- School of Civil Engineering, Guangzhou University, Guangzhou, China

The aggregate skeleton of hot-mix recycled asphalt mixture comprises reclaimed asphalt pavement (RAP) and new aggregate and is a complex skeleton system containing old and new aggregates. The RAP content in the mixture directly determines the mechanical response characteristics of the composite skeleton, thus affecting the road performance. In order to explore the effect of RAP content on the characteristics of composite skeleton, in this study, the contact points in the composite skeleton were classified into three types: “new–new,” “new–old,” and “old–old.” On the basis of digital image technology and weight analysis methods, the distribution characteristics of the contact type of AC-13 mixture skeletons with different RAP contents were investigated; the correlation between the weight parameters of the contact type and the macroscopic mechanical properties of the mixture was studied. The results indicate that grading is the main factor that affects the total number of contact points; with increasing RAP content, the overall trend of “new–new” contact points is decreasing; the “old–old” contact points increase monotonously and then rapidly after the RAP content reached 40%; and the “new–old” contact points increase first and then decrease, with a peak corresponding to 30% RAP. With the increasing number of “new–old” contact points, the mechanical indexes of the recycled asphalt mixture were enhanced. The weight analysis method can more simply and clearly reflect the correlation between the contact type of coarse aggregate and the mechanical parameters of the mixture. In the mixing ratio design of the recycled asphalt mixtures, choosing a mixture with more “new–old” contact points achieved better road performance; therefore, effectively increasing RAP content may be one of the potential ways to enhance road performance.

Introduction

At present, the waste and old asphalt mixture produced by China’s highway maintenance and repair reaches hundreds of millions of tons every year (Chen, 2011; Zhang et al., 2020). The “Twelfth Five-Year Plan” clearly proposed that the recycling rate of highway old pavement material should reach over 95% in 2030, indicating that the strategic focus of China’s highway development gradually shifts from large-scale construction to equal emphasis on construction and maintenance. With more and more environmental considerations and the rising cost of construction materials, the addition of reclaimed asphalt pavement (RAP) to asphalt pavement mixture has become a necessary and economic method (Cong et al., 2016). Although many countries set 50% as the maximum RAP content, in practice, the content is mostly 15–30%, and RAP is even not allowed to be used in the surface layer of the road in some countries (Plati, 2019). Studies have shown that the RAP content of hot-mix recycled asphalt mixture is mostly controlled within the range 20–30%. High RAP content significantly reduces the durability of hot-mix recycled asphalt mixture (Valdés et al., 2011; Arshad and Qiu, 2013). Han et al. (2019) considered that the RAP content of the recycled mixture significantly affects its performance. With increasing RAP content, the tensile strength of the mixture usually increased, but the tensile strain decreased. Ai-Qadi et al. (2007, 2009) found that, although the use of RAP can enhance rutting performance, it may not necessarily improve its fatigue performance. The reason is that the higher stiffness of the old asphalt increases the strength of the mixture, which is more prone to fatigue cracking and low-temperature embrittlement. Zhang et al. (2019) pointed out that the use of RAP, instead of natural aggregates, significantly enhanced the dynamic stability of the recycled asphalt mixture. According to the result of the three-point bending test, RAP weakens the cracking resistance of the recycled asphalt mixture at low temperature. Mannan et al. (2015) pointed out that the incorporation of RAP would reduce the fatigue life of the mixture. The comparison between the fatigue performance of the asphalt mixture with 35% RAP and ordinary asphalt mixture indicated that the fatigue performance of the recycled asphalt mixture deteriorates, as evidenced by the four-point bending test, but that of the recycled asphalt mixture with aged asphalt is enhanced, as observed by the dynamic shear rheometer test. Wang D. et al. (2019) studied the performance of recycled asphalt mixtures using the repeated recycled RAP and experimentally evaluated the durability of the recycled asphalt mixtures. The results indicated that during the primary and the secondary aging processes, the creep performance of the recycled asphalt mixture both reduces and the mixture exhibits a brittle failure. Ma et al. (2015) reported that RAP was beneficial to enhancing the water stability of warm mix asphalt and hot-mix Asphalt mixtures. Furthermore, the water stability of the mixture increased with increasing RAP content. Based on the in-lab test on mixtures, Pradyumna et al. (2013) concluded that the addition of RAP can improve the performance of all the asphalt mixtures with 20% RAP.

The existing researches mainly focus on asphalt aging, regeneration mechanism, grading, etc., but did not fully consider the characteristics of RAP itself and the contact/fusion with new materials. From the perspective of material composition, asphalt mixture is a typical multi-phase granular material. Several researchers investigated and determined the morphology of the coarse aggregate skeleton of asphalt mixture via digital image technology (Tan et al., 2009; Lopes et al., 2016; Li et al., 2019). Wang et al. (2016) concluded that, at the same aggregate particle size, the thickness of the asphalt film increased with increasing amount of asphalt. At the same asphalt content, the thickness of the asphalt film increased with decreasing size of aggregate. Moaveni et al. (2016) pointed out that the asphalt film has a certain effect on the size and shape properties of RAP particles. Li et al. (2018) studied the effect of aggregate contact situations on the stability of asphalt mixture skeletons and concluded that, with increasing temperature, the aggregate skeleton significantly affected the stability of the asphalt mixture skeletons. The contact situations had a greater effect on the stability of the mixture at high temperatures. However, with increasing temperature, the effect of asphalt changed from viscous action to a lubricating effect; therefore, it became unfavorable for the stability of the mixture.

The recycled asphalt mixture containing RAP has interfaces with different strengths (Chen et al., 2020a). These contact interfaces restrain each other and affect the deformation consistency of the mixture together, which in turn affects the rheological properties of the material. Therefore, considering the characteristics of the composite skeleton system of the recycled asphalt mixture consisting of RAP and new aggregates is valuable (Ma et al., 2018; Ding et al., 2019; Chen et al., 2020b; Zhu et al., 2020). On this basis, the effect of RAP content on the characteristics of the composite skeleton is explored. In this study, the contact points in the composite skeleton were classified into three types: “new–new,” “new–old,” and “old–old.” Based on digital image technology and weight analysis method, the AC-13-type composite skeleton with different RAP contents was analyzed, and the distribution characteristics of the contact type were studied to find the correlation between the weight parameters of the contact type and the macroscopic mechanical properties of the mixtures.

Digital image processing technology was born in the 1960s. After continuous development, digital image processing technology has been widely used in various research fields (Chen et al., 2019; Tang et al., 2020). Digital image technology can be used to evaluate the internal structure of asphalt mixtures. Based on digital image processing technology, this paper analyzes the contact characteristics of coarse aggregates of recycled asphalt mixture and defines the three types of contact of coarse aggregates in the mixture.

Raw Materials

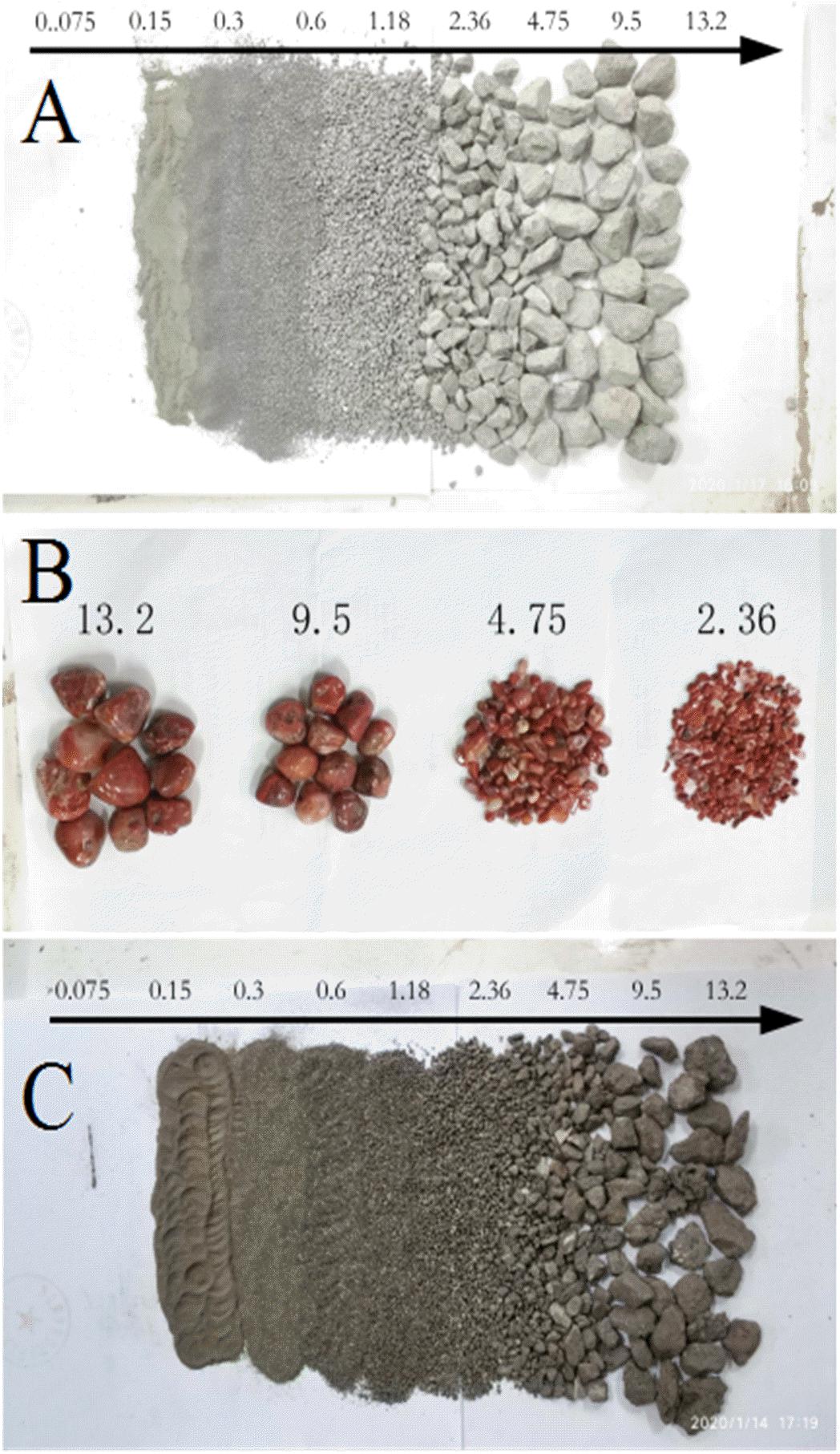

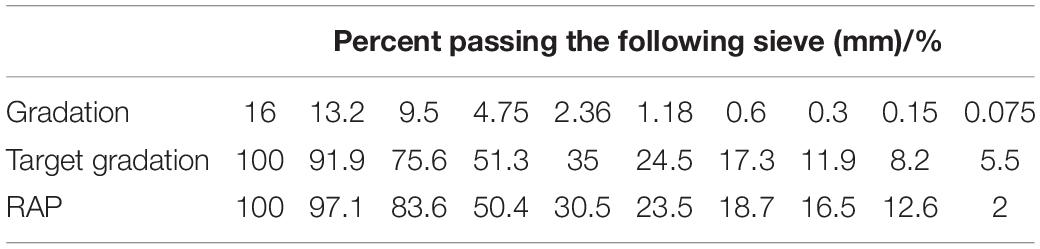

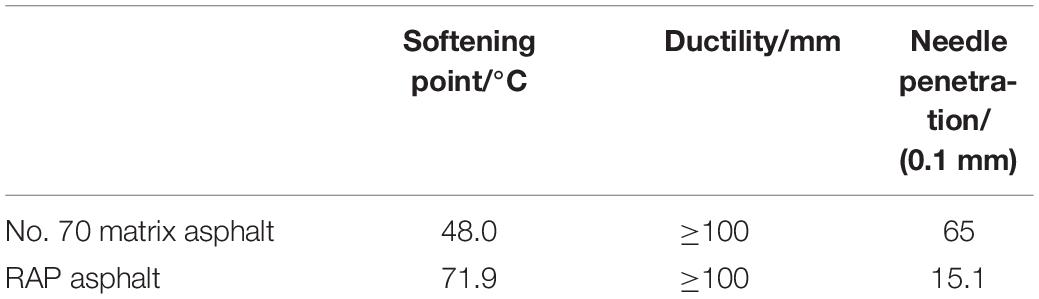

The aggregates used in the test include granite, agate, and old aggregate, as shown in Figure 1.

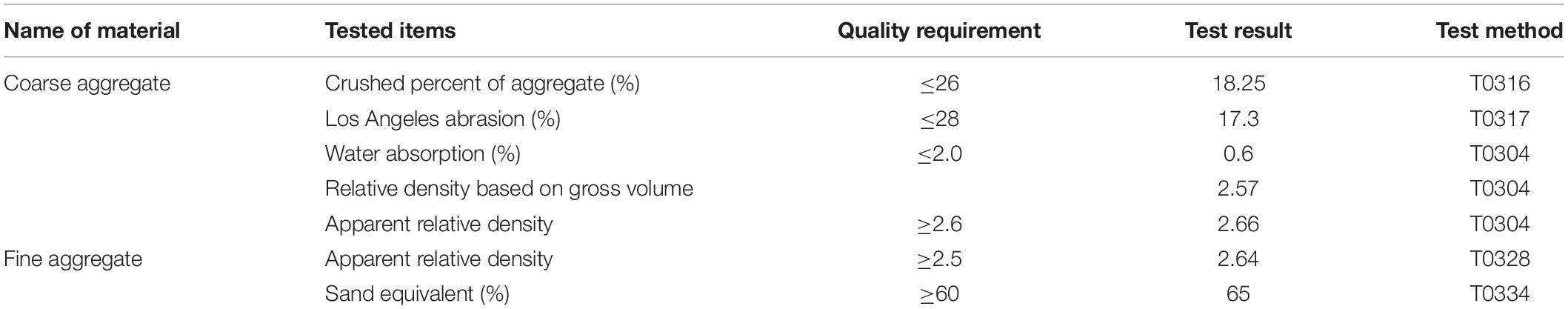

Among them, granite and old aggregate were taken from the Guangzhou Municipal Maintenance Office. Asphalt is No. 70 matrix asphalt with asphalt–aggregate ratio of 4.6%. The composition of gradation with RAP and target gradation is listed in Table 1. The relevant indexes of raw materials all meet the requirements in the “Technical Specifications for Construction of Highway Asphalt Pavement” (JTG F40-2017), and the technical indexes of the materials are listed in Tables 2, 3.

Experimental Design

Mixture Design

The aggregate used in this test consists of granite and RAP. The asphalt used is No. 70 matrix asphalt. The composition of the target gradation is listed in Table 1. The RAP and granite were mixed proportionally, with RAP contents of 10, 20, 30, 40, and 50%. A cylindrical test piece was formed using a Marshall compactor after compacting 75 times on both sides. According to the aforementioned five contents, five sets of test pieces were formed. Ten test pieces were shaped from each set with diameter and height of 101.6 ± 0.2 and 63.5 ± 1.3 mm, respectively. The stability and flow value tests indicated the final asphalt–aggregate ratio to be 4.6%, which is the same as that of the old aggregate.

Uniaxial Penetration and Uniaxial Compression Test

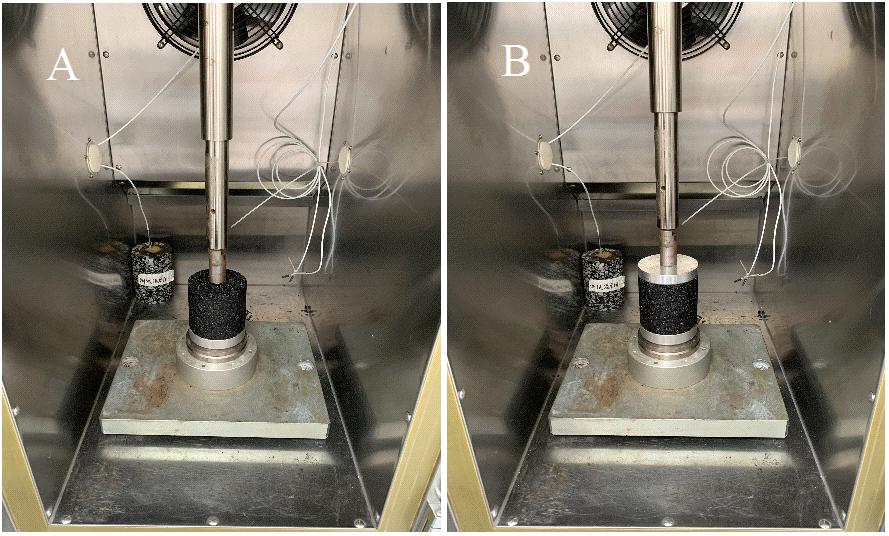

The uniaxial penetration test is a test method proposed by Bi and Sun (2005) for evaluating the shear resistance of asphalt mixtures. Peng et al. (2007) investigated that rotation compaction has less effect on uniformity than Marshall compaction and wheel shaping. Therefore, a Superpave Gyratory Compactor (SGC) was used to form cylindrical test pieces for the test after gyratory compaction of 50 times. The test piece for the uniaxial penetration test has a diameter of 100 mm and a height of 100 mm. For each RAP content, the set to be tested had six test pieces, of which three are used for uniaxial penetration test and the remaining three are used for uniaxial compression test. The test temperatures of the uniaxial compression test and the uniaxial penetration test are both 60°C, and the loading speed is 1 mm⋅s–1. The uniaxial penetration test uses a circular penetration surface with a diameter of 28.5 mm, as shown in Figure 2.

Classification of the Contact Between Old and New Aggregates

Digital Image Processing Technology

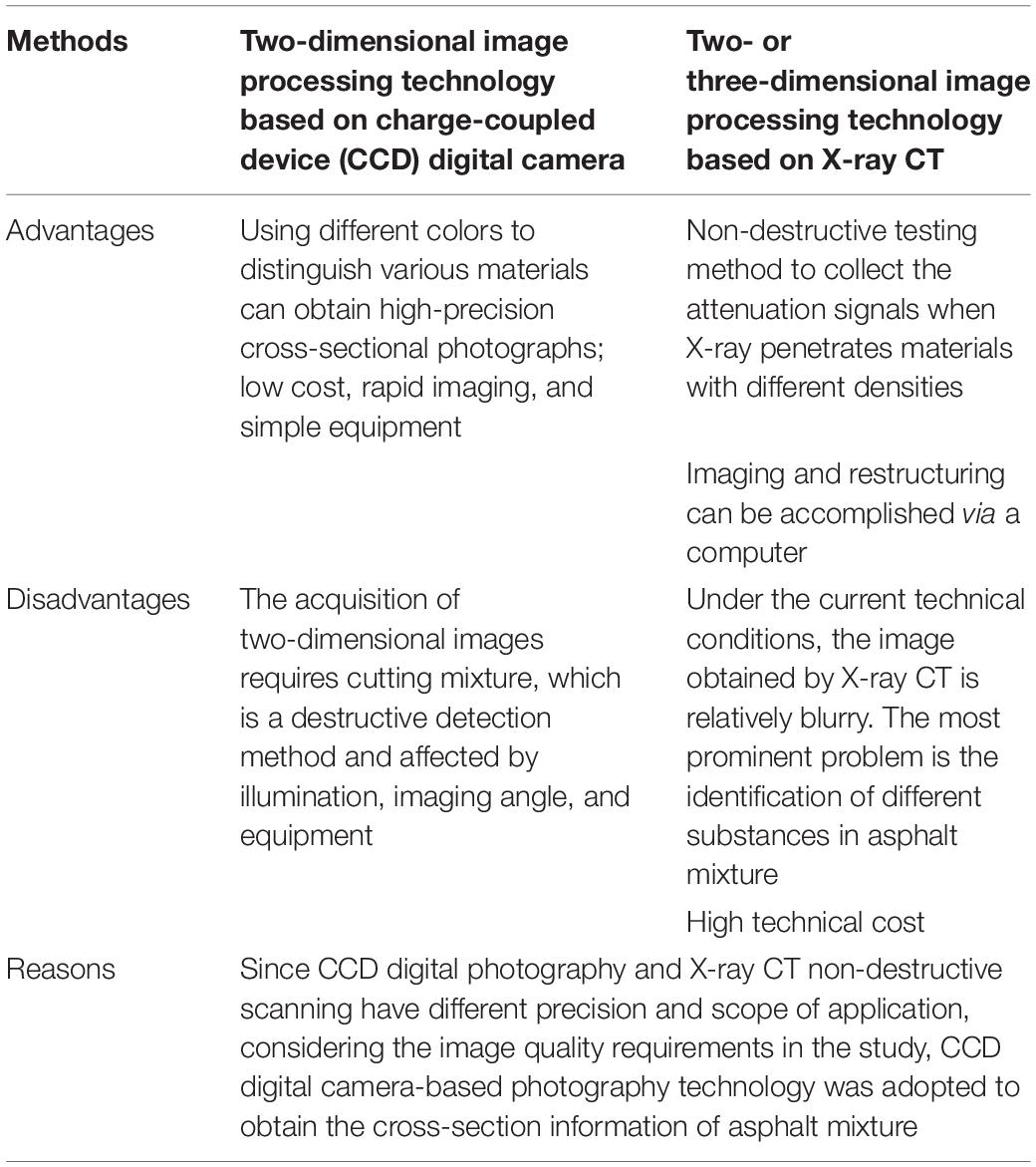

The analysis of contact characteristics of aggregate in asphalt mixture is based on digital image technology. At present, there are two commonly used processing techniques for the image analysis of asphalt mixture: the two-dimensional image processing technology is based on charge-coupled device (CCD) digital camera and the 2D or 3D image processing technology is based on X-ray CT (Cai, 2013). In these two methods, a more suitable CCD digital camera-based technology was chosen according to the requirements and their advantages and disadvantages. The comparison is shown in Table 4.

Analysis of Contact Points in Coarse Aggregate

Wei Hong proposed the concept of “contacting pair” in the analysis of the spatial proximity relationship between aggregate particles and deemed that, when the boundary pixel distance of any two adjacent aggregates is less than a certain threshold, the aggregates contact with each other (Cai, 2013). However, because the asphalt mixture is a typical three-phase matter, the noise in the spatial domain limits the image effect not meeting the requirements of fine analysis during the process of taking digital images by digital camera. The resulting large errors especially affect the sharpness of the material edge of the image. In order to get more accurate data, the following processing was performed:

First, apply CCD digital camera to the cut test piece for collecting the cross-section information of the asphalt mixture. Use iPas to perform preliminary processing on the image, such as filter denoising, image enhancement, and determining the threshold.

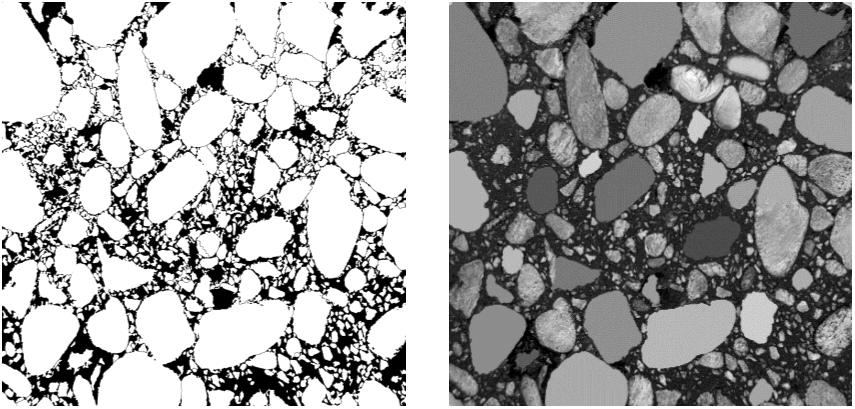

Second, use the multi-resolution adaptive window segmentation algorithm to initially extract the aggregate boundary and binarize the image, as shown in Figure 3.

Subsequently, perform virtual screening on the binarized image slices, extract coarse and fine aggregates, and number them.

Finally, calculate the spatial proximity relationship between the aggregates, count the number of contact points, and mark the positions of the contact points.

Determination of Contact Threshold

Based on the literature data, the selection of contact threshold has a crucial effect on the number of contact points. By analyzing the contact probability and referring to the reported results, it is reasonable to select 20–25% of the minimum calculated particle size of aggregate as the contact threshold (Elseifi et al., 2008; Duan, 2011; Coenen et al., 2012). Therefore, in this study, the contact threshold is directly taken as 20% of the minimum calculated particle size of the aggregate and will not be discussed in detail.

Dividing and Extraction of Contact Types

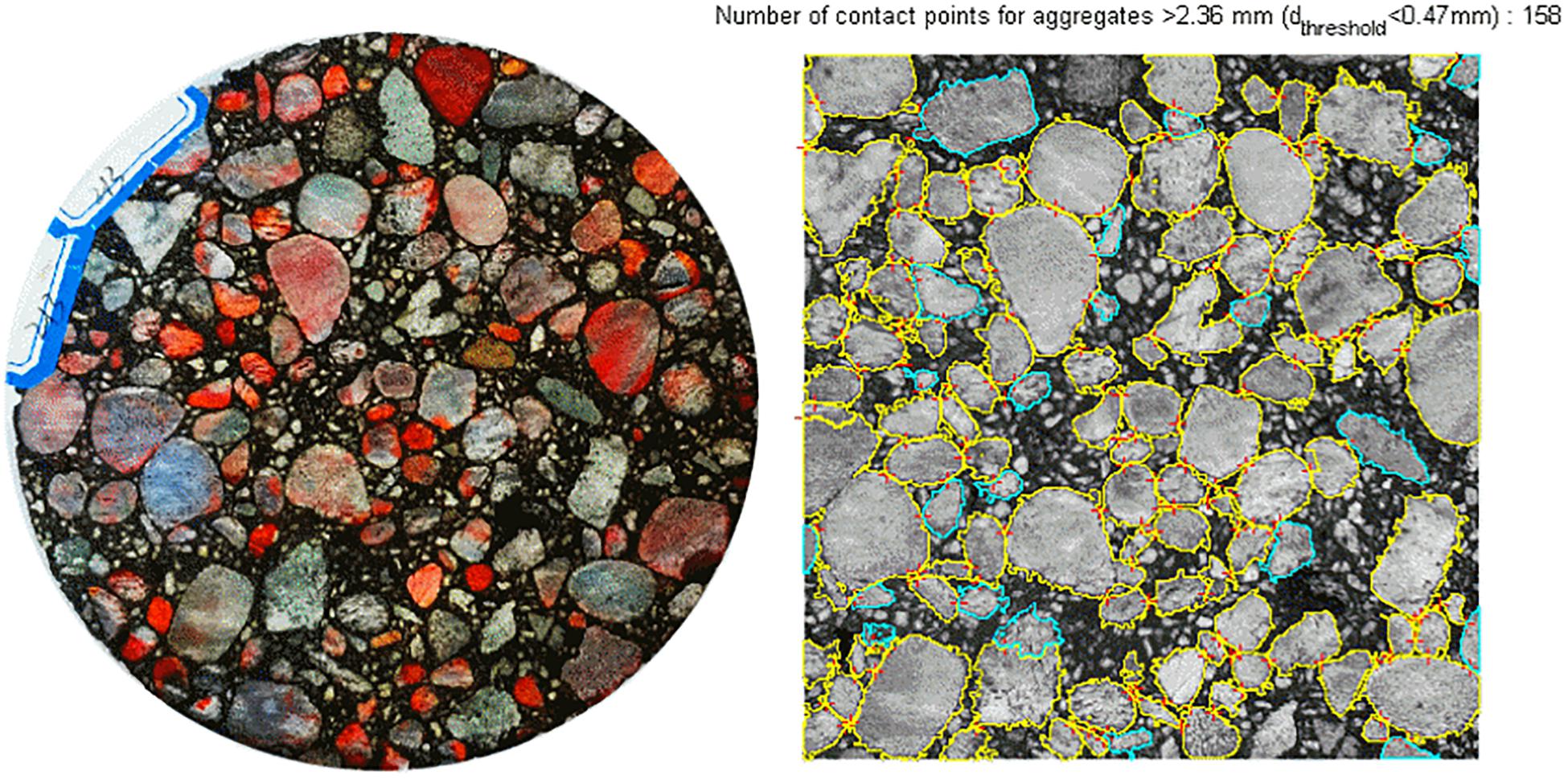

In order to observe the contact between new and old aggregates more clearly, the coarse aggregates in the new aggregates were replaced with agate to form additional gyratory-compacted specimens. Among the contact points exceeding the contact threshold, the contact points composed of old materials and agate stone are defined as “new–old” type, the old materials and old materials are composed of “old–old” type, and the agate stone and agate stone are “new–new” type. According to the density of the material, the added amount of agate stone is determined by equal volume conversion and the gradation curve adopted was the same as the target gradation. In order to study the distribution of the three contact types at different RAP contents, the RAP content was set to 20, 30, 40, 60, and 80%. In the test, the cylindrical test pieces were formed after 50 times of gyratory compaction by the SGC. For every RAP content, two test pieces, with a diameter of 100 mm and a height of 100 mm, were shaped. Each test piece was cut using a cutting machine to get five circular slices. A CCD digital camera was used to capture the pictures of each section under the same lighting conditions, and the photographs were numbered. A total of eight cross-sectional photographs were obtained for each specimen.

Using iPas software, the two-dimensional cross-section image of asphalt mixture was processed and then associated with the method of manual observation and counting to combine the processed map and the physical distribution (Sefidmazgi, 2011; Sefidmazgi and Bahia, 2014; Cai et al., 2018). Finally, the number of the three types of contact points was counted, as shown in Figure 4.

Weight Analysis of Contact Type

Weight analysis is a decision method that combines qualitative analysis and quantitative analysis. This method can be applied to the decision-making process of various issues with multiple objectives and multiple criteria. In general, the contribution of each factor to target is different. For some issues, the contributions are significant enough to be measured by a number. The weight analysis method quantitatively provides contribution of various factors to the target through the analysis and the comparison of various factors.

Due to the difference in the amount of RAP used in the mechanical test and the dividing contact types, using cubic spline interpolation, quadratic fitting, and cubic fitting methods is necessary to first obtain the distribution of contact types corresponding to 10 and 50% RAP. On this basis, weight analysis was used to establish the correlation between the contact type and the mechanical parameters such as Marshall stability, uniaxial compressive strength, and uniaxial penetration. The specific method is as follows:

Set the weighting factor to be X, then the weight vector is (X1, X2, X3)T. The data obtained from the test results in the target matrix B = [b1, b2, …, b5]T, and c is a constant. Considering the relationship between the contact point type and RAP content, there are three types of contact point and five RAP contents, which can be combined to form a matrix (1):

Therefore, the equation, AX = cB was obtained, with c being constant. Apply MATLAB to solve the equation and obtain the weights of the three types of contact point.

Experimental Results and Data Analysis

Results of Marshall Stability Test

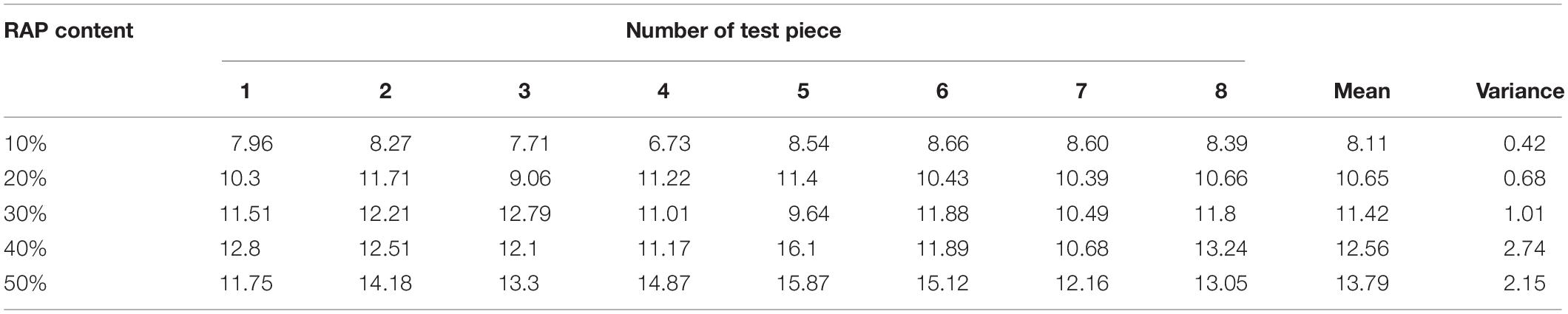

The Marshall stability test is used to determine the breaking load and deformation resistance of the asphalt mixture test piece. The stabilities obtained by the Marshall test are listed in Table 5, where the mean value is the arithmetic average value after removing the maximum value and the minimum value.

Table 5 shows that the Marshall stability of the asphalt mixture increases with increasing RAP content, mainly because with increasing amount of old asphalt, the strength and the rigidity of the asphalt binder gradually increase, making the recycled asphalt mixture exhibit higher Marshall stability macroscopically.

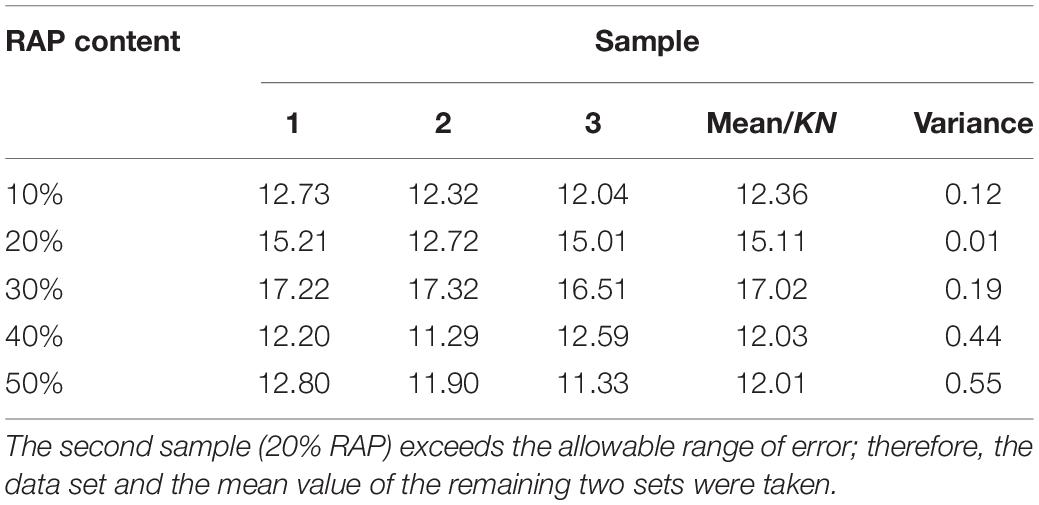

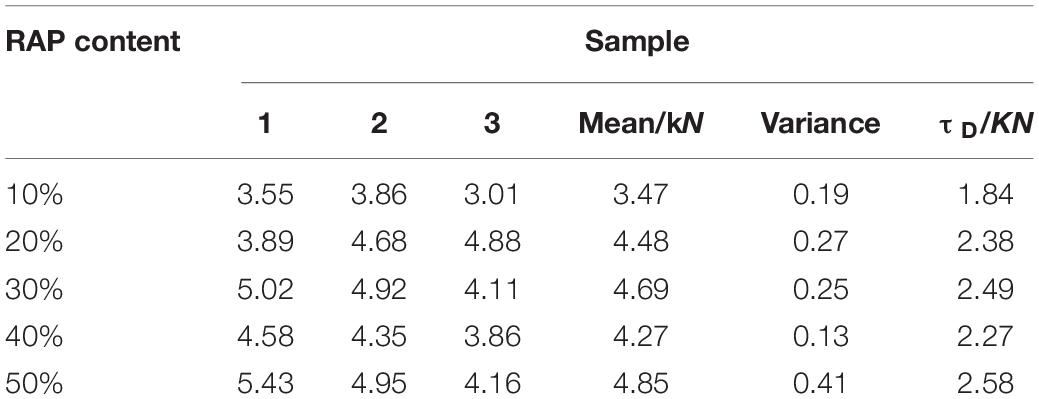

Results of Uniaxial Compression and Uniaxial Penetration Tests

According to the T0713-2011 method in the specification JTG E20-2011, the results of uniaxial compression and uniaxial penetration tests are shown in Tables 6, 7, respectively.

Table 6 shows that, with increasing RAP content, the compressive strength of the recycled asphalt mixture increases first, then decreases, and reaches the maximum at 30% RAP. Table 7 shows that, with increasing RAP content, the penetration strength of the recycled asphalt mixture also increases. Unlike the result of the uniaxial compression test, there was no significant peak value in the penetration strength.

Statistics of Contact Types in Composite Skeleton

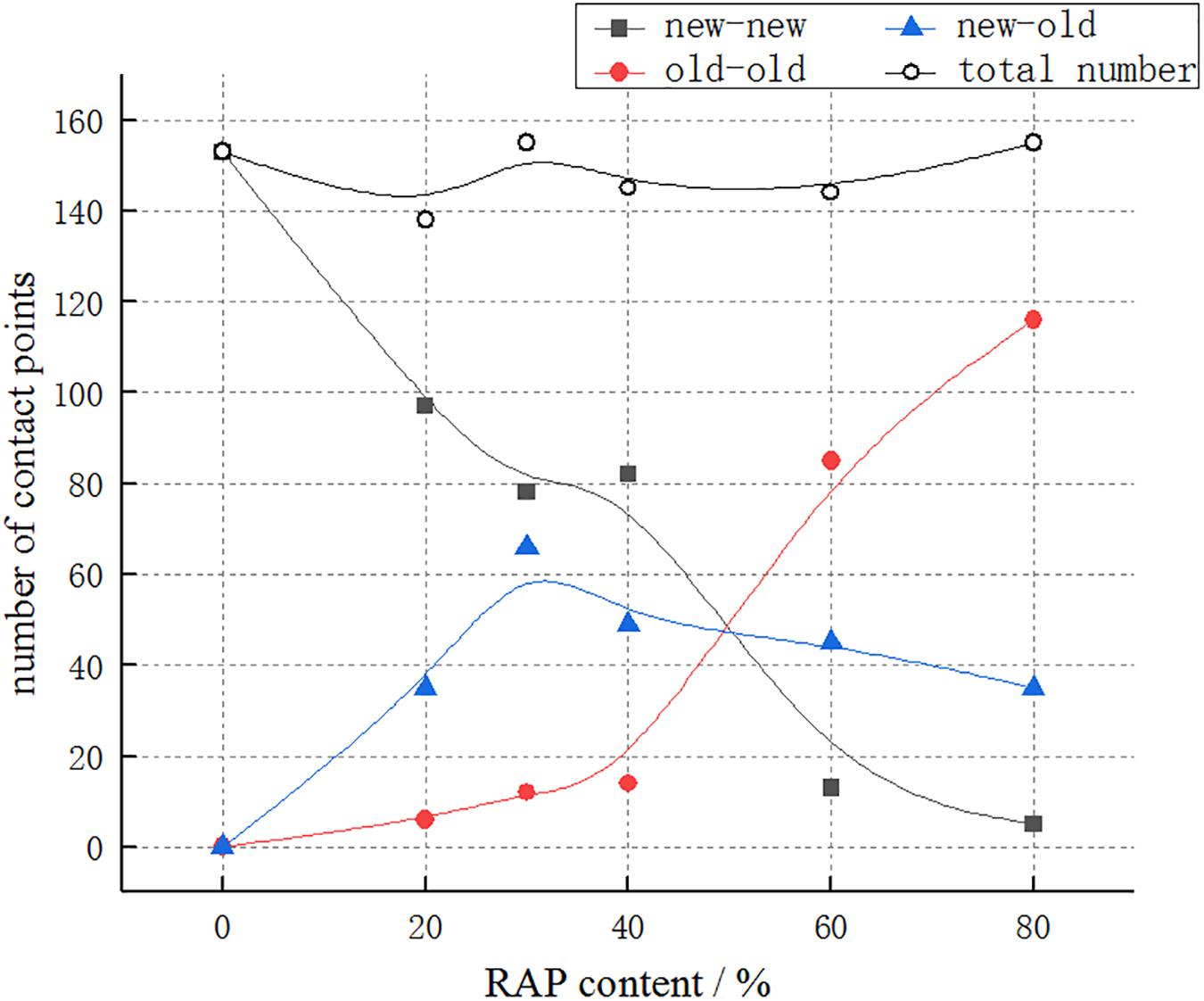

The statistical data obtained as a result of combining digital technology and manual statistics to process and classify the contact points are shown in Figure 5.

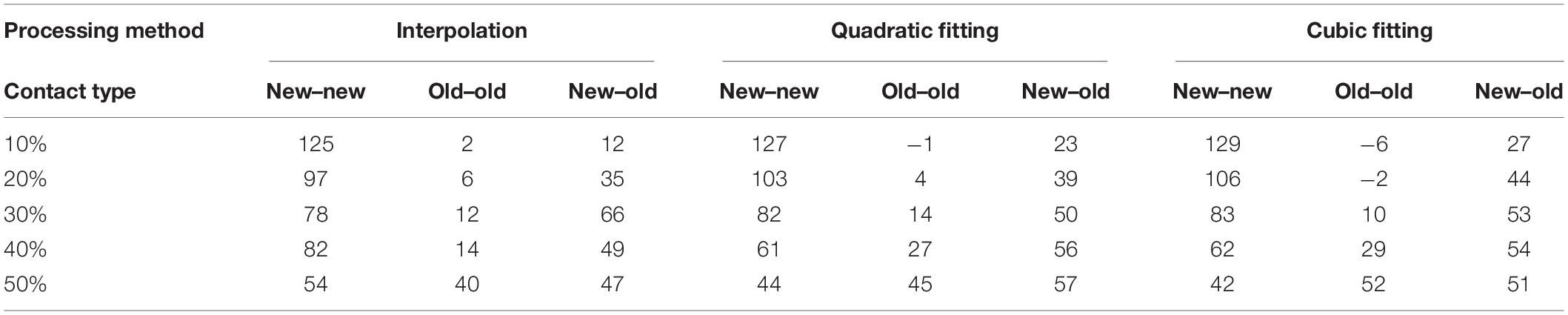

Figure 4 shows that, for consistent gradation, the total number of contact points is basically close. In this study, the total number of contact points at the same gradation is assumed to be the same to obtain the number of contact points corresponding to 0% RAP. With increasing RAP content, the number of new–new contact points decreases, while that of old–old contact points increases; the number of new–old contact points increases monotonously at first and then decreases monotonously after reaching the peak at 30% RAP. The statistical data of the three contact types were used to calculate the number of contact points at 10, 20, 30, 40, and 50% RAP by cubic spline interpolation, quadratic fitting, and cubic fitting, as listed in Table 8.

Table 8 shows that the results obtained by the different fitting methods are different as well. From the perspective of distribution of contact types, the numbers of “new–old” contact points obtained by quadratic fitting and cubic fitting are more than that obtained by interpolation fitting, while the numbers of “new–new” contact points exhibit an opposite trend.

Weight Analysis of Contact Type

According to the method introduced in “Dividing and Extraction of Contact Types”, the data in Table 8 were used to obtain the data of weight, as shown in Table 9.

As listed in Table 9, the weight data obtained by quadratic fitting and cubic fitting are very close, especially on the weight of the old–old contact points, but they obviously differ from the interpolation data. For the old–old contact point of the uniaxial compression test, the negative sign of weight represents its weakening effect on the strength. An extreme situation is assumed: when the test piece is fully composed of RAP, the compression strength of the test piece should be weakened to its extreme value and even expands. However, the test piece still has a relatively good compressive strength for the full RAP. Therefore, the interpolation method having less effect of old–old contact point on the compressive strength is more reasonable. In addition, the numbers of old–old contact points in quadratic and cubic fittings show negative values at 10% RAP, which is not in line with the practical situation. In summary, the data obtained by interpolation fitting are selected for the next analysis.

Relevant Weight of Marshall Stability

Table 9 shows that the new–old contact point accounts for the largest weight in affecting the stability. The old–old contact point type has the second largest weight but also very close to the new–old contact point. Because the total number of contact points remains unchanged, less new–new contact points mean an increase in other contact points, also explaining the continuous increase in stability. The new–old and the old–old contact points contribute more to stability and are in agreement with the results of the weight analysis.

Relevant Weight of Uniaxial Compression Strength

Combined with the statistics of contact points in Figure 5 and the weight analysis in Table 6, the rapid growth before 30% RAP results from the contribution of new–old contact points exceeding that of new–new contact points and increasing the compressive strength. The weight reaches a peak value at 30% RAP and then decreases, and the downward trend of new–new contact points tends to be smooth at 40% RAP, exhibiting an overall compressive strength without a significant change.

Relevant Weight of Uniaxial Penetration Strength

The literature data indicate that the high temperature stability of asphalt mixture is proportional to the RAP content, and it can be further concluded that the shear modulus of the three types of contact point is in the following order: old–old (RAP is 100%) > new–old (RAP is between 0 and 100%) > new–new (RAP is 0%), which is consistent with the results obtained by the weight analysis (Cheng et al., 2018; Wang Z. Y. et al., 2019). Combining with the trend of the contact points shown in Figure 4, the shear strength increases with increasing RAP content because the number of new–old and old–old contact points gradually increases. The significant drop after 30% is because the number of new–old contact points reaches its peak at 30%. The increase again at 40% results from the number of old–old contact points that continue to increase, and the proportion of the three types of contact point reaches a balance at 40%, exhibiting an extreme value. After the RAP content exceeds 40%, the number of old–old contact points increases sharply, and its contribution to the overall shear modulus becomes greater, exhibiting a continuous increase in strength.

Conclusion

In conclusion, digital image processing technology and weight analysis methods were used in combination to study the types of contact points and mechanical properties of the recycled asphalt mixtures with different RAP contents and explore their correlations. The following conclusions were obtained:

1. The statistical data show that, at a constant gradation condition, the total number of the three types of contact point does not change with increasing RAP content.

2. With the increase of RAP content, the variations in the three types of contact point have their own characteristics. The overall trend of new–new contact points is decreasing, but there are small fluctuations at 30 and 40%. The overall trend of old–old contact points is increasing, but the increase at 40% becomes larger. The new–old contact point presents a parabolic trend, with a peak at 30%

3. In the uniaxial penetration test, the shear modulus of the three contact points jointly determines the strength of the mixture, and the strength changes with the number of three contact points. In the uniaxial compression test, the force situation is more complicated than that in the uniaxial penetration test; the strength is mainly determined by the new–new and the new-old contact points. In the stability test, the old–old contact point and the new–old contact point account for larger weights; therefore, the stability increases with increasing RAP content. The above analysis indicates that the new–old contact point always plays an important role. The optimal performance of a material can be enhanced by increasing the number of new–old contact points, as one of the possible means.

4. Weight analysis is an auxiliary analysis method, providing the correlation between the changing factor and the test results based on actual data, therefore explaining the data analysis results in a better way. The weight analysis results of the contact type indicate that this method can effectively obtain the main factors that affect the performance of the asphalt mixture.

5. Limitations of this study: Only the AC-13 asphalt mixture was analyzed. The results cannot characterize the dense-framework and void-type mixtures. The use of agate stone changes the friction between the particles, which results in the uniformity of the material under the same mixing process being different from the mixture using the new aggregate. The author’s future research direction would be to carry out more types of mixture test research and explore the feasibility of improving the road performance of recycled asphalt mixture from the perspective of uniformity.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author Contributions

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

Funding

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 51708144 and 51878193).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Supplementary Material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fmats.2020.00203/full#supplementary-material

References

Ai-Qadi, I. L., Carpenter, S. H., Roberts, G. L., Ozer, H., and Aurangzeb, Q. (2009). “Investigation of working binder in hot-mix asphalt containing recycled asphalt pavements,” in Proceedings of the 88th Annual Meeting of the Transportation Research Board, Washington, DC.

Ai-Qadi, I. L., Elseifi, M., and Carpenter, S. H. (2007). Reclaimed Asphalt Pavement—A Literature Review. Research Report FHWA- ICT- 07-001. Rantoul, IL: IDEALS.

Arshad, H., and Qiu, Y. J. (2013). Effect of reclaimed asphalt pavement on the properties of asphalt binders. Proc. Eng. 54, 840–850. doi: 10.1016/j.proeng.2013.03.077

Bi, Y. F., and Sun, L. J. (2005). Study on shear test method of asphalt mixture. J. Tongji Univ. Nat. Sci. Ed. 33, 1036–1040.

Cai, X. (2013). Rutting Resistance Evaluation and Structure Optimization of Asphalt Pavement. PhD thesis, South China University Technology, Guangzhou.

Cai, X., Wu, K. H., Huang, W. K., and Wan, C. (2018). Study on the correlation between aggregate skeleton characteristics and rutting performance of asphalt mixture. Constr. Build. Mater. 179, 294–301. doi: 10.1016/j.conbuildmat.2018.05.153

Chen, J. Y. (2011). Experimental Research on Recycling Method of Asphalt Pavement. PhD thesis, Dalian University of Technology, Dalian.

Chen, M., Tang, Y., Zou, X., Huang, K., Li, L., and He, Y. (2019). High-accuracy multi-camera reconstruction enhanced by adaptive point cloud correction algorithm. Opt. Lasers Eng. 122, 170–183. doi: 10.1016/j.optlaseng.2019.06.011

Chen, T., Luan, Y., Ma, T., Zhu, J., Huang, X., and Ma, S. (2020a). Mechanical and microstructural characteristics of different interfaces In cold recycled mixture containing cement and asphalt emulsion. J. Clean. Product. 258:120674. doi: 10.1016/j.jclepro.2020.120674

Chen, T., Ma, T., Huang, X., Ma, S., Tang, F., and Wu, S. (2020b). Microstructure of synthetic composite interfaces and verification of mixing order in cold-recycled asphalt emulsion mixture. J. Clean. Product. 263:121467. doi: 10.1016/j.jclepro.2020.121467

Cheng, P. F., Kou, H. Y., and Li, J. H. (2018). Influence of the amount of used materials on the temperature and performance of mixing and compaction of hot recycled asphalt mixture. China Foreign Highway 38, 193–198. doi: 10.14048/j.issn.1671-2579.2018.05.042

Coenen, A. R., Kutay, M. E., Sefidmazgi, N. R., and Bahia, H. U. (2012). Aggregate structure characterisation of asphalt mixtures using two-dimensional image analysis. Road Mater. Pavement 13, 433–454. doi: 10.1080/14680629.2012.711923

Cong, P., Zhang, Y., and Liu, N. (2016). Investigation of the properties of asphalt mixtures incorporating reclaimed SBS modified asphalt pavement. Constr. Build. Mater. 113, 334–340. doi: 10.1016/j.conbuildmat.2016.03.059

Ding, X., Chen, L., Ma, T., Ma, H., Gu, L., Chen, T., et al. (2019). Laboratory investigation of the recycled asphalt concrete with stable crumb rubber asphalt binder. Constr. Build. Mater. 203, 552–557. doi: 10.1016/j.conbuildmat.2019.01.114

Duan, Y. H. (2011). Basic Properties of Asphalt Mixture Based on X-ray CT. Ph.D. thesis, South China University of Technology, Guangzhou.

Elseifi, M. A., Ai-Qadi, I. L., Yang, S.-H., and Carpenter, S. H. (2008). Validity of asphalt binder film thickness concept in hot-mix asphalt. Transp. Res. Rec. 2057, 37–45. doi: 10.3141/2057-05

Han, S., Cheng, X. P., Liu, Y. M., and Zhang, Y. C. (2019). Laboratory performance of hot mix asphalt with high reclaimed asphalt pavement (RAP) and fine reclaimed asphalt pavement (FRAP) content. Materials 12:2536. doi: 10.3390/ma12162536

Li, J., Li, P., Su, J., Yang, L., and Wu, X. (2019). Coarse aggregate movements during compaction and their relation with the densification properties of asphalt mixture. Int. J. Pavement Eng. 1–12. doi: 10.1080/10298436.2019.1659263

Li, P., Su, J., Ma, S., and Dong, H. (2018). Effect of aggregate contact condition on skeleton stability in asphalt mixture. Int. J. Pavement Eng. 21, 196–202. doi: 10.1080/10298436.2018.1450503

Lopes, M., Mouillet, V., Bernucci, L., and Gabet, T. (2016). The potential of Attenuated Total Reflection imaging in the mid-infrared for the study of recycled asphalt mixtures. Constr. Build. Mater. 124, 1120–1131. doi: 10.1016/j.conbuildmat.2016.08.108

Ma, T., Wang, H., Huang, X., Wang, Z., and Xiao, F. (2015). Laboratory performance characteristics of high modulus asphalt mixture with high-content RAP. Constr. Build. Mater. 101, 975–982. doi: 10.1016/j.conbuildmat.2015.10.160

Ma, T., Zhang, D., Zhang, Y., Wang, S., and Huang, X. (2018). Simulation of wheel tracking test for asphalt mixture using discrete element modelling. Road Mater. Pavement 19, 367–384. doi: 10.1080/14680629.2016.1261725

Mannan, U. A., Islam, M. R., and Tarefder, R. A. (2015). Effects of recycled asphalt pavements on the fatigue life of asphalt under different strain levels and loading frequencies. Int. J. Fatigue 78, 72–80. doi: 10.1016/j.ijfatigue.2015.04.004

Moaveni, M., Cetin, S., Brand, A. S., Dahal, S., Roesler, J. R., and Tutumluer, E. (2016). Machine vision based characterization of particle shape and asphalt coating in reclaimed asphalt pavement. Transp. Geotech. 6, 26–37. doi: 10.1016/j.trgeo.2016.01.001

Peng, Y., Sun, L. J., Shi, Y. J., and Wang, Y. Q. (2007). Influencing factors of shear strength of asphalt mixtures. J. Southeast Univ. Nat. Sci. Ed. 37, 330–333.

Plati, C. (2019). Sustainability factors in pavement materials, design, and preservation strategies: a literature review. Constr. Build. Mater. 211, 539–555. doi: 10.1016/j.conbuildmat.2019.03.242

Pradyumna, T. A., Mittal, A., and Jain, P. K. (2013). Characterization of reclaimed asphalt pavement (RAP) for use in bituminous road construction. Proc. Soc. Behav. Sci. 104, 1149–1157. doi: 10.1016/j.sbspro.2013.11.211

Sefidmazgi, N. R. (2011). Defining Effective Aggregate Skeleton in Asphalt Mixture using Digital Imaging. master’s thesis, University of Wisconsin, Madison, WI.

Sefidmazgi, N. R., and Bahia, H. U. (2014). Effect of compaction conditions on aggregate packing using 2-dimensional image analysis and the relation to performance of HMA. Mater. Struct. 47, 1313–1324. doi: 10.1617/s11527-014-0275-x

Tan, Y. Q., Song, X. H., Ji, L., Chen, G. M., and Wu, X. T. (2009). Influence of coarse aggregate performance on high temperature performance of asphalt mixture. China J. Highway Transp. 22, 29–33. doi: 10.19721/j.cnki.1001-7372.2009.01.005

Tang, Y., Chen, M., Wang, C., Luo, L., Li, J., and Zou, X. (2020). Recognition and localization methods for vision-based fruit picking robots: a review. Front. Plant Sci. 11:510. doi: 10.3389/fpls.2020.00510

Valdés, G., Pérez-Jiménez, F., Miró, R., Martínez, A., and Botella, R. (2011). Experimental study of recycled asphalt mixtures with high percentages of reclaimed asphalt pavement (RAP). Constr. Build. Mater. 25, 1289–1297. doi: 10.1016/j.conbuildmat.2010.09.016

Wang, D., Cannone Falchetto, A., Moon, K. H., Riccardi, C., Pei, J., and Wen, Y. (2019). Artificially prepared Reclaimed Asphalt Pavement (RAP)—an experimental investigation on re-recycling. Environ. Sci. Pollut. Res. 26, 35620–35628. doi: 10.1007/s11356-019-05970-w

Wang, Z. Y., Li, J. U., Lou, M. L., Fang, K. J., Shi, Y., and Wang, P. (2019). Effect of RAP contents on performance of reactive cold mix recycled asphalt mixture. J. Changsha Univ. Sci. Technol. Nat. Sci. Ed. 16, 35–41.

Wang, H., Zhang, R., Chen, Y., You, Z., and Fang, J. (2016). Study on microstructure of rubberized recycled hot mix asphalt based X-ray CT technology. Constr. Build. Mater. 121, 177–184. doi: 10.1016/j.conbuildmat.2016.05.166

Zhang, J., Zhang, X., Liang, M., Jiang, H., Wei, J., and Yao, Z. (2020). Influence of different rejuvenating agents on rheological behavior and dynamic response of recycled asphalt mixtures incorporating 60% RAP dosage. Constr. Build. Mater. 238:117778. doi: 10.1016/j.conbuildmat.2019.117778

Zhang, J. Z., Sun, H., Jiang, H. G., Xu, X. B., Liang, M., Hou, Y., et al. (2019). Experimental assessment of reclaimed bitumen and RAP asphalt mixtures incorporating a developed rejuvenator. Constr. Build. Mater. 215, 660–669. doi: 10.1016/j.conbuildmat.2019.04.202

Keywords: RAP, RAP content, contact points, composite skeleton, shear modulus

Citation: Xiao H, Qiu Y, Wu K, Huang W, Zhang R, Chen L, Cai X and Luo Q (2020) Analysis of Composite Skeleton Characteristics of Recycled Asphalt Mixture via Weight Analysis Method. Front. Mater. 7:203. doi: 10.3389/fmats.2020.00203

Received: 02 May 2020; Accepted: 03 June 2020;

Published: 09 July 2020.

Edited by:

Hui Yao, Beijing University of Technology, ChinaReviewed by:

Tao Ma, Southeast University, ChinaYunchao Tang, Zhongkai University of Agriculture and Engineering, China

Copyright © 2020 Xiao, Qiu, Wu, Huang, Zhang, Chen, Cai and Luo. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xu Cai, Y3hfY2FpeHVAMTYzLmNvbQ==; Qiang Luo, bHVvcV95YW5AZ3podS5lZHUuY24=

Han Xiao

Han Xiao Yuzhuang Qiu

Yuzhuang Qiu Xu Cai

Xu Cai