Fatigue Life Assessment Method for Prestressed Concrete Sleepers

- 1Railway Dynamic Division, Railway Technical Research Institute, Tokyo, Japan

- 2Birmingham Centre for Railway Research and Education, School of Engineering, University of Birmingham, Birmingham, United Kingdom

- 3Track Technology Division, Railway Technical Research Institute, Tokyo, Japan

A commentary on

We have closely read with interest the paper published by You et al. (2017) about the fatigue life assessment method for prestressed concrete sleepers. This article shows that there is a possibility that the assessment method, which is commonly used to evaluate the fatigue life of the reinforcing bar and prestressed steel for railway concrete structures, is also applicable to the prestressed steel of the concrete sleepers. Establish of the assessment method for the prestressed steel on the concrete sleepers can be benefit when it comes to maintenance (e.g., replacement cycles and priority of replacement locations, etc.).

However, in the experiments conducted by Parvez (2015) and Parvez and Foster (2017) to verify the applicability of the assessment method for the prestressed steel of prestressed concrete sleepers, the upper limit of the cyclic load was set to 240 kN to make sure that the prestressed steel fractures. The use of this load shows that very heavy vehicles with severely flat wheels may run repeatedly on poorly maintained tracks. In Japan, the ballasted track, in which prestressed concrete sleeper is a vital component, is selected under the assumption of regular maintenance (Railway Technical Research Institute, 2014). Hence, such a high load which makes prestressed concrete sleepers cracked rarely occurs. For this reason, it should be discussed whether fatigue fracture of a prestressed steel can occur in the actual environment during the service life of prestressed concrete sleepers.

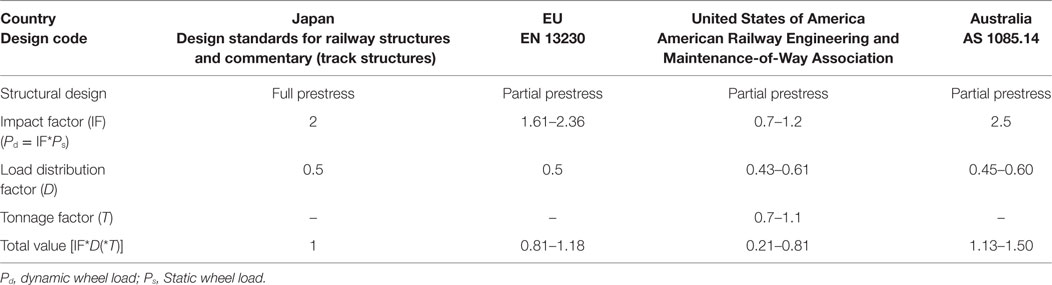

In the design of Japanese prestressed concrete sleepers, as shown Table 1, dynamic wheel load for the serviceability limit state is specified as twice as high as the static wheel load. The concrete stress of the prestressed concrete sleeper is normally needed to be in compressive region against that dynamic load, which is called full prestress design (Antoine, 2012). In addition, the event probability of the dynamic load is estimated to be about 0.1% or less (Wakui and Okuda, 1999). Therefore, it is rare that cracks on prestressed concrete sleepers will occur. Even if high load over that dynamic force is added to the tracks, it is easy to imagine that the number of the occurrences is limited within design service life of the prestressed concrete sleepers. In evidence, there are no reports that a sleeper has broken due to fatigue fracture of the prestressed steel. Thus, the check about fatigue fracture of prestressed steels of the prestressed concrete sleeper is almost omitted in the design of Japanese prestressed concrete sleepers.

On the other hand, when focusing on prestressed concrete sleepers in service, some of them exceed the design service life which is generally set to 50 years (Railway Technical Research Institute, 2014). The fatigue life of prestressed steels may be an important indicator for determining the appropriate replacement time of prestressed concrete sleepers. In other countries, the importance of this indicator increases because prestressed concrete sleepers are normally designed with partial prestress design (FIP Commission on Prefabrication, 1987; Antoine, 2012) which allows generation of tension stress on sleeper’s concrete when train load is added as shown Table 1. Therefore, developing fatigue life assessment method for prestressed steels of prestressed concrete sleepers will become more important in the future.

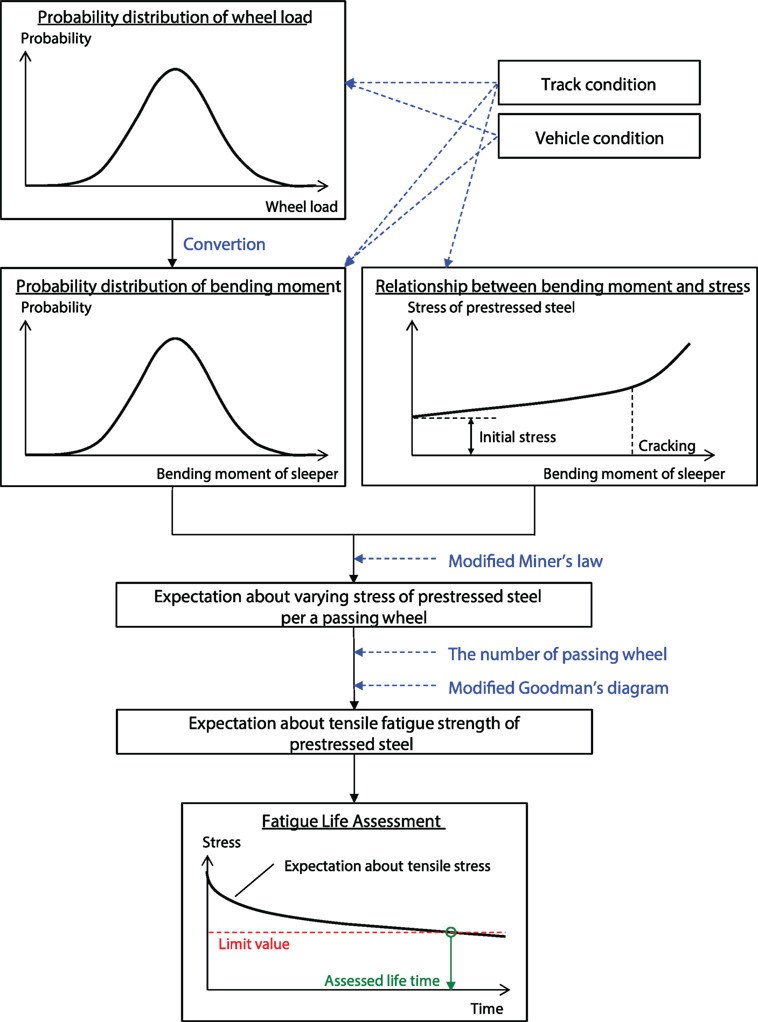

To assess the fatigue life of prestressed concrete sleepers on service tracks more accurately and reasonably, it is necessary to establish fatigue life assessment method according to the situation of the individual service line. Figure 1 shows the image of the assessment method. First of all, it is important to obtain the relationship between wheel load acting to tracks and the probability. Secondly, the relationship is needed to be converted to the relationship between bending moment of the prestressed concrete sleeper and the probability. At the same time, it is also important to ascertain the between the wheel load and the stress of prestressed steel. And then, by multiplying these, expectation about the stress of prestressed steel per a passing wheel is calculated through modified Miner’s law (Miner, 1945). In addition, taking into account the number of passing wheel and modified Goodman’s diagram (Nordby, 1958), expectation value about the tensile fatigue strength of prestressed steel at certain period can be calculated. Finally, the expected value is compared to the limit value for fatigue fracture of prestressed steel (Wakui and Okuda, 1999; Goto et al., 2012, 2017). In that time, it is necessary to sufficiently grasp the influence of each parameter (Watanabe et al., 2016) which is concerning the track and the vehicle condition on expectation value of the tensile fatigue strength of prestressed steel.

Author Contributions

All the authors equally contributed to the manuscript. TW, MH, and SM searched for literature to support main content of the manuscript. KG and TW drafted the manuscript. KG and MH revised manuscript and gave final approval to submit this manuscript. However, all the authors agreed to submit this manuscript.

Conflict of Interest Statement

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The handling editor declared a shared affiliation, though no other collaboration, with one of the authors, KG.

References

Antoine, E. N. (2012). Prestressed Concrete Analysis and Design: Fundamentals. Ann Arbor: University of Michigan, 1176.

FIP Commission on Prefabrication. (1987). State of Report on Concrete Railway Sleepers. London: Thomas Telford.

Goto, K., Shintaro, M., Watanabe, T., and Fumiaki, U. (2017). “Fatigue life of railway girder considering dynamic response,” in Proceedings of the Symposium on Developments in Prestressed Concrete, Kobe, 24.

Goto, K., Sogabe, M., Tokugnaga, M., and Todoroki, S. (2012). Fatigue design considering simultaneous high speed train loading on double-track concrete bridges. J. JSCE 68, I_741–I_750. doi:10.2208/jscejam.68.I_741

Parvez, A. (2015). Fatigue Behaviour of Steel-Fibre-Reinforced Concrete Beams and Prestressed Sleepers. Sydney: The University of New South Wales.

Parvez, A., and Foster, S. J. (2017). Fatigue of steel-fibre-reinforced concrete prestressed railway sleeper. Eng. Struct. 141, 241–250. doi:10.1016/j.engstruct.2017.03.025

Railway Technical Research Institute (RTRI). (2014). Design Standards for Railway Structures and Commentary (Track Structure). Maruzen, 431.

Wakui, H., and Okuda, H. (1999). A study on limit-state design method for prestressed concrete sleepers. Concr. Lib. JSCE. 33, 1–25.

Watanabe, T., Matsuoka, K., and Minoura, S. (2016). “Numerical analysis for the dynamic response characteristic of the prestressed concrete sleeper,” in ECCOMAS Congress 2016, Crete.

Keywords: railway, prestressed concrete sleeper, fatigue life, assessment method, ballasted track

Citation: Goto K, Watanabe T, Hosoda M and Minoura S (2018) Commentary: Fatigue Life Assessment Method for Prestressed Concrete Sleepers. Front. Built Environ. 4:19. doi: 10.3389/fbuil.2018.00019

Received: 20 December 2017; Accepted: 09 March 2018;

Published: 22 March 2018

Edited by:

Min An, University of Salford, United KingdomReviewed by:

Serdar Dindar, University of Illinois at Urbana–Champaign, United StatesAndris Freimanis, Riga Technical University, Latvia

Copyright: © 2018 Goto, Watanabe, Hosoda and Minoura. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Keiichi Goto, Z290by5rZWlpY2hpLjkwJiN4MDAwNDA7cnRyaS5vci5qcA==

Keiichi Goto

Keiichi Goto Tsutomu Watanabe1

Tsutomu Watanabe1