- Beacon Research, Market Harborough, United Kingdom

This mini-review review examines the role of animal by-products (ABP), produced by the process known as rendering. It explains how the use of rendered products has evolved and changed over the last 50 years and how the bovine spongiform encephalopathy (BSE) epidemic in the UK and the rest of Europe challenged the survival of the industry. The subsequent changes to the rendering industry resulting from BSE are described by way of key research and regulatory changes. As a result of the developments in the modern rendering industry, it has evolved into an important component of the current human food chain. The role of the rendering industry in producing a wide range of safe, high quality, sustainable products from ABP materials is explored.

1 Introduction

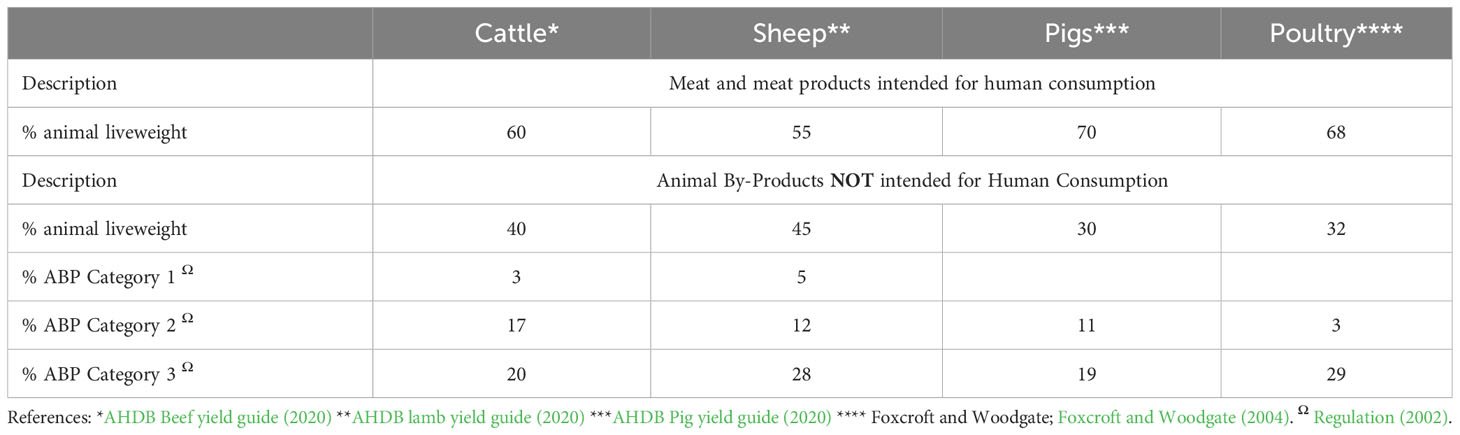

Animal by-products (ABPs) are produced as a direct consequence of livestock farming for production of meat, milk and eggs but they are often ignored by many in the livestock industry. It is therefore necessary to emphasise the importance and relevance of ABPs to the livestock industry. Table 1 illustrates the typical proportions of food (meat) and ABP contributed by each of the four main species or types of land animal farmed for the production of human food in Europe. The evolution and rationale for the risk-based categorisation of ABP by the European Union (EU) is described in full in Section 2. ABPs play a very significant role in the economics and dynamics of the European meat industry, as the portion of the animal not utilised as food (meat) can range from 25-50% of its liveweight. This significant ABP portion of the liveweight requires prompt processing by the rendering industry to ensure that the raw material does not degrade due to microbiological activity. This processing thus ensures the continued operation of the meat industry.

Table 1 Typical composition of meat, meat products and Animal By-Products (ABP) from livestock farmed for food and the categorisation of ABP in Europe.

The rendering process is described in full by Woodgate & Wilkinson (2021). In essence the following steps involve using steam at high pressure to indirectly heat ABPs (following size reduction) to; i) evaporate the water present (typically 55-80% moisture), ii) to break open the cellular structure to allow the fat to be separated (rendered) from the protein meal iii) to microbiologically sterilise the final products of rendering, i.e. protein meal (meat and bone meal [MBM] and rendered fat [Tallow]). The former and latter were traditionally used as ingredients in the manufacture of compound feeds for animals, and the latter in the soap and the preparation of industrial fatty acids (oleochemicals) industry. The resulting products, a high protein meal and a rendered fat are therefore dehydrated, stable and microbiologically sterile such that the MBM was safe to be used by the animal feed industry. In the early development of the rendering industry, the rendering process was operated as a batch process, but during the 1960’s and into the 1970’s the majority of batch processes were replaced by continuous systems (Burnham, 1978). Until 1980, ABPs were generally processed as a mixture of all types of raw material from all species in local rendering plants servicing abattoirs and farms within a relatively compact local area. However, while rendering is, in principle, a simple process, there were many different commercial processes on the market. In practice, the dynamic aspects of rendering, such as particle size, retention time and temperature ranges throughout the process were poorly characterised prior to 1985. Nonetheless at the time, the criterion for approval of rendering plants relied upon the protein meal being free from any salmonella bacteria. (PAPO, 1981).

Following confirmation of the link between feeding MBM and bovine spongiform encephalopathy (BSE), (Wilesmith et al., 1988), a radical overhaul of the rendering industry resulted in the complete re-evaluation of ABPs, rendering processes and utilisation of rendered products. As the economic value of ABPs declined, disposal of ABPs became an additional cost to the animal production and meat sectors, and the economic viability of the rendering industry declined.

2 Bovine spongiform encephalopathy and rendering

BSE is a fatal neurological disease in cattle identified in 1986 (Wells et al., 1987) which resulted in over 175,000 infected animal cases in the UK by 2000 (BSE Inquiry, 2000). However, it was not considered to be a zoonotic disease until 1996 when research concluded that there was a strong causal link between BSE in cattle and new variant Creudzfeldt-Jacob disease (v CJD) in young humans (Dorrell, 1996). An indirect consequence of this finding in the UK, was the establishment of the European Food Safety Authority (EFSA) (EFSA, 2001) with the acknowledgement that the rendering industry was considered to be key link in the human food chain. A comprehensive narrative review of the Bovine Spongiform Encephalopathy (BSE) epidemic, from the perspective of the European rendering industry was given by Woodgate and Wilkinson (2021). This paper describes the research background concerning the design and trials conducted to determine if any rendering process was able to inactivate the BSE and/or scrapie agents (both members of the Transmissible Spongiform Encephalopathy (TSE) family of prion diseases). Full details of the research into the inactivation of BSE and sheep scrapie are given in Taylor et al. (1995) and Taylor et al. (1997) respectively. In summary, the results indicated that one of the rendering systems was unable to inactivate TSE agents, and others showed only limited ability to inactivate TSE agents. One system, a high-pressure steam process, provided the greatest level of TSE inactivation. Subsequently, the results of these inactivation trials were used to inform the European Commission and new EU legislation was enacted immediately, as described by Woodgate and van der Veen (2004)

One of the key features resulting from the BSE epidemic was an animal feed ban, introduced in stages, from the UK in 1989 to the entire EU in 2001 (Regulation, 2001). This ban prohibited all rendered animal proteins for use in animal feeds for monogastric, ruminant and aquatic animals farmed for food production. The only practical exemption allowed use of rendered animal proteins in pet foods, as companion and pet animals are not considered to be part of the food chain. This regulation was, in principle, temporary therefore no time limit was set. As such, the rendering industry was in a dilemma about how it could continue even though it was considered to be an essential component of the slaughter and meat production industry. Although the EU regulations in place by 2002 indicated that the rendering industry appeared to have a future, albeit a different future to that expected in the last 25 years, many were uncertain that it would survive. Consequently, the options for rendering and alternative processes for the future were explored by Woodgate (2006) who considered potential replacements for the methods of processing ABPs but without the products being used in animal feeds. One of the areas explored in depth was combustion of the organic content of MBM (75-80 g/100g) by developmental or commercial incinerators to assess if they could both destroy any potential prion contamination and yield enough energy, such as steam or electricity, to be commercially viable. As will be described later, development of technologies of this type became invaluable for the future direction of the rendering industry.

A vital aspect of the key EU regulation (Regulation, 2002) was the introduction of categories of ABP according to risk to animal and human health, since in 2002, BSE was considered the most important risk to be managed. All of the requirements introduced by this regulation are currently active in the EU and the UK, although the original 2002 regulation was amended (Regulation, 2009 and Commission Regulation, 2011). It is important to note that the 2002 regulation marked a significant change between rendered animal proteins produced before 2002 (termed MBM) and those produced after (termed PAP or MBM according to category of ABP). Regulation (2002) defined three categories of ABP as follows; Category 1: BSE risk materials and deadstock containing BSE risk materials; Category 2: Deadstock and ABP condemned at a slaughterhouse; Category 3: ABP from animals fit for human consumption, slaughtered in an approved abattoir. Importantly, processing standards that could be validated and the potential applications for the products of each category of ABP (now termed derived products) were set down in the EU regulation (Regulation, 2002). Category 1 products are required to be disposed of by incineration (directly or indirectly after rendering) or by rendering followed by combustion of the products to avoid the possibility of contamination of the food chain, via animal feed. Category 2 products may be disposed of by the same route as Category 1 products or if the high-pressure steam process is applied, the MBM produced could be used as a component in organic fertiliser and the rendered fat used as an ingredient in biodiesel. Importantly, proteins and fats derived from Category 1 and 2 ABP are not approved for use within animal feeds and hence do not enter the food chain. Only Category 3 derived products (processed animal protein (PAP) and rendered fat) produced from approved and validated processes may be used in animal feeds, subject to the TSE regulations, i.e., no ruminant proteins in feed for any animal, compliance with the intra-species feed ban for monogastric animals (aquafeed, pigs, poultry), (Regulation, 2001).

3 Rendering: opportunities in a post-BSE world

3.1 Alternative uses for rendered products

The requirement to incinerate Category 1 ABP led to the development of new technologies to combust the products of rendered Categories 1 and 2 ABP, i.e. the protein meal (MBM) and the rendered fat to ensure that they posed no further TSE risk. Accordingly, rendered fat was developed as a bio-fuel replacement for fossil fuel in steam raising boilers and MBM was used as fuel in fluid bed combustors to raise steam that powered turbines to produce electricity. A consequence of this process was the production of significant amounts of bone ash (225,000 tonnes per annum in the UK), as the ash content of MBM ranges between 20-25g/100g. The ash material was initially designated as waste for disposal in landfill sites incurring additional cost to the livestock industry. Research was therefore initiated to determine how the chemical structure of bone was affected by combustion of the organic component and to determine if there were any potential use options available (Etok et al., 2007; Dybowska et al., 2009). In summary, the research highlighted important phosphorus-related properties of the bone ash such that the research focus altered to consider if the bone ash could be used as a renewable source of phosphorus fertiliser. Following farm studies to evaluate the benefit to crops, bone ash is now widely used as source of renewable phosphorus in UK agriculture.

The evolution of biofuels in the form of MBM and rendered fat led to consideration that they could partly replace fossil fuels used for steam generation required by the rendering process and this in turn, could reduce the environmental impact of rendering. Accordingly, research was initiated to study the impact of rendering and rendered products resulting from these changes with the focus on assessment of the energy consumption by the UK rendering industry and the quantification of greenhouse gases (GHG) produced using Life Cycle Assessment (LCA). System boundaries were described in accordance with the current ABP categorisation, i.e. Category 1 (and Category 2) ABP rendered products used as a carbon neutral fuel to provide the steam required to process Category 3 ABP into PAP for use in animal feeds (Ramirez et al., 2012).The results of this study illustrated the potential for the rendering industry to provide fats and protein sources with a lower global warming potential than traditional vegetable-based alternatives such as palm oil and soyabean meal. Data from the research above and LCA studies of rendered products in the EU (EFPRA, 2020) are currently being used in LCA projects that are considering the environmental impact of all types of feed ingredients used in livestock production. The recently operational Global Feed LCA Institute (GFLI) is the product of an international consortium that was formed to establish a global standard for calculating the carbon impact of feed ingredients (including rendered products) for animal feeds, (GFLI, 2022).

3.2 Rendering: new opportunities for animal feeds

The EU regulations of 2001 (Regulation, 2001) and their successors set out the conditions under which certain PAPs may be used in animal feeds. Accordingly, research was conducted to determine the species identity of PAPs, a pre-requisite for their approval in animal feeds. The specific conditions laid down in EU animal feed regulations stipulated that a) no ruminant protein should be present in any animal feed and b) that there is no intra-species recycling of proteins (no porcine to porcine, no poultry to poultry and no fish to fish-although fish caught in the open sea were exempted from this constraint). The first research challenge was the preparation of standardised species-specific PAP products by rendering. Thereafter a series of experimental methods were assessed to determine the most appropriate method to detect a target species protein within a mixture. The criteria included the accuracy, sensitivity, and reproducibility. The results of the research published by Woodgate et al. (2009) resulted in a focus being placed on Polymerase Chain Reaction (PCR) techniques which appeared to be more suitable for the detection of low levels of potentially heat denatured proteins in PAPs. Subsequent research at the EU Research Laboratory for PAP (EURL-PAP) (Fumiere et al., 2012) resulted in the EU regulatory approval of PCR methods for the detection of ruminant protein in mixtures of PAPs and animal feeds, (Commission Regulation, 2013a). The situation regarding the potential for safe use of PAPs in animal feeds at the time was reviewed by Woodgate (2012). This paper updated the progress of applying HACCP principles to rendering (Woodgate, 2010), to ensure that rendering processes producing PAPs were compliant with the approved regulatory standard.

It is important to recognise that PAPs are essentially a new potential feed ingredient from 2002 onwards, with no prior history of nutritional evaluation in farmed animals. Even then, PAPs were not approved for use in animal feeds until species identity tests were validated and feed legislation updated. This fact explains the limited number of nutritional studies until post 2013 (in aqua feeds) and post 2021 (for pigs and poultry). Nonetheless, the utilisation of processed animal proteins (PAPs) in several marine fish species was studied in a university setting by Davies et al. (2009). The PAPs evaluated were produced under characterised, validated process conditions which enabled the nutritional data to be more meaningfully interpreted. The investigation produced valuable data for the digestibility coefficients of essential amino acids such that these can be used in feed formulations that include specification limits for digestible amino acids in the diets of three temperate marine species, namely European sea bass, gilthead sea bream and turbot. In addition to the nutritional data yielded, this paper was used as evidence by the European Commission to show the efficacy of PAPs in aquafeed. Subsequently, the use of non-ruminant PAP in feeds for aquatic species was approved, (Commission Regulation, 2013b), and the use of animal proteins in aquatic species was reviewed and updated by Woodgate et al. (2021). Details of the analytical and nutritional profiles of modern PAPs, are described by Woodgate and Wilkinson (2021). More recently, the use of pig or poultry PAP in diets for poultry and pigs respectively was approved (Commission Regulation, 2021). Recent research on the use of poultry PAP in the diet of weaned and growing pigs indicated that it may be used as a sustainable protein ingredient in pig diets (Davin and Bikker, 2021; Davin et al., 2021). It is expected that future nutritional studies will focus on comparison of terrestrial PAPs with PAPs produced from fish by-products (Fishmeal or fish PAP) or Insect PAP which may compete for the same space in feed formulations. However, it is important to note that Insect PAP for use in animal feed can only be produced from feedstock free from ABP. In effect, insects manufactured into insect PAP, must have been feed on a vegetarian feedstock which might affect its production costs and therefore its commercial potential.

Importantly for the rendering industry and the economy of the meat processing chain, the use of PAPs in pet foods has continued since 2002 and has matured to be able to utilise the ruminant and mixed species PAPs that are not able to be used in feeds for food producing animals. The use of PAPs in petfood are regulated by EU and UK rendering and feed regulations and their use in the petfood market is both encouraged and significant (75% of all EU PAPs are currently used in petfood products). Furthermore, PAPs are accepted as important and declared ingredients for omnivore and carnivore pets (dogs and cats) by nutritionists and pet food manufacturers.

However, it is clear to many that meeting safety standards per se is not necessarily the only factor in any assessment that consumers might consider when considering the use of PAP in animal feeds. Consumers (essentially represented by supermarkets) appear to resist the concept of using PAPs even if their use is in full compliance with the intra-species feeding ban. It seems that consumers expect not only that rendered products should meet maximum health safety standards for both animals and humans, but also have a low environmental impact and make a positive contribution to the nutrition, health and welfare of animals farmed for food.

3.3 Rendering: an integrated environmentally responsible process?

The amounts of ABP produced by the EU livestock industry are considerable, amounting to 18.5 mega tonnes per annum (Mtpa). Following rendering, the derived products (of all categories of ABP) amount to approximately 4 Mtpa of protein meals and 3 Mtpa of rendered fats per year (Alm, 2021). Table 2 describes the options for the processing of the different EU categories of ABPs taking the one or two process steps necessary to produce the final derived products. The potential utilisation of the products, in one or more applications, is shown by way of coloured circles. Table 2 also includes data showing the major use by each application in Europe, in 2021.

Table 2 Potential applications and amounts of derived products from the rendering of ABPs in the EU.

Interestingly, not all the possible application opportunities described are realised simultaneously due to changing global circumstances, such as supply and demand for proteins, fat and energy. Economics play a crucial role in directing the utilisation of rendered products and this feature is illustrated in practice when considering the role of renewable (or short carbon cycle) rendered products, several of which are confirmed as having excellent sustainability credentials (EFPRA, 2020). Should these renewable products, such as rendered fat, be encouraged as replacement for fossil derived fuels, by given a carbon saving credit? Unless this occurs, rendered fat will be utilised by industries, such as biodiesel and oleochemical processors that are willing to pay for the commodity based on supply and demand. If this occurs, the potential for reducing the environmental impact LCA of ABPs and of the primary product, meat, may be lost. Nonetheless, Table 2 illustrates the wide range of possible uses for the products derived from the essential processing of ABPs from the animal production.

4 Conclusions

This review has been written from an EU perspective that includes the UK. Interestingly, the advent of Brexit may in the future offer opportunities for the UK to develop innovative technologies and products for non-EU markets that are not constrained by the EU regulations described in the review. Nonetheless, the processing of ABPs by rendering has undergone reformatory changes over the last 50 years. The catalyst for change was the BSE epidemic in UK and rest of Europe such that even though the basic process remains unchanged, the way the industry operates has been transformed. Rendering is now considered to be an essential component in an integrated livestock system that prioritises human and animal health. The modern rendering process may be considered to be a bio-refinery that produces a wide range of safe, environmentally sustainable and economically valuable products that are able to contribute to society as a whole.

Author contributions

SLW: Writing – original draft, Conceptualization.

Funding

The author declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

AHDB beef yield guide (2020). Available at: https://ahdb.org.uk/beef-yield-guide (Accessed February 12, 2023).

AHDB lamb yield guide (2020). Available at: https://ahdb.org.uk/lamb-yield-guide (Accessed February 12, 2023).

AHDB pig yield guide (2020). Available at: https://ahdb.org.uk/pork-yield-guide (Accessed February 12, 2023).

Alm M. (2021). Overview of the animal by-products industry in europe in 2021 in webinar ‘Circular bio economy’ Schothorst, NL (Schothorst, NL).

Commission Regulation (2011). Commission Regulation (EU) of 25 February 2011 on implementing Regulation (EC) No. 1069/2009 of the European Parliament and of the Council laying down health rules as regards animal by-products and derived products not intended for human consumption (142/2011). Off. J. Eur. Communities L54, 1.

Commission Regulation (2013a). Commission Regulation (EC) of 16 January 2013 on amending Regulation (EC) No. 152/2009 as regards the methods of analysis for the determination of constituents of animal origin for the official control of feed (51/2013). Off. J. Eur. Communities L184, 43.

Commission Regulation (2013b). Commission Regulation (EC) of 16 January 2013 on amending Annexes 1 and IV to Regulation (EC) No. 999/2001 of the European Parliament and of the Council laying down rules for the prevention, control and eradication of certain transmissible spongiform encephalopathies (56/2013). Off. J. Eur. Communities L21, 3.

Commission Regulation (2021). Commission Regulation (EU) 2021/1372 of 17 August 2021 amending Annex IV to Regulation (EC) No 999/2001 of the European Parliament and of the Council as regards the prohibition to feed non-ruminant farmed animals, other than fur animals, with protein derived from animals. Off. J. Eur. Communities L295, 1.

Davies S. J., Gouveia A., Laporte J., Woodgate S. L., Nates S. (2009). Nutrient digestibility profile of premium animal protein by-products for temperate marine fish species (European sea bass, gilthead sea bream and turbot). Aquaculture Res. 06/2009; 40 (15), 1759–11769.

Davin R. J., Bikker P. (2021). Abstracts of the 72nd Annual Meeting of the European Federation of Animal Science Replacement of soybean meal with poultry based processed animal proteins in growing pigs. p325. doi: 10.3920/978-90-8686-918-3

Davin R. J., Van Baal J., Bikker P. (2021). Abstracts of the 72nd Annual Meeting of the European Federation of Animal Science Replacement of soybean meal with poultry-based processed animal proteins in weaned pigs. p324.

Dorrell S. (1996). Available at: https://api.parliament.uk/historic-hansard/commons/1996/mar/20/bse-health.

Dybowska A., Manning D. A. C., Collins M. J., Wess T., Woodgate S. L., Valsami-Jones E. (2009). An evaluation of the reactivity of synthetic and natural apatites in the presence of aqueous metals. Sci. Total Environ. 02/2009; 407 (8), 2953–2965. doi: 10.1016/j.scitotenv.2008.12.053

EFSA (2001). Regulation (EC) of the European Parliament and of the Council laying down the general principles and requirements of food, establishing the European Food Safety Authority and laying down procedures in matters of food safety (No. 178). Off. J. Eur. Communities L31, 1–24.

Etok S. E., Valsami-Jones E., Wess T. J., Hiller J. C., Maxwell C. A., Rogers K. D., et al. (2007). Structural and chemical changes of thermally treated bone apatite. J. Material Sci. 42, 9807–9816. doi: 10.1007/s10853-007-1993-z

Foxcroft P. D., Woodgate S. L. (2004). Temperton fellowship: full utilisation of the poultry carcase ( UK: arper Adams University College).

Fumiere O., Marien A., Berben G. (2012) EURL-AP implementation test. Gembloux, Belgium: Walloon Agricultural Research Centre. Available at: http://eurl.craw.eu/img/page/interlaboratory/EURL_AP_PCR_ ILS_2012_final_version.pdf

GFLI (2022). Available at: https://globalfeedlca.org (Accessed November 15, 2022).

Inquiry B. S. E. (2000). The report, evidence and supporting papers (House of Commons Papers) (London, England: Stationery Office Books).

PAPO (1981). “The diseases of animals (protein processing) order 1981,” in Statutory instruments 1981 (London, England: Her Majesty’s Stationery Office).

Ramirez A. D., Humphries A. C., Woodgate S. L., Wilkinson R. G. (2012). Greenhouse gas life cycle assessment of products arising from the rendering of mamMalian animal by-products in the UK. Environ. Sci. Technol. 46, 447–453. doi: 10.1021/es201983t

Regulation (2001). Regulation (EC) 22 May 2001 of the European Parliament and of the Council of laying down rules for the prevention, control and eradication of certain transmissible spongiform encephalopathies (999/2001). Off. J. Eur. Communities L147, 1.

Regulation (2002). Regulation (EC) of the European Parliament and of the Council of 3 October on laying down health rules concerning animal by-products not intended for human consumption. Off. J. Eur. Communities L273, 1

Regulation (2009). Regulation (EC) 21 October 2009 of the European Parliament and of the Council of on laying down health rules as regards animal by-products and derived products not intended for human consumption and repealing Regulation (EC) No. 1774/2002 (animal by-products regulation) (No. 1069/2009). Off. J. Eur. Communities L300, 1.

Taylor D. M., Woodgate S. L., Atkinson M. J. (1995). Inactivation of the bovine spongiform encephalopathy agent by rendering procedures. Veterinary Rec. 137, p605–p610.

Taylor D. M., Woodgate S. L., Fleetwood A. J., Cawthorne R. J. G. (1997). Effect of rendering procedures on the scrapie agent. Veterinary Rec. 141, p643–p664.

Wells G. A. H., Scott A. C., Johnson C. T., Gunning R. F., Hancock R. D., Jeffrey M., et al. (1987). A novel progressive spongiform encephalopathy in cattle. Veterinary Rec. 121, 419–420. doi: 10.1136/vr.121.18.419

Wilesmith J. W., Wells G. A. H., Cranwell M. P., Ryan J. B. M. (1988). Bovine spongiform encephalopathy: epidemiological studies. Veterinary Rec. 123, 638–644.

Woodgate S. L. (2006). “What would a world without rendering look like?,” in Essential Rendering: All about the animal by-products industries. Ed. Meeker D., 277.

Woodgate S. L. (2010) Process validation: an essential step in establishing a rendering HACCP system. Available at: www.rendermagazine.com.

Woodgate S. L. (2012). “Ensuring the safe supply of animal-derived ingredients for animal feed,” in Animal feed contamination: Effects on Livestock and Food Safety. Ed. Fink-Gremmels J., 589.

Woodgate S. L., van den Hoven S., Vaessen J., Margry R. (2009). Control tools to detect processed animal proteins in feed and in animal by-products: specificity and challenges. Biotechnology, Agronomy, Society and Environment 13, 9–13.

Woodgate S. L., van der Veen J. T. (2004). The use of fat processing and rendering in the European Union animal production industry. Biotechnology Agronomy Soc. Environ. 8, 283–294.

Woodgate S. L., Wan A. H. L., Hartnett F., Wilkinson R. G., Davies S. J. (2021). The utilisation of European processed animal proteins as safe, sustainable and circular ingredients for global aquafeeds. Rev. Aquac. 00, 1–25.

Keywords: meat, by-products, ABP, BSE, rendering, PAP, sustainability

Citation: Woodgate SL (2023) Meat industry by-products: a bio-refinery approach to the production of safe, value added products for sustainable agriculture applications. Front. Anim. Sci. 4:1259200. doi: 10.3389/fanim.2023.1259200

Received: 15 July 2023; Accepted: 28 August 2023;

Published: 11 September 2023.

Edited by:

Jeff Wood, University of Bristol, United KingdomReviewed by:

Mara Miele, Cardiff University, United KingdomLuciano Pinotti, University of Milan, Italy

Copyright © 2023 Woodgate. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Stephen L. Woodgate, c3RlcGhlbmx3b29kZ2F0ZUBnbWFpbC5jb20=

Stephen L. Woodgate

Stephen L. Woodgate