- Department of Construction Economics and Management, Faculty of Engineering and Built Environment, University of Cape Town, Cape Town, South Africa

The study examines the dimensions and components of construction safety culture and whether the application of BIM technologies to the dimensions of construction safety culture improves the safety maturity levels among construction workers. The study employed a systematic literature review and grounded theory in achieving the research objectives. The dimensions and components of construction safety culture were found to comprise of a safety management system, safety behavior, and safety climate. A bim-enabled conceptual model of construction safety culture was developed as an output of the study. The model demonstrates how the dimensions of construction safety culture change the maturity levels of safety among construction workers as enabled by BIM technologies. The model has implications for improved construction safety management practices through the use of BIM on construction projects. The study concludes with implications for practice and future research.

Introduction

The dimensions and components of construction safety culture and its interaction with BIM technologies are examined in this study. Construction safety management is an important construction project success criteria due to the hazardous nature of the construction environment (Bansal, 2011). Construction safety management entails the safety-related activities and responsibilities undertaken by construction managers toward ensuring the safety of construction workers and resources of construction firms and on construction sites (Tam et al., 2004; Mohamed and Chinda, 2011). The socio-technical nature of the construction environments (construction firms and construction sites) requires construction safety management to be significantly based on construction safety culture (Mohamed, 1999; Fang et al., 2004; Zhao and Lucas, 2015). This is because construction safety culture is an integral aspect of construction safety management as a result of the regular movement of construction workers and activities between construction firms and construction sites (Fang et al., 2006; Zhang and Fang, 2013); and promotes the understanding of safety management performance, and long-term effect of construction safety culture on safety management (Fung et al., 2005).

The need to understand the concept of safety culture in the construction sector is necessitated by the lack of understanding of the dimensions of construction safety culture (Mohamed, 1999; Chinda and Mohamed, 2008; Biggs et al., 2013). This lack of understanding according to Choudhry et al. (2007) has made it difficult to develop a positive construction safety culture that is favorable to good construction safety management performance. Maintaining a positive construction safety culture requires a number of construction safety management elements such as safety improvement, integration of safety into the organization, training of safety officers, safety attitudes and behavior, safety resources, and safety factors (access route, site topography, thermal comforts, environmental conditions) and safety awareness (Ding et al., 2014; Eleftheriadis et al., 2017).

More importantly, there is a lack of understanding of how to integrate elements of construction safety management into construction safety culture. Zhou et al. (2012) and Ding et al. (2014) concluded that the use of new technologies such as Building Information Modeling (BIM) technologies would enable the integration of construction safety management elements into construction safety culture. Recently, the application of BIM technologies in construction safety management practices has gained widespread attention because it is object-oriented (Eleftheriadis et al., 2017); and are being promoted as an acceptable method of improving the efficiency and effectiveness of construction safety management practices (Ding et al., 2014; Zhao and Lucas, 2015). However, without an understanding of the components of construction safety culture, an efficient and effective application of BIM technologies in construction safety management practices will be difficult.

Therefore, the aim of this study is to investigate the concept of construction safety culture, identify the dimensions of construction safety culture, establish maturity levels for construction safety culture, and ascertain applicable BIM technologies for improving the construction safety culture maturity level; and whether the use of BIM technologies in construction safety management improves construction safety culture and maturity levels among construction workers.

The study proposes that models developed will enable the assessment of safety culture on construction sites, enable effective planning of the components of safety culture, and thereby improve construction safety maturity levels and management practices among construction workers. Secondly, the study proposes that the model will enable optimal use of BIM technologies in construction safety management practices. The framework developed will provide an opportunity for researchers to identify future BIM-related safety management research.

Section Theoretical Grounding presents the theoretical grounding for dimensions of safety culture and BIM technologies that apply to construction safety management. Methods for developing the models are discussed in section Method. Following the theoretical foundation in section Theoretical Grounding, the dimensions of construction safety culture and safety-related BIM technologies were synthesized to develop the BIM-integrated construction safety culture model outlined in section Developing a Model of Building Information Modeling—Enabled Construction Safety Culture Maturity. The study concludes with a discussion of the implications of the findings for theory, practice, and society in section Conclusions and Implications.

Theoretical Grounding

The Concept, Dimensions, and Components of Construction Safety Culture

Construction safety culture is the set of beliefs and values that influence safety-related behaviors and perceptions of construction workers, management personnel, and associated parties (Fang and Wu, 2013). Construction safety culture refers to construction safety management practices (work schedule, decision-making, construction technology, construction methods and systems, and business strategy) that are adopted on a construction project and the effectiveness of the resources, policies, practices, procedures, attitudes, and habitual practices of workers (Choudhry et al., 2007).

Although these situate safety culture within the domain of construction environment, they are conceptually blurred and inconsistent. However, patterns of behavior and associated construction safety management practices are the common themes in these descriptions of construction safety culture. In this study, these two common themes will be adapted. Hence, construction safety culture is described as the atmosphere of safety in a construction environment (construction firms and construction sites) as created by the construction safety management practices and the pattern of behavior of construction workers and management personnel.

Construction safety culture is a dynamic combination of the determinants of construction safety management such as the safety-related attitude of and safety-related behavior of workers and management personnel (Bansal, 2011; Fang and Wu, 2013). Various studies such as Edwards et al. (2013) and Petitta et al. (2017a) have proposed basic dimensions for safety culture. Several of these studies conceptualized safety culture as a subset of organizational culture, while few studies developed safety culture dimensions based on construction processes and safety management practices. For example, Edwards et al. (2013) conceptualized safety culture using four dimensions of safety outcomes, organizational policies and procedures, behavioral practices and norms, and beliefs and attitudes. Petitta et al. (2017a) identified seven dimensions of safety culture, namely autocratic, bureaucratic, clan-patronage, technocratic, cooperative, safety compliance, and supervisor enforcement.

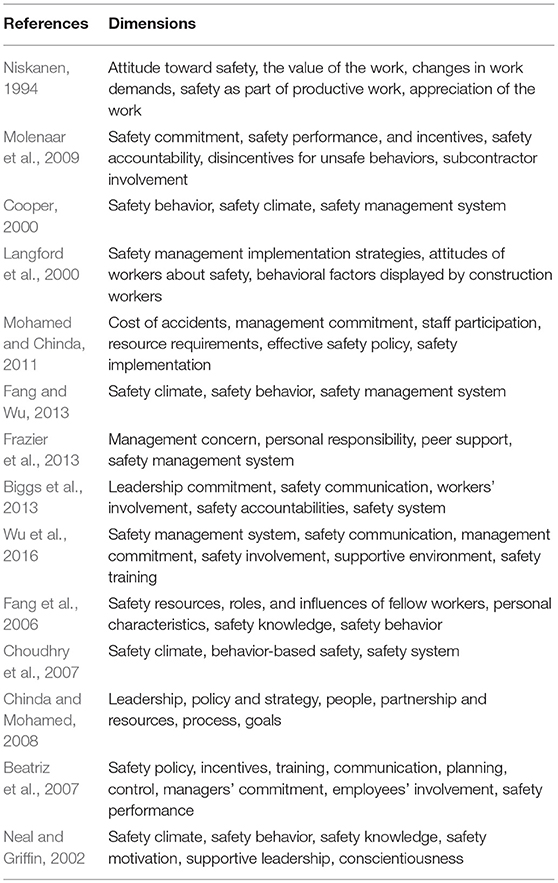

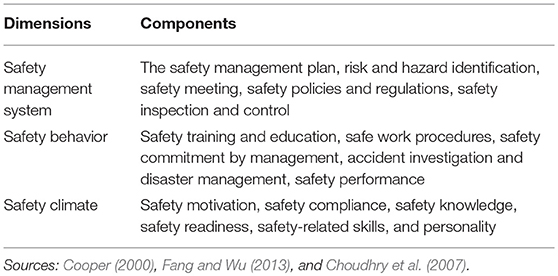

Construction projects require different project organizations with different organizational culture to work together. Hence safety culture in the context of construction projects according to Reiman and Rollenhagen (2014) should be conceptualized in the settings of construction processes and safety management practices. The dimensions of safety culture in the settings of construction processes and safety management practices developed by earlier scholars are shown in Table 1. Most of the studies reported the factors influencing safety culture as its dimensions. Only Cooper (2000), Choudhry et al. (2007), and Fang and Wu (2013) objectively identified the dimensions of safety culture and presented consistent dimensions. Also, the dimensions of safety culture given by Cooper (2000), Choudhry et al. (2007), and Fang and Wu (2013) are in line with Bansal's definition of safety culture—the definition of safety culture adopted in this study. Hence, the safety culture model proposed by Cooper (2000), Choudhry et al. (2007), and Fang and Wu (2013) is adopted by this study to explain the dimensions and components of safety culture. These studies explain that safety management system brings about safety behavior, while safety behavior creates a safety climate. The components of each of the safety culture dimensions as reported by these studies are summarized in Table 2.

Application of BIM Technologies in Construction Safety Culture

BIM refers to a set of interacting tools, processes, and technologies that constitutes a project management methodology that is essential to building planning, design, construction, operation, and management (Wang et al., 2013). The BIM technologies described in this section were derived from the analysis of texts in the application of BIM technologies in construction safety. The use of BIM technologies in construction safety management is an effective way to enhance safety culture in the construction environment because it enhances the safety practices of construction firms and influences the safety behavior of construction workers (Zhao and Lucas, 2015). Five BIM technologies were identified, discussed, and supported by important studies.

Visualization

Visualization has been described as time-lapse photographs (Kamat and Martinez, 2001), comprehensive but static visual images (Wang et al., 2014), and real-time rendering (Kumar et al., 2011) of an event. The usefulness of visualization in construction safety include construction sequence review (Bansal, 2011), risk and hazard evaluation (Ding et al., 2014), promotion of safety awareness and communication (Zhang et al., 2015), integration of safety into construction site layout plan (Zhang et al., 2015), development of educational materials for safety training and education (Park and Kim, 2013), and provision of information on the boundary conditions of risk elements (Park and Kim, 2013). Besides, visualization can be used for measuring the blind spots of equipment, identifying safety requirements for high-risk activities, integrating safety measures into the construction schedule, and linking safety measures with temporary structures and building components (Zhou et al., 2012). BIM-enabled visualization is usually developed in 3D and 4D BIM environments. With regard to the application of 4D BIM visualization in safety culture; Hu et al. (2010) developed a 4D BIM visualization of structural safety analysis of the Beijing stadium; Hameed et al. (2012) developed 4D BIM visualization model of protection measures against falling (guardrail and safety net), housekeeping and means of access (storage area and temporary access), scaffolding and shoring, and reserved workspace for heavy machinery and self-propelled vehicle; and Zhou et al. (2013) proposed a 4D BIM visualization for safety management in metro construction. Also, there are examples of the application of 3D BIM visualization in safety culture. For instance, Riaz et al. (2014) developed a BIM-enabled visualization of confined spaces for easy assessment of the physical condition and safety of operators, Zhang et al. (2015) developed a BIM-enabled visualization of job hazard analysis for masonry construction, and Cheng et al. (2017) proposed a 3D BIM visualization for building fire prevention and disaster relief.

Simulation

The computational images of a system or scenarios that are displayed in chronological order of events and each event change the state of the system are referred to as simulation (Peavey et al., 2012). Simulation is different from visualization in that it gives a dynamic visual image of scenarios (Rüppel and Schatz, 2011). The visual images in the simulation are active because it combines the analysis of the scenario with visualization. For example, the simulation of a construction task will require the analysis of the resources required for the task, analysis of the rules guiding the task, analysis of the managerial decisions to be made during the task execution, and analysis of the stochastic nature of the task (Kamat and Martinez, 2001). In safety culture, simulation is useful for planning escape routes (building egress), planning the maintenance of fire safety equipment, modeling of workers' safe behavior, and planning safety measures (Park and Kim, 2013; Wang et al., 2015).

Other usefulness of simulation in construction safety include modeling of crowd evacuation and crowd behavior during evacuation (Wang et al., 2015), modeling of safe installation of building elements and assembly of building components (Young et al., 2014), modeling of the removal of safety equipment (Zhang et al., 2015), and modeling of space-time conflict (analysis of workspace congestion, space obstructions, potential work interruptions, and workspace competition between different construction activities) (Zhou et al., 2012). In the practical sense, simulation has been used to develop an algorithm for an automatic BIM-enabled fall hazard identification and planning (Zhang et al., 2015) and to develop a BIM-enabled simulation of the safe erection of reinforced concrete structure (Wang et al., 2014). Other practical applications of simulation in safety culture include BIM-enabled simulation of evacuation assessment and escape route planning for fire safety management (Wang et al., 2015) and BIM-enabled fire-fighting simulations (Chen et al., 2014).

Animation

Animation creates interactive and realistic scenarios from simulation models by combining simulation with visualization (Fukuchi and Kobayashi, 1997). Animation is more realistic and suitable for complex construction safety events because it considers the transformation of space and limitations of working space, which is important to safety problems such as maneuverability of earth-moving operations, visibility restriction of the crane operator, overcrowding in work zones, and collision between two machines (Fukuchi and Kobayashi, 1997). Studies on BIM related safety management have identified the usefulness of animation in safety culture. Park and Kim (2013) confirmed that animation is useful in developing site safety inspection task, improving workers' cognition of safety risks that are related to their work activities, and enabling construction workers to pre-experience activity-specific safety risks before work execution.

Also, Zhang et al. (2015) claimed that animation of the use of personal protective equipment, safe operation of plants and equipment, safety behaviors, safety code checking and planning, and safety rules, are ways to utilize BIM technologies in safety culture. Scholars have demonstrated the identified usefulness of animation in safety culture. For example, Fukuchi and Kobayashi (1997) reported the use of animation for integrating construction expertise into design systems and construction management processes of dam construction, industrial readjustment, and highway reconstruction. Shi and Zhang (1999) reported the animation of crane operation showing activities such as the lifting of objects to the position, dropping off of an object, picking up of the object, and returning the object to pick up position. Other recent studies that demonstrated the application of animation in safety culture include animation-based construction schedule review (Songer et al., 2001), animation of hand models to illustrate the use of hands for powerful work and fine motor manipulations (Irene et al., 2003), and animation of construction schedules for safe erection of a structural steel frame (Behzadan and Kamat, 2006).

Digital Fabrication

Environmental factors and construction methods contribute to safety in numerous ways. Aggressive construction environments such as deserts, seismic-prone area, and chemical contamination sites pose a unique challenge to construction activities and construction workers (Buswell et al., 2007). In the same way, building materials, especially concrete, are sensitive to environmental changes and require the avoidance of cracks in the temporary structures that are used in the conventional construction methods (Lloret et al., 2015). As noted by Lloret et al. (2015), the use of conventional formwork systems is wasteful, expensive, and unsafe construction methods. However, digital fabrication provides a safe construction method and serves as one of the technological solutions to a hazardous construction environment (Buswell et al., 2007; Kostakis and Papachristou, 2014).

Digital fabrication is a prefabrication technology that uses digital information from building information models to communicate design parameters to construction machines such as CNC plasma-arc, routers, water-jet, and laser-cutters (Kolarevic, 2001). The technology entails milling, eroding, cutting, lamination, 3D printing, extrusions, and automated assembly (Agustí-Juan and Habert, 2017). As a safe, value-adding, and ecologically sustainable construction method, digital fabrication integrates the properties of construction materials with that of structural properties in order to create structures with complex shapes and integrate hazardous construction environment (Lloret et al., 2015; Gattas and Yu, 2016). Recently, studies have been conducted on the usefulness of digital fabrication in creating structures with complex shapes and in mitigating hazardous construction environment. For instance, Lloret et al. (2015) proposed the digital fabrication process for complex reinforced concrete structures, Gattas and Yu (2016) presented a digital fabrication process for folded sandwich structures, Marriage and Sutherland (2014) reported the use of digital fabrication for building construction in a seismically active zone in New Zealand, and Agustí-Juan and Habert (2017) demonstrated the use of digital fabrication in reducing the overall environmental impact of multi-functional building elements.

Virtual Reality

Virtual reality (VR) is a type of human experience enabled by the feeling of being inside a fictitious environment (a realistic, real-time, and interactive prototype of an environment) using its representation. VR is different from visualization in that VR uses the fictitious experience to create mental images; while visualization makes use of time-lapse photography to create visual images. There are two types of VR—immersive and non-immersive. Immersive VR has perception process which runs on input from different sensory channels and allows users to explore the immersive fictitious environment with head movements, walking navigation, and hand gestures (Paes et al., 2017). The usefulness of VR include the modeling of the construction process and site constraints management (Cheng and Teizer, 2013; Ding et al., 2014), risk and hazard evaluation (Bansal, 2011), training of workers in a risk-free and realistic virtual construction site (Zhou et al., 2014), virtual safety information and checklists (Park and Kim, 2013), and evaluating alternative construction methods (Cheng and Teizer, 2013). According to Zhou et al. (2012), VR is useful for mock-up of different scenarios for preventing the occurrence of an accident due to safety hazard in construction projects, mock-up of common unsafe acts and conditions supplemented with accident reports, regulations, and precautions, virtual experiments of innovative construction technologies, systems, and processes, modeling a dynamic construction site environment to enable dynamic navigation of construction site, modeling on-site construction situations and operations, modeling site planning and layout, and mock-up of job safety analysis and safe working procedures. Further, the practicality of VR in safety culture has been explored for creating a prototype VR system of accident scenarios (Park and Kim, 2013), a VR mock-up of workers' proximity to hazards and safety training of ironworkers (Cheng and Teizer, 2013), and a VR environment for evaluating workers' behavior in several unsafe work scenarios (Hilfert et al., 2016). Equally, Teizer et al. (2013) reported the use of VR for advancing safety training and education of ironworkers. The VR reported by Teizer et al. (2013) showed a parametric virtual worker displaying the appropriate safety skills in a 3D virtual environment.

Synthesis

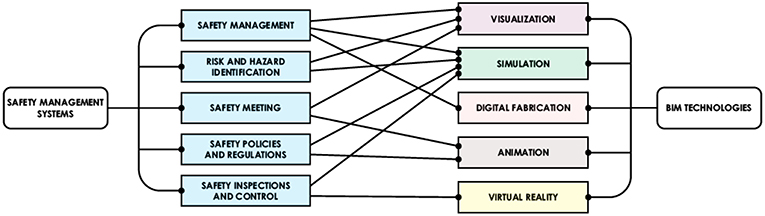

In the context of construction environment (projects and organizations), safety culture encompasses the safety management system, safety behavior, and safety climate. The safety management system as a dimension of safety culture refers to the tactics, methods, and strategies employed by managers to manage safety in the construction environment (Frazier et al., 2013). The components it entails include a safety management plan, risk, and hazard identification, safety meeting, safety policies and regulations, and safety inspections and control. These components will initiate the safety culture process and therefore require lots of factors before they can put in place. Ismail et al. (2012) identified these factors to include safety equipment, leadership, management commitment, communication, incentives, and personal relationship. All of the six BIM technologies that were identified to be applicable in safety culture were found to be useful in the safety management system. Visualization is useful in identifying risks and hazards and in safety meeting and also useful for giving orientations on work methods, procedures, and regulations (Bansal, 2011; Ding et al., 2014). Also, Visualization is useful for reviewing lessons learned, sorting relevant hazard scenarios, and safety reports at safety meetings (Hu et al., 2010; Zhao and Lucas, 2015). Simulation is the most useful BIM technologies in safety management system as it is useful in identifying risks and hazards, useful in conveying safety policies and regulations, and useful in managing safety inspections and control (Zhou et al., 2012; Park and Kim, 2013; Young et al., 2014; Zhang et al., 2015). Digital fabrication is useful as a safety management plan because it is a safe construction method (Lloret et al., 2015). The animation is useful in conveying safety policies and regulations. Animation allows scenarios to be selected in order of priorities which helps to prevent overloading of safety rules and regulations (Zhang et al., 2015). Lastly, Virtual Reality is useful in managing safety inspections and control and in identifying risks and hazards (Zhou et al., 2012; Teizer et al., 2013). In general, Simulation and Visualization prove to be the most useful BIM technologies in safety management system as they are useful in more than two components of the safety management system. Safety management plan utilizes more BIM technologies (Visualization, Simulation, and Digital Fabrication) than the other components. It is closely followed by risk and hazard identification which utilizes three BIM technologies (Visualization, Simulation, and Virtual Reality). The application of BIM technologies in safety management system leads to a speedy transition to safety behavior.

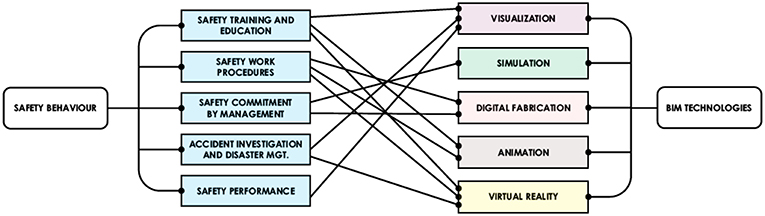

The safety behavior composed of safety training and education, safe work procedures, safety commitment by management, accident investigation and disaster management, and safety performance. Among the six BIM technologies that are applicable in safety culture, only Virtual Reality and Visualization are found to be useful for more than two components of safety behavior. Virtual Reality is useful in safety training and education, safety work procedures, and accident investigation and disaster management (Cheng and Teizer, 2013; Park and Kim, 2013); while Visualization is useful in safety training and education, accident investigation and disaster management, and safety performance (Zhou et al., 2012). A virtual reality-based safety training and education allows for customizing workers' safety training to specific tasks and working environments. For example, training on safe work procedures in a confined or dynamic environment will greatly benefit from virtual reality-based safety training. Section Animation also shows that animation is closely related to Virtual Reality, as it is also useful in safety training and education and safe work procedures. With animation, the simulation of real-life experience is made possible. The real-life experience that animation provides allows construction workers to familiarize with work-specific hazards and safe-work procedures without real-injury experience (Fukuchi and Kobayashi, 1997). So also, animation allows a more engaged visual feeling and exploration of scenarios from multiple angles (Shi and Zhang, 1999). Visualization is useful for safety training and education and safety performance (Park and Kim, 2013). Simulation and Digital Fabrication prove useful in safety commitment by management, accident inspection and disaster management, and safety work procedures (Zhang et al., 2015; Agustí-Juan and Habert, 2017). Among the dimensions of safety culture, safety behavior utilizes BIM technologies more than a safety management system and safety climate. Three components (safety training and education, safe work procedure, and accident investigation and disaster management) out of five components of safety behavior utilizes three BIM technologies; while the remaining two components utilize two BIM technologies. The heavy usefulness of BIM technologies in safety behavior supports its unique position among the dimensions of safety culture.

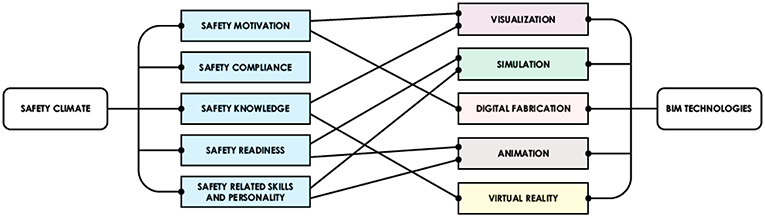

In BIM-enabled safety climate, according to sections Simulation and Animation, Simulation and Animation are both useful for safety readiness and safety-related skills and personality (Behzadan and Kamat, 2006; Young et al., 2014). Visualization and Virtual Reality are useful in safety knowledge (Zhang et al., 2015; Hilfert et al., 2016). For example, the safety knowledge is composed of safety policies, rules and regulations; this knowledge must be exhibited by construction workers to bring about safety climate in the construction environment. The use of virtual reality provides a new way of assessing the safety knowledge of construction workers (Li et al., 2012). Digital Fabrication and Visualization motivate workers to acquire and exhibit safety behavior (Park and Kim, 2013; Agustí-Juan and Habert, 2017). BIM technologies are reasonably utilized in safety climate as none of its components utilizes more than two BIM technologies. This is because the safety climate represents the metrics for assessing the effectiveness of the other dimensions of safety culture (Goncalves Filho and Waterson, 2018).

The enablement of the safety management system, safety behavior, and safety climate by BIM technologies have shown that an improved construction safety culture can be achieved in the construction environment. BIM technologies ensure an improved construction safety culture because they are object-oriented.

Method

The study adopted a-Grounded Theory approach, a general methodology to develop and validate the model. Grounded Theory approach is appropriate for this study because of its usefulness in providing a thorough theoretical explanation for a well-integrated set of concepts (Corbin and Strauss, 1990). The Grounded Theory methodology was conducted according to the five-stage process outlined by Wolfswinkel et al. (2013). The five-stage process includes defining the selection criteria for the dataset, searching and selection process, dimensions identification (open coding), category development (axial coding), and meta-synthesis (selective coding). The dataset required for this study is research articles because of the need to provide a theoretical grounding for the model to be developed. The inclusion of research articles in the dataset for this study was based on the following criteria (i) the research articles must be a peer-reviewed article (ii) the research articles must be within the domain of safety management and BIM technologies in the construction industry (iii) the research articles must contain relevant texts on the topic of the study (iv) the research articles must be written in English Language.

All the research articles that did not meet all these four criteria were excluded from the dataset. However, because the domains of safety management and BIM technologies are quite broad, the objective of this study—examining the dimensions of construction safety culture was used to narrow down the dataset to the appropriate fields of research. Based on the most relevant texts on the objective of this study and the familiarity with the constituting fields, the following specific search terms were generated: (i) safety culture (ii) dimensions of safety culture (iii) safety culture maturity model/levels (iv) application of 4D visualizations in safety culture/safety management (v) application of construction simulation in safety culture/safety management (vi) application of digital fabrication in safety culture/safety management (vii) application of animations in safety culture/safety management (viii) application of virtual reality mock-up in safety culture/safety management. The search for and selection of research articles to be included in the dataset were conducted in the five databases including Engineering Village, Science Direct, Scopus, Web of Science, and Google Scholar database. Relevant research articles were filtered using the journal outlet, title, abstract, and keyword to decide the research articles that comply with the selection criteria that were set out in stage one of the process. The search process covered from 1997 to 2018. Top journals in the field of BIM, safety science and safety management were considered. These include Journal of cleaner production, Safety science, International Journal of Project Management, Automation in construction, Computers, Environment and Urban Systems, Engineering, Construction and Architectural Management, Accident Analysis & Prevention, Renewable and Sustainable Energy Reviews, Journal of construction engineering and management, Journal of safety research, Journal of Civil Engineering Information Processing System, Journal of Contingencies and Crisis Management, Engineering Mechanics, Journal of computing in civil engineering, Telematics and Informatics, Journal of Information Technology in Construction (ITcon), Computer-Aided Design, Australian Journal of management, Advanced Engineering Informatics, Construction Innovation, Energy and Buildings, Construction Management and Economics, and International journal of injury control and safety promotion. Also, duplicates were removed from the dataset and a total of 64 journals and 5 conference proceedings remained.

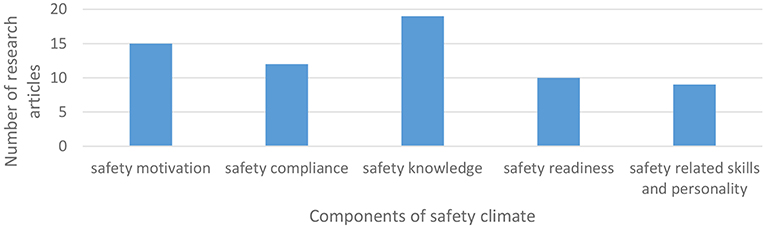

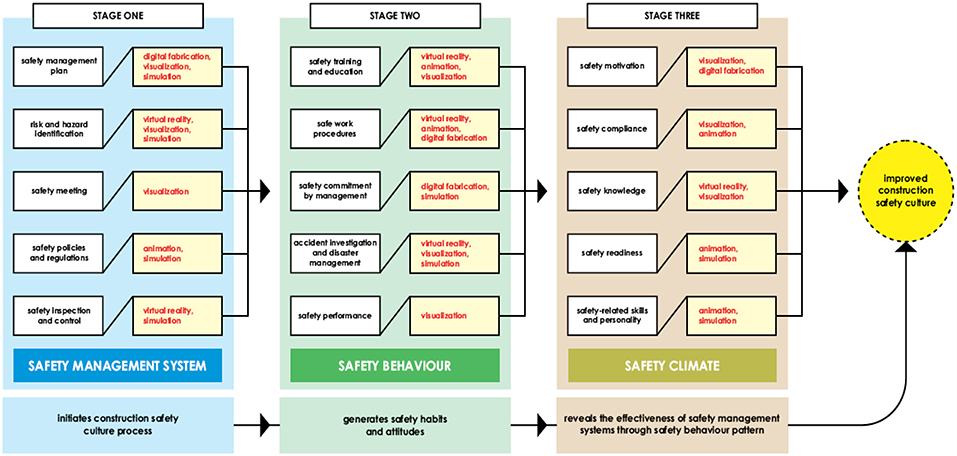

Identification of dimensions (open coding) was conducted for each of the search terms by analyzing the dataset to identify the set of concepts that constitute each of the search terms. Three dimensions—safety climate, safety behavior, and safety management system were identified for safety culture, and the number of research articles supporting the three dimensions identified for safety culture is presented in Figure 1. A total of 15 components of safety culture, distributed by the three dimensions of safety climate, safety behavior, and safety management system were identified. These components were categorized under the dimensions that were initially identified for safety culture. Figure 1 shows that a total of 125 articles were reviewed for safety culture, distributed by 38 for safety climate, 35 for safety behavior and 42 for the safety management system. The components categorization and the number of research articles that supported the categorization is presented in Figures 2–4. A meta-synthesis was conducted on the components and dimensions of safety culture based on the dataset collected from literature for the application of BIM technologies in safety management. Interrelationships between the dimensions of construction safety culture and BIM technologies (4D visualizations, construction simulation, digital fabrication, animations, and virtual reality) were identified and illustrated as shown in Figures 5–8.

Developing a Model of Building Information Modeling—Enabled Construction Safety Culture Maturity

This section presents a conceptually grounded theoretical model of BIM-enabled construction safety culture. The theoretical explanation for the model is derived from the synthesis of the theoretical background (section Synthesis). The model emerged from the dataset (theoretical background of BIM technologies and construction safety culture) through the understanding of the application of BIM technologies to the components of the dimensions of construction safety culture. The synthesis guides the analysis of the model with respect to the fit, comprehension, and control (the requirements for Grounded Theory-based model). The model represents an abstract construction or conceptual interpretation of the dataset.

The model development process includes investigating the dimensions and components of construction safety culture (the identification of the components was necessitated by the need to match them with suitable BIM technologies), identifying the BIM technologies that support the improvement of safety management system (Figure 5), identifying the BIM technologies that support the improvement of safety behavior (Figure 6), identifying the BIM technologies that support the improvement of safety climate (Figure 7), and outlining the role of BIM technologies in improving construction safety culture.

As shown in Figure 5, the relationships between BIM technologies and safety management system (BIM-enabled safety management system) represents the first stage in the BIM integrated safety culture model; while the relationships between BIM technologies and safety behavior (BIM-enabled safety behavior) represents the second stage in the BIM integrated safety culture model (Figure 6). This stage is an essential dimension of safety culture because it generates safety habits and attitudes (Fugas et al., 2012; Choudhry, 2014; Guo et al., 2016).

Safety culture is revealed at safety climate because safety climate is the atmosphere that makes known the effectiveness of safety management system through the safety behavior of workers and management personnel at a given point in time in a construction setting (Petitta et al., 2017b; Goncalves Filho and Waterson, 2018; Newaz et al., 2018). The relationships between BIM technologies and safety climate is shown in Figure 7 and it represents the peak or the last stage of construction safety culture. In general, Figures 5–7 highlight the design and dynamics of the model by showing the interrelationships that occur between BIM technologies and the components of the dimensions of construction safety culture. Hence, the model was therefore considered validated based on the criteria of Grounded Theory, as what was represented in the model showed the BIM technologies that are applicable to each of the components of the safety management system, safety behavior, and safety climate.

The BIM-enabled safety culture model (Figure 8) is stage-based and entails safety management practices progressing through one stage before beginning the next. The model is represented as a stage because of the complexity of safety culture. By representing the model as a stage, the development of safety culture through the application of BIM is shown to occur in a linear process. A linear model of development allows for the relationships between the dimensions of safety culture to be represented in the stages. As conceptualized in the model, the achievement of each stage is influenced by the components of each of the dimensions of safety culture. BIM technologies are integrated with safety culture by applying appropriate BIM technologies to the components of each of the dimensions of safety culture. The transitions within the model are depicted with arrows which signaled the end and the beginning of the stages. The transitions marked a shift in safety culture as enabled by the achievement of the dimensions. Since the model is stage-based, the achievement of one dimension signaled the readiness to shift toward the next stage. This theorized safety culture maturity as depicted by the relationship between the safety management system, safety behavior, and safety climate. In this relationship, safety culture begins with safety management system such as developing a safety management plan and organizing safety meeting. Following the implementation of a safety management system in the construction environment, construction workers and managers start to exhibit safety behaviors. For example, the construction managers start to organize safety training, while construction workers start to adhere to safe work procedures. Safety climate is at the highest maturity level because it reveals the effectiveness of the safety management system via safety behaviors. Safety climate is created in the construction environment when construction workers comply with safety rules and undertake construction activities with safety knowledge and safety-related skills.

As shown in Figure 8, the influence of safety management system on construction safety culture is to initiate the process of construction safety culture in a construction environment; while safety behavior is required to generate safety habits and attitude. Safety climate influences construction safety culture by revealing the effectiveness of the safety management system through a safety behavior pattern. Therefore, it can be inferred that, in a given construction environment, the safety culture is determined by the effectiveness of the safety management system, an exhibition of safety behavior, and the quality of safety climate.

The application of BIM technologies to the dimensions of safety culture makes it so effective; while a combination of a BIM integrated safety management system, safety behavior, and safety climate gives a BIM integrated safety culture model. The model is stage-based and supports safety management planning toward ensuring safety culture in a construction environment. The model explains the stages involved in achieving safety culture by organizing the stages (dimensions of safety culture) into a set of interacting concepts (see Figure 8). Two distinct relationships are represented within the model using the linear transitions of the stages. The first relationship is the transition from the safety management system to safety behavior, and the second transition is the transition from safety behavior to safety climate. The model shows that the interrelationships between these dimensions of safety culture complete the processes to be undertaken in order to ensure safety culture in a construction environment. Also, the model illustrates the steps (components of the dimensions) to be taken in order to complete each of the stages. More importantly, the model provides information on suitable BIM technologies to be selected for the effective completion of the steps (components) contained in the stages (dimensions).

Conclusions and Implications

Safety culture is a multidisciplinary concept. However, there is a limited understanding of what safety culture entails in a construction environment. As a result, this paper investigates the dimensions of construction safety culture and how the use of BIM technologies in construction safety management improves construction safety culture and maturity levels among construction workers.

The key dimensions identified for construction safety culture highlights that the understanding of safety culture in the construction environment relate to the safety management system, safety behavior, and safety climate as the dimensions of construction safety culture. The paper concludes that BIM-enabled construction safety culture is achievable through the utilization of visualization, simulation, animation, digital fabrication, and virtual reality. A series of examples of the application of these BIM technologies in construction safety culture were presented to describe and support BIM-enabled construction safety culture. The model is stage-based according to the identified dimensions of construction safety culture. Although each stage in the BIM-enabled construction safety culture and maturity model is critical, safety behavior is more critical because it is a central aspect of ensuring construction safety culture.

The BIM-enabled construction safety culture and maturity model has implications for safety management practices in a construction environment. The model shows that construction managers need to utilize appropriate BIM technologies to facilitate an improved safety culture in the construction environments where they operate. Unfortunately, BIM technologies have not become an integral part of safety management practices. However, the usefulness of BIM technologies apply across the dimensions of construction safety culture and will help construction managers to ensure safety behavior in the safety culture of their environment. Workers need safety training and education in order to make meaning of safety rules and regulations. The implication of these models as relating to safety training and education is that safety training and education become meaningful and impactful with the utilization of BIM technologies. The models will also prove useful for construction managers in planning the most effective safety management toward achieving the safety goals within a planned time frame. This paper has provided a fresh way to achieve safety culture in the construction environment. However, there are limitations of this study that are essential to the future research and the understanding of BIM integrated construction safety culture (a) a need for cross-validation of the dimensions of safety culture (b) empirical validation of the interactive relationships between the dimensions of safety culture (c) need for an in-depth qualitative investigation of safety culture (e) detailed investigation of the impact of BIM integration into construction safety culture. (f) empirical validation of the interrelationships between construction safety culture and BIM technologies.

Author Contributions

All authors listed have made a substantial, direct and intellectual contribution to the work, and approved it for publication.

Funding

This work has been funded by the University of Cape Town (UCT) and the National Research Foundation (NRF). The opinions expressed, and conclusions arrived at, are those of the authors and are not necessarily to be attributed to UCT or NRF.

Conflict of Interest Statement

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

Agustí-Juan, I., and Habert, G. (2017). Environmental design guidelines for digital fabrication. J. Clean. Prod. 142, 2780–2791. doi: 10.1016/j.jclepro.2016.10.190

Bansal, V. K. (2011). Application of geographic information systems in construction safety planning. Int. J. Proj. Manag. 29, 66–77. doi: 10.1016/j.ijproman.2010.01.007

Beatriz, F., Montes-Peón, J. M., and Vázquez-Ordás, C. J. (2007). Safety culture: analysis of the causal relationships between its key dimensions. J. Saf. Res. 38, 627–641. doi: 10.1016/j.jsr.2007.09.001

Behzadan, A. H., and Kamat, V. R. (2006). “Animation of construction activities in outdoor augmented reality,” in Proceedings of the 11th International Conference on Computing and Decision Making in Civil and Building Engineering (ICCCBE-XI) (Montreal, QC).

Biggs, S. E., Banks, T. D., Davey, J. D., and Freeman, J. E. (2013). Safety leaders' perceptions of safety culture in a large Australasian construction organisation. Saf. Sci. 52, 3–12. doi: 10.1016/j.ssci.2012.04.012

Buswell, R. A., Soar, R. C., Gibb, A. G., and Thorpe, A. (2007). Freeform construction: mega-scale rapid manufacturing for construction. Autom. Constr. 16, 224–231. doi: 10.1016/j.autcon.2006.05.002

Chen, L. C., Wu, C. H., Shen, T. S., and Chou, C. C. (2014). The application of geometric network models and building information models in geospatial environments for fire-fighting simulations. Comput. Environ. Urban Syst. 45, 1–12. doi: 10.1016/j.compenvurbsys.2014.01.003

Cheng, M. Y., Chiu, K. C., Hsieh, Y. M., Yang, I. T., Chou, J. S., and Wu, Y. W. (2017). BIM integrated smart monitoring technique for building fire prevention and disaster relief. Autom. Constr. 84, 14–30. doi: 10.1016/j.autcon.2017.08.027

Cheng, T., and Teizer, J. (2013). Real-time resource location data collection and visualisation technology for construction safety and activity monitoring applications. Autom. Constr. 34, 3–15. doi: 10.1016/j.autcon.2012.10.017

Chinda, T., and Mohamed, S. (2008). Structural equation model of construction safety culture. Eng. Constr. Archit. Manag. 15, 114–131. doi: 10.1108/09699980810852655

Choudhry, R. M. (2014). Behaviour-based safety on construction sites: a case study. Accid. Anal. Prev. 70, 14–23. doi: 10.1016/j.aap.2014.03.007

Choudhry, R. M., Fang, D., and Mohamed, S. (2007). The nature of safety culture: a survey of the state-of-the-art. Saf. Sci. 45, 993–1012. doi: 10.1016/j.ssci.2006.09.003

Cooper, M. D. (2000). Towards a model of safety culture. Saf. Sci. 36, 111–136. doi: 10.1016/S0925-7535(00)00035-7

Corbin, J. M., and Strauss, A. (1990). Grounded theory research: procedures, canons, and evaluative criteria. Qual. Sociol. 13, 3–21. doi: 10.1007/BF00988593

Ding, L., Zhou, Y., and Akinci, B. (2014). Building Information Modelling (BIM) application framework: the process of expanding from 3D to computable nD. Autom. Constr. 46, 82–93. doi: 10.1016/j.autcon.2014.04.009

Edwards, J. R., Davey, J., and Armstrong, K. (2013). Returning to the roots of culture: a review and re-conceptualisation of safety culture. Saf. Sci. 55, 70–80. doi: 10.1016/j.ssci.2013.01.004

Eleftheriadis, S., Mumovic, D., and Greening, P. (2017). Life cycle energy efficiency in building structures: a review of current developments and future outlooks based on BIM capabilities. Renew. Sustain. Energy Rev. 67, 811–825. doi: 10.1016/j.rser.2016.09.028

Fang, D., Chen, Y., and Wong, L. (2006). Safety climate in the construction industry: a case study in Hong Kong. J. Constr. Eng. Manag. 132, 573–584. doi: 10.1061/(ASCE)0733-9364(2006)132:6(573)

Fang, D., and Wu, H. (2013). Development of a Safety Culture Interaction (SCI) model for construction projects. Saf. Sci. 57, 138–149. doi: 10.1016/j.ssci.2013.02.003

Fang, D. P., Xie, F., Huang, X. Y., and Li, H. (2004). Factor analysis-based studies on construction workplace safety management in China. Int. J. Proj. Manag. 22, 43–49. doi: 10.1016/S0263-7863(02)00115-1

Frazier, C. B., Ludwig, T. D., Whitaker, B., and Roberts, D. S. (2013). A hierarchical factor analysis of a safety culture survey. J. Safety Res. 45, 15–28. doi: 10.1016/j.jsr.2012.10.015

Fugas, C. S., Silva, S. A., and Meli,á, J. L. (2012). Another look at safety climate and safety behaviour: deepening the cognitive and social mediator mechanisms. Accid. Anal. Prev. 45, 468–477. doi: 10.1016/j.aap.2011.08.013

Fukuchi, Y., and Kobayashi, I. (1997). Computer graphics animation for construction management. J. Civ. Eng. Inf. Process. Syst. 6, 263–269.

Fung, I. W., Tam, C. M., Tung, K. C., and Man, A. S. (2005). Safety cultural divergences among management, supervisory and worker groups in the Hong Kong construction industry. Int. J. Proj. M. 23, 504–512. doi: 10.1016/j.ijproman.2005.03.009

Gattas, J. M., and Yu, Z. (2016). Design and digital fabrication of folded sandwich structures. Autom. Constr. 63, 79–87. doi: 10.1016/j.autcon.2015.12.002

Goncalves Filho, A. P., and Waterson, P. (2018). Maturity models and safety culture: a critical review. Saf. Sci. 105, 192–211. doi: 10.1016/j.ssci.2018.02.017

Guo, B. H., Yiu, T. W., and González, V. A. (2016). Predicting safety behaviour in the construction industry: development and test of an integrative model. Saf. Sci. 84, 1–11. doi: 10.1016/j.ssci.2015.11.020

Hameed, M. A., Counsell, S., and Swift, S. (2012). A conceptual model for the process of IT innovation adoption in organizations. J. Eng. Technol. Manage. 29, 358–390. doi: 10.1016/j.jengtecman.2012.03.007

Hilfert, T., Teizer, J., and König, M. (2016). “First person virtual reality for evaluation and learning of construction site safety,” in ISARC Proceedings of the International Symposium on Automation and Robotics in Construction, Vol. 33 (Vilnius: Vilnius Gediminas Technical University, Department of Construction Economics and Property), 1. doi: 10.22260/ISARC2016/0025

Hu, Z. Z., Zhang, J. P., and Zhang, X. L. (2010). 4D construction safety information model-based safety analysis approach for scaffold system during construction. Eng. Mech. 27, 192–200. Available online at: http://en.cnki.com.cn/Article_en/CJFDTotal-GCLX201012032.htm

Irene, A., Haber, J., and Seidel, H. P. (2003). “Construction and animation of anatomically based human hand models,” in Proceedings of the 2003 ACM SIGGRAPH/Eurographics Symposium on Computer Animation (San Diego, CA: Eurographics Association), 98–109.

Ismail, Z., Doostdar, S., and Harun, Z. (2012). Factors influencing the implementation of a safety management system for construction sites. Saf. Sci. 50, 418–423. doi: 10.1016/j.ssci.2011.10.001

Kamat, V. R., and Martinez, J. C. (2001). Visualizing simulated construction operations in 3D. J. Comput. Civ. Eng. 15, 329–337. doi: 10.1061/(ASCE)0887-3801(2001)15:4(329)

Kolarevic, B. (2001). Digital Fabrication: Manufacturing Architecture in the Information Age. Pennsylvania, PA: ACADIA.

Kostakis, V., and Papachristou, M. (2014). Commons-based peer production and digital fabrication: the case of a RepRap-based, Lego-built 3D printing-milling machine. Telemat. Inform. 31, 434–443. doi: 10.1016/j.tele.2013.09.006

Kumar, S., Hedrick, M., Wiacek, C., and Messner, J. I. (2011). Developing an experienced-based design review application for healthcare facilities using a 3D game engine. J. Info. Technol. Constr. 16, 85–104. Available online at: http://www.scopus.com/inward/citedby.url?scp=79751481664&partnerID=8YFLogxK

Langford, D., Rowlinson, S., and Sawacha, E. (2000). Safety behaviour and safety management: its influence on the attitudes of workers in the UK construction industry. Eng. Constr. Archit. Manag. 7, 133–140. doi: 10.1108/eb021138

Li, H., Chan, G., and Skitmore, M. (2012). Visualizing safety assessment by integrating the use of game technology. Autom. Constr. 22, 498–505. doi: 10.1016/j.autcon.2011.11.009

Lloret, E., Shahab, A. R., Linus, M., Flatt, R. J., Gramazio, F., Kohler, M., et al. (2015). Complex concrete structures: merging existing casting techniques with digital fabrication. Comp. Aided Des. 60, 40–49. doi: 10.1016/j.cad.2014.02.011

Marriage, G., and Sutherland, B. (2014). “New digital housing typologies: CNC fabrications of CLT structure and BIM cladding,” in Across: Architectural Research Through to Practice: 48th International Conference of the Architectural Science Association (Genoa), 383–394.

Mohamed, S. (1999). An empirical investigation of construction safety management activities and performance in Australia. Saf. Sci. 33, 129–142. doi: 10.1016/S0925-7535(99)00028-4

Mohamed, S., and Chinda, T. (2011). System dynamics modelling of construction safety culture. Eng. Constr. Archit. Manag. 18, 266–281. doi: 10.1108/09699981111126179

Molenaar, K. R., Park, J. I., and Washington, S. (2009). Framework for measuring corporate safety culture and its impact on construction safety performance. J. Constr. Eng. Manag. 135, 488–496. doi: 10.1061/(ASCE)0733-9364(2009)135:6(488)

Neal, A., and Griffin, M. A. (2002). Safety climate and safety behaviour. Aust. J. Manag. 27(Suppl. 1), 67–75. doi: 10.1177/031289620202701S08

Newaz, M. T., Davis, P. R., Jefferies, M., and Pillay, M. (2018). Developing a safety climate factor model in construction research and practice: a systematic review identifying future directions for research. Eng. Constr. Archit. Manage. 25, 738–757. doi: 10.1108/ECAM-02-2017-0038

Niskanen, T. (1994). Safety climate in the road administration. Saf. Sci. 17, 237–255. doi: 10.1016/0925-7535(94)90026-4

Paes, D., Arantes, E., and Irizarry, J. (2017). The immersive environment for improving the understanding of architectural 3D models: comparing user spatial perception between immersive and traditional virtual reality systems. Autom. Constr. 84, 292–303. doi: 10.1016/j.autcon.2017.09.016

Park, C. S., and Kim, H. J. (2013). A framework for construction safety management and visualisation system. Autom. Constr. 33, 95–103. doi: 10.1016/j.autcon.2012.09.012

Peavey, E. K., Zoss, J., and Watkins, N. (2012). Simulation and mock-up research methods to enhance design decision making. HERD 5, 133–144. doi: 10.1177/193758671200500313

Petitta, L., Probst, T. M., and Barbaranelli, C. (2017a). Safety culture, moral disengagement, and accident underreporting. J. Bus. Ethics 141, 489–504. doi: 10.1007/s10551-015-2694-1

Petitta, L., Probst, T. M., Barbaranelli, C., and Ghezzi, V. (2017b). Disentangling the roles of safety climate and safety culture: multi-level effects on the relationship between supervisor enforcement and safety compliance. Accid. Anal. Prev. 99, 77–89. doi: 10.1016/j.aap.2016.11.012

Reiman, T., and Rollenhagen, C. (2014). Does the concept of safety culture help or hinder systems thinking in safety? Accid. Anal. Prev. 68, 5–15. doi: 10.1016/j.aap.2013.10.033

Riaz, Z., Arslan, M., Kiani, A. K., and Azhar, S. (2014). CoSMoS: a BIM and wireless sensor based integrated solution for worker safety in confined spaces. Autom. Constr. 45, 96–106. doi: 10.1016/j.autcon.2014.05.010

Rüppel, U., and Schatz, K. (2011). Designing a BIM-based serious game for fire safety evacuation simulations. Adv. Eng. Inform. 25, 600–611. doi: 10.1016/j.aei.2011.08.001

Shi, J. J., and Zhang, H. (1999). “Iconic animation of construction simulation,” in Proceedings of the 31st Conference on Winter Simulation: Simulation—A Bridge to the Future, Vol. 2 (Phoenix, AZ: ACM), 992–997.

Songer, A. D., Diekmann, J. E., and Karet, D. (2001). Animation-based construction schedule review. Constr. Innov.1, 181–190. doi: 10.1108/14714170110814596

Tam, C. M., Zeng, S. X., and Deng, Z. M. (2004). Identifying elements of poor construction safety management in China. Saf. Sci. 42, 569–586. doi: 10.1016/j.ssci.2003.09.001

Teizer, J., Cheng, T., and Fang, Y. (2013). Location tracking and data visualization technology to advance construction ironworkers' education and training in safety and productivity. Automat. Constr. 35, 53–68. doi: 10.1016/j.autcon.2013.03.004

Wang, S. H., Wang, W. C., Wang, K. C., and Shih, S. Y. (2015). Applying building information modelling to support fire safety management. Autom. Constr. 59, 158–167. doi: 10.1016/j.autcon.2015.02.001

Wang, X., Love, P. E., Kim, M. J., Park, C. S., Sing, C. P., and Hou, L. (2013). A conceptual framework for integrating building information modelling with augmented reality. Autom. Constr. 34, 37–44. doi: 10.1016/j.autcon.2012.10.012

Wang, X., Truijens, M., Hou, L., Wang, Y., and Zhou, Y. (2014). Integrating augmented reality with building information modelling: onsite construction process controlling for the liquefied natural gas industry. Autom. Constr. 40, 96–105. doi: 10.1016/j.autcon.2013.12.003

Wolfswinkel, J. F., Furtmueller, E., and Wilderom, C. P. (2013). Using grounded theory as a method for rigorously reviewing literature. Eur. J. Info. Syst. 22, 45–55. doi: 10.1057/ejis.2011.51

Wu, C., Wang, F., Zou, P. X., and Fang, D. (2016). How safety leadership works among owners, contractors, and subcontractors in construction projects. Int. J. Proj. Manag. 34, 789–805. doi: 10.1016/j.ijproman.2016.02.013

Young, C. H., Chen, Y. L., and Chen, P. C. (2014). Heat insulation solar glass and application on energy efficiency buildings. Energy Build. 78, 66–78. doi: 10.1016/j.enbuild.2014.04.012

Zhang, M., and Fang, D. (2013). A cognitive analysis of why Chinese scaffolders do not use safety harnesses in construction. Constr. Manag. Econ. 31, 207–222. doi: 10.1080/01446193.2013.764000

Zhang, S., Sulankivi, K., Kiviniemi, M., Romo, I., Eastman, C. M., and Teizer, J. (2015). BIM-based fall hazard identification and prevention in construction safety planning. Saf. Sci. 72, 31–45. doi: 10.1016/j.ssci.2014.08.001

Zhao, D., and Lucas, J. (2015). Virtual reality simulation for construction safety promotion. Int. J. Inj. Contr. Saf. Promot. 22, 57–67. doi: 10.1080/17457300.2013.861853

Zhou, W., Whyte, J., and Sacks, R. (2012). Construction safety and digital design: a review. Autom. Constr. 22, 102–111. doi: 10.1016/j.autcon.2011.07.005

Zhou, Y., Ding, L. Y., and Chen, L. J. (2013). Application of 4D visualisation technology for safety management in metro construction. Autom. Constr. 34, 25–36. doi: 10.1016/j.autcon.2012.10.011

Keywords: Building Information Modeling (BIM), BIM technologies, grounded theory, safety, safety culture, safety management practices, safety climate

Citation: Olugboyega O and Windapo A (2019) Building Information Modeling—Enabled Construction Safety Culture and Maturity Model: A Grounded Theory Approach. Front. Built Environ. 5:35. doi: 10.3389/fbuil.2019.00035

Received: 28 September 2018; Accepted: 04 March 2019;

Published: 16 April 2019.

Edited by:

Patrick Ackom Manu, University of Manchester, United KingdomReviewed by:

Ke Chen, Huazhong University of Science and Technology, ChinaAbdul-Majeed Mahamadu, University of the West of England, United Kingdom

Copyright © 2019 Olugboyega and Windapo. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Oluseye Olugboyega, b29sdWdib3llZ2FAeWFob28uY29t

Oluseye Olugboyega

Oluseye Olugboyega Abimbola Windapo

Abimbola Windapo