- 1Department of Construction Science, The University of Texas at San Antonio, San Antonio, TX, United States

- 2School of Civil and Environmental Engineering, Georgia Institute of Technology, Atlanta, GA, United States

Highway construction work zones are hazardous environments characterized by a dynamic and limited workspace. A host of interactions between workers, passing commuter vehicles, and moving construction equipment occurs in highway work zones, fostering dangerous situations that can result in injury or death. Active strategies, such as the deployment of intrusion sensing and alert technologies in highway work zones and in transportation infrastructure construction and maintenance, can be effective at mitigating these unforeseen conditions. The main objective of this study was to conduct both conceptual analysis and experimental evaluation of intrusion sensing technologies for work zone safety. To achieve the objectives of this research, an exploratory review of the applicable technologies was conducted to identify the intrusion technologies that can be implemented for work zone safety. An objective assessment of each technology was provided based on selected evaluation metrics to elicit their capabilities. Candidate commercially available technologies were selected and evaluated using field experiments in simulated work zones. The findings of the study indicate that the commercially available technologies have the potential to enhance safety of work zone workers by providing warning alerts when hazardous situations exist. This research contributes to the body of knowledge by providing strategies for selecting and implementing intrusion sensing technologies for active work zone safety.

Introduction

Work zone safety is a major concern for many community members, including government agencies, legislatures, and the traveling public (Chambless et al., 2002; Ullman et al., 2008). Transportation infrastructure provides many social benefits to any society and plays a critical role in the proper functioning of the economy (Andrijcic et al., 2013). The need to maintain and rehabilitate existing roadway systems rises as traffic volume increases and highway infrastructure ages (Cerezo et al., 2011). Thus, the maintenance, reconstruction, and constant upgrading of these infrastructures are pivotal to meeting the ever-increasing needs of a growing economy (Duranton and Turner, 2012). The increasing number of roadway widening, rehabilitation, and reconstruction projects has made work zone safety a critical concern (Cerezo et al., 2011) due to increase in construction workers' exposure to hazardous conditions.

Highway construction and maintenance operations commonly require personnel to work near ongoing traffic, a situation that creates significant safety risks for both the construction employees and traveling motorists (Gambatese and Lee, 2016). One commonly implemented control strategy is to place traffic control devices near work zone areas to alert motorists (Noyce and Smith, 2003). However, drivers often disregard or ignore work zone traffic control devices and other warning systems which has led to serious accidents during a work zone intrusion (Hourdos, 2012). Since the work environment on the highway is often chaotic and noisy, it can be difficult for personnel to spot an errant vehicle in time to take appropriate action (Fyhrie, 2016). Inattentive or speeding drivers, careless workers, misplaced traffic control devices, and hazardous roadway conditions can lead to crashes and ultimately work zone injuries and fatalities (Khattak et al., 2002; Gambatese and Lee, 2016).

A need exists for a management approach that considers not only the implementation of active intrusion sensing technologies, but also their effectiveness in alerting both the pedestrian workers and vehicle drivers in work zones. As vehicle miles traveled, driver distraction, work zone activity, and nighttime work increase, safety incidents, and work zone crashes can be expected to rise (Pratt et al., 2001; Krupa, 2010; Gambatese and Lee, 2016). Complex situations such as those present in work zones require active monitoring to provide real-time information about the conditions of the work environment. To reduce the incidence of and potential for incidents on highway construction and maintenance sites, some government authorities have deployed safety devices and systems to safeguard employees using intrusion alarms (Krupa, 2010; Phanomchoeng et al., 2010). Intrusion alarms are used primarily in temporary work zones with short work duration where adding a positive protection system such as concrete barrier is not feasible (Givechi, 2015).

The purpose of this research is to provide an evaluation of the applicable intrusion technologies for work zone safety and to implement commercially available intrusion sensing technologies in a simulated highway work zone testbed through field experimentation. To achieve this, a contextual study was conducted to determine the previous applications of intrusion alarm systems for work zone safety. Information about work zone intrusion sensing technologies from the manufacturers' specifications documents and published research results were collected and evaluated. Candidate intrusion sensing technologies were selected and implemented for work zone safety using field experiments in simulated work zones.

Literature Review

Construction work zones on roadways are hazardous areas and motorists are exposed to unfamiliar situations in a normally familiar setting; such unexpected unfamiliarity could lead to accidents (Bathula et al., 2009). Improvement is necessary for highway construction projects to experience less fatalities, injuries, illnesses, and financial loss due to accidents. The following review presents work zone safety statistics, an overview of work zone intrusion technologies, and selected previous applications of intrusion alarm systems for work zone safety. This section also presents a research needs statement derived from the.

Work Zone Safety Statistics

Over the past decade, a considerable amount of work zone crashes has occurred, leading to damage of property, injuries to workers, and loss of lives (Li and Bai, 2008). In the U.S., an average of 595 work-zone-related fatalities occurred every year within the past 5 years (FHWA, 2016). In 2014, 669 fatalities occurred in work zones nationwide, representing 2% of all highway fatalities (NWZSIC, 2016). Highway work zones accounted for nearly 24% of non-recurring congestion, or 888 million vehicle hours of delay in 2014 (FHWA, 2016). Furthermore, more than 20,000 workers are injured in work zones each year in the U.S in which 12% result from traffic incidents (Krupa, 2010). These injuries and fatalities have cost implications on the economy of the nation. In 2010 for instance, the total economic cost of motor vehicle crashes in the U.S. was $242 billion (Blincoe et al., 2015).

Many of the crashes near work zone areas occur when drivers fail to heed traffic warnings and control measures upstream of the work zone area, often due to distracted driving (Hourdos, 2012). The cited statistics of work zone incidents indicate a great need for improved safety performance in and around construction highway work zones. This information also projects a need for more effective strategies to reduce and eventually eradicate these fatalities and delays in work zones.

Work Zone Intrusion Technologies

Work zone hazard awareness systems can be divided into three major categories: mechanical systems, electronic systems, and dedicated observers (Bryden and Mace, 2002). Mechanical systems use mechanisms, such as impact-activated or pressure-activated systems, which are triggered by the physical contact or impact of intruding vehicles (Sun et al., 2007). Electronic systems apply sensing technologies, such as laser switch systems, that require the alignment of transmitters and receivers to detect intruding objects (Liu et al., 2007). These sensing technologies can be categorized as ultra-wideband (UWB), Global Positioning Systems (GPS), radio-frequency identification (RFID), magnetic field, radar, infrared, laser, video, and several others. If a receiver fails to receive signals from a transmitter, the system activates an alarm. Other practices employ dedicated observers, such as workers or flaggers, to spot intrusions, and trigger alarms (Tsai, 2011).

Intrusion alarms are a technology which utilizes one or more sensors mounted on typical work zone barriers such that when an errant vehicle contacts a sensor, an alarm would be activated to warn workers that their protective zone has been violated (Wang et al., 2011). The concept of such systems is that the alarm mechanism would warn workers with enough reaction time to move away from the hazardous location (Wang et al., 2011). Some intrusion alarm systems consist of a detection unit and a receiving unit in which the alarm is activated when the detection unit is triggered or activated (Ozbay et al., 2012). The alarm could also possibly alert a distracted or drowsy driver and permit them to avoid the work zone or decelerate prior to reaching workers or their equipment (Wang et al., 2011).

The first set of work zone intrusion alarm systems was developed under the Strategic Highway Research Program (SHRP) where ultrasonic and infrared beams were used for detection (Wang et al., 2011; Ozbay et al., 2012). Two types of intrusion alarm systems developed by the SHRP utilized microwave and infrared wireless technology in respective models that mounted on work zone barriers (Ozbay et al., 2012). The systems used either microwave signals or beams of infrared light to connect to base units (Wang et al., 2011). When a vehicle crossed into the work zone and interrupted the signal or beams, a high-pitched alarm was sounded by the base station near the workers. A third type utilized pneumatic tubes placed on the ground such that the tubes were laid around the working area. When a vehicle drove into the area and over the tubes, an alarm was activated (Wang et al., 2011). Other similar intrusion alarms have been developed using microwave, pressure activated tubes, and laser technologies (Khan, 2007; Ozbay et al., 2012). Another type of work zone intrusion alarm system, a kinematic model, was identified by Fyhrie (2016). The kinematic models, usually mounted on a traffic cone (or other similar hardware), produce an alarm when the change in orientation angle of the cone indicates it has been tipped over (Khan, 2007). This system works based on the assumption that an errant vehicle has knocked over the hardware and has entered the work area (Khan, 2007).

Previous Assessments of Intrusion Alarms for Work Zone Safety

A few work zone safety devices from the Strategic Highway Research Program (SHRP) were evaluated under the direction of the Kentucky Transportation Cabinet through trial use (Agent and Hibbs, 1996). Five intrusion alarm systems were evaluated, including one microwave system, one infrared system, and three pneumatic tube systems. Modifications based on feedback from various state, county, and private agencies were implemented, mostly concentrated on increasing the ease of setup and the volume of the alarm (Agent and Hibbs, 1996). Although the devices were found to be durable, workers were generally not enthusiastic about using the devices. Consequently, a definitive recommendation was not made due to the continuous modifications, but devices were supposedly accepted to have potential for use on major projects, with cost being a limiting factor (Agent and Hibbs, 1996).

A microwave-based alarm system was rejected by the Alabama, Colorado, Iowa, and Pennsylvania Departments of Transportation (DOTs) because of setup problems and false alarms due to difficulties in keeping the devices aligned (Carlson et al., 2000). The Iowa Department of Transportation attempts to minimize the amount of time that crews are exposed to traffic, coupled with the time needed for setup of the intrusion alarms meant that the amount of time a crew needed to do their job was extended (Fyhrie, 2016). It was noted that false alarms were so frequent that workers ignored the alerts (Trout and Ullman, 1997). Although potential benefits were identified from these work zone intrusion sensing systems, multiple limiting factors have been experienced. These limitations include nuisance alerts that can desensitize work zone employees (Trout and Ullman, 1997), the significant space required to install the system (Carlson et al., 2000), time and effort required for set-up (Trout and Ullman, 1997), durability of the system (Carlson et al., 2000), and misalignment of the detection area (Novosel, 2014).

Research Needs Statement

Although intrusion alarm systems have the potential to warn workers when an errant vehicle intrudes the work zone, existing studies show certain limitations in their capabilities, effectiveness, and wide-spread implementation. The previous applications of these systems indicate the need to improve the systems to ensure maximum benefits are derived from their deployment for work zone safety. Research needs exist to complete a contextual analysis of the applicable intrusion sensing technologies to identify and experimentally evaluate the commercially available technologies that can be implemented to enhance work zone safety. Exploratory review and experimentation were selected as the methods for approaching the presented problem. This study is expected to provide information on the capabilities of these intrusion sensing technologies in order to elicit their benefits and areas for improvement.

Methods

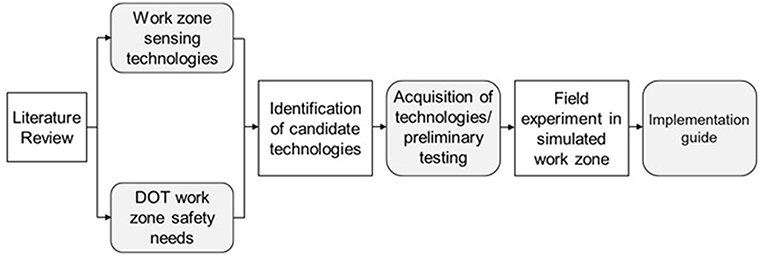

The methods adopted in achieving the objectives of this research involved two parts. The first part involves the contextual review of applicable intrusion technologies while the second aspect involves the experimental evaluation of selected intrusion sensing technologies for work zone safety. The research methodology framework is presented in Figure 1.

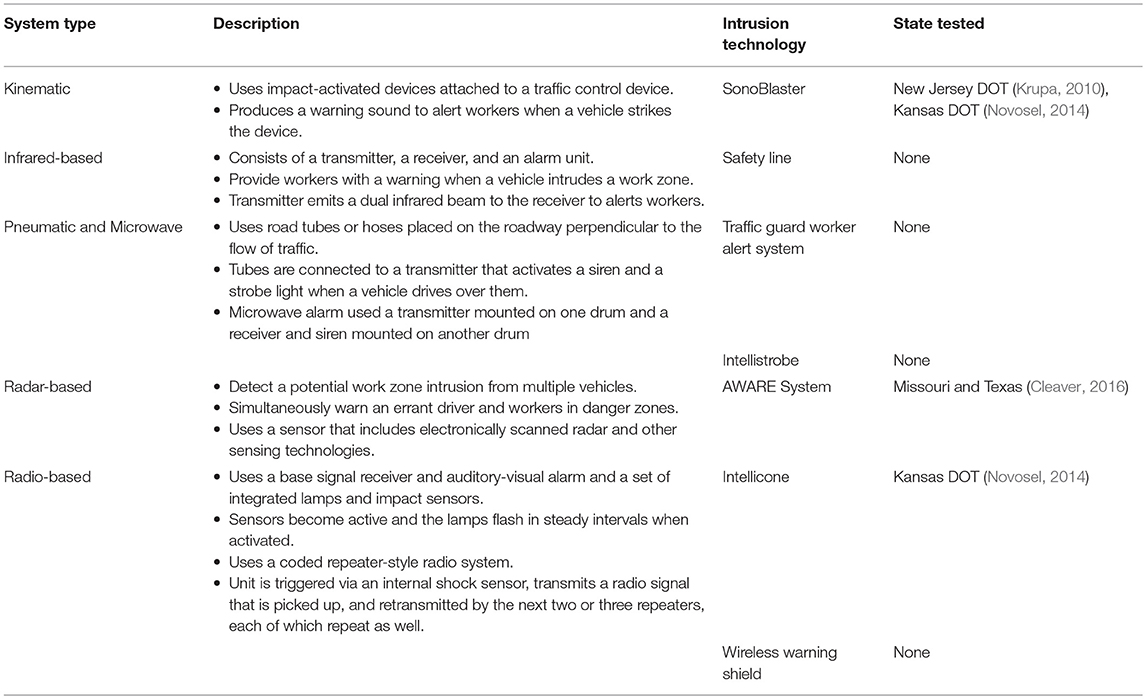

A review of intrusion technologies from previous applications and manufacturers' documents was conducted. Based on the review, these five categories of intrusion technology systems were identified: (1) Kinematic Intrusion Technology Systems, (2) Infrared-Based Intrusion Technology Systems, (3) Pneumatic and Microwave Intrusion Technology Systems, (4) Radar-Based Intrusion Technology Systems, and (5) Radio-Based Intrusion Technology Systems. The different types of applicable intrusion technology devices under each of these categories were identified and assessed using selected evaluation metrics. The review culminated in the selection of candidate commercially available technologies which were then evaluated using experimental trials to assess their implementation for work zone safety.

Applicable Work Zone Intrusion Technology Systems

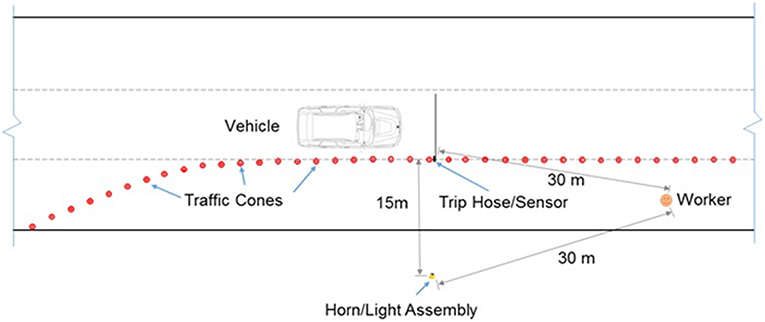

A review of applicable intrusion sensing technologies indicates that a few commercially available intrusion alarm systems exist. Table 1 presents the summary of work zone intrusion technology systems and the commercially available devices that can be implemented in highway work zones. The intrusion alarm technologies in bold in Table 1 indicate the commercially available work zone intrusion technology systems.

Many of these systems have been evaluated by researchers. Table 2 provides a summation of much of the current research on work zone intrusion alert systems.

Experimental Set-up and Data Collection

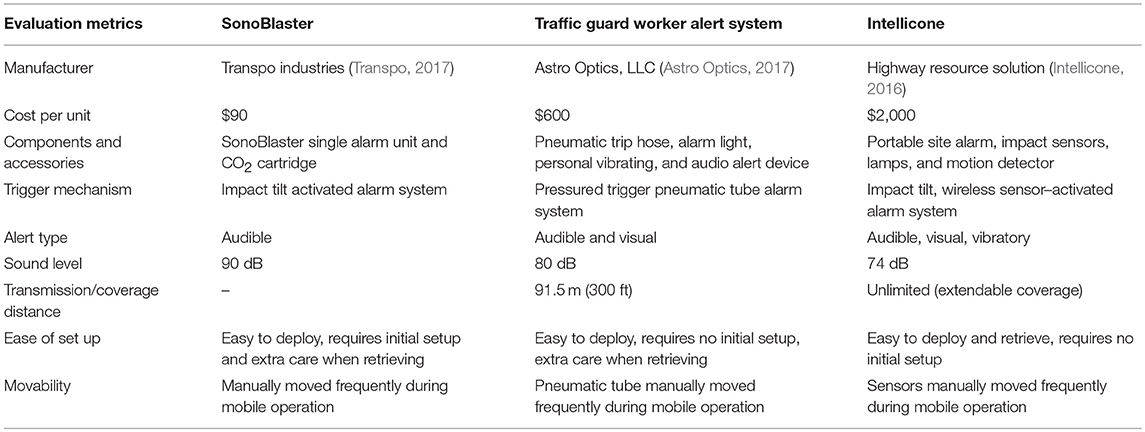

This section presents the procedure for the experimental evaluation of selected commercially available intrusion technologies based on the review of applicable technologies for work zone safety. As presented in Table 1, one commercially available technology device was selected for each of kinematic, pneumatic/microwave, and radio-based intrusion alarm systems. Preliminary testing was first carried out on the technologies to test if they function well and provide the required alerts. Field experimental trials were then carried out to implement the technologies for work zone safety in a simulated work environment. Discussion points are provided based on findings from the implemented experimental methodologies. The experiments were created to simulate an actual highway work zone environment.

The test bed was established on an abandoned straight concrete roadway with minimal grade on the selected site for experimental trials as shown in Figure 2. About 300 m of the roadway was marked out for the experimental trials. Traffic cones were placed at 6 m intervals along the roadway for approximately 300 m. A taper was created with the traffic cones at the beginning of the test bed to simulate a lane closure.

The setting up of the radio-based alarm involved mounting five impact sensors on consecutive traffic cones (Figure 2). The radio-based alarm PSA was mounted on another traffic cone located at 9 m from the impact sensors for sets 1 and 2 of the experimental trials, and at 15 m for set. The pneumatic/microwave alarm was set up by placing a pneumatic trip hose with attached sensor lining the traffic cones along the testbed. The horn/light assembly was located away from the pneumatic trip hose sensor. The kinematic alarm was set up by attaching the unit to a traffic cone. Figure 2 shows the test bed of the experimental trials for the testing of the radio-based alarm system.

A video recorder and time lapse camera were positioned to record the experimental trials. Three sets of experimental trials were conducted for each of the technologies. In the first set, a worker was made to stand at 9 m from the alarm speaker. A member of the research team drove a vehicle at the speed of 40 km per hour (25 miles per hour) and a rod protruding from the vehicle was made to hit the cone on which the impact sensor was mounted to activate the alarm. This technique was used for the testing of the radio-based and kinematic alarm technologies while the vehicle crossed over the air pressure hose to trigger the alarm during the testing for the pneumatic/microwave alarm. Figure 3 shows the layout of the experimental trials site for the testing of pneumatic/microwave alarm.

The sound level was measured from the alarm speaker to the worker's location using a sound meter and the process was repeated for a total of 15 trials. The worker's reaction time as well as the time taken for the vehicle to come to a complete stop after the impact were then extracted from the video recording. The stopping distance was also measured and computed using the vehicle speed and stopping time after the activation of the alarm. The worker stood 15 and 30 m away from the alarm speaker for the second and third sets of experimental trials, respectively, while the vehicle was driven at 72 km per hour (45 miles per hour) for both sets of experimental trials. The same procedure used for the first set of experimental trials was used for the remaining two sets. Attempts to test the kinematic alarm were unsuccessful as the unit did not provide the warning alarm when the cone on which it was mounted was impacted by the traveling vehicle.

Results

The data analysis, results, and discussion of the experimental trials are presented in this section. The analysis of the sound level provided by the two intrusion alarm technologies is presented and discussed. The worker's reactions to the alarm technologies are assessed and discussed. The reaction of the vehicle driver was also evaluated in terms of the vehicle stopping time and the vehicle stopping distance. The implication of the experimental outcomes for work zone safety is also discussed.

Sound Levels of the Intrusion Alarm Technologies

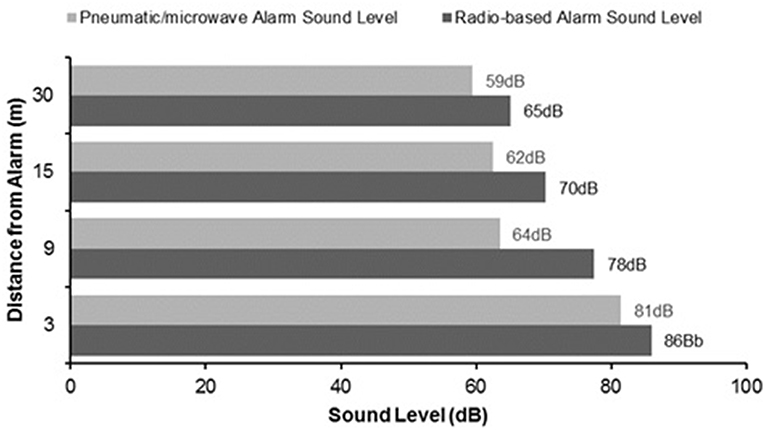

The sound levels of the two alarm systems measured at different distances from the alarm source with the aid of a sound meter are presented in Figure 4. The sound meter used to measure the sound level of the alarms was calibrated using the sound decibel levels of three common noise sources. The sound levels of a handsaw, electric drill, and hair drier were used. The alarm duration of the radio-based alarm was 60 s which was much longer than that produced by the pneumatic/microwave alarm which lasted for just 5 s. The sound levels were determined by extracting the sound level at the start of the alarm, the lowest and peak sound levels as well as the sound level at the end of the alarm from the graphed sound profile. These sound level points for 15 trials were used to compute the average sound level of each of the two technologies at distances of 3, 9, 15, and 30 m from the alarm speaker. The results showed that the sound levels provided by these two systems were very close at the different distances as illustrated in Figure 4 with the radio-based alarm generally having a higher sound level than the pneumatic/microwave alarm.

As expected, the sound level decreased as the distance of the sound meter from the alarm speaker increased with the radio-based alarm still having the louder sound level throughout the distances. The sound levels of the two alarm technologies were also tested with construction equipment (a backhoe was in use on a construction site near the test area). Although dependent on the distance of the construction equipment from the alarm source, the sound level of the two alarm technologies was found to be distinct and higher than the sound produced by the backhoe.

Worker's Reaction to the Intrusion Alarm Technologies

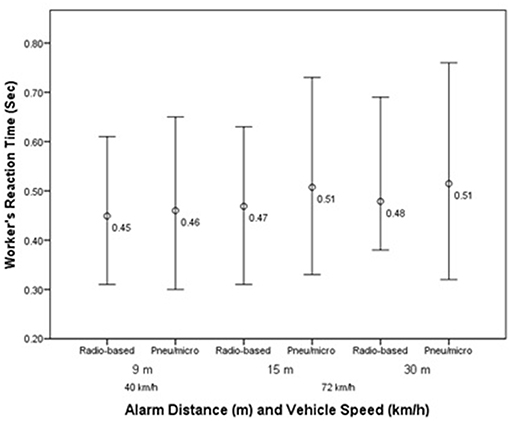

The results of the worker's reaction to the alarm produced by the two systems tested are presented in Figure 5. The results indicate that worker reacted to the alerts provided by both alarm technologies. The worker reacted a little faster to the radio-based intrusion alarm than the pneumatic/microwave alarm even as the distance of the alarm from the worker as well as the vehicle speed varied. The shorter reaction time recorded for radio-based alarm could be because of the higher sound volume produced by the radio-based alarm, which may have also been amplified by the sound made from the collision of the intruding vehicle with the cone on which the impact activated sensor alarm was placed.

As expected, the average reaction time increased as the distance of the worker from the alarm increased as indicated in Figure 5. This implies that the closer the worker is to the alarm, the shorter the reaction time (i.e., the faster the worker reacts to the alarm). The results also indicate that the reaction time increased slightly with an increase in the speed of the intruding vehicle by a margin of 0.02–0.05 s, with the pneumatic/microwave alarm having the higher margin. Although the pneumatic/microwave alarm provided an extra Personal Safety Device (PDS), which gives the worker an additional vibrating alarm when a vehicle runs over the hose, this PDS was not found to be effective because the vibrating alert had delays ranging from 1 to 2.5 s, with an average delay of 0.37 s over the 15 trials performed in the experiment.

Response of Vehicle Driver to the Intrusion Alarm Technologies

The vehicle driver's response to the intrusion alarm technologies was evaluated in terms of the amount of time it took the driver to bring the alarm to a complete stop after hearing the sound from the alarm and possibly also observing the visual alert. The distance covered during this time was also measured and computed to establish the relative dynamic position of the intruding or errant vehicle from pedestrian workers at work zones. The vehicle stopping distance was computed using Equation (1).

Where SD is the vehicle stopping distance in meters (m), v is the vehicle speed in miles per hour (mph), and t is the vehicle stopping time in seconds (s).

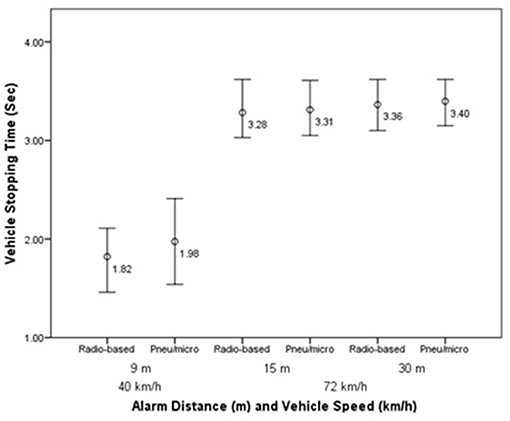

Vehicle Stopping Time

The results of the vehicle stopping time at vehicle speed of 40 and 72 km per hour are presented in Figure 6. The results of the experimental trials show that the driver took a longer time to stop the vehicle when the pneumatic/microwave alarm was used than the radio-based alarm. This could be because of the higher sound volume produced by the radio-based alarm together with the impact sound when the cone is knocked down. The fact that the alarm is activated when the vehicle runs over the pneumatic trip hose in the pneumatic/microwave alarm without a loud impact sound may not give the driver that additional alert apart from the sound produced from the alarm and the directional light from the alarm system.

As expected, the vehicle stopping time increased as the vehicle speed was increased from 40 to 72 km per hour with a difference ranging between 1.42 and 1.54 s for the pneumatic/microwave alarm and radio-based alarm, respectively. The decision on the positioning of the alarm source should be carefully thought out because irrespective of how well the position of both the pedestrian worker and the vehicle is considered, it might be wiser to give more preference to the pedestrian worker for faster response. In this case, the worker's response time is compared to the time taken by the driver to bring the vehicle to a complete stop. The results from the previous section indicated that the worker took an average of 0.45 s to respond to the alarm provided by the radio-based alarm, while it took the driver 1.82 s to bring the vehicle traveling at 40 km per hour (i.e., 25 miles per hour) to a complete stop. This implies that the distance covered by the vehicle in 0.45 s (which is approximately equal to 2.52 m) in the direction of the pedestrian worker should be less than the position of the worker. Similarly, in the case of the pneumatic/microwave alarm, the distance covered by a vehicle traveling at 72 km per hour (i.e., 45 miles per hour) in 0.51 s (which is ≈5.14 m) in the direction of the pedestrian worker should be less than the position of the worker.

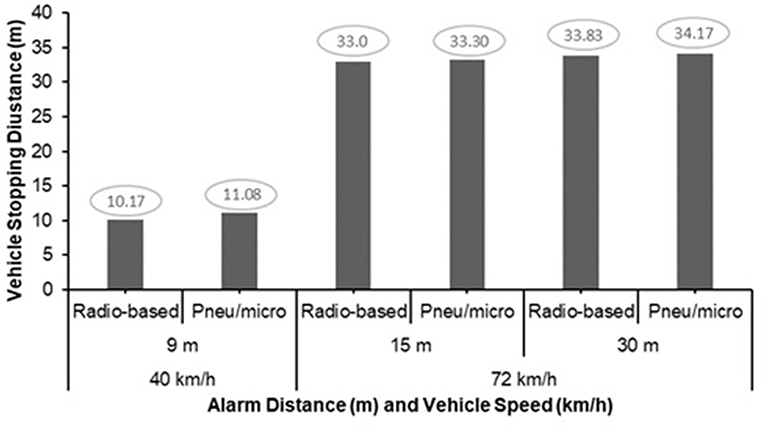

Vehicle Stopping Distance

Figure 7 illustrates the results of the vehicle stopping distance at vehicle speed of 40 and 72 km per hour when the two alarm systems were used one after the other. The experimental findings indicate that a longer distance was covered before the vehicle was brought to a complete stop when the pneumatic/microwave alarm was used than when the radio-based alarm was deployed, as depicted in Figure 7. This again could be because of the louder sound produced by the radio-based alarm.

The consideration of these vehicle stopping distances is paramount in the planning of the layout for the implementation of these intrusion alarm technologies. These distances with an extra factor of safety may perhaps be set as the minimum allowable distance between the intrusion sensor and the pedestrian workers.

Implications of the Experimental Findings for Work Zone Safety

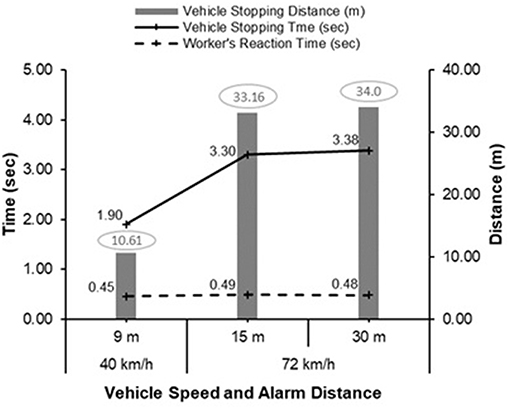

The results of the experimental investigation imply that warning alerts can be provided to the workers and vehicle drivers around work zones when a hazardous situation occurs. This implication can be observed in the experimental results as depicted in Figure 8. On average, it took a worker < 1 s to respond to warning alerts produced by the tested intrusion sensing technologies. This result is satisfactory, but cannot be considered in isolation because the response of the vehicle driver is vital in determining if the pedestrian worker is fully protected from being hit by the vehicle.

The minimum stopping distance for a vehicle is determined by the effective coefficient of friction between the tires and the road, and the driver's reaction time in a braking situation, assuming proper operation of brakes on the vehicle. Using the results of this experimental evaluation, the work area should not be < 10.61 m away from the intrusion sensing device, while it should be a minimum of 34.00 m if the posted vehicle speed is 72 km per hour (i.e., 45 miles per hour). These results would have been compared to the posted stopping distances obtained from past transportation studies, but there is no uniformity in the values determined as these values vary from one document to the other.

Though the experimental findings may not be generalized because other factors not investigated may also influence the responses of workers and vehicle drivers warning alerts, it is relevant to note that these results can be used in planning the work zone layout when some of these technologies are deployed to mitigate injuries and fatalities.

Implementation Guide

Adopting new technology and innovation is vital for government entities to conduct business effectively for its employees. One major challenge of capturing and realizing the multitude of benefits produced by innovative safety technologies is the proper implementation of such systems. This guide provides recommendations and best practices for implementing intrusion sensing and alert systems for enhancing safety of workers in highway construction zones.

Highway construction zones of transportation infrastructure provide unique challenges for ensuring the safety of Department of Transportation (DOT) personnel. Construction equipment and ground workers are often required to operate at close proximity to traveling vehicles. Highway work zone intrusion alert systems can provide real-time alerts to pedestrian workers and equipment operators when a hazard is present. Through wireless communication using various technologies and systems, work zone intrusion alert systems can provide alerts to highway work zone personnel when hazardous situations are detected.

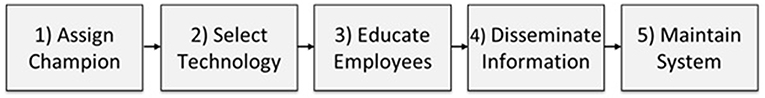

This guide was created in an effort to effectively implement highway work zone intrusion alerts systems for work zone personnel. For proper implementation, several steps were created and discussed in this research. Figure 9 presents the steps for implementation. Subsequent sections of this guide describe in detail the best practices for each implementation step shown in Figure 9.

Step 1: Assign Champion

One of the most effective steps in implementing a highway work zone intrusion alert system for enhancing safety in highway work zones is to designate a “champion” of implementing the system. The selected champion is an employee of the DOT that is familiar with implementing systems or technologies. This person must be committed to implementing the selected technology. Although the champion may have other responsibilities, implementing this system should be one of the person's top priorities. The champion should have the following characteristics:

A basic understanding of the challenges of safety with DOT employees in a highway work zone;

Previous experience with implementing systems within a DOT environment;

A desire to understand highway work zone intrusion alert systems.

Before other steps of the implementation process, the champion must fully understand the highway work zone intrusion alert systems. The champion must read this guide and create a plan based on best practices presented.

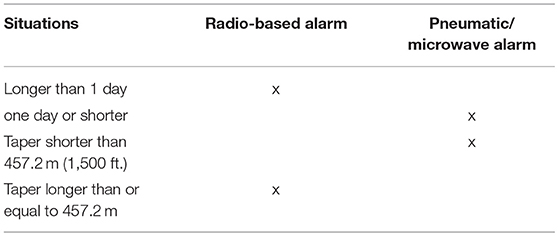

Step 2: Select Technology

Based on results of the review and experimental evaluation, several recommendations have been made for selecting and implementing work zone sensing technology. The implementation of the radio-based alarm for longer tapers in construction highway work zones where traffic barrels or other longer term temporary devices are deployed is recommended. The pneumatic/microwave alarm is recommended for short tapers and short term or mobile highway work zone projects. Each manufacturer provides specific step-by-step instructions on how to deploy and maintain the highway work zone intrusion alert systems. Table 3 provides a selection guide for work zone intrusion detection devices.

Step 3: Educate Employees

After assigning an implementation champion and selecting a highway work zone intrusion alert system, end users of the system must be educated. DOT employees who work in highway work zones should be instructed about the value of work zone intrusion alerts, functionality of the systems, and how to maintain the devices. This educational component can be integrated into existing DOT employee training and should be tailored toward those employees who will be the end users of the systems–DOT personnel in highway work zones. The training must include the following: (1) Instructions and demonstrations of how to set-up the system, including mounting locations for all devices; (2) proper calibration of the system to the desired alert distance; and (3) explanation of the functionality of the system during use. The champion should create and organize the training materials, as well as conduct the training for the employees. Several sets of highway work zone intrusion alert systems should be available for demonstration by the employees after the information is given. After all employees have received the required training, the systems should be deployed in initial field trials before extending to all active work zone projects.

Step 4: Disseminate Information

Once the system is deployed in an initial field trial, workers using the system should be surveyed. Employees should be questioned about their ability to use the system, if they encountered any limitations, and suggested changes. Changes to the education, calibration, and other variables should be made by the champion based on the results of the initial trials. Feedback from employees should be acted on and communicated to the workers because they will be the end users of the system.

Step 5: Maintain System

The champion should implement strategies to maintain the highway work zone intrusion alert system. These strategies should include requiring workers to check the battery status before deployment (to know when a simple replacement of battery is required), maintain the system, and understand the requirements for updating training for workers utilizing the system. Workers should be re-trained or updated at least every year for usage of the highway work zone alert system.

Conclusion

The limited work space and ever-changing nature of highway construction work zones make the work environment very dangerous for pedestrian workers (Fyhrie, 2016; Gambatese and Lee, 2016). Active sensing and alert devices are not readily available in highway work zones and in transportation infrastructure construction and maintenance. The applicable intrusion technologies for work zone safety were reviewed in this paper. Commercially available technologies were evaluated using experimental trials. This research contributes to the body of knowledge by providing strategies for selecting and implementing intrusion sensing technologies for active work zone safety.

It is important to note that commercially available intrusion sensing technological systems are varied in their complexity and capabilities. This variation may or may not be reflected in the cost of the system. Furthermore, it was not concluded that commercially available technologies can be useful in every highway work zone situation. Highway work zone environments provide unique challenges that can cause failure of commercially available systems.

The findings of this review indicate that a few states have had difficulty in using most of the early intrusion alarm systems despite the efforts made by the device manufacturers to improve these systems. Some of the shortcomings of the technologies are lengthy set up time, false alarms, misfires, and alignment difficulties. This has continued to hinder the widespread application of these technologies for work zone safety. For instance, there were challenges with the use of the kinematic alarm, which led to the inability of the research team to evaluate the technology at the time the radio-based and pneumatic/microwave alarms were evaluated.

The results of the experimental evaluation of the radio-based and pneumatic/microwave alarms indicate that the two technologies produce more than one type of alert which can be used to warn workers when a vehicle intrudes a construction work zone. The findings also indicate that workers and vehicle drivers responded to the warning alerts provided by these technologies as observed in the reaction times obtained in the experimental trials. As expected, the worker's reaction time was on average < 1 s, while the vehicle stopping time was less that the posted stopping time for vehicle traveling at the same speed used in this experimental evaluation. Additionally, the performance of the two technologies evaluated by the research team was satisfactory in terms of power consumption as no issues were encountered with batteries running down. The batteries supplied the required power throughout the duration of the experiments. The technologies were relatively easy to set up and no cases of false alarms were experienced while testing the radio-based and pneumatic/microwave alarms.

By implementing a highway work zone intrusion alert system, pedestrian workers in work zones can be alerted when they are located near a hazard. The implementation guide provides best practices associated with implementing and maintaining a highway work zone intrusion alert system. Further testing in a variety of scenarios can further demonstrate the benefits and limitations of these systems. These technology systems as well as others can provide an additional layer of safety protection for DOT personnel in hazardous work environments.

Author Contributions

All authors listed have made a substantial, direct and intellectual contribution to the work, and approved it for publication.

Conflict of Interest Statement

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

Agent, K., and Hibbs, J. (1996). Evaluation of SHRP Work Zone Safety Devices. Research Report No. KTC-96-30, Lexington, KY: Kentucky Transportation Center.

Andrijcic, E., Haimes, Y. Y., and Beatley, T. (2013): public policy implications of harmonizing engineering technology with socio-economic modeling: application to transportation infrastructure management. Transport Res. Part A 50, 62–73. doi: 10.1016/j.tra.2013.01.027

Astro Optics (2017). Traffic Guard Worker Alert System. Astro Optics, LLC. Available online at: http://www.astrooptics.com/products/traffic-guard-worker-alert-system

Bathula, M., Ramezanali, M., Pradhan, I., Patel, N., Gotschall, J., and Sridhar, N. (2009). A sensor network system for measuring traffic in short-term construction work zones. Comput. Sci. 5516, 216–230. doi: 10.1007/978-3-642-02085-8_16

Blincoe, L. J., Miller, T. R., Zaloshnja, E., and Lawrence, B. A. (2015). The Economic and Societal Impact of Motor Vehicle Crashes, 2010. Report No. DOT HS 812 013. Washington, DC: National Highway Traffic Safety Administration.

Bryden, J., and Mace, D. (2002). Guidelines for Design and Operation of Nighttime Traffic Control for Highway Maintenance and Construction. NCHRP Report 476, Washington, DC: Transportation Research Board.

Carlson, P., Fontaine, M., and Hawkins, H. (2000). Evaluation of Traffic Control Devices for Rural High-Speed Maintenance Work zones. Austin, TX: Texas Transportation Institute, The Texas A&M University System, College Station.

Cerezo, V., Do, M., and Violette, E. (2011). “A global approach to warn the drivers before a curve by considering the decrease of skid resistance due to the rain,” in 3rd International Conference on Road Safety and Simulation (Indianapolis, IN).

Chambless, J., Ghadiali, A., Lindly, J., and McFadden, J. (2002). Multistate work-zone crash characteristics. Inst.Transport. Eng. 72, 46–50.

Cleaver, L. (2016). Oldcastle Materials Creates AWARE to Save Lives. Oldcastle Materials. Available online at: http://www.forconstructionpros.com/article/12181842/oldcastle-materials-creates-aware-to-save-lives (Accessed February 8, 2017).

Duranton, G., and Turner, M. (2012). Urban growth and transportation. Rev. Econom. Stud. 79, 1407–1440. doi: 10.1093/restud/rds010

FHWA (2016). NCHRP Report 350: Devices in Work Zones. U.S. Department of Transportation. Available online at: https://safety.fhwa.dot.gov/roadway_dept/policy_guide/road_hardware/nchrp_350/ (Accessed February 8, 1985).

Fyhrie, P. (2016). Work zone Intrusion Alarms for Highway Workers: Preliminary Investigation. Caltrans Division of Research, Innovation and System Information. California Department of Transportation.

Gambatese, J., and Lee, H. (2016). Work Zone Intrusion Alert Technologies: Assessment and Practical Guidance. SPR Research Program Second-Stage Problem Statement FY 2016. ODOT Research Unit. Oregon Department of Transportation.

Givechi, M. (2015). Cones Sound a Warning of Work Zone Intrusion. Kansas LTAP Newsletter, Kansas University Transportation Center.

Hourdos, J. (2012). Portable, Non-Intrusive Advance Warning Devices for Work Zones With or Without Flag Operators. Final Report. Minnesota Department of Transportation Research Services. Minnesota Department of Transportation.

Intellicone (2016). About Intellicone. Available online at: http://www.intellicone.co.uk/about (Accessed February 7, 2017).

Khan, A. (2007). “Microsimulation of traffic in highway work zones for testing ITS-based traffic management measures,” in 11th World Conference on Transport Research. Shanghai: Elsevier.

Khattak, A., Khattak, A., and Council, F. (2002). Effects of work zone presence on injury and non-injury crashes. Accid. Anal. Prevent. 34, 19–29. doi: 10.1016/S0001-4575(00)00099-3

Krupa, C. (2010). Work Zone Intrusion Alarm Effectiveness. Report NJ-2010-004. New Jersey Department of Transportation.

Li, Y., and Bai, Y. (2008). Development of crash-severity-index models for the measurement of work zone risk levels. Accid. Anal. Prevent. 40, 1724–1731. doi: 10.1016/j.aap.2008.06.012

Liu, Y., Li, C., He, Y., Wu, J., and Xiong, Z. (2007). “A perimeter intrusion detection system using dual-mode wireless sensor networks,” in 2007 Second International Conference on Communications and Networking in China. (Shanghai: IEEE). p. 861–865. doi: 10.1109/CHINACOM.2007.4469520

Novosel, C. (2014). Evaluation of Advanced Safety Perimeter Systems for Kansas Temporary Work Zones. MThesis. S. Lawrenceville, KS: Civil, Environmental, and Architectural Engineering, University of Kansas.

Noyce, D., and Smith, C. (2003). Driving simulators for evaluation of novel traffic-control devices: protected-permissive left-turn signal display analysis. Transport. Res. Rec. 1844, 25–34. doi: 10.3141/1844-04

NWZSIC (2016). National Work Zone Safety Information Clearinghouse. Fatalities in Motor Vehicle Traffic Crashes by State and Work Zone (2014). U.S. Department of Transportation Federal Highway Administration. Available online at: https://www.workzonesafety.org/crash-information/workzone-fatalities/workzone-fatalitiesmotor-vehicle-traffic-crashes-2014/ (Accessed February 3, 2017).

Ozbay, K., Bartin, B., Yang, H., and Chien, S. (2012). Traffic Control and Work Zone Safety for High Volume Roads: Final Report. Center for Advanced Infrastructure and Transportation (CAIT) Rutgers, The State University of New Jersey. New Jersey Department of Transportation.

Phanomchoeng, G., Rajamani, R., and Hourdos, J. (2010). Directional sound for long-distance auditory warnings from a highway construction work zone. IEEE Trans. Vehic. Technol. 59, 2266–2276. doi: 10.1109/TVT.2010.2042090

Pratt, S., Fosbroke, D., and Marsh, S. (2001). Building Safer Highway Work Zones: Measures to Prevent Worker Injuries From Vehicles and Equipment. No. DHHS (NIOSH) Publication, Center for Disease Control.

Sun, B., Osborne, L., Xiao, Y., and Guizani, S. (2007). Intrusion detection techniques in mobile ad hoc and wireless sensor networks. IEEE Wireless Commun. 14, 56–63. doi: 10.1109/MWC.2007.4396943

Transpo (2017). SonoBlaster Work Zone Intrusion Alarm. Transpo Industries Inc. Available online at: http://www.transpo.com/SonoBlaster.html (Accessed February 4, 2017).

Trout, N., and Ullman, G. (1997). Devices and Technology to Improve Flagger/Worker Safety. Research Report 2963-1F. Austin, TX: Texas Transportation Institute, College Station.

Tsai, Y. (2011). Development of a Sensing Methodology for Intelligent and Reliable Work-Zone Hazard Awareness. Final Report for Highway IDEA Project 139. Washington, DC: Transportation Research Board of the National Academics.

Ullman, G., Finley, M., Bryden, J., Srinivasan, R., and Council, F. (2008). Traffic Safety Evaluation of Nighttime and Daytime Work Zones. Project 17-30 Report, Washington, DC: Transportation Research Board.

Keywords: construction safety, intrusion alarms, sensing technology, work zone safety, pro-active safety

Citation: Awolusi I and Marks ED (2019) Active Work Zone Safety: Preventing Accidents Using Intrusion Sensing Technologies. Front. Built Environ. 5:21. doi: 10.3389/fbuil.2019.00021

Received: 18 October 2018; Accepted: 12 February 2019;

Published: 04 March 2019.

Edited by:

Fidelis A. Emuze, Central University of Technology, South AfricaReviewed by:

Shuichi Ishida, Ritsumeikan University, JapanHongling Guo, Tsinghua University, China

Jolanta Tamošaitienė, Vilnius Gediminas Technical University, Lithuania

Copyright © 2019 Awolusi and Marks. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ibukun Awolusi, SWJ1a3VuLmF3b2x1c2lAdXRzYS5lZHU=

Eric D. Marks, ZXJpYy5tYXJrc0BjZS5nYXRlY2guZWR1

Ibukun Awolusi

Ibukun Awolusi Eric D. Marks

Eric D. Marks