- Office for Risk Assessment & Research (BuRO), Netherlands Food and Consumer Product Safety Authority (NVWA), Utrecht, Netherlands

In the Netherlands, a pilot was initiated of a mobile slaughter unit (MSU) for the killing of cull dairy cattle not fit for transport but suitable for slaughter, in order to save valuable meat. The Office for Risk Assessment & Research (BuRO) was asked to assess the risks for animal welfare. As a thorough risk assessment would have been very time consuming, a qualitative framework was used instead. The goal of the current study was to qualitatively describe the relevant risks for cow welfare involved in the use of an MSU compared with current practice by carrying out a rapid comparative risk assessment of animal welfare. The assessment framework consisted of the following steps: identification and description of scenarios, followed by assessment and comparison of the most relevant animal welfare risks in these scenarios, including hazard identification, hazard characterization, exposure, and characterization of the risk to animal welfare. Two main scenarios were identified, one with and one without an MSU. The second scenario was split into three sub-scenarios: killing on the farm/in a housing unit, emergency slaughter, and conventional transport to the slaughterhouse. The most relevant risks associated with operating an MSU were as follows: leaving the cow alive on the farm when it was not fit for slaughter; forcing the cow to walk to and into the MSU (however, this risk is likely higher under conventional transport of unfit cows); and insufficient stunning and bleeding, leading to questionable unconsciousness (however, this risk is likely higher in an emergency slaughter scenario). The MSU is a means of preventing the exacerbation of welfare deterioration in cows that are unfit for transport but fit for slaughter, and it reduces exposure to stressors (hazards) that are conventionally present during transport and at a stationary slaughterhouse. This rapid comparative risk assessment of animal welfare supported swift decision-making: the national competent authority (i.e., the NVWA in the Netherlands) and policymakers were able to improve and develop risk-mitigating actions and to decide on allowing the use of an MSU. When appropriately designed and used, and with sufficient supervision, mobile slaughter facilities can reduce welfare risks in cull dairy cows that are unfit for transport but fit for slaughter.

Introduction

In the Netherlands, almost 1.6 million dairy cows were kept on over 15,000 farms in 2021 (CBS, 2022). The yearly outflow is approximately 28% (GD, 2019). In dairy farming, cull cows are generally transported to the slaughterhouse alive. To ensure animal welfare, the European Transport Regulation 2005/1/EC (EC, 2005) mandates that cows should be fit for transport in order to undergo the journey to the slaughterhouse: “No animal shall be transported unless it is fit for the intended journey, and all animals shall be transported in conditions guaranteed not to cause them injury or unnecessary suffering.” Several conditions are described in this Transport Regulation under which animals are not allowed to be transported. For instance, animals are not fit for transport if “they are unable to move independently without pain or to walk unassisted”. However, on-farm killing of cows that cannot be transported may lead to the loss of meat suitable for human consumption, and consequently loss of income to the farmer. In the case of euthanasia of a cow, in addition to income loss, veterinary costs are incurred and the meat cannot be sold. Although it is legally prohibited, animals unfit for transport still arrive at livestock assembly centers and at Dutch slaughterhouses, posing a risk to animal welfare (2Solve Investigations, 2019; BuRO, 2021).

Surrounding countries (Germany, Belgium) incidentally notify the National Contact Point of the arrival of unfit cattle from the Netherlands (varying from 1 to 25 animals yearly, mainly in Belgium; 2016–2018) (2Solve Investigations, 2019; NVWA, 2020a). In addition, there are reports in other countries, such as Denmark, of unfit animals arriving at the slaughterhouse (Dahl-Pedersen et al., 2018b). It may not always be clear, however, whether the animals were fit (enough) at the time of loading. Moreover, the Transport Regulation 2005/1/EC (EC, 2005) leaves room for interpretation as to whether animals are clearly fit for transport or not, especially in stating: “However, sick or injured animals may be considered fit for transport if they are: (a) slightly injured or ill and transport would not cause additional suffering; in cases of doubt, veterinary advice shall be sought [ … ] However, such transport shall be permitted only where no unnecessary suffering or ill treatment is caused to the animals concerned”. Differences in interpretation between official veterinarians (OVs) are (according to them) related to factors such as familiarity of the OV with to the symptoms displayed by the cow (i.e., ultimately evaluating a welfare consequence as less severe) and differences in judgment regarding the acceptability of these symptoms; differences between OVs in terms of education and experience; and differences in views with respect to the relative importance of animal versus economic interests. In addition, some sector representatives may seek out the lower limits of acceptability with respect to animal welfare, in order to operate in as cost-effective a manner as possible (BuRO, 2021).

Using a mobile slaughterhouse (MSh) is a way of reducing welfare consequences by eliminating the necessity of (long-duration) transport. An MSh is “a self-contained processing unit that can be moved between farms” (Hultgren et al., 2020). Such facilities have been developed for different animal species (such as fish, poultry, and livestock) and are used worldwide, mainly on a small scale (Hultgren, 2022). For example, salmon can be stunned next to their cages in units on stationary pontoons or boats; chickens can be slaughtered in trailers; cattle can be killed and dressed in a mobile slaughterhouse and thereafter sent to a cutting plant; and pastured cattle or bison can be killed by rifle stunning and then bled on the farm (Hultgren, 2022). In the United States, mobile slaughterhouses have been used for years and may travel from farm to farm, or may be regionally located at collection sites (Johnson and Cowan, 2016; USDA, 2017). In Canada, MSh facilities are used for cull dairy cows in some jurisdictions (Stojkov et al., 2018) and in niche markets such as bison meat (McCorkell et al., 2013). In the EU, mobile slaughter is allowed by Regulation 2009/1099/EC (EC, 2009), Regulation 2004/853/EC (EC, 2004), and delegated Regulation 2021/1374/EU (EU, 2021), but MShs are not very common. The total slaughter volume by MShs or comparable facilities in the EU and abroad is unknown (Hultgren et al., 2020; Hultgren, 2022). In Sweden, an MSh was used for several years, but the facility was not economically viable (Hultgren et al., 2018; ATL, 2019). In addition, innovative facilities for mobile killing and/or slaughter of cattle have been developed in Germany, Switzerland, and Austria (Die Landforscher, 2019; Eurogroup for Animals and Porta, 2019; Jakob and Zweifel, 2019), and the Flemish Council for Animal Welfare in Belgium has endorsed the potential welfare benefits of such mobile facilities (Flemish Animal Welfare Council, 2019). However, scientific knowledge about the application of mobile slaughterhouses is limited.

National competent authorities (CAs) have to approve MShs, in accordance with Commission Delegated Regulation (EU) 2021/1374 (EU, 2021). Until 2018, no MSh was commercially available for cattle in the Netherlands, but in 2018 a pilot was requested (Tweede Kamer, 2018). The Dutch Ministry of Agriculture, Nature and Food Quality (LNV) and the Netherlands Food and Consumer Product Safety Authority (NVWA) considered and approved the authorization of a 3–6-month pilot of a mobile slaughter unit (MSU) in accordance with a set of conditions [LNV (2018) and Memorandum 18/10/2018 in Annex 1 of BuRO (2020)]. Implementation of this Dutch MSU was explored by means of a pilot starting in December 2018.

One major difference between this Dutch MSU and more commonly used MShs, such as those used in the US, is that the Dutch MSU was suitable only for the killing and bleeding of cattle and not for processing of the carcasses: that is, officially it was not a slaughter unit, but a unit for killing of cattle (the carcasses were transported to a stationary slaughterhouse for further processing). However, during the course of this pilot, concerns arose in society and a political debate emerged regarding the possible risks for animal welfare, animal health, and food safety. It was suggested that use of the MSU would cause prolonged suffering in cows, as farmers may withhold medical treatment or painkillers from the animals because such substances may not be allowed to enter the food chain [e.g., De Regt and Strijker (2019)]. Therefore, the Office for Risk Assessment & Research (BuRO) of the NVWA was asked to perform a risk assessment of the MSU as a basis for further risk-management discussions.

As time was a limiting factor for decision-making by risk managers with respect to the utilization of the MSU, the risk assessment needed to be rapid. Furthermore, a thorough risk assessment was not necessary, as the relevance of the assessment was identification of the benefits and disadvantages of the MSU as compared with current practice. Therefore, a rapid comparative risk assessment was performed in a relatively short time frame to aid in evaluating the animal welfare risks caused by implementing the Dutch MSU.

The results of the Dutch MSU pilot were presented by us in an advice document (BuRO, 2020) and are used in the current paper. The aim of this paper is to report on the relevant comparative risks for cow welfare when an MSU is used.

Materials and methods

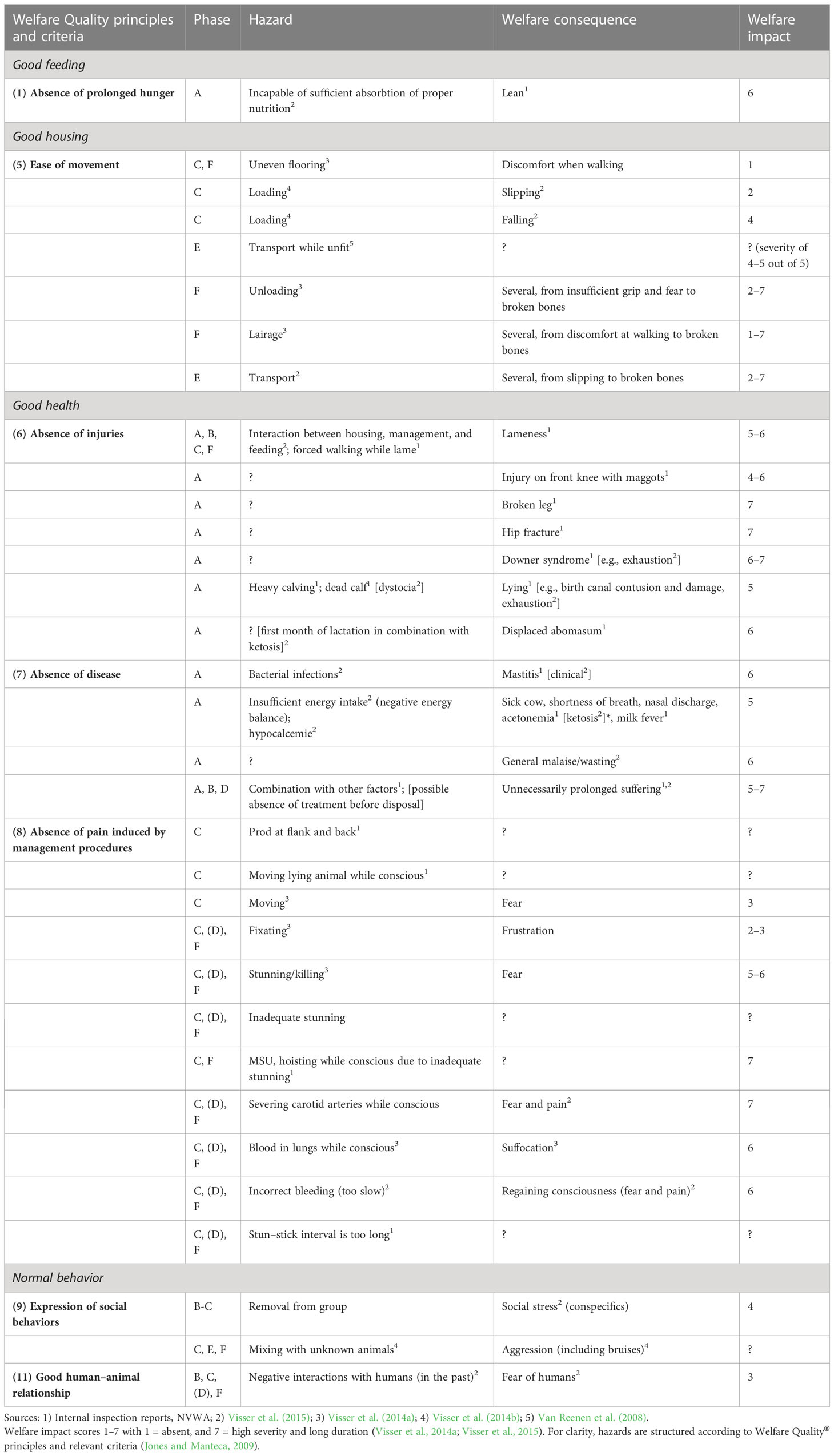

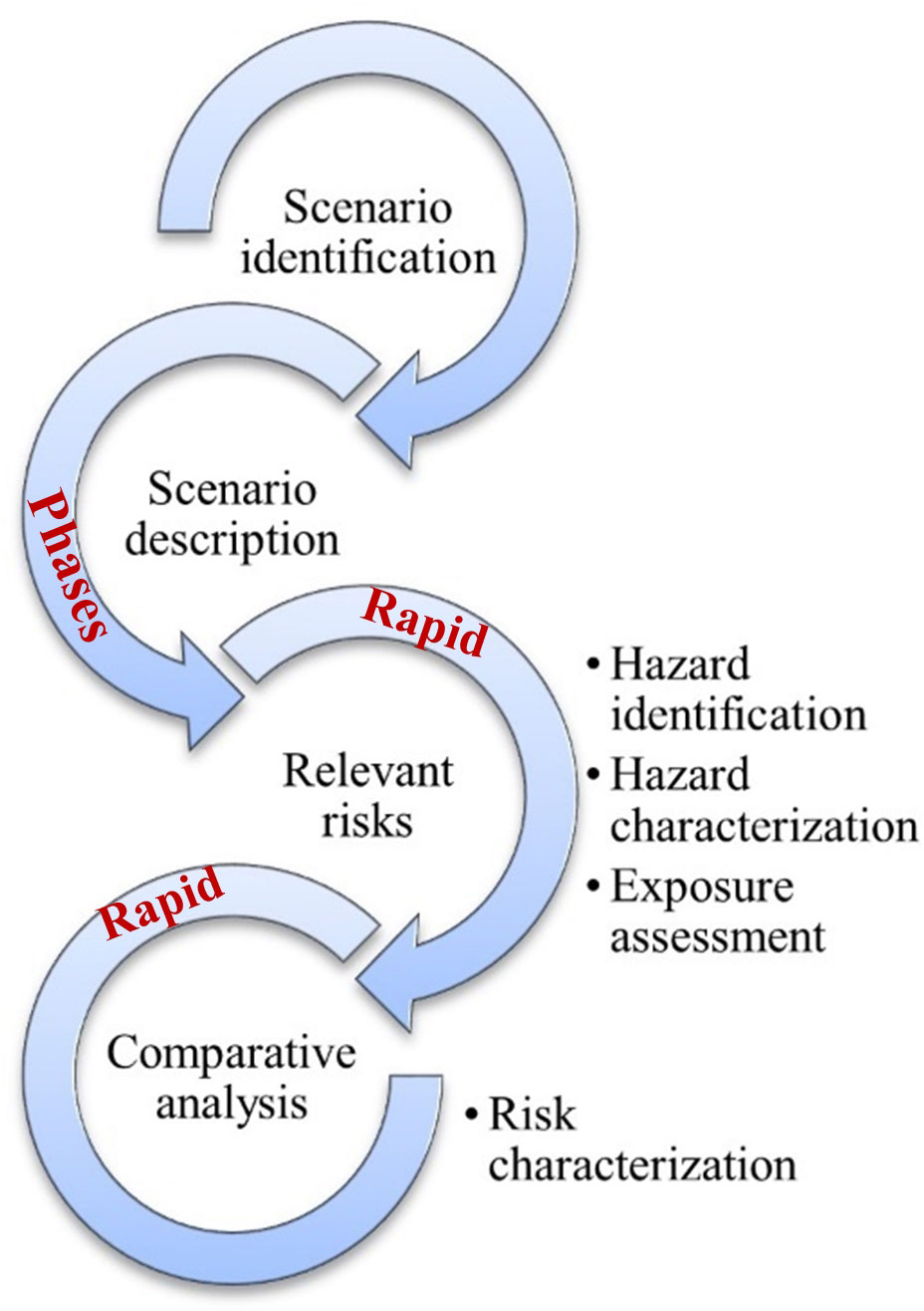

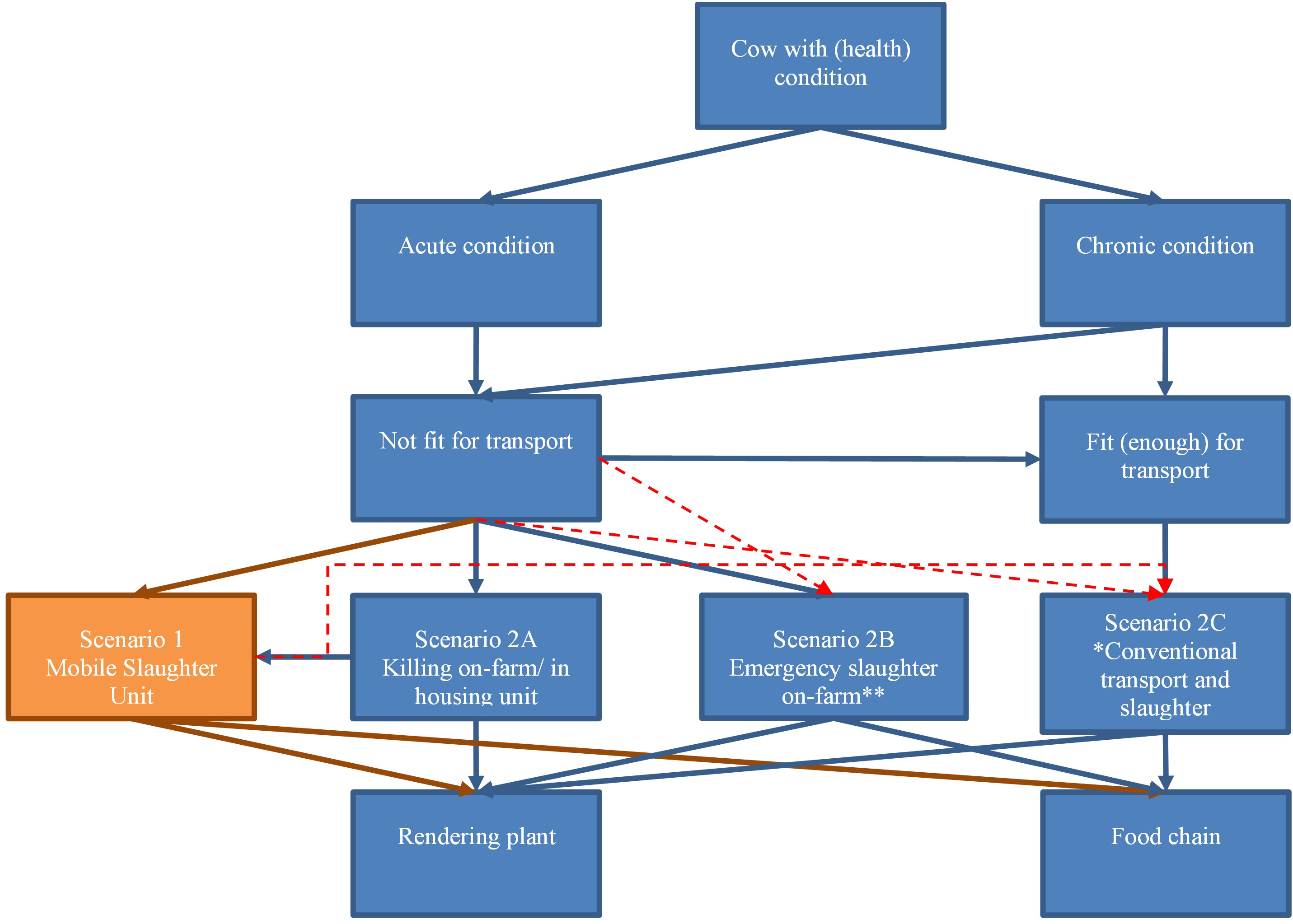

This descriptive study comprised several steps (Figure 1). First, the two main scenarios (with and without the Dutch MSU) were identified and described. Second, the most relevant animal welfare risks were assessed, including hazard identification, hazard characterization, and exposure. Third, the most relevant animal welfare risks were characterized and compared.

Figure 1 Distinct steps in the rapid comparative risk assessment for animal welfare. The label “Phases” indicates where breakdown into recognizable scenarios is conducted to later enable more rapid identification of relevant risks and comparison of scenarios. The label “Rapid” indicates where the process is faster than a rigorous comparative risk assessment.

Ethical approval

The MSU pilot was already in place and had been approved by the competent authorities when BuRO was asked to conduct a risk assessment. The use of mobile slaughterhouses is allowed according to Commission Delegated Regulation (EU) 2021/1374 (EU, 2021), under the condition that national competent authorities approve them [paragraph 6 and Annex 3, 1c(e)]. The Ministry of Agriculture, Nature and Food Quality (LNV) and the Netherlands Food and Consumer Product Safety Authority (NVWA) considered and approved the authorization of a pilot of an MSU under specific conditions [LNV (2018) and Memorandum 18/10/2018 in Annex of BuRO (2020)]. Therefore, no ethical approval was required for the current descriptive study.

The MSU was owned by a Dutch slaughterhouse and could only operate on-farm in the presence of an official veterinarian (OV) of the CA (i.e., the NVWA) (Memorandum 18/10/2018 in Annex of BuRO (2020)). All on-farm and MSU-based actions and observations by NVWA employees were part of (routine) activities related to Ante Mortem (AM) inspections and supervision by the CA of animal welfare and the slaughter process. Farmers voluntarily offered the animals for slaughter at the MSU; the animals were therefore an inherent component of the entire mandatory surveillance process and no consent from the owner of the cows was required. BuRO risk assessors did not intervene in the process of moving and killing the animals.

Identification and description of scenarios

Two main scenarios were identified, one without and one with the MSU. Each scenario was divided into several relevant and comparable phases and described in terms of practice, based on practical experience and legislation. In order to describe and assess the MSU in operation, a working visit (two farms, four cows, November 2019) was conducted, and qualitative information was provided by the OVs of the NVWA and the MSU operator. A meeting with involved OVs and NVWA inspectors also took place to enable sharing of practical experiences with the MSU and joint inspections.

Rapid comparative animal welfare risk assessment

The animal welfare risk assessment methodology used by BuRO is based on EFSA (mainly EFSA-AHAW Panel, 2009; AHAW Panel, 2012a; AHAW Panel, 2012b), which is in line with the Codex Alimentarius, also referred to as the “Food Code” (FAO/WHO, 1995; FAO, 2023) and Regulation (EC) No. 178/2002 (EC, 2002). In short, a risk assessment consists of four basic steps: hazard identification (threats to animal welfare), hazard characterization (the effect on animal welfare), exposure to the hazards (likelihood of threats), and risk characterization (overall assessment based on effect and chance).

For hazard identification and hazard characterization, the scenario identifications and descriptions were used, and additional knowledge about practice was acquired through internal NVWA documentation. This information was combined with information from expert sessions conducted for previous BuRO risk assessments of animal supply chains, and the scientific literature (see the literature search section). For the exposure assessment, the same information was used and collected. Data were analyzed (see the data collection and analysis section) to estimate the target population of the MSU in the Netherlands. For clarity, the duration of exposure to specific hazards is included, where applicable, under hazard identification and characterization rather than under exposure assessment. In risk characterization, the focus was placed on the qualitative and relevant estimated differences—quantified in terms of “lower”, “higher”, or “equal”—between the risks of the different scenarios (comparative risk assessment) instead of the actual magnitude of the risks as such. Only risks that led to welfare consequences with a welfare impact of 5 or higher on a 7-point scale [with 1 indicating no welfare impact and 7 indicating the highest welfare impact; adapted from Dalla Villa et al. (2009)] were considered the most relevant [estimates retrieved from Visser et al. (2014a) and Visser et al. (2015)]. Welfare impact (i.e., magnitude) is part of the hazard characterization (i.e., analysis of the effect on animal welfare) and is based on the combination of the severity (i.e., intensity) and duration of welfare consequences, estimated through Expert Knowledge Elicitation (EKE) (EFSA-AHAW Panel, 2012a). Severity ranged from absent to very severe (measured on a 5-point scale) and duration ranged from short to long (measured on a 3-point scale) (Visser et al., 2015).

Literature search

The search engines SCOPUS and Google Scholar were used (between October 2019 and January 2020) to find relevant scientific works, mainly to describe scenarios and to identify and characterize hazards in order to find relevant risks. In SCOPUS, titles, abstracts, and keywords were explored using the following terms or combinations of terms: mobile, slaughterhouse, abattoir, dairy, cattle, cow, captive bolt, stunning, stun*, conscious*, load*, lame*, transport, fit for transport, bleeding, method, killing, slaughter, handling, animal, welfare. Terms marked with * were automatically expanded in the search engine in various ways. In Google Scholar, the following terms were used: “mobile slaughter animal welfare”, “culling rate dairy cows”, “culling dairy cows Netherlands”, “dairy cow lameness”, “fitness for transport”, and “dairy cow lameness review”. EFSA opinions and reports from WUR on previous red meat and dairy supply chain risk assessments were actively searched for. After the publication of the advice document and the end of the MSU pilot (in April 2020), the literature review was updated for the current paper by conducting quick scans (in 2020, 2022, and 2023) in SCOPUS to explore the literature for new publications related to mobile slaughter facilities (by checking titles, abstracts, and keywords for the terms mobile, slaughter*, and cattle).

Gray literature was retrieved from Google using the following phrases: “mobile slaughter unit animal welfare”, “reason for dairy cattle disposal”, “mobile slaughter”, “mobile schlachtanlage”, and “Mobile schlachteinheit”. Furthermore, EUR-lex was used to download online EU legislative documents. National legislative documents were found at the online laws database of the Dutch Government (“Wettenbank” at “Overheid.nl”).

For both scientific and gray literature, the snowball method (RU, 2022) was used to find other related work in the retrieved literature. As time was a limiting factor, both scientific and gray literature were scanned but not systematically reviewed.

Data collection and analysis

General data were retrieved from the Livestock Identification & Registration (I&R) database of the Netherlands Enterprise Agency (RVO.nl) and the Registration of Slaughter Information (RSG) database on red meat, produced by the NVWA, to gain more insight into the target population of the MSU. The information was analyzed (in the form of descriptive statistics) with respect to the transport movements and whereabouts of conventional cull dairy cattle (the MSU target population) during the last phase of their lives. The MSU operated only in the northern region of the Netherlands; therefore, general data were—where relevant and possible—obtained for the Netherlands and also for the northern region of the Netherlands only. These data provided information about (the number of) cows offered under the different (sub-)scenarios.

Although the MSU pilot ultimately ran for over a year (December 2018 until April 2020) (LNV, 2020), data collection for the current study by BuRO covered only 1 year (December 2018 to December 2019). Food Chain Information (FCI) forms with information about the cows (e.g., on their health status and the use of veterinary medicines) provided by the farmer were collected, and from July 2019 to October 2019, notes with information on the ante-mortem (AM) inspections by the OVs were also gathered. From November 2019 to December 2019, extra information (e.g., information about culling reason, whether or not the animal was considered fit for transport, lameness score when the animal was approved for slaughter) was requested during the AM inspections carried out by the OV when the MSU was in operation, and also during random, unannounced joint inspections (5 days; 38 farms; 57 cows offered to MSU, December 2019). Between 13 December 2018 and 1 November 2019, 10 days were randomly selected and the dossiers of 115 cows offered to the MSU were reviewed for culling reason. This selection was made for practical reasons, as analyzing all available dossiers would have been labor intensive and time costly. This information was used to gain insight into utilization of the MSU, and the possible hazards and welfare consequences observed in cows subjected to this scheme.

Results

Identification and description of scenarios

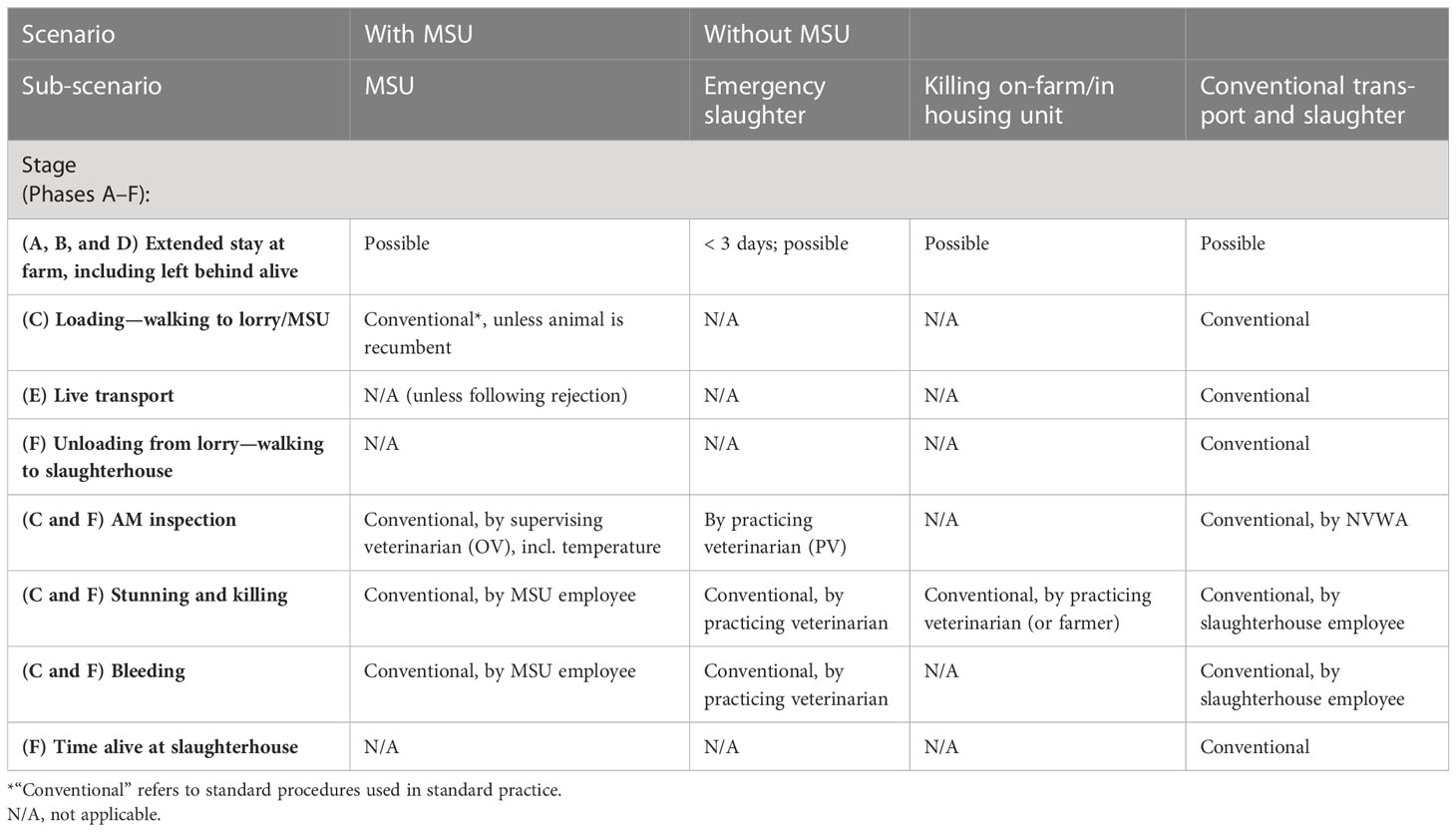

As the aim was to consider the absence versus the presence of the MSU, the identified scenarios were as follows: (1) scenario with MSU (future/pilot scenario) and (2) scenario without MSU (realistic/current scenario). However, the second scenario in practice took the form of multiple sub-scenarios (killing on-farm/in the housing unit; emergency killing on-farm; and conventional transport and slaughter), as described below.

Scenario 1: mobile slaughter unit

When a cow suffers a (health) condition, the condition can be either acute or (semi-)chronic. An acute condition is characterized by a (seemingly) spontaneous event, such as a broken leg caused by slipping. A (semi-)chronic condition is characterized by a longer duration and a situation that is likely to be enduring: for example, lameness due to osteoarthritis. Council Regulation EC/1/2005 (EC, 2005) stipulates that animals with either an acute condition or a chronic condition can be deemed unfit for transport.

The MSU pilot, as described here (Figure 2, scenario 1), considered mainly dairy cows that were unfit for transport, but were suitable for slaughter and human consumption. Occasionally, animals designated for emergency slaughter were also allowed, with the restriction that use of the MSU must conform to the emergency slaughter regulation: that is, slaughter would take place within 3 days of onset of the acute condition. Feral animals in nature reserves were—after initial participation—withdrawn from the pilot by the Dutch national forest service, and were therefore excluded from the present study. It was decided beforehand that healthy animals should be excluded from the MSU pilot, although regulations did not prevent them being killed using an MSU (LNV, 2018; BuRO, 2020).

Figure 2 Flow chart illustrating possible disposal routes for cull dairy cows with an acute or chronic (health) condition [adapted from (BuRO, 2020)]. Two scenarios were identified: (1) with mobile slaughter unit (MSU), and (2) without MSU, with the second scenario being split into three sub-scenarios (2A–2C). Blue: disposal routes which are in accordance with the current legal framework (scenario without MSU). Orange/brown: disposal route using the MSU. Red dotted lines: potentially unauthorized routes. *The conventional route to the slaughterhouse may involve transport to an assembly center and/or fattening pasture first. **Emergency slaughter de facto also involves killing on-farm/in the housing unit, but only of cows with an acute condition.

The MSU was developed and operated by a single Dutch slaughterhouse. The MSU operated in the northern part of the Netherlands (three provinces: Groningen, Friesland, and Drenthe). The MSU operating location was on-farm. In this Dutch MSU, the animal was killed and bled in the unit, whereas subsequent steps in the slaughter process, after killing and bleeding, were carried out at the stationary slaughterhouse. The MSU is a transport vehicle in which it is possible to create individual stands for a maximum of six cows. In this scenario, there were four distinct phases:

A. before registration;

B. after registration;

C. arrival at the farm;

D. leaving the farm.

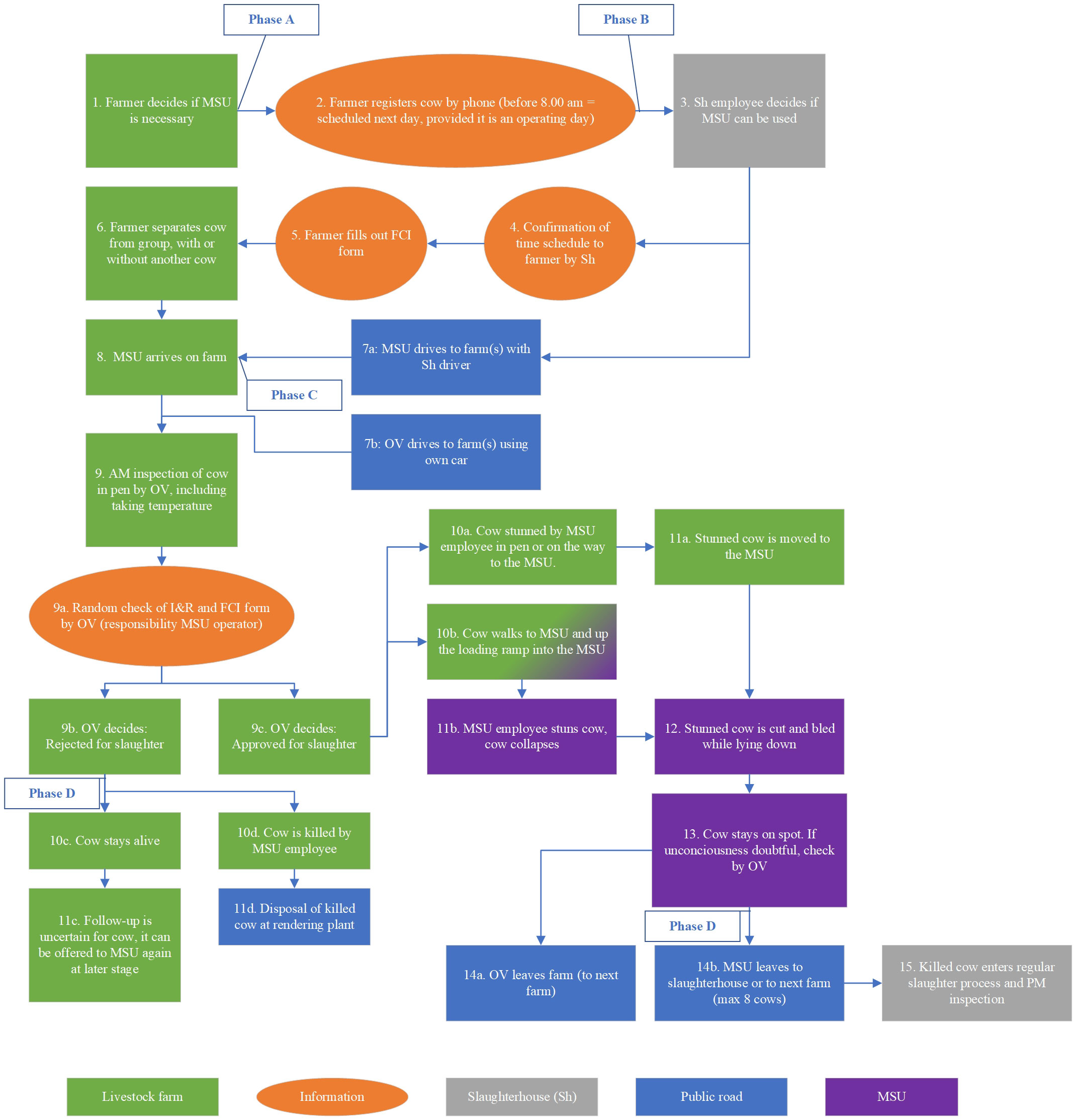

In short, during phase A the livestock farmer determined whether a cow had a (health) condition and decided whether it was appropriate to register the cow for killing at the MSU (see Figure 3 for process flow). The MSU operator could reject the cow and suggest that the animal be euthanized by a practicing veterinarian (personal communication, MSU operator, 2019). After approval by the slaughterhouse (phase B), the slaughterhouse determined a day and a time schedule for the MSU route and requested an OV to join the MSU. At the earliest, the MSU was scheduled to be on site the next day if registration took place before 8.00 am. The MSU operated 3 days per week. During the course of the pilot, it appeared, however, that the MSU schedule and route was adapted by the operator during operating days to include, for example, cows for emergency slaughter or exclude cows that were not free from fever according to the farmer. The MSU operator required that the registered cow be separated from the group before the arrival of the MSU (personal communication during MSU visit, 2019).

Figure 3 Flow chart of processes relevant to animal welfare before, during, and after operation of the MSU. Green = livestock farm; orange = processing of information; gray = slaughterhouse (Sh); blue = public road; purple = mobile slaughter unit (MSU). Phases indicated are: (A) before registration, (B) after registration, (C) arrival of MSU, (D) and departure of MSU.

On the operating day (phase C), both the MSU and the OV arrived on-farm (Figure 3). The OV carried out the AM inspection to decide whether the cow was admissible for slaughter. If the cow was allowed to enter the MSU, it was—if possible—directed by the farmer to the MSU via the loading ramp. In the MSU—or, if entry was not possible, in the housing unit or before the loading ramp—the MSU employee stunned the cow using a captive bolt pistol, and bled and killed it by severing the carotid arteries while the cow was in a recumbent position. The pin of the captive bolt penetrates the skull and, if it is applied correctly, heavy, irreversible damage to the brain occurs, meaning that the animal loses consciousness and cannot regain consciousness (Oliveira et al., 2018), but is not yet dead. Therefore, it was necessary to employ a method of killing after the stunning procedure; this was achieved by bleeding. Consciousness was checked if stunning was doubtful. The whole process, until bleeding of the cow, was supervised by the OV. The MSU left the farm (start of phase D) while the cow was still bleeding. The cow was kept in the MSU until all farms on the route had been visited; it was then delivered to the stationary slaughterhouse. If the cow was rejected at AM inspection, it could be stunned and killed by the MSU employee on-farm/in the housing unit (personal communication, NVWA meeting, 2020) and sent to the rendering plant. If rejected for slaughter at the MSU and not killed on the spot, the cow was left behind alive on-farm to follow a different (sub-)scenario or to recover until it was fit for slaughter and could be registered again for slaughter at the MSU.

Scenario 2: without MSU

Under this scenario, the same type of cows were considered (with a (health) condition, unfit for transport, fit for slaughter) as those approved for slaughter in the MSU, but here conventional practice (including several sub-scenarios) is described, as if the MSU was not in place. These sub-scenarios are:

2A. Killing on-farm/in the housing unit.

2B. Emergency killing on-farm.

2C. Conventional transport and slaughter.

Scenario 2A: without MSU—killing on-farm/in the housing unit

A cow with a chronic or acute condition that cannot regain fitness and is not fit for slaughter (i.e., not suitable for human consumption) has to be euthanized by a veterinarian or other qualified person (Figure 2, scenario 2A). In this sub-scenario, comparable phases were identified as in the scenario with the MSU (see phase A–D in scenario 1).

The owner of an animal decides upon its end-of-life situation (Deelen et al., 2022). In the case of a cow with a (health) condition (phase A), a decision is made by the farmer to let the animal try to recover (i.e., to do nothing), to provide (medical) treatment, or to have it killed by a practicing veterinarian (start of phase B). It may also happen that the cow is euthanized by another (qualified) person (e.g., a farmer or slaughterhouse employee) (personal communication, NVWA meeting, 2020), but data on this scenario are lacking. The animal may be separated from the group and relocated to another pen. Upon arrival of the practicing veterinarian (phase C), the cow remains in the on-farm housing unit and receives a lethal injection (anesthetic overdose) or is stunned by a captive bolt pistol and killed by destruction of the brain through pithing, with both methods supposedly producing a humane death (Hindle et al., 2010; Shearer, 2018). The animal is then offered to a rendering plant (phase D). The cow may be left alive, for example, if medical treatment is still possible, but information on this scenario is lacking.

Scenario 2B: without MSU—emergency killing on-farm

In the conventional situation, a cow with an acute (health) condition can be subjected to emergency killing on-farm, subsequently offered for slaughter, and used for consumption if it was deemed fit for slaughter (i.e., the cow is not suffering from any diseases) but not for transport (NVWA, 2017) (Figure 2, scenario 2B). This should be done within 3 days after the incident leading to the acute condition (e.g., an accident that led to a fracture). Animals with a chronic (health) condition are generally not suitable for emergency slaughter. This sub-scenario was also found to have four phases (phases A–D, as presented in scenario 1).

After determining the presence of a cow with an acute condition (phase A), the farmer requests emergency slaughter (phase B), to be carried out by a practicing veterinarian (NVWA, 2017). Before killing, the practicing veterinarian may act temporarily as an OV (NVWA, 2021) and carry out the AM inspection of the cow (phase C). In the Netherlands, stunning and killing of the cow are usually carried out by using a penetrating captive bolt pistol for stunning (personal communication, NVWA, 2020) and severing the carotid arteries to bleed and kill the animal (NVWA, 2017). The carcass of the cow is transported to a stationary slaughterhouse and the practicing veterinarian leaves the farm (phase D). Rejection at AM inspection is possible; therefore, a scenario in which the cow is left alive on-farm cannot be ruled out. However, due to the acute (health) condition, this is not likely, and it is more likely that the procedures presented in scenario 2A are followed for the cow.

Scenario 2C: without MSU—conventional transport and slaughter

The animals in this pilot were assumed to be unfit for transport and therefore should not have been transported. However, (1) it is not always clear whether an animal is fit (enough) for transport [based on Council Regulation EC/1/2005 (EC, 2005)], and (2) it seems plausible that some unfit animals are (e.g., for economic reasons) knowingly transported anyway (BuRO, 2018; Edwards-Callaway et al., 2019; BuRO, 2021). Therefore, the scenario where the cow is conventionally transported and slaughtered was retained as one of the disposal routes, possibly an unauthorized one (Figure 2, scenario 2C).

Chronically affected cows and cows with a transient acute condition can be directly or indirectly offered (usually via a livestock assembly center (NVWA, 2019)) for conventional slaughter at a stationary slaughterhouse. In this scenario, the same four phases were identified as those described in scenarios 1, 2A, and 2B, but with two additional phases (E–F):

E. Conventional transport.

F. Unloading at the slaughterhouse and conventional slaughter.

A farmer identifies an animal with a (health) condition (phase A) and can register it (phase B) for slaughter at a slaughterhouse and as being fit for transport. Upon arrival of the truck on site (phase C), the driver should verify that the cow is fit enough to endure transport (phase E) to the slaughterhouse or assembly center (EFSA-AHAW Panel, 2022). If the cow is transported to an assembly center, the cow is unloaded, usually mixed with other cows, and placed in a pen at the center, where the animals usually stay overnight. Animals are then selected for slaughter either in another (neighboring) country (export) (NVWA, 2019) or at a Dutch slaughterhouse. In the case of export, prior to reloading, an inspection is carried out in the pen or at the loading ramp by an OV for export certification. This inspection is less thorough than an AM inspection, as animals are usually inspected groupwise and not all animals are individually checked for body temperature (NVWA, 2019). Thereafter, the cow undergoes the remaining journey to a slaughterhouse abroad.

Upon arrival at the slaughterhouse, the cow is unloaded, after which the conventional process is followed until slaughter if the animal seems fit enough (phase F). If the cow is deemed unfit, the severity of its condition is checked and a decision is made whether or not to kill the animal on the spot (NVWA, 2022).

Animal welfare risks rapidly explored

The six identified phases (A–F) were used (see Figure 3 with phases A–D) to identify relevant hazards and welfare consequences, and thereby potential risks.

Hazard identification and characterization in each phase

Phase A: On the farm before registration

In this first phase, cows are in their normal on-farm situation. Many types of hazards may lead to a (health) condition making the cow unfit for transport. As hazards may interact with each other (EFSA-AHAW Panel, 2012a), it is relevant to consider the state of the animal in this first phase, as this may affect the welfare impact of hazards in later phases. To gain insight into the types of animals that were offered to the MSU (the target animals), a condensed list of hazards and welfare consequences is provided (Table 1); with respect to phase A, only hazards/welfare consequences for which a welfare impact score could be provided are presented in this table [see full list in Annex 7 of (BuRO, 2020)].

The welfare consequences varied from lameness to downer syndrome with a physical condition or disease. The welfare impact of the welfare consequences varied from 4 to 7 (with 7 being the worst score, indicating a very severe impact with a long duration), but score 4 was provided only once (Table 1). This implies that the welfare impact of the welfare consequences observed in cows offered to the MSU is substantial.

Among a selected set of cows offered to the MSU (n = 115 on 10 randomly selected days over the course of 1 year and n = 57 combi-inspections), 87% and 77% from these subsets, respectively, proved to be lame (with claw injuries, hock injuries, or other injuries leading to lameness). Another 12% of selected animals (n = 57) proved to be downers due to, for example, heavy calving or an accident.

Phase B: On the farm after registration

The waiting time for the cow to be killed or transported may vary among the different (sub-)scenarios, but there are no data on this. The cow may also be rejected from one of the (sub-)scenarios for variable reasons (e.g., the waiting period for veterinary medicines, its health status, or a full MSU schedule). The number of cows rejected during registration for the MSU or one of the other sub-scenarios is unknown. Hazards that were already present during phase A may remain present. Welfare consequences may persist with or without (medical) treatment. Newly introduced hazards for this phase are forced walking while lame, removal of the cow from familiar conspecifics to relocate it to a temporary pen or sick bay, and negative human–animal interactions (Table 1).

Relevant welfare consequences under phase B are, for example, unnecessary prolonged suffering, lameness, social stress, and fear of humans (Table 1). The welfare impact of the different welfare consequences was estimated to be moderate to very high (with scores falling within the range of 3–7 out of 7). No further information with respect to the prevalence of welfare consequences relating to phase B was available at the time of assessment.

Phase C: Arrival of slaughterhouse employee, practicing veterinarian, or transporter at the farm

Relevant hazards in this phase—some of which are similar to those mentioned in relation to previous phases—are inadequate flooring to walk across, careless loading (inadequate diligence (EFSA-AHAW Panel, 2004)), forced walking while lame, separation from familiar conspecifics, use of a prod, fixation of the cow, negative human–animal interactions (whether or not these have occurred in the past), inadequate stunning, and inadequate bleeding (too late or too slow), which may lead to the cow regaining consciousness (Table 1). Human handling is dependent on the variable set of persons present, namely the farmer, practicing veterinarian or OV, MSU operator, and/or transporter.

Relevant welfare consequences vary from discomfort around walking to fear and pain (Table 1). Welfare impact varies from none/limited (for inadequate flooring) to very high (for inadequate stunning and bleeding), with scores falling in the range 1–7 out of 7. The level of stress associated with being herded from the AM inspection location to the stunning area and with time of sticking in the MSh is very much dependent on the way in which the animals are guided or forced to this area (Hultgren et al., 2017). There were no data on herding time to the MSU, but this is expected to be short, as the MSU truck was placed as close to the holding pen of the cow as possible. Hultgren et al. (2017) state that short handling time and minimal negative interactions between human and animal can limit the welfare impact for cattle. In the Swedish study, the mean time to arrive in the stunning area of the MSh was 3 minutes for (probably healthy) cattle (range: 0:05–18:41 minutes). The mean time spent in the stunning area of the MSh was 30 seconds (0:08–2:08 minutes) (Hultgren et al., 2017).

The method of stunning affects the stress response of the animals as well as meat quality (reviewed in Eriksen et al., 2013). In the Swedish MSh, 10% of the animals needed to be stunned again because the first stunning attempt was not effective (Hultgren et al., 2017). Several studies have evaluated the effectiveness of stunning in cattle. Stunning with a penetrating captive bolt has been found to be ineffective in 2%–12% of animals, making multiple gunshots necessary. When stunning is performed using a captive bolt without a penetrating pin, 29%–46% of cattle require re-stunning (Neves et al., 2016; Oliveira et al., 2018). Most bovine animals (99%) stunned with a penetrating captive bolt collapse after shooting. In 1% of animals, behaviors occur that imply consciousness, such as eye rolling and attempting to stand up (Oliveira et al., 2018). In the study by Neves et al., no signs of consciousness (tongue squeezing, eye blinking, rhythmic breathing) were observed at 20 seconds or 60 seconds after stunning (Neves et al., 2016). Gibson et al. (2019) confirmed via electroencephalogram (EEG) that all animals (bulls) were stunned adequately on first application of the penetrating captive bolt (Gibson et al., 2019).

The stun-to-stick interval is unknown for the current MSU, but in a study with lambs slaughtered in an MSh, the time between stunning and sticking was ± 5.8-15.4 seconds higher compared to conventional slaughter at a stationary slaughterhouse (Eriksen et al., 2013). In the 2017 Swedish study with cattle, the stun-to-stick interval was on average 90 seconds (range: 0:24 minutes–3:22 minutes), with longer intervals for cows than for bulls (Hultgren et al., 2017). In a later Swedish study, the stun-to-stick interval was 104 seconds for the MSh and 44 seconds at a stationary—but small-scale—slaughterhouse (Hultgren et al., 2018). The stun-to-stick interval should not be longer than 30 s in mechanically stunned animals, in order to ensure that the animal remains unconscious during bleeding [Grandin and Committee 2013 in Verhoeven (2016)]. In (un-stunned) ritually slaughtered animals, it is not uncommon for blood to enter the airway of the animals. However, this phenomenon is also seen in animals that are stunned with a captive bolt, kept standing by fixation, and then bled. Blood in airways can lead to suffering if unconsciousness is insufficient (Gregory et al., 2009). In the MSU, cows are bled in a recumbent position.

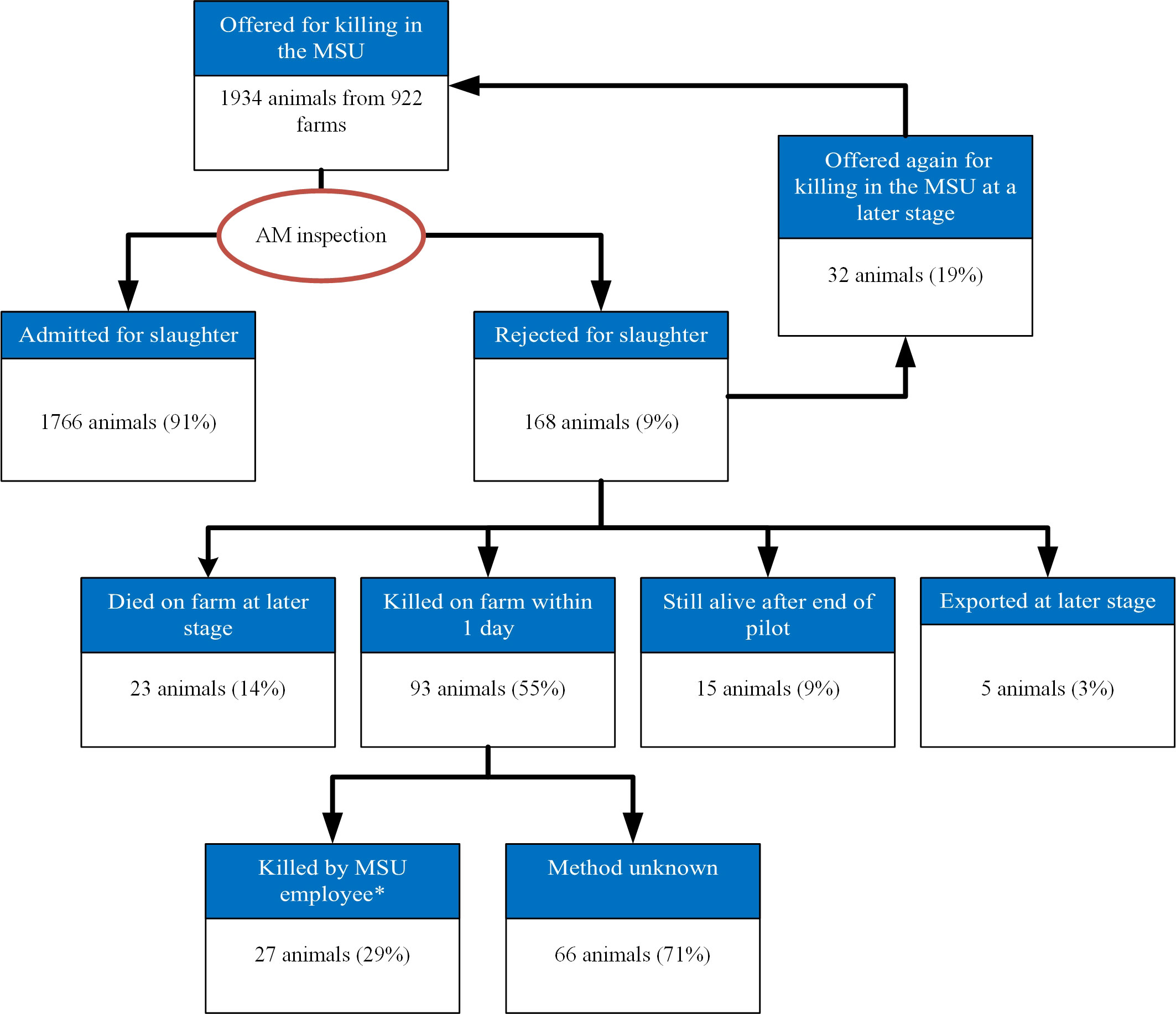

During phase C, the OV conducts the AM inspection and rejects some animals from entry to the MSU (Figure 4). At this time, 11% of cows were down and 8.7% were rejected for participation. Another 2.4% were rejected for consumption after PM inspection. It is unknown how many animals are rejected for emergency slaughter.

Figure 4 Flow chart of number of animals offered to the Dutch mobile slaughter unit that were either approved for or rejected for slaughter (December 2018–December 2019). Animals (n = 32) that were offered multiple times are included in the flow chart multiple times (i.e., 1,934 animals are not all unique animals). *Estimation based on selected MSU dataset.

Phase D: After the slaughterhouse employee, practicing veterinarian, or transporter has left the farm

The relevant hazards for cow welfare while the animal remains alive with a (health) condition have already been presented in relation to phases A and B, but especially relevant in phase D are those involving withholding of necessary care or treatment, which may lead to unnecessarily prolonged suffering (Table 1). Welfare impact remains similar to the impact during phases A and B, with unnecessarily prolonged suffering being the most relevant welfare consequence, with a welfare impact of high to very high (severe, with short to long duration). If animals are killed during this phase, hazards and welfare impact are comparable to those occurring during phase C, with inadequate stunning and killing having the highest welfare impact, as these lead to fear and pain, suffocation, and recovery to consciousness (Table 1).

In total, 32 animals that were rejected at AM inspection were later offered again to the MSU (Figure 4). One animal was offered three times. Of the rejected cows, 93 were killed on the same day or the day after (registered as “natural cause of death” in I&R data, although these deaths were not due to a natural cause). Whether these animals were killed by the MSU employee, by a practicing veterinarian (euthanasia), or otherwise was untraceable. Based solely on inspection reports from December 2018 to September 2019 (i.e., partial information), 29% of rejected animals were killed by the MSU employee and sent to the rendering plant. At the time of analysis, 9% of rejected animals (n = 15 out of 168) were still alive (I&R data), five animals were exported, and the remainder were registered as dead due to natural causes (which may include euthanasia) more than 2 days after the MSU visit.

Phase E: Conventional transport

The risks and underlying hazards of conventional transport of animals are thoroughly described by EFSA (EFSA-AHAW Panel, 2004; AHAW Panel, 2011; and now also EFSA-AHAW Panel, 2022) and by Wageningen Livestock Research (WLR) (Van Reenen et al., 2008; Van Dixhoorn et al., 2010; Visser et al., 2014b). Relevant factors during this phase were as follows: being unfit for transport, human handling, unfamiliarity of being transported, insufficient inspections (by the transporter) before and during transport, social (group) instability/mixing of unfamiliar animals, insufficient feed and water intervals, insufficient stocking density, insufficient roof height, unsuitable climate, travel time, resting periods, rough driving, introduction of pathogens, and administrative aspects such as emergency contact(s) and education of the animal caretaker/transporter. As transport is not present in the MSU scenario, hazards related to this phase have largely been summarized and are not presented separately in Table 1. An assessment of the prevalence of welfare consequences was therefore not needed for the rapid comparative risk assessment.

Transport is a major stressor in animals (EFSA-AHAW Panel, 2004; Eriksen et al., 2013). Transport hazards for healthy animals are associated with physiological stress observed by behavior, heart rate, respiration rate, rectal temperature, cortisol level, and epinephrine level (McCorkell et al., 2013). In bison, slaughter in an MSh has been found to result in fewer carcass bruises that need to be cut out compared to the incidence in bison transported to a stationary slaughterhouse. Bison have also been found to behave in a more agitated manner during the pre-slaughter phase when transported, which may indicate impaired welfare. Although domesticated cattle behave more calmly than bison (McCorkell et al., 2013), higher levels of agitation and more bruising may be relevant in transported cows as well.

Welfare consequences that occur as a result of transport of dairy cattle are diverse and vary from slipping to broken bones (Table 1). Welfare impact therefore varies from relatively low to very high (scores falling in the range 2–7 out of 7), with a very high welfare impact in dairy cattle already suffering from a condition such as lameness (Visser et al., 2015). Existing health conditions may deteriorate during transport (Dahl-Pedersen et al., 2018b; Edwards-Callaway et al., 2019), but travel time is not always associated with deterioration of the animal (Hultgren et al., 2018).

Phase F: Unloading at the slaughterhouse and conventional slaughter

Hazards at unloading are identified in detail by Wageningen Livestock Research (Visser et al., 2014a) and are related to the design of the unloading spot (presence of a steep slope or high steps; small size) and passage to the waiting area; flooring (slipperiness, holes); partitions/gates (sharp protrusions, corners, openings); climate (draughty, cold, warm, damp); and human handling (slamming of gates, yelling, high-speed movement, use of prods). Unloading should be conducted with care (EFSA-AHAW Panel, 2004). Hazards after unloading are related to the design of the waiting area and passage to the stunning and killing area, and include factors such as flooring, gates, and sharp protrusions (Visser et al., 2014a). These hazards are not all presented separately here, as this phase (F) is fully absent under use of the MSU. Assessment of the prevalence of welfare consequences was therefore also not needed for this rapid comparative risk assessment.

Hazards at time of stunning and killing are, again, related to the design of the area, flooring, and handling, and also to fixation and position of the animal, the stunning equipment, and (stunning and handling) methods, including implementation of an emergency plan, stun-to-stick interval, presence of blood in the respiratory tract while animal is conscious, and continuation of the slaughter process while the animal is insufficiently stunned (Visser et al., 2014a).

Exposure to the process from unloading to stunning and killing results in a cascade of reactions to the stressors present on the part of cattle (e.g., heightened levels of glucocorticoids, increased heart rate, increased respiration rate, and increased vocalizations), although it might not always be clear whether these reactions are actually attributable to transport stress (reviewed in Eriksen et al., 2013).

Many welfare consequences are similar to the consequences seen during transport. In addition, the welfare consequences related to stunning and killing are similar to those mentioned in phase C (Table 1) (Visser et al., 2014a). Welfare impact varies from very low to very high (with scores in the range 1–7 out of 7).

Estimation of exposure of cows

Animals presented to the MSU pilot

In total, 1,934 animals were offered for slaughter under the MSU pilot from December 2018 to December 2019 (Figure 4). After AM inspection, 1,766 animals were approved for slaughter. The animals came from a total of 922 farms and 930 locations (I&R data), covering 21% of the dairy farms in the northern part of the Netherlands. One-third of these locations offered one animal and one-quarter of the locations offered two animals. One location offered as many as 80 animals. The mean age of the slaughtered animals was 5.6 years, with the oldest cow being 18.2 years of age. In total, 7% of slaughtered cows from farms participating in the MSU pilot were killed by the MSU. These cows accounted for 2% of total cull cows aged over 2 years in the northern part of the Netherlands.

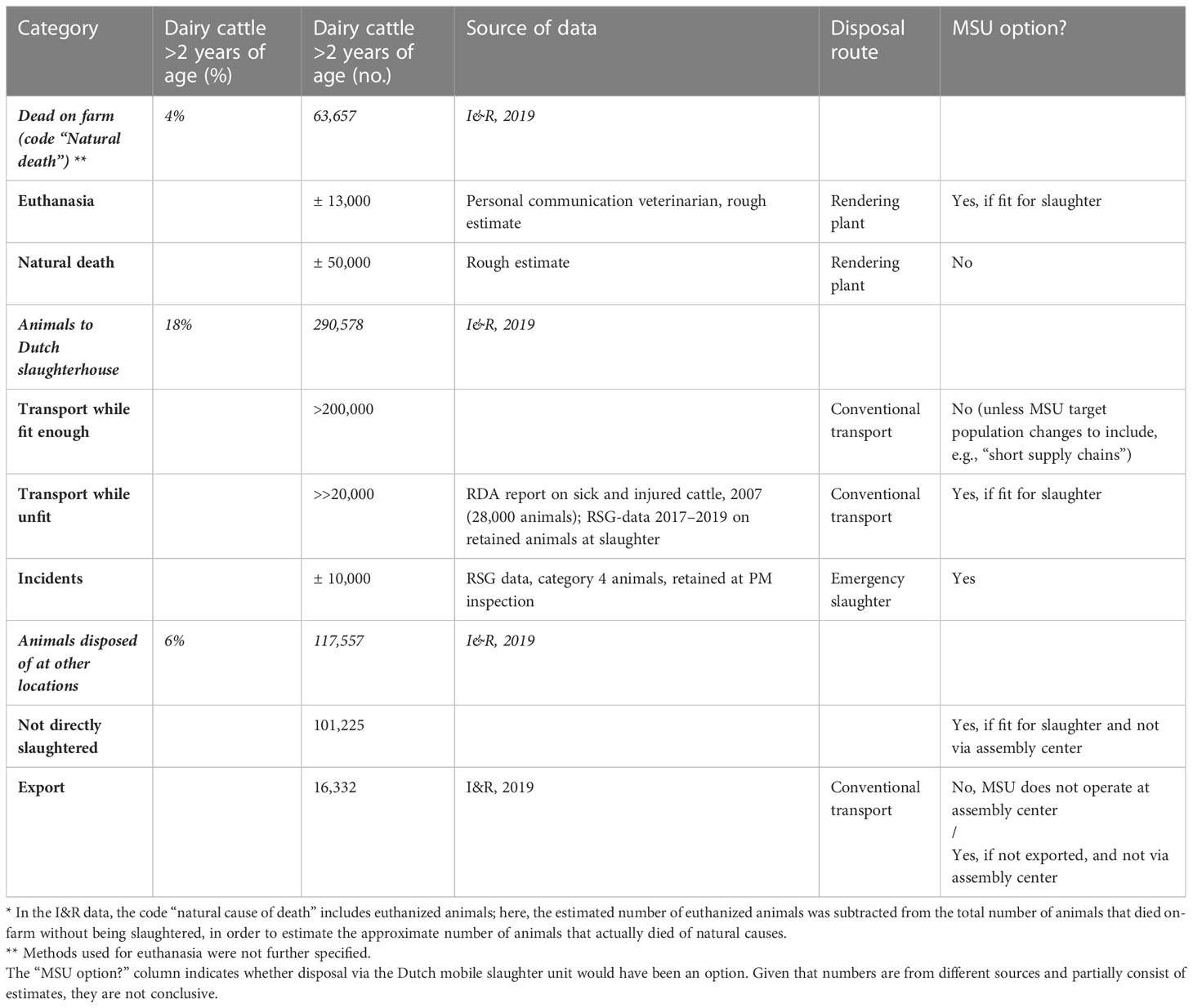

MSU target animals based on current sub-scenarios

To estimate the number of animals that are currently exposed to the different sub-scenarios 2A–C and how many cows may be target animals for the MSU (scenario 1), data or rough estimations from specific disposal and culling routes were extracted (Table 2).

The Dutch population of adult dairy cows (> 2 years of age) is approximately 1.6 million animals (CBS, 2022). In 2019, the annual replacement of 471,792 animals (28%) represented 63,657 animals (4%) that were reported dead on-farm (by both natural death and euthanasia), 290,578 animals (18%) that were presented to a Dutch slaughterhouse, and 117,547 animals (6%) displaced to other locations (e.g., sent to other farms for fattening or exported) (I&R data for 2019). Disposal was partly via cattle markets or assembly centers.

On-farm euthanasia (sub-scenario 2A) accounts for roughly 13,000 animals (personal communication, veterinarian, 2019) and emergency slaughter (sub-scenario 2B) accounts for approximately 10,000 animals (RSG NVWA data for 2017–2018). Regarding disposal by transport, 16,332 animals were exported to neighboring countries. A study in the Netherlands (RDA, 2007) indicated that roughly 28,000 sick or injured cows (of a population of 1.4 million adult dairy cattle in 2006) were sent to a Dutch slaughterhouse, of which approximately 10% were rejected at post-mortem (PM) inspection, as they should have been euthanized on-farm and offered for rendering. Furthermore, NVWA data (RSG 2017–2019) showed that approximately 20,000 cattle were identified as having health issues at AM inspection at Dutch slaughterhouses (sub-scenario 2C).

As presented previously, the farms participating in the MSU pilot assigned approximately 7% of their cull cows to the MSU. This indicates an estimated target population of between 14,000 and 33,000 animals per year (7% of 471,792 annual replacement cows, minus 50,000 cows that die a natural death, 200,000 fit cows, and 16,332 exported cows = 14,382; and 7% of 471,792 annual replacement cows = 33,025; see also Table 2). As the popularity of the MSU doubled during the year, this might even be an underestimate of the target population. Moreover, based on the RSG data, the disposal of 20,000 out of 290,578 animals at Dutch slaughterhouses implies that 6.9% of transported cull cows may be transported in an unfit condition (see Table 2). Therefore, it is estimated that the MSU target group of animals not fit for transport but fit for slaughter amounts to at least 20,000 animals per year in the Netherlands (scenario 1).

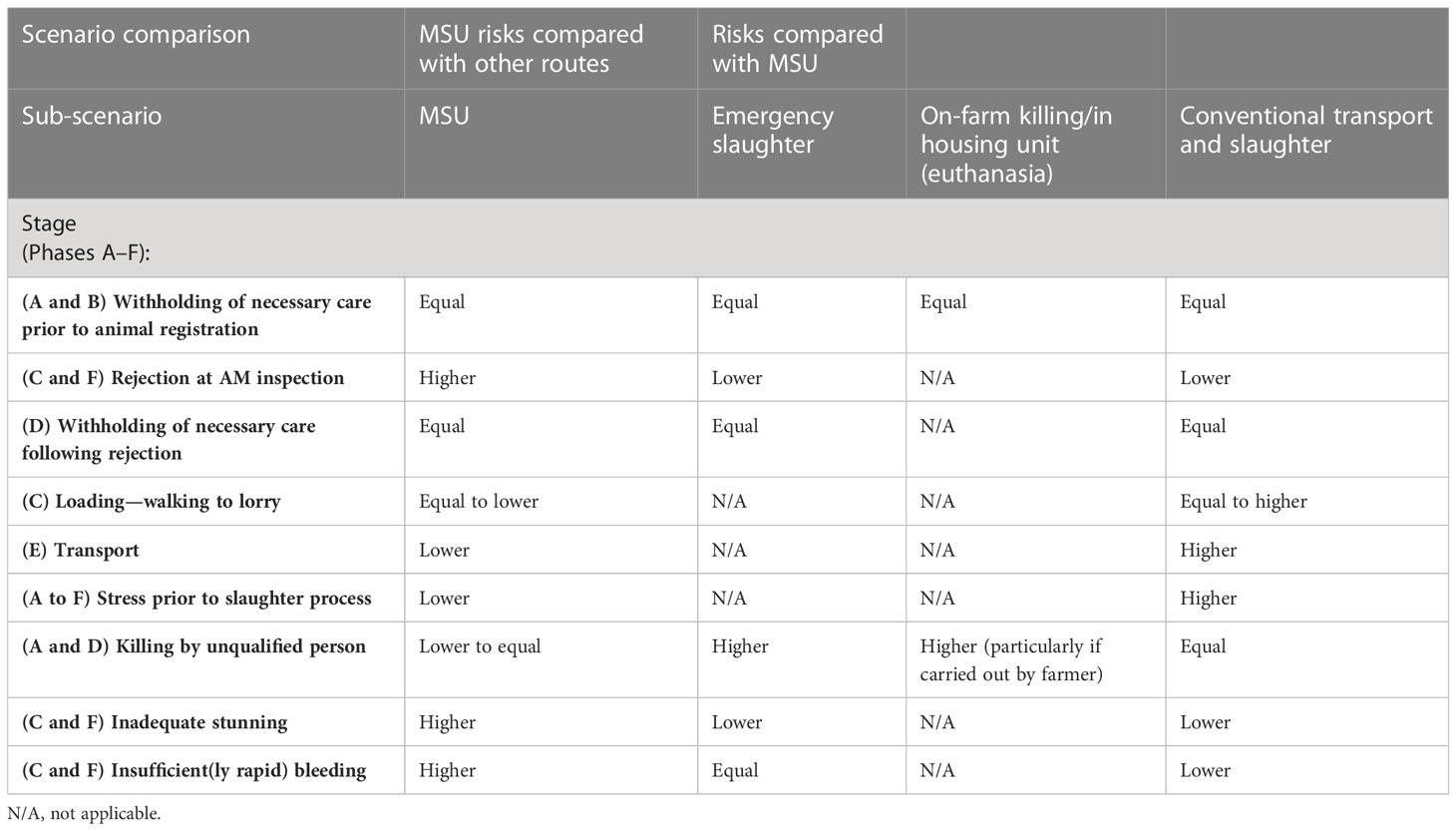

Comparison of scenarios through characterization of the risks

The (sub-)scenarios described above share several similarities and differences. In this section, risks resulting in welfare consequences with the highest expected welfare impact (scores of 5–7 out of 7) are considered. Risks may be aggregated or reformulated for practical reasons. The most relevant differences between (sub-)scenarios in terms of practices and risks are presented in Tables 3, 4, mainly with qualitative reasoning.

Table 4 Expected relevant differences between sub-scenarios and their phases, in terms of lower, equal, or higher risks.

Both scenarios start similarly, i.e., at the farm. The on-farm hazards and welfare consequences in phase A exist independent of which scenario is under consideration (i.e., with or without the MSU). Up until registration for one of the options, therefore, no differences in welfare risks are expected between the scenarios.

When the decision was made to use the MSU, lameness was the usual reason for disposal of the selected cows that were offered for slaughter to the MSU (see hazard characterization). Animals disposed of due to fertility issues, udder health, or low productivity are likely to be fit enough for transport to the slaughterhouse (Eurogroup for Animals et al., 2012; Consortium of the Animal Transport Guides Project (2017-rev1), 2018). Therefore, it is expected that when an MSU is available, there is a difference between the animals subjected to the different scenarios with respect to types of welfare consequence. However, the underlying welfare risks that lead to the different welfare consequences are not related to the different scenarios and are therefore not considered as relevant risks for comparison of the MSU with other scenarios.

A relevant risk to explore is the withholding of necessary care from animals with a (health) condition prior to registration (during phase A and B) in the different scenarios; this was one of the major concerns at the onset of this study (based on internal NVWA inspection reports). However, this risk is expected to be present in all (sub-)scenarios and there was no evidence pointing in the direction of a difference between the scenarios (Table 4). This risk may be related to withholding periods necessary for veterinary medicines, which are applicable only when animals are offered for slaughter and meant for consumption (under the MSU, emergency slaughter, and conventional slaughter scenarios). If no other treatment is given, existing welfare consequences, which can have a major welfare impact (Table 1), will persist and the welfare of the animal may deteriorate.

Registration of an animal to be killed by the MSU is conducted via the slaughterhouse that operates the MSU (transition from phase A to phase B). It was not possible to determine how often a waiting period was introduced by the slaughterhouse before the animal was offered for AM inspection, e.g., due to limited MSU capacity or a necessary withholding period for a veterinary product. Such a waiting period may result in an increase in welfare impact, as welfare consequences persist for a longer period of time, and severity may increase as well. Although there are no data, it is plausible that decisions regarding treatment are postponed when disposal via the MSU is under consideration. In addition, when the sub-scenario of killing on-farm/in the housing unit (by pithing or lethal injection) is followed, the farmer might await the arrival of the practicing veterinarian for another purpose to reduce veterinary costs, leading to prolonged suffering of the animal (Hindle et al., 2010).

Every animal offered to the MSU received an extensive AM inspection, including a body temperature check. If the body temperature deviated from normal values, the animal was rejected for slaughter at the MSU for food safety reasons (BuRO, 2020). It is more likely that animals offered to the MSU are rejected at this AM inspection because of this extensive inspection process (phases C and F) (Table 4). Approximately 9% of animals offered to the MSU were rejected for slaughter at AM inspection. When animals are exported, an inspection of the cows to check whether they are fit for transport is carried out by the OV. This inspection occurs groupwise rather than per individual animal and is conducted in the pen or on the loading ramp. It must be noted that transport from the farm to the export facility has already occurred before this check. In the case of domestic livestock transport, the truck driver and farmer decide whether an animal is fit for transport, and an AM inspection is carried out at the stationary slaughterhouse. At a stationary slaughterhouse, the OV checks the body temperature of animals only when this is deemed necessary. Approximately 1% of animals are rejected for slaughter at the stationary slaughterhouse (BuRO, 2020). When a practicing veterinarian is hired for the emergency slaughter of a cow, a less thorough AM inspection is conducted (NVWA, 2017). No data are available with respect to rejection for emergency slaughter. In the case of euthanasia (lethal injection or pithing), carcasses are sent to the rendering plant and are not used for consumption; therefore, AM inspection and checking of body temperature are unnecessary.

Rejection of an animal for slaughter may lead to further withholding of necessary care from the animal (phase D) (Table 4). If it is rejected in any of the (sub-)scenarios, no difference is expected between those scenarios with respect to withholding of necessary care. Rejection for slaughter is not applicable in cases of euthanasia, as these animals are not offered for slaughter.

Only animals offered to the MSU and for conventional slaughter may need to walk to and onto a truck (phase C) (Table 4). In the case of the MSU, however, it is also possible to stun and kill the animal in the pen (in the case of a downer) or on the way to the loading ramp. The risk that animals with a (health) condition are forced to walk (on)to the truck is, therefore, expected to be equal to or lower for the MSU scenario than for the conventional transport and slaughter scenario. In the sub-scenarios in which animals are offered for emergency slaughter or otherwise killed on-farm, animals do not need to be moved while still alive.

Stressors prior to the slaughter process (phases A–F) occur in all (sub-)scenarios. However, animal welfare risks during transport (phase E) and the additional risks at a stationary slaughterhouse (phase F) do not occur when animals are subjected to the MSU process, nor when they are subjected to emergency slaughter or otherwise killed on-farm (Table 4). In a study involving an MSh for bison, it was stipulated that on-farm slaughter indeed means that animals are not transported, but they are also not exposed to an unfamiliar environment or deprived of food and water (McCorkell et al., 2013). In addition, it likely takes a longer period of time for animals to be stunned and killed when they are offered for conventional slaughter at a slaughterhouse than when they are offered to the MSU, subjected to emergency slaughter, or killed via another killing method (euthanasia by lethal injection or pithing); however, there are no data on this. Animal indicators seem to suggest that stunning and killing in a mobile facility can be considered less stressful than conventional stunning and killing at a slaughterhouse. In lambs, less vocalizing and less aggressive behavior (including mounting) are observed at a mobile facility than at a conventional slaughterhouse. There are also indications that mobile-slaughtered lambs have lower levels of blood cortisol and higher blood glucose levels, in combination with a lower meat pH level and more tender meat, compared to those subjected to conventional slaughter at a slaughterhouse (Eriksen et al., 2013). In bison, cortisol levels have also been found to be lower at mobile slaughter than conventional slaughter (McCorkell et al., 2013). However, not all results have been equally unequivocal in indicating lower stress in mobile-slaughtered animals, and the physiological results do not clearly indicate at which points higher or lower levels of welfare are experienced during the entire process. In addition, the speed of recovery to basal levels is relevant for accurate interpretation of possible differences between scenarios (Eriksen et al., 2013).

If an animal is not fit for transport or emergency slaughter, the farmer may decide to kill the animal by other means to limit additional veterinary costs (Hindle et al. (2010); personal communication, meeting with NVWA inspectors and OVs) (phases A and D). If killing is carried out by an unqualified person—which is expected to occur rarely—the chance of insufficient killing is likely to increase, which may lead to suffering for the animal, but there are no data on this. Availability of the MSU may decrease these odds (Table 4).

No estimation of the welfare impact of inadequate stunning (phases C and F) was available (Table 1). However, stunning itself leads to fear, with a high to very high impact on welfare. Further processing of conscious animals also results in a (very) high welfare impact for individual animals. Therefore, the relevant risks for welfare for comparison are considered to be inadequate stunning and insufficient bleeding (Table 4). At the MSU, the slaughterhouse employee shoots the animal whilst positioned next to it. This means that the employee moves his/her arm across a partition and has only limited space to stun the cow. In addition, the head of the cow is kept in position by the employee using a rope halter, and this requires a high level of professional skill. MSU design may affect stunning efficacy, but conversely, MSU employees have a high level of experience. Practicing veterinarians, in contrast, often lack this high level of experience in stunning and bleeding of animals; it is estimated that they handle a penetrating captive bolt gun only once or perhaps a small handful of times per month. The chances of inaccurate stunning are higher, therefore, in cases of emergency slaughter than at a stationary slaughterhouse (NVWA, 2017), and thus also than at the MSU. In sheep, the quality of stuns has usually been found to be sufficient at both mobile and stationary slaughterhouses, although some incidents have occurred at stationary slaughterhouses in which animals showed signs of consciousness (rhythmic breathing and eye reflexes) (Eriksen et al., 2013). A comparison between a small-scale stationary slaughterhouse and a mobile slaughterhouse showed a higher occurrence of corrective stuns at the mobile facility (Hultgren et al., 2018).

With respect to bleeding sufficiency, use of the “open head” slaughtering method (throat cutting from ear to ear), in combination with the way the animal collapses and lies down in the MSU, seems (based on an MSU visit) to be critical in correctly severing the carotid arteries. Both in MSU slaughter and during emergency slaughter, the cow is bled while lying down. Bleeding while in a recumbent position, i.e., with the carotid artery pressed or clogged, might slow down blood flow. The onset of death may take 10 minutes in the case of recumbent bleeding (Terlouw et al., 2016). The welfare impact of incorrect bleeding was estimated to be very high (Table 1). In case of doubt, the OV present at the MSU would double check (in addition to the check performed by the MSU employee) for loss of consciousness after stunning and bleeding. Thereafter, the MSU leaves the farm (as it is under high time pressure) and no further check for correct bleeding or consciousness can be conducted during transit. In a stationary slaughterhouse, animals are hoisted and bled, ensuring sufficient blood flow, and the cow is further processed immediately afterward, meaning that it is not possible for the onset of death to take 10 minutes under the conventional slaughter scenario.

Discussion

The Dutch MSU has been described and a rapid comparative risk assessment of animal welfare carried out, comparing the MSU with conventional practice.

Animal welfare and the use of mobile facilities for killing

The rapid comparative risk assessment of cow welfare presented above has provided insight into the probable most prevalent conditions of cows when they are offered for slaughter to a Dutch MSU. Lameness was most prevalent, but another important reason for cows to be considered unfit for transport during this pilot was the presence of injuries due to accidents and diseases. It is likely that lame cows are at the greatest risk of being transported in an unfit condition while the MSU remains unavailable in practice, as this is an important reason for culling, and assessment of fitness for transport of lame cows is not too uncommon among farmers, veterinarians, and truck drivers (e.g., Dahl-Pedersen et al. (2018a)). Lameness is, however, not a risk of the MSU itself, but a reason for a farmer to involve an MSU to avoid transportation of lame cows to the slaughterhouse or disposal of meat safe for human consumption at a rendering plant. In dairy farming, a total of 15%–25% of cows are clinically lame (Amory et al., 2006; Boer et al., 2013; Visser et al., 2015; Cook et al., 2016), up to 80% are sub-clinically lame (reviewed in (Bruijnis, 2012)), and 15% of cull cattle are slaughtered due to lameness (Boer et al., 2013).

The MSU itself does not affect existing on-farm risks to animal welfare. However, the state in which an animal is offered for slaughter to an MSU may affect the welfare impact of other hazards that an animal is exposed to during the process. For example, driving a lame animal to the MSU may worsen suffering, but there is no evidence to support this. In addition, it can be argued that exploitation of the MSU may occur in the form of lower levels of effort by farm management to reduce the existing risks that cause lameness, as the availability of the MSU enables cows to be disposed of for an economic profit despite lameness. However, without access to an MSU, farmers may keep a lame cow for a longer period of time while trying to regain its fitness (thereby prolonging its suffering). In such cases, the MSU provides an opportunity to dispose of the cow earlier.

Higher animal welfare risks when using an MSU are related to a higher expected chance of rejection at AM inspection due to the more thorough inspection of individual cows that is conducted before they enter the MSU, and a higher chance of inadequate stunning and insufficient bleeding due to the design of the MSU (i.e., its effect on ease of shooting) and the fact that the cow is not hoisted. If animals are rejected after AM inspection and not directly killed, welfare consequences already present in the animal persist and its condition may deteriorate further. The uncertainty in this case arises from the fact that a CA, such as the NVWA, does not have full and structural insight into what happens on the farm after rejection. This lack of insight also applies to the other sub-scenarios in which animals may be rejected and left behind alive, namely, emergency slaughter and transport to the slaughterhouse. This potential risk has not been acknowledged before with respect to mobile slaughter, likely because the Dutch MSU is specifically used for unfit dairy cattle, likely with a higher chance of rejection, whereas other mobile facilities have usually been used for fit animals (e.g., Hultgren et al. (2017) and USDA (2017)). The efficacy of stunning in relation to mobile slaughter is mentioned by Hultgren; shooting firearms or captive-bolt guns at a right angle may be difficult (Hultgren, 2022). The risk of insufficient bleeding has, to the best of our knowledge of the literature, not been specifically associated with mobile slaughter before, but has been associated more generally with the use of a recumbent lying position, which may obstruct blood flow (Terlouw et al., 2016). For example, in the study examining mobile slaughter of lambs, the lambs were shackled and hoisted into the mobile unit after collapsing (Eriksen et al., 2013) and not bled while recumbent.

Other identified welfare consequences and their underlying risks related to mobile slaughter are likely to have a lower impact on welfare (Table 1) and/or are of less relevance in the comparison of scenarios. It is unknown whether a difference between the (sub-)scenarios should be expected with respect to periods where a cow needs to await the next step of the process (especially after registration for a scenario, with delays arising for practical or economic reasons) under the different scenarios, as sufficient information is lacking for all (sub-)scenarios.

Greater difficulty may be associated with stunning, bleeding, and the development of adequate tools in the case of mobile slaughterhouses than in the case of stationary slaughterhouses. Such mobile facilities are likely to be more prone to capacity issues with respect to availability of employees, and also to technical issues (Eriksen et al., 2013). In the case of the privately owned Dutch unit involved in this pilot, intended for animals with a relatively low economic value, experience showed that the route of the MSU was tightly scheduled time-wise (time is money). This may have resulted in high time pressure for MSU employees and may affect the quality of the procedures performed, for example the practice of further bleeding the animal while driving to the next location. Lambooij et al. (2011) state that the feasibility of a mobile slaughterhouse is largely dependent on the scale of use of such facilities: that is, the more days they are in use, the more affordable they are (Lambooij et al., 2011). The success of such facilities may benefit from practical experience and research, which may lead to “a more liberal view of local meat and mobile slaughter” (Hultgren, 2022).

Other relevant beneficial aspects of the MSU associated with farm management are mortality registration and disposal of animal products such as blood. When a cow is killed on-farm, it needs to be signed off in the Livestock I&R system of RVO, resulting in registered on-farm mortality (RVO, 2022). High registered on-farm mortality is unfavorable for operational management of the farm (BuRO, 2021). If an MSU is used, registration of slaughter or death (in cases in which the animal was killed by an MSU employee but was not fit for slaughter) is attributed to the slaughterhouse. In addition, use of an MSU may be preferable to emergency slaughter for reasons relating to hygiene and animal health, as bleeding of the animal is performed in the MSU instead of on-farm in the housing unit, where blood cannot be captured.

In the current study, the available information was very limited; the data were not suitable for proper statistical analysis, and in this respect, information was often not specific to the MSU. A lack of knowledge exists with respect to animal welfare in mobile killing and slaughter facilities, and the differences between such facilities and conventional practice (Hultgren, 2022). The rather obvious animal welfare benefits of implementing an MSU scheme are prevention of the transport of unfit animals and reduction of the number of risks that cows encounter when offered for slaughter at an MSU compared with those offered for conventional slaughter at a stationary slaughterhouse. Hultgren (2022) also acknowledges this beneficial effect of mobile abattoirs on animal welfare, stating that they can avoid “unnecessary handling and transport of live animals to slaughter” (Hultgren, 2022). The total reduction in risks to animal welfare when the whole process, from transport to slaughter in a stationary slaughterhouse, is replaced by slaughter in a mobile facility outweighs the potential increase in animal welfare risks associated with a mobile facility. Furthermore, the few existing experimental studies of mobile slaughter facilities have considered animals of different species (sheep, cattle, and bison), animal categories (e.g., bulls, heifers, and cows), and breeds (e.g., beef and dairy breeds); all these studies have involved healthy animals, or at least the presence of unfit animals is not mentioned (e.g., Eriksen et al., 2013; McCorkell et al., 2013; Hultgren et al., 2017). These studies do not specifically consider cull dairy cattle with a (health) condition, which was the target population of the current Dutch pilot of an MSU. Therefore, extrapolation of animal welfare risks from these studies to the current rapid comparative risk assessment should be considered with caution.

Management response, policy decision, and MSU implementation

Considering multiple existing scenarios is essential to be able to put possible animal welfare risks associated with the MSU in the perspective of the entire dairy farming sector. We determined the benefits of an MSU to be greater than the potential risks, provided that additional conditions are set by the authorities. We advised use of the experience gained during the pilot and the risk assessment to define better protocols and conditions, and to advocate for formalization of these protocols and conditions by the Minister of LNV. In addition, we advised that specific conditions be set for every farm animal species and for feral animals that may be offered for slaughter to the MSU in future. We also advised that the use of (illegal) pain medication in the cows most likely to be at risk of being transported in an unfit condition should be monitored, as there is a relationship between this practice and food safety as well (BuRO, 2018; BuRO, 2020). This practice also indicates a larger system failure if farmers feel the need to use such means to make a profit.

This advice was adopted in full by the Inspector General of the NVWA, as stated in the response of the management, leading to the introduction of mitigating measures (NVWA, 2020b). These mitigating measures were, for example, random joint inspections by an inspector and OV of the NVWA at farms that offer animals to the MSU, in order to protect the welfare of cows that are left behind alive; the addition of professional competence requirements for the MSU employee to the MSU protocol of the slaughterhouse, which will be enforced by the OV of the NVWA; tightening of the fit-for-transport criteria at export certification; more attention to the supply of animals at small- and medium-sized slaughterhouses (which lack permanent supervision); and a risk analysis at livestock farms to supervise the timely treatment or disposal of unfit animals (NVWA, 2020b).

As a follow-up, the evaluation of the MSU pilot (NVWA, 2020b) marked the end of the pilot, and the future structural use of the MSU could be considered afterwards (LNV, 2020; Tweede Kamer, 2020). The Dutch politically determined goal was to bring MSUs into operation in 2022 (Tweede Kamer, 2021), after the approval of new EU legislation for mobile facilities [Commission delegated Regulation (EU) 2021/1374 (EU, 2021)]. However, NVWA capacity was insufficient for the supervision of active MSUs, as they all need the full-time presence of an OV during the stunning and killing of animals (Tweede Kamer, 2021). At present, the use of an MSU is considered to be economically unviable due to strict limitations on the number of carcasses [three, on the basis of the adjusted EU Council Regulation 853/2004 (EC, 2004)] that can be transported by the MSU in a single run for reasons of processing time and hygiene. The economic viability of mobile slaughterhouses has also been presented as an important issue by others (Carlsson et al., 2007; Hultgren et al., 2018). However, economic profits thanks to mobile slaughter facilities have also been proposed in the case of small-scale farming, possibly preventing shrinkage and reducing trim loss due to exclusion of transport (for bison; McCorkell et al., 2013), and creating value-added meat based on, for example, claims of good animal welfare. The latter aspect is likely to be highly related to the presence of consumers that “have a positive attitude, feel morally obligated to take action, perceive supportive social norms, and believe in their own ability to buy MSU meat” (Hoeksma et al., 2017).

The wish of the European Parliament (EC, 2019) is to support options for on-farm and mobile slaughter by Member States to improve animal welfare, among other considerations. Furthermore, the target population of MSUs will likely increase in the Netherlands and in the EU as a whole when enforcement with respect to transport fitness is intensified in future (BuRO, 2020). However, both the legislation and the standards in place are not necessarily suitable for new mobile facilities (Hultgren, 2022).

Conclusion

The risks of the MSU that are expected to be most relevant (compared with conventional practice) are:

● not killing the cow when it is not approved for slaughter at AM inspection (the cow is left alive on farm while having a (health) condition);

● forcing the unfit cow to walk to and onto the MSU (although the risk associated with this is lower than that associated with the conventional transport of an unfit cow);

● insufficient stunning and bleeding, which may result in the cow regaining consciousness (although the risk associated with this is lower than that associated with emergency slaughter).

The most beneficial outcomes of the MSU, by far, are expected to be:

● not transporting unfit (and less fit) animals, thereby preventing a greater deterioration of welfare during transport than occurs in the case of fit animals;

● not exposing the animal to the multiple conventional stressors present at the stationary slaughterhouse.

When a mobile slaughter unit is operated appropriately and with sufficient supervision, its use can potentially reduce the welfare risks for dairy cattle that are unfit for transport but fit for slaughter. Such facilities may be beneficial to a possibly growing population of unfit cattle when more strict regulations are set in place with respect to transport fitness.

The rapid comparative risk assessment of the MSU for animal welfare supported swift decision-making by risk managers. Policymakers ended the MSU pilot, and measures were developed by the enforcement agency to mitigate potential risks if the MSU is adopted for operation. Although the current approach entails high levels of uncertainty due to missing data, it does aid in bringing researchers, risk assessors, enforcement agencies, policymakers, and sector representatives in the field of animal welfare closer together. It is important to develop an appropriate experimental design for studying future mobile facilities in order to collect sufficient data and to monitor animal welfare risks alongside existing rules and practice.

Author’s note

This article is based on the (copyright-free) Advice of the Director of the BuRO-NVWA on animal welfare, animal health and food safety risks of the mobile slaughter unit pilot in the northern Netherlands region [see (BuRO, 2020)], i.e., sections of the advice document and this article are similar. The focus in the current article is on animal welfare only; recent literature was explored and added.

Data availability statement

Public data used for this study can be found online (CBS.nl), further information is available upon reasonable request at NVWA: dy53LnVyc2ludXNAbnZ3YS5ubA==.

Ethics statement

Ethical review and approval was not required for the study of animals in accordance with the local legislation and institutional requirements.

Author contributions

WU wrote the original draft of the manuscript and took primary responsibility for the risk assessment. AV revised the manuscript and took primary responsibility for data collection and analyses. JB revised manuscript, acted as project leader, and took primary responsibility for general information and context. DS revised the manuscript and took primary responsibility for the research design. All authors read and approved the final paper.

Funding

This research was financially supported by the Office for Risk Assessment & Research (BuRO) as an independent part of the Netherlands Food and Consumer Product Safety Authority (NVWA). The NVWA is an independent agency within the Dutch Ministry of Agriculture, Nature and Food Quality (LNV). No additional funding was obtained.

Acknowledgments