflicts. J. Comput. Civil Eng. 25, 159–171. doi: 10.1061/(ASCE)CP.1943-5487.0000075

Chau, K. W., Anson, M., and Zhang, J. P. (2005). 4D dynamic construction management and visualization software: 1. Development. Autom. Constr. 14, 512–524. doi: 10.1016/j.autcon.2004.11.002

Chavada, R. D., Kassem, M., Dawood, N. N., and Naji, K. K. (2012). “A framework for construction workspace management: a serious game engine approach,” in Proceedings of the International Conference on Computing in Civil Engineering, (Clearwater Beach, FL: ASCE).

Chen, S.-M., Griffis, F. H., Chen, P.-H., and Chang, L.-M. (2012). Simulation and analytical techniques for construction resource planning and scheduling. Autom. Constr. 21, 99–113. doi: 10.1016/j.autcon.2011.05.018

Cho, K., Hong, T., and Hyun, C. T. (2013). Space zoning concept-based scheduling model for repetitive construction process. J. Civil Eng. Manage. 19, 409–421. doi: 10.3846/13923730.2012.757561

Choi, B., Lee, H.-S., Park, M., Cho, Y. K., and Kim, H. (2014). Framework for workspace planning using four-dimensional BIM in construction projects. J. Constr. Eng. Manage. 140, 1–13. doi: 10.1061/(ASCE)CO.1943-7862.0000885

Dagan, D., and Isaac, S. (2015). Planning safe distances between workers on construction sites. Autom. Constr. 50, 64–71. doi: 10.1016/j.autcon.2014.12.008

Dawood, N., and Mallasi, Z. (2006). Construction workspace planning: assignment and analysis utilizing 4D visualization technologies. Comput. Aided Civil Infrastruct. Eng. 21, 498–513. doi: 10.1111/j.1467-8667.2006.00454.x

Dong, N., Ge, D., Fischer, M., and Haddad, Z. (2012). A genetic algorithm-based method for look-ahead scheduling in the finishing phase of construction projects. Adv. Eng. Inform. 26, 737–748. doi: 10.1016/j.aei.2012.03.004

Easa, S. M., and Hossain, K. M. A. (2008). New mathematical optimization model for construction site layout. J. Constr. Eng. Manage. 134, 653–662. doi: 10.1061/(ASCE)0733-93642008134:8(653)

Elbeltagi, E., Hegazy, T., and Eldosouky, A. (2004). Dynamic layout of construction temporary facilities considering safety. J. Constr. Eng. Manage. 130, 534–541. doi: 10.1061/(ASCE)0733-93642004130:4(534)

Farmakis, P. M., and Chassiakos, A. P. (2018). Genetic algorithm optimization for dynamic construction site layout planning. Org. Technol. Manage. Constr. 10, 1655–1664. doi: 10.1515/otmcj-2016-0026

Francis, A. (2004). La Modélisation Chronographique de la Planification des Projets de Construction. Dissertation Thesis. Montreal, QC: École de technologie supérieure.

Francis, A. (2013). The chronographical approach for construction project modelling. Manage. Procurem. Law 166, 188–204. doi: 10.1680/mpal.12.00009

Francis, A. (2016). A chronographic protocol for modelling construction projects. Manage. Procurem. Law 169, 168–177. doi: 10.1680/jmapl.15.00039

Francis, A. (2019). Chronographical spatiotemporal scheduling optimization for building projects. Front. Build. Environ. 5:36. doi: 10.3389/fbuil.2019.00036

Francis, A., and Miresco, E. (2006). A chronographic method for construction project planning. Can. J. Civil Eng. 33, 1547–1557. doi: 10.1139/l06-148

Francis, A., Miresco, E., and Le Meur, E. (2019). Spatiotemporal chronographical modeling of procurement and material flow for building projects. Adv. Comput. Des. 4, 119–139. doi: 10.12989/acd.2019.4.2.119

Francis, A., and Morin-Pepin, S. (2017). The concept of float calculation based on the site occupation using the chronographical logic. Proced. Eng. 196, 690–697. doi: 10.1016/j.proeng.2017.07.235

Frandson, A., and Tommelein, I. D. (2014). “Development of a Takt-time Plan: a case study,” in Proceedings of the Construction Research Congress 2014, (Atlanta, GA: ASCE).

Grant, M. J., and Booth, A. (2009). A typology of reviews: an analysis of 14 review types and associated methodologies. Health Inform. Lib. J. 26, 91–108. doi: 10.1111/j.1471-1842.2009.00848.x

Güden, H., and Süral, H. (2019). The dynamic p-median problem with mobile facilities. Comput. Ind. Eng. 135, 615–627. doi: 10.1016/j.cie.2019.06.024

Huang, C., and Wong, C. K. (2015). Optimisation of site layout planning for multiple construction stages with safety considerations and requirements. Autom. Constr. 53, 58–68. doi: 10.1016/j.autcon.2015.03.005

Isaac, S., Su, Y., Lucko, G., and Dagan, D. (2017). Work-path modeling and spatial scheduling with singularity functions. J. Comput. Civil Eng. 31, 1–14. doi: 10.1061/(ASCE)CP.1943-5487.0000650

Jin, H., Nahangi, M., Goodrum, P. M., and Yuan, Y. (2017). Model-based space planning for temporary structures using simulation-based multi-objective programming. Adv. Eng. Inform. 33, 164–180. doi: 10.1016/j.aei.2017.07.001

Jongeling, R., Kim, J., Fischer, M., Mourgues, C., and Olofsson, T. (2008). Quantitative analysis of workflow, temporary structure usage, and productivity using 4D models. Autom. Constr. 17, 780–791. doi: 10.1016/j.autcon.2008.02.006

Jongeling, R., and Olofsson, T. (2007). A method for planning of work-flow by combined use of location-based scheduling and 4D CAD. Autom. Constr. 16, 189–198. doi: 10.1016/j.autcon.2006.04.001

Kassem, M., Dawood, N., and Chavada, R. (2015). Construction workspace management within an industry foundation class-compliant 4D tool. Autom. Constr. 52, 42–58. doi: 10.1016/j.autcon.2015.02.008

Kenley, R., and Seppänen, O. (2009). Location-Based Management for Construction: Planning, Scheduling and Control. New York, NY: Routledge.

Kim, K., and Cho, Y. K. (2015). Construction-specific spatial information reasoning in building information models. Adv. Eng. Inform. 29, 1013–1027. doi: 10.1016/j.aei.2015.08.004

Kumar, S. S., and Cheng, J. C. P. (2015). A BIM-based automated site layout planning framework for congested construction sites. Autom. Constr. 59, 24–37. doi: 10.1016/j.autcon.2015.07.008

Lee, H.-Y. (2012). Renovation scheduling to minimize user impact of a building that remains in operation. Autom. Constr. 22, 398–405. doi: 10.1016/j.autcon.2011.09.018

Li, H., Chan, G., Skitmore, M., and Huang, T. (2015). A 4D automatic simulation tool for construction resource planning: a case study. Eng. Constr. Architect. Manage. 22, 536–550. doi: 10.1108/ECAM-07-2014-0093

Li, H., and Love, P. E. D. (1998). Site-level facilities layout using genetic algorithms. J. Comput. Civil Eng. 12, 227–231. doi: 10.1061/(ASCE)0887-3801199812:4(227)

Lucko, G., Gomes Araujo, L., and Cates, G. R. (2016). Slip chart-inspired project schedule diagramming: origins, buffers, and extension to linear schedules. J. Constr. Eng. Manage. 142, 1–11. doi: 10.1061/(ASCE)CO.1943-7862.0001089

Lucko, G., Said, H. M. M., and Bouferguene, A. (2014). Construction spatial modeling and scheduling with three-dimensional singularity functions. Autom. Constr. 43, 132–143. doi: 10.1016/j.autcon.2014.03.008

Ma, Z., Shen, Q., and Zhang, J. (2005). Application of 4D for dynamic site layout and management of construction projects. Autom. Constr. 14, 369–381. doi: 10.1016/j.autcon.2004.08.011

Mallasi, Z. (2006). Dynamic quantification and analysis of the construction workspace congestion utilising 4D visualisation. Autom. Constr. 15, 640–655. doi: 10.1016/j.autcon.2005.08.005

Mirzaei, A., Nasirzadeh, F., Jalal, M. P., and Zamani, Y. (2018). 4D-BIM dynamic time-space conflict detection and quantification system for building construction projects. J. Constr. Eng. Manage. 144, 1–14. doi: 10.1061/(ASCE)CO.1943-7862.0001504

Moher, D., Liberati, A., Tetzlaff, J., Altman, D. G., and Prisma, G. (2009). Preferred reporting items for systematic reviews and meta-analyses: the PRISMA statement. PLoS Med. 6:e1000097. doi: 10.1371/journal.pmed.1000097

Moon, H., Kim, H., Kim, C., and Kang, L. (2014). Development of a schedule-workspace interference management system simultaneously considering the overlap level of parallel schedules and workspaces. Autom. Constr. 39, 93–105. doi: 10.1016/j.autcon.2013.06.001

Osman, H. M., Georgy, M. E., and Ibrahim, M. E. (2003). A hybrid CAD-based construction site layout planning system using genetic algorithms. Autom. Constr. 12, 749–764. doi: 10.1016/S0926-5805(03)00058-X

Papadaki, I. N., and Chassiakos, A. P. (2016). Multi-objective construction site layout planning using genetic algorithms. Proc. Eng. 164, 20–27. doi: 10.1016/j.proeng.2016.11.587

Razavialavi, S., and Abourizk, S. (2015). A hybrid simulation approach for quantitatively analyzing the impact of facility size on construction projects. Autom. Constr. 60, 39–48. doi: 10.1016/j.autcon.2015.09.006

Riddell, T. (2017). Major Events Affecting the Construction Industry. Available online at: https://constructionexec.com/article/major-events-affecting-the-construction-industry (accessed June 17, 2020).

Riley, D. R. (1994). Modeling the Space Behavior of Construction Activities. Dissertation thesis, Pennsylvania State University, State College, PA.

Riley, D. R., and Sanvido, V. E. (1995). Patterns of construction-space use in multistory buildings. J. Constr. Eng. Manage. 121, 464–473. doi: 10.1061/(ASCE)0733-93641995121:4(464)

Riley, D. R., and Sanvido, V. E. (1997). Space planning method for multistory building construction. J. Constr. Eng. Manage. 123, 171–180. doi: 10.1061/(ASCE)0733-93641997123:2(171)

Rodriguez-Ramos, W. E. (1982). Quantitative Techniques for Construction Site Layout Planning. Dissertation thesis, University of Florida, Gainesville, FL.

Sadeghpour, F., Moselhi, O., and Alkass, S. T. (2006). Computer-aided site layout planning. J. Constr. Eng. Manage. 132, 143–151. doi: 10.1061/(ASCE)0733-93642006132:2(143)

Said, H., and El-Rayes, K. (2013). Optimal utilization of interior building spaces for material procurement and storage in congested construction sites. Autom. Constr. 31, 292–306. doi: 10.1016/j.autcon.2012.12.010

Said, H. M. M., and Lucko, G. (2016). Float types in construction spatial scheduling. J. Constr. Eng. Manage. 142, 1–12. doi: 10.1061/(ASCE)CO.1943-7862.0001202

Seppänen, O., Evinger, J., and Mouflard, C. (2014). Effects of the location-based management system on production rates and productivity. Constr. Manage. Econ. 32, 608–624. doi: 10.1080/01446193.2013.853881

Su, X., and Cai, H. (2016). Enabling construction 4D topological analysis for effective construction planning. J. Comput. Civil Eng. 30, 1–10. doi: 10.1061/(ASCE)CP.1943-5487.0000463

Tao, S., Wu, C., Sheng, Z., and Wang, X. (2018). Space-time repetitive project scheduling considering location and congestion. J. Comput. Civil Eng. 32, 1–19. doi: 10.1061/(ASCE)CP.1943-5487.0000745

Thabet, W. Y., and Beliveau, Y. J. (1994). Modeling work space to schedule repetitive floors in multistory buildings. J. Constr. Eng. Manage. 120, 96–116. doi: 10.1061/(ASCE)0733-93641994120:1(96)

Thabet, W. Y., and Beliveau, Y. J. (1997). SCaRC: space-constrained resource-constrained scheduling system. J. Comput. Civil Eng. 11, 48–59. doi: 10.1061/(ASCE)0887-3801199711:1(48)

Tommelein, I. D. (1989). SightPlan – An Expert System that Models and Augments Human Decision-Making for Designing Construction Site Layouts. Dissertation thesis, Stanford University, Standford (CA).

Tommelein, I. D., Levitt, R. E., Hayes-Roth, B., and Confrey, T. (1991). SightPlan experiments. Alternate strategies for site layout design. J. Comput. Civil Eng. 5, 42–63. doi: 10.1061/(ASCE)0887-380119915:1(42)

Tommelein, I. D., and Zouein, P. P. (1993). Interactive dynamic layout planning. J. Constr. Eng. Manage. 119, 266–287. doi: 10.1061/(ASCE)0733-93641993119:2(266)

U.S. Bureau of Labor Statistics (2019). Labor Productivity and Costs. Available online at: https://www.bls.gov/lpc/construction.htm#:~:text=On%20September%2026%2C%202019%20the,four%20construction%20industries%20through%202018.&text=The%20construction%20sector%20makes%20up,were%20attributable%20to%20this%20sector (accessed June 17, 2020).

Wang, H. J., Zhang, J. P., Chau, K. W., and Anson, M. (2004). 4D dynamic management for construction planning and resource utilization. Autom. Constr. 13, 575–589. doi: 10.1016/j.autcon.2004.04.003

Winch, G. M., and North, S. (2006). Critical space analysis. J. Constr. Eng. Manage. 132, 473–481. doi: 10.1061/(ASCE)0733-93642006132:5(473)

Xu, J., and Li, Z. (2012). Multi-objective dynamic construction site layout planning in fuzzy random environment. Autom. Constr. 27, 155–169. doi: 10.1016/j.autcon.2012.05.017

Yeh, I. C. (1995). Construction-site layout using annealed neural network. J. Comput. Civil Eng. 9, 201–208. doi: 10.1061/(ASCE)0887-380119959:3(201)

Zouein, P. P., and Tommelein, I. D. (1999). Dynamic layout planning using a hybrid incremental solution method. J. Constr. Eng. Manage. 125, 400–408. doi: 10.1061/(ASCE)0733-93641999125:6(400)

Keywords: spatiotemporal planning, scheduling, construction projects, space, location

Citation: Ardila F and Francis A (2020) Spatiotemporal Planning of Construction Projects: A Literature Review and Assessment of the State of the Art. Front. Built Environ. 6:128. doi: 10.3389/fbuil.2020.00128

Received: 09 April 2020; Accepted: 13 July 2020;

Published: 05 August 2020.

Edited by:

Marwa ElCheikh, University of Birmingham, United KingdomReviewed by:

Martin Theaker, Independent Researcher, Birmingham, United KingdomMehran Eskandari Torbaghan, University of Birmingham, United Kingdom

Copyright © 2020 Ardila and Francis. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Adel Francis, YWRlbC5mcmFuY2lzQGV0c210bC5jYQ==

Fabian Ardila

Fabian Ardila Adel Francis

Adel Francis