- Centre for Conservation and Utilisation of Blue Green Algae, Division of Microbiology, Indian Agricultural Research Institute, New Delhi, India

The impending danger of climate change and pollution can now be seen on the world panorama. The concentration of CO2, the most important Green House Gas (GHG), has reached to formidable levels. Although carbon capture and storage (CCS) methods have been largely worked upon, they are cumbersome in terms of economy and their long term environmental safety raises a concern. Alternatively, bio-sequestration of CO2 using microalgal cell factories has emerged as a promising way of recycling CO2 into biomass via photosynthesis which in turn could be used for the production of bioenergy and other value-added products. Despite enormous potential, the production of microalgae for low-value bulk products and bulk products such as biofuels, is heretofore, not feasible. To achieve economic viability and sustainability, major hurdles in both, the upstream and downstream processes have to be overcome. Recent technoeconomic analyses and life-cycle assessments of microalgae-based production systems have suggested that the only possible way for scaling up the production is to completely use the biomass in an integrated biorefinery set-up wherein every valuable component is extracted, processed and valorized. This article provides a brief yet comprehensive review of the present carbon sequestration and utilization technologies, focusing primarily on biological CO2 capture by microalgae in the context of bio-refinery. The paper discusses various products of microalgal biorefinery and aims to assess the opportunities, challenges and current state-of-the-art of microalgae-based CO2 bioconversion, which are essential to the sustainability of this approach in terms of the environment as well as the economy.

Introduction

The increased concentration of Green House Gases (GHGs) are causing dramatic climatic changes (rise in temperature, changes in the distribution, intensity and pattern of rainfall, rising sea levels, floods, droughts and increased occurrence of extreme climatic phenomena) as a result of well-known phenomenon “Global Warming” (Alexander et al., 2006; Church and White, 2006; Rignot and Kanagaratnam, 2006; Meinshausen et al., 2009; Rockstrom et al., 2009; Solomon et al., 2009; Dawson et al., 2011). The temperature of the planet has risen by 0.85°C from 1880 to 2012 and it has been forecasted that by the end of this century, a rise of 1.4–5.8°C would be witnessed (De Silva et al., 2015). The concentration of CO2, the most important GHG and the major contributor to global warming, has reached to formidable levels. Corresponding to a 32% increase, from around 280 ppm to 400 ppm, since the industrial revolution (De Silva et al., 2015). The primary causes being irrational use of fossil fuels and change in land use pattern (Goldemberg, 2007; Atsumi et al., 2009). Not merely global warming, the increased CO2 concentration in the atmosphere has also led to a 30% increase in the ocean acidity, which in turn is affecting the biodiversity adversely (Doney et al., 2009; Hofmann and Schellnhuber, 2010; Farrelly et al., 2013). The Kyoto Protocol and the Paris Agreement (2015), have set a number of policy actions for participating countries to curb climate change impact. The major requirement being reduced CO2 emissions by reduced fossil fuel utilization and increased carbon capture and sequestration (Cheah et al., 2016; Pires, 2017). This minireview aims to discuss briefly yet comprehensively the various CCS methodologies, focusing mainly on the potential of microalgae mediated carbon capture within the framework of a biorefinery approach: bioconversion and valorization of captured CO2, current state of the technology, recent developments, challenges and future prospects.

CO2 Capture and Storage Methods

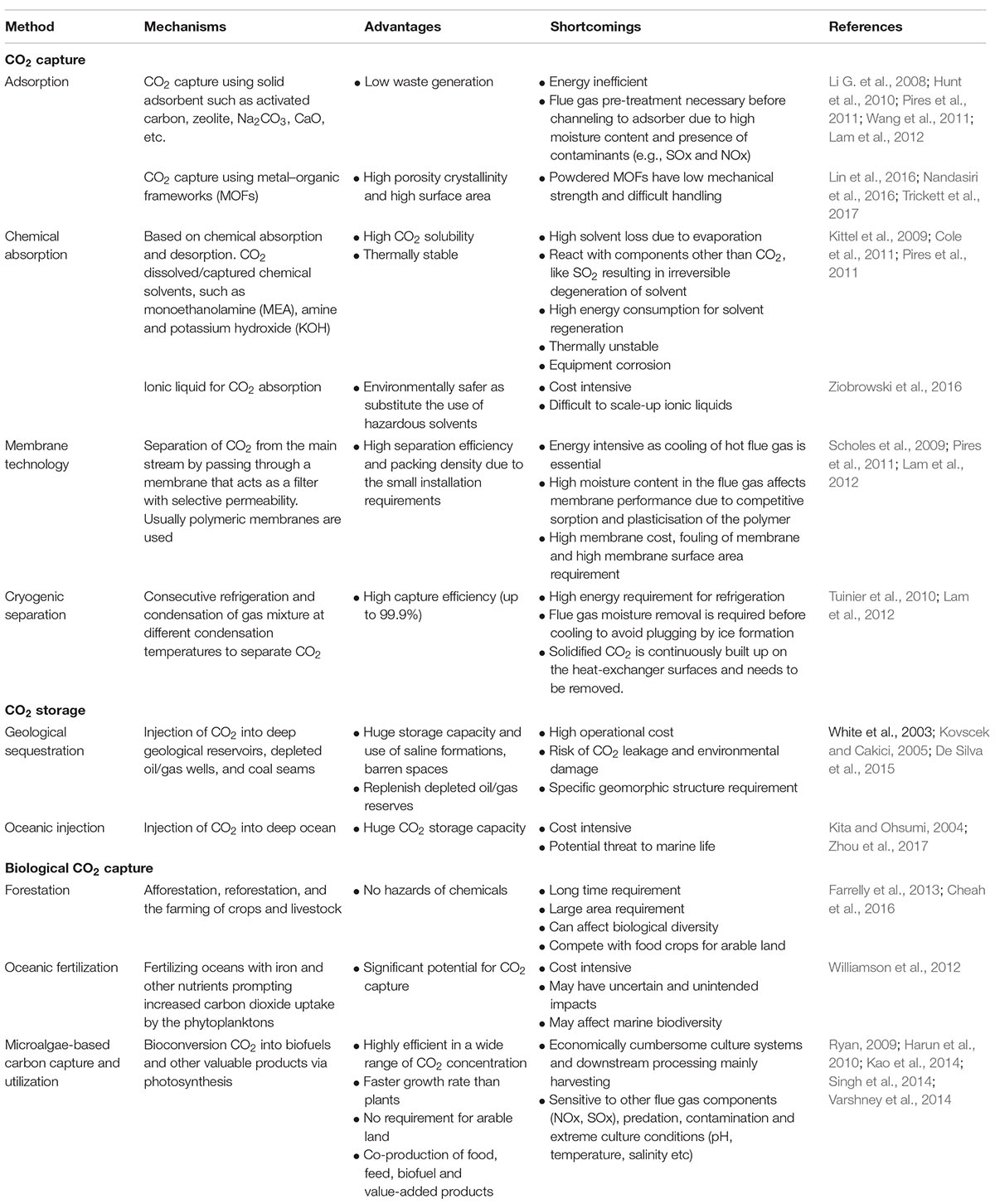

Currently there are many physico-chemical carbon capture and sequestration strategies that are combinedly categorized as carbon capture and storage (CCS) methodologies. CCS operate over 3 major steps: CO2 capture, CO2 transportation and CO2 storage. CO2 capture is done from large point sources such as power plants and cement manufacturing plants. The separation and capture of CO2 from other exhaust components is usually done via following methods: (i) chemical absorption; (ii) physical adsorption; (iii) membrane separation; and (iv) cryogenic distillation (Figueroa et al., 2008; Pires et al., 2011, 2012). This highly concentrated CO2 is then compressed and transported to storage points via pipelines or ship (Svensson et al., 2004; McCoy and Rubin, 2008). Next, the captured CO2 is stored into reservoirs, viz. geological storage, oceanic storage wherein the CO2 is directly injected deep into the ocean, saline formations, aquifers or depleted oil/gas wells (Lackner, 2003). Despite remarkable storage potential of the aforementioned CCS, considerable drawbacks remain, including expensive operation and transportation, environmental threat of long term CO2 leakage and other uncertainties (Lam et al., 2012; De Silva et al., 2015). Moreover, physico-chemical CCS methods are practically successful only for capturing CO2 from point sources producing high concentrations of CO2 i.e., diffused, non-point emissions and low concentrations of CO2 cannot be captured (Nouha et al., 2015). Table 1 briefly illustrates the various CCS methodologies, their mechanisms, merits and limitations with respective references. Aside to physical and chemical CCS, the biological route can be taken for capturing CO2 via natural sinks: (i) forestation; afforestation, reforestation, and the farming of crops and livestock, the biomass can be further valorized (Farrelly et al., 2013; Cheah et al., 2016). (ii) ocean fertilization; fertilizing oceans with iron and other nutrients prompting increased carbon dioxide uptake by the phytoplanktons (Williamson et al., 2012) (iii) microalgae cultivation (Lam et al., 2012; Cheah et al., 2016; Yadav and Sen, 2017; Zhou et al., 2017).

CO2 Capture by Microalgae

The term “microalgae” is generally used for both prokaryotic blue green algae (cyanobacteria) and eukaryotic microalgae including green algae, red algae, and diatoms. Microalgae are being sought as alluring biofactories for the sequestration of CO2 and simultaneous production of renewable biofuels, food, animal and aquaculture feed products and other value-added products such as cosmetics, nutraceuticals, pharmaceuticals, bio-fertilizers, bioactive substances (Ryan, 2009; Harun et al., 2010). Microalgae possess strategies, well known as CO2 concentrating mechanism (CCM) for efficiently photosynthesizing by acquiring inorganic carbon even from very low atmospheric CO2 concentrations (Whitton, 2012). These microorganisms surpass other feedstocks in terms of their abilities to flourish in extreme environments and simple yet versatile nutritional requirements. Microalgae do not require arable land and are capable of surviving well in places that other crop plants cannot inhabit, such as saline-alkaline water, land and wastewater (Searchinger et al., 2008; Wang et al., 2008). Furthermore, microalgae can be fed with notorious waste gasses such as CO2 and NOx, SOx from flue gas, inorganic and organic carbon, N, P and other pollutants from agricultural, industrial and sewage wastewater sources so as to provide us with opportunities to transform them into bioenergy, valuable products and forms that cause least harm to the environment (Chisti, 2007; Hu et al., 2008; Pires et al., 2012; Singh and Thakur, 2015). The uncomplicated cellular structures and rapid growth of microalgae endow them with CO2 fixation efficiency as higher as 10–50 folds than terrestrial plants (Li Y. et al., 2008; Khan et al., 2009).

Recently, many research studies have come up showing the positive impact of growing microalgae under high concentrations of Ci in the form of pure gaseous CO2, real or simulated flue gas, or soluble carbonate (bicarbonate), reporting increased carbon bio-fixation and biomass productivity (Ho et al., 2010; Sydney et al., 2010; Yoo et al., 2010; Tang et al., 2011; Singh et al., 2014; Aslam et al., 2017; Kuo et al., 2017). Detailed information can be found in elaborated reviews by Lam et al. (2012); Cheah et al. (2015); Thomas et al. (2016); Vuppaladadiyam et al. (2018). The fate of the supplied carbon can end up in making skeleton for lipids, proteins, sugars and pigments (Sydney et al., 2010). Despite such remarkable potential, the production of microalgae for low-value bulk products, such as proteins for food/feed applications, fatty acids for nutraceuticals or bulk products such as biofuels, is heretofore, not economically feasible (Williams and Laurens, 2010; Zhou et al., 2017). Recent technoeconomic analyses and life-cycle assessments of microalgae-based production systems have suggested that the only possible way of realizing the potential production is to completely use the biomass in an integrated biorefinery set-up wherein every valuable component is extracted, processed and valorized (Chew et al., 2017).

Biorefinery Concept of Microalgal Biomass

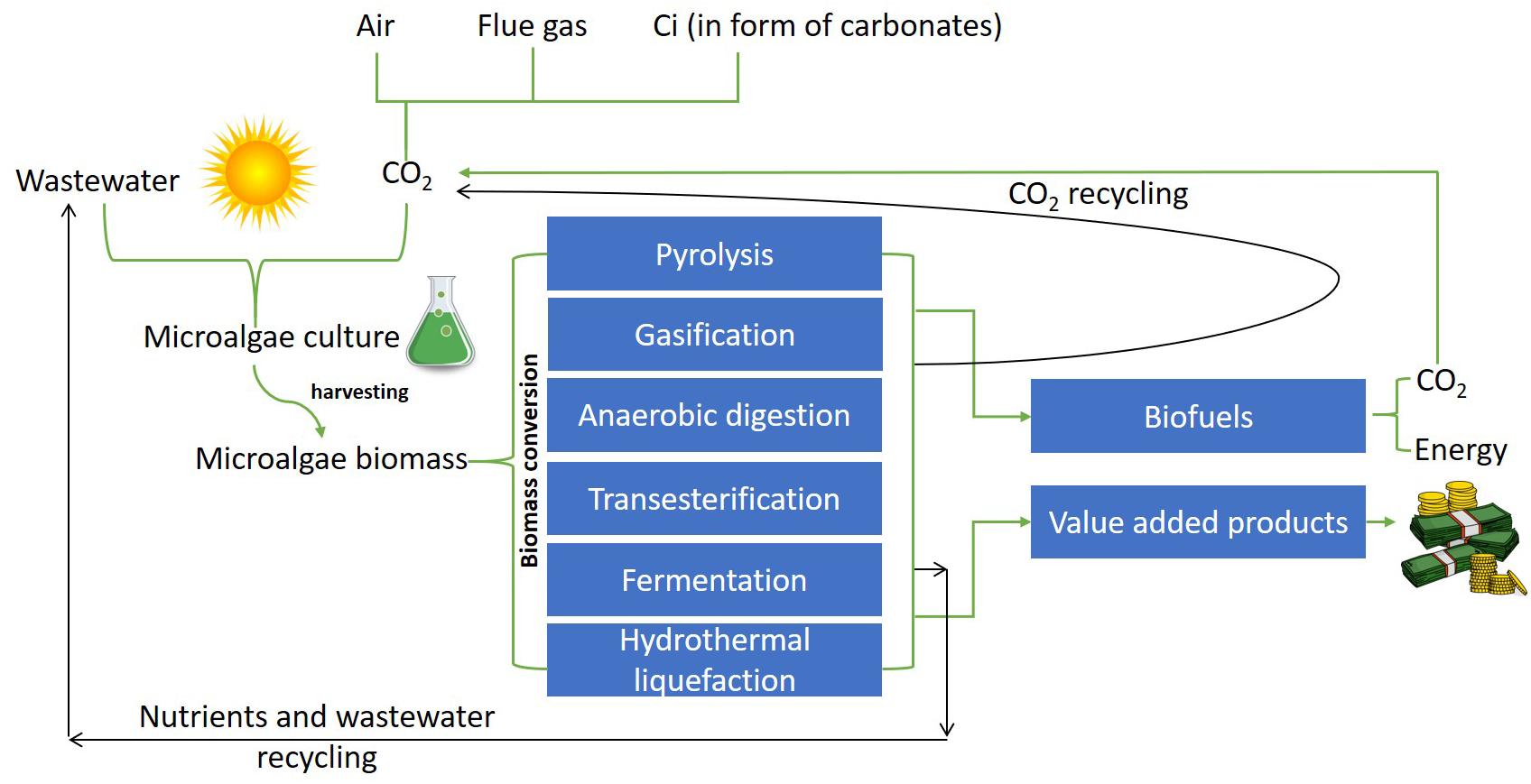

The concept of valorization of a raw material into marketable products is well known in fossil fuel refinery, similarly biorefinery concept refers to the conversion of biomass into multiple commercially valuable products and fuels (Pérez et al., 2017). Figure 1 depicts a simplistic microalgal based biorefinery system. The various high value and low value marketable products that can be produced in an integrated biorefinery system are discussed in the following sections.

Biofuels

Rising CO2, resultant global warming and depleting oil reserves are fueling the search for more eco-friendly forms of alternative energy. The microalgal biomass majorly constituted of lipids (7–23%), proteins (6–71%) and carbohydrates (5–64%), depending upon the microalgal specie and culture conditions (Brown, 1991; Becker, 2007; Mata et al., 2010). Microalgae have received great attention as feedstocks for production of biodiesel, biogas, biohydrogen, bioethanol, biobutanol. Biofuels from microalgae, production system, conversion technologies, life cycle analyses have been extensively reviewed, hence detailed description is not presented in this review.

Biodiesel

Microalgae are known to accumulate remarkable amount of lipid. As reviewed by Mata et al. (2010), the lipid content of common microalgae such as Chlorella, Dunaliella, Isochrysis, Nannochloris, Nannochloropsis, Neochloris, Phaeodactylum, Porphyridium, and Schizochytrium, varies between 20 and 50% of cell dry weight, that can be augmented to higher levels by manipulating environmental and other growth factors, process optimization and genetic modifications of the production strain. Nitrogen starvation and salinity stress are known to induce an increase in TAG (triacylglycerol) accumulation and relative content of oleic acid in most of the microalgal species (Choi et al., 2011). The fatty acid composition of most of the microalgae is dominated by C14:0, C16:0, C18:1, C18:2, and C18:3 fatty acids, yet the relative composition varies from species to species (Gouveia and Oliveira, 2009). Also, the role of HCO3- in inducing TAG accumulation has been widely illustrated recently (Gardner et al., 2012, 2013; Lam et al., 2012; White et al., 2013). The lipids can be converted into FAMEs (fatty acid methyl esters) via transesterification for biodiesel production. The major by-product- glycerol also finds enormous industrial application opportunities. Furthermore, the residual de-oiled microalgal biomass can be used for animal feed.

Biogas

Microalgal biomass can be efficiently used for the production of biogas, including methane, hydrogen, and biohythane (combination of methane and 5–25% hydrogen gas) (Ghimire et al., 2017). The resistance of cell wall to enzyme hydrolysis is one of the prime bottleneck in the Anaerobic digestion (AD) process. The overall economic feasibility of the process depends on the factors affecting AD, microalgal strain, biomass pretreatment, and culture methods (Jankowska et al., 2017). Lately, to make the system economically viable and environmentally sustainable, a closed-loop production scheme is being adopted wherein AD effluents are recycled and used as an input in the first step of AD. Jankowska et al. (2017) have presented a detailed review microalgae’s cultivation, harvesting and pretreatment for AD for biogas production.

Bioethanol

The carbohydrate part (mainly glucose, starch, cellulose, and hemicellulose) of the microalgal dry biomass can be used for transforming into bioethanol via fermentation. Although, microalgae accumulate relatively low quantities of sugars, the absence of lignin from microalgal structure makes them advantageous over other feedstock such as corn, sugarcane, and lignocellulosic biomass (Odjadjare et al., 2015; Jambo et al., 2016). Isochrysis galbana, Porphyridium cruentum, Spirogyra sp., Nannochloropsis oculate, Chlorella sp., are mainly exploited microalgae for the production of carbohydrates (Markou and Nerantzis, 2013).

Biobutanol

The green residual after microalgae oil extraction can be utilized for the production of biobutanol. The higher energy density of biobutanol and its molecular similarity to gasoline makes it more suitable than biomethanol or bioethanol as biofuel. Aside to being a biofuel, it can also be used as a solvent for industrial purposes (Yeong et al., 2018). Despite having notable significance, limited number of studies have reported laboratory stage work on the fermentation of microalgae biomass to butanol (Cheng et al., 2015; Gao et al., 2016; Wang et al., 2016). Microalgal strains with high starch and convertible sugars concentrations would be ideal for biobutanol production research. Tetraselmis subcordiformis, Chlorella vulgaris, Chlorella reinhardtii, and Scenedesmus obliquus could be among the potential candidates (Yeong et al., 2018).

Value-Added Products

In the context of biorefinery approach, intracellular compounds and metabolites have gained immense importance owing to their high monetary value. Microalgal pigments: chlorophyll a and b, lutein, astaxanthin, β-carotene, phycobilins, C- phycocyanin have found wide application in dyes, cosmetics, food and feed additives, nutraceuticals and pharmaceuticals, as natural colors, bioactive components, anti-oxidants, nutritive and neuro-protective agents (Koller et al., 2014; Begum et al., 2016). Microalgae are also exploited as rich source of amino acids (leucine, asparagine, glutamine, cysteine, arginine, aspartate, alanine, glycine, lysine, and valine), Carbohydrates (β1–3- glucan, amylose, starch, cellulose, and alginates), Vitamins and minerals (vitamin B1, B2, B6, B12, C, and E; biotin, folic acid, magnesium, calcium, phosphate, iodine) that are widely used in Food additives, health supplements and medicine. Microalgae, such as Nannochloropsis, Tetraselmis, and Isochrysis are used for extraction of long chain fatty acids popularly known as the omega fatty acids such as DHA (Docosahexaenoic Acid) and EPA (Eicosapentaenoic Acid), have lately gained prime attention as essential for human brain development and health. Other than these, microalgae are also used for production of Extracellular Polymeric Substances (EPSs) which have many industrial applications and Polyhydroxyalkanoates (PHAs). PHAs can be used for manufacturing bioplastics that are very sought after because of their biodegradability (Markou and Nerantzis, 2013; Koller et al., 2014).

State-of-the-Art

Although many have reported successful utilization of microalgal biomass for the production of bioproducts within a biorefinery framework, the economic feasibility is unrealized and the microalgae biorefinery is way much expensive (’t Lam et al., 2017; Zhou et al., 2017). To attain feasibility and sustainability, both upstream processing (USP) and downstream processing (DSP) need to be efficiently simplified and integrated. The efficiency of the USP is determined by microalgal strain selection, nutrient supply (CO2, N, and P) and culture conditions (temperature, light intensity) (Vanthoor-Koopmans et al., 2013). Whereas, the constraints at the DSP level are mainly characterized by harvesting, cell disruption, and extraction methods. DSP, specifically harvesting accounts for 20–40% of the total production costs and for a multi-product biorefinery, the cost increases to 50–60% (’t Lam et al., 2017).

Bioprospecting suitable microalgae is a crucial but time intensive step, high throughput screening techniques like 96-well microplate swivel system (M96SS) have made processing upto 768 microalgal samples at the same time, possible (Han et al., 2012; Zhou et al., 2017). Microalgal production strains can be improved by induced acclimation through manipulation of various environmental stresses (Chen et al., 2017; Schüler et al., 2017). Aslam et al. (2017) showed that mixed diverse community of microalgae, dominated by Desmodesmus spp., could be adapted over a time of many months to survive in 100% flue gas from an unfiltered coal-fired power plant containing 11% CO2. Carbohydrate and starch accumulation in Chlorella sp. AE10 was improved by a two staged process wherein the CO2 concentration, light intensity, nitrogen concentration was changed drastically and cells were diluted at onset of 2nd stage resulting in a 42% increase in carbohydrate accumulation (Cheng et al., 2017). Besides stress manipulation and acclimatization, desirable traits of the microalgal strains can be effectively improved by genetic and metabolic engineering/synthetic biology. Lately, genome editing tools such as Clustered Regularly Interspaced Short Palindromic Repeats – CRISPR associated protein 9 (CRISPR-Cas9) and Transcription Activator-Like (TAL) Effector Nucleases (TALEN) are being used in microalgal gene alterations. Moreover, gene-interfering tools, such as CRISPR-dCas9, micro RNA (miRNA), and silence RNA (siRNA) are being explored to alter the gene expression unlike gene modification. Synthetic biology engages the use of “biobricks” to create artificial regulatory pathways that can control a desired cellular trait by modifying the metabolism. Interchangeable units such as promoters, ribosome-binding sites (RBS), terminators, trans-elements and regulatory molecules serve as the biobricks. Recent developments in microalgal genetic and metabolic engineering can be found in detailed reviews by Ng et al. (2017) and Jagadevan et al. (2018). Recently, Yang et al. (2017), genetically engineered the calvin cycle of Chlorella vulgaris enhancing its photosynthetic capacity by ∼1.2-fold, by introducing the cyanobacterial fructose 1,6-bisphosphate aldolase, guided by a plastid transit peptide. Kuo et al. (2017), screened an alkali-tolerant, Chlorella sp. AT1 mutant strain by NTG (N-methyl-N′-nitro-N-nitrosoguanidine) mutagenesis that survived well 10% CO2 for prospective CO2 sequestration.

Large scale microalgal cultivation and nutrient supply pose huge economic burden. In this context emphasis is being laid on biofilm based attached cultivation rather than aqua-suspend methods that have massive water requirement, low biomass productivity, energy intensive and cannot be easily scaled up (Kesaano and Sims, 2014; Wang et al., 2017). Microalgal production using wastewater from industrial, agricultural and sewage sources is a promising way to reduce the ecological footprints substantially (Pires et al., 2012; Singh and Thakur, 2015). Digestates, effluents from biogas production units and AD (containing concentrated nutrients including nitrogen in the form of ammonia, potassium, phosphorous, sulfur, and recalcitrant organic substances), are also being used in microalgal cultivation systems. A recent elaborated review has been done by Koutra et al. (2018).

The main DSP unit operations are harvesting, cell disruption and extraction. Centrifugation is the most efficient (>95% efficiency) method for harvesting microalgae. However, being very cost intensive, it is not suitable for large scale systems. Flocculation is a low-cost alternative. Cationic chemical flocculants and polymeric flocculants are generally used (Brennan and Owende, 2010), but can negatively affect the toxicity of the biomass and output water (Ryan, 2009). Zhou et al. (2012) reported a novel fungi assisted bioflocculation technique, in which a filamentous fungal spores were added to the algal culture under optimized conditions and the pellets were formed after 2 days that can be harvested by simple filtration. Attached culture can also make harvesting simple (Wang et al., 2017). Conventional disruption methods like bead beating, homogenizers, heating, applying high pressure and chemicals or enzymes for lysis is costly and pose risk of loss of desired multi products in biorefinery concept. Physical disruption by pulsed electric field (PEF) is a promising alternative technology as it is a low-shear technology that operates on low temperature and can aid the extraction of hydrophobic constituents of the biomass (Goettel et al., 2013; ’t Lam et al., 2017). In the case of extraction technologies, ionic liquids (ILs) appear to be promising as they are advantageous over conventional solvents. ILs are organic salts that are non-volatile at room temperature. Also, they can be used for extraction of hydrophilic proteins. Imidazolium-based ILs have been successfully used for cell disruption for lipid extraction from microalgal biomass (Orr and Rehmann, 2016).

Concluding Remarks

Microalgae based carbon capture technologies are certainly promising but their successful implementation is still to be realized. Recent advances and breakthroughs in bioprospecting new strains, innovation in culture strategies and process optimization are certainly making us optimistic about the future of microalgal biorefinery. But, the prospects of successful commercial deployment lie in unsophisticated innovations in DSP, particularly harvesting, cell disruption and extraction, which can actually cut down the costs at a biorefinery level, along with process integration. Lastly, the vast data gathered through omics and labeling analysis needs to critically and holistically studied to gain in depth knowledge of the microalgal CCM, biosynthetic pathways and stress mediated responses ensuing the creation avant-garde strains and metabolic circuits via genetic/metabolic engineering approaches, that can revolutionize the whole microalgal biorefinery concept.

Author Contributions

Both authors contributed equally toward the preparation of the manuscript. DD was involved in detailing and overall preparation of the manuscript. JS collected the available literature and drafted the manuscript.

Funding

This work was supported by grants from Department of Science and Technology (PDF/2015/001067), Government of India (GoI), New Delhi, India.

Conflict of Interest Statement

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

Alexander, L. V., Zhang, X., Peterson, T. C., Caesar, J., Gleason, B., Tank, A. M. G. K., et al. (2006). Global observed changes in daily climate extremes of temperature and precipitation. J. Geophys. Res. Atmos 111, 1–22. doi: 10.1029/2005JD006290

Aslam, A., Thomas-Hall, S. R., Mughal, T. A., and Schenk, P. M. (2017). Selection and adaptation of microalgae to growth in 100% unfiltered coal-fired flue gas. Bioresour. Technol. 233, 271–283. doi: 10.1016/j.biortech.2017.02.111

Atsumi, S., Higashide, W., and Liao, J. C. (2009). Direct photosynthetic recycling of carbon dioxide to isobutyraldehyde. Nat. Biotechnol. 27, 1177–1180. doi: 10.1038/nbt.1586

Becker, E. W. (2007). Micro-algae as a source of protein. Biotechnol. Adv. 25, 207–210. doi: 10.1016/j.biotechadv.2006.11.002

Begum, H., Yusoff, F. M., Banerjee, S., Khatoon, H., and Shariff, M. (2016). Availability and utilization of pigments from microalgae. Crit. Rev. Food Sci. Nutr. 56, 2209–2222. doi: 10.1080/10408398.2013.764841

Brown, M. (1991). The amino-acid and sugar composition of 16 species of microalgae used in mariculture. J. Exp. Mar. Biol. Ecol. 45, 79–99. doi: 10.1016/0022-0981(91)90007-J

Cheah, W. Y., Ling, T. C., Juan, J. C., Lee, D. J., Chang, J. S., and Show, P. L. (2016). Biorefineries of carbon dioxide: from carbon capture and storage (CCS) to bioenergies production. Bioresour. Technol. 215, 346–356. doi: 10.1016/j.biortech.2016.04.019

Cheah, W. Y., Show, P. L., Chang, J. S., Ling, T. C., and Juan, J. C. (2015). Biosequestration of atmospheric CO2 and flue gas-containing CO2 by microalgae. Bioresour. Technol. 184, 190–201. doi: 10.1016/j.biortech.2014.11.026

Chen, B., Wan, C., Mehmood, M. A., Chang, J.-S., Bai, F., and Zhao, X. (2017). Manipulating environmental stresses and stress tolerance of microalgae for enhanced production of lipids and value-added products-A review. Bioresour. Technol. 244(Pt 2), 1198–1206. doi: 10.1016/j.biortech.2017.05.170

Cheng, D., Li, D., Yuan, Y., Zhou, L., Li, X., Wu, T., et al. (2017). Improving carbohydrate and starch accumulation in Chlorella sp. AE10 by a novel two-stage process with cell dilution. Biotechnol. Biofuels 10:75. doi: 10.1186/s13068-017-0753-9

Cheng, H. H., Whang, L. M., Chan, K. C., Chung, M. C., Wu, S. H., Liu, C. P., et al. (2015). Biological butanol production from microalgae-based biodiesel residues by Clostridium acetobutylicum. Bioresour. Technol. 184, 379–385. doi: 10.1016/j.biortech.2014.11.017

Chew, K. W., Yap, J. Y., Show, P. L., Suan, N. H., Juan, J. C., Ling, T. C., et al. (2017). Micro algae biorefinery: high value products perspectives. Bioresour. Technol. 229, 53–62. doi: 10.1016/j.biortech.2017.01.006

Chisti, Y. (2007). Biodiesel from microalgae. Biotechnol. Adv. 25, 294–306. doi: 10.1016/j.biotechadv.2007.02.001

Choi, G.-G., Kim, B.-H., Ahn, C.-Y., and Oh, H.-M. (2011). Effect of nitrogen limitation on oleic acid biosynthesis in Botryococcus braunii. J. Appl. Phycol. 23, 1031–1037. doi: 10.1007/s10811-010-9636-1

Church, J. A., and White, N. J. (2006). A 20th century acceleration in global sea-level rise. Geophys. Res. Lett. 33:L01602. doi: 10.1029/2005GL024826

Cole, I. S., Corrigan, P., Sim, S., and Birbilis, N. (2011). Corrosion of pipelines used for CO2 transport in CCS: is it a real problem? Int. J. Greenhouse Gas Control 5, 749–756. doi: 10.1016/j.ijggc.2011.05.010

Dawson, T. P., Jackson, S. T., House, J. I., Prentice, I. C., and Mace, G. M. (2011). Beyond predictions: biodiversity conservation in a changing climate. Science 332, 53–58. doi: 10.1126/science.1200303

De Silva, G. P. D., Ranjith, P. G., and Perera, M. S. A. (2015). Geochemical aspects of CO2 sequestration in deep saline aquifers: a review. Fuel 155, 128–143. doi: 10.1016/j.fuel.2015.03.045

Doney, S. C., Fabry, V. J., Feely, R. A., and Kleypas, J. A. (2009). Ocean acidification: the other CO2 problem. Annu. Rev. Mar. Sci. 2009, 169–192. doi: 10.1146/annurev.marine.010908.163834

Farrelly, D. J., Everard, C. D., Fagan, C. C., and McDonnell, K. P. (2013). Carbon sequestration and the role of biological carbon mitigation: a review. Renew. Sustain. Energy Rev. 21, 712–727. doi: 10.1016/j.rser.2012.12.038

Figueroa, J. D., Fout, T., Plasynski, S., McIlvried, H., and Srivastava, R. D. (2008). Advances in CO2 capture technology – the US Department of Energy’s Carbon sequestration program. Int. J. Greenhouse Gas Control 2, 9–20. doi: 10.1016/S1750-5836(07)00094-1

Gao, K., Orr, V., and Rehmann, L. (2016). Butanol fermentation from microalgae-derived carbohydrates after ionic liquid extraction. Bioresour. Technol. 206, 77–85. doi: 10.1016/j.biortech.2016.01.036

Gardner, R. D., Cooksey, K. E., Mus, F., Macur, R., Moll, K., Eustance, E., et al. (2012). Use of sodium bicarbonate to stimulate triacylglycerol accumulation in the chlorophyte Scenedesmus sp. and the diatom Phaeodactylum tricornutum. J. Appl. Phycol. 24, 1311–1320. doi: 10.1007/s10811-011-9782-0

Gardner, R. D., Egan, J., Lohman, E. J., Cooksey, K. E., Robin Gerlach, R., and Peyton, B. M. (2013). Cellular cycling, carbon utilization, and photosynthetic oxygen production during bicarbonate-induced triacylglycerol accumulation in a Scenedesmus sp. Energies 6, 6060–6076. doi: 10.3390/en6116060

Ghimire, A., Kumar, G., Sivagurunathan, P., Shobana, S., Saratale, G. D., Kim, H. W., et al. (2017). Bio-hythane production from microalgae biomass: key challenges and potential opportunities for algal bio-refineries. Bioresour. Technol. 241, 525–536. doi: 10.1016/j.biortech.2017.05.156

Goettel, M., Eing, C., Gusbeth, C., Straessner, R., and Frey, W. (2013). Pulsed electric field assisted extraction of intracellular valuables from microalgae. Algal Res. 2, 401–408. doi: 10.1016/j.algal.2013.07.004

Goldemberg, J. (2007). Ethanol for a sustainable energy future. Science 315, 808–810. doi: 10.1126/science.1137013

Gouveia, L., and Oliveira, A. C. (2009). Microalgae as a raw material for biofuels production. J. Ind. Microbiol. Biotechnol. 36, 269–274. doi: 10.1007/s10295-008-0495-6

Han, W., Li, C., Miao, X., and Yu, G. (2012). A novel miniature culture system to screen CO2- sequestering microalgae. Energies 5, 4372–4389. doi: 10.3390/en5114372

Harun, R., Singh, M., Forde, G. M., and Danquah, M. K. (2010). Bioprocess engineering of microalgaeto produce a variety of consumer products. Renew. Sustain. Energy Rev. 14, 1037–1047. doi: 10.1016/j.rser.2009.11.004

Ho, S. H., Chen, W. M., and Chang, J. S. (2010). Scenedesmus obliquus CNW-N as a potential candidate for CO2 mitigation and biodiesel production. Bioresour. Technol. 101, 8725–8730. doi: 10.1016/j.biortech.2010.06.112

Hofmann, M., and Schellnhuber, H. J. (2010). Ocean acidification: a millennial challenge. Energy Environ. Sci. 3, 1883–1896. doi: 10.1039/c000820f

Hu, Q., Sommerfeld, M., Jarvis, E., Ghirardi, M., Posewitz, M., Seibert, M., et al. (2008). Microalgal triacylglycerols as feedstocks for biofuel production: perspectives and advances. Plant J. 54, 621–639. doi: 10.1111/j.1365-313X.2008.03492.x

Hunt, A. J., Sin, E. H. K., Marriott, R., and Clark, J. H. (2010). Generation, capture, and utilizationof industrial carbon dioxide. ChemSusChem 3, 306–322. doi: 10.1002/cssc.200900169

Jagadevan, S., Banerjee, A., Banerjee, C., Guria, C., Tiwari, R., Baweja, M., et al. (2018). Recent developments in synthetic biology and metabolic engineering in microalgae towards biofuel production. Biotechnol. Biofuels 11:185. doi: 10.1186/s13068-018-1181-1

Jambo, S. A., Abdulla, R., Azhar, S. H. M., Marbawi, H., Azlan, G. J., Ravindra, P., et al. (2016). A review on third generation bioethanol feedstock. Renew. Sustain. Energy Rev. 65, 756–769. doi: 10.1016/j.rser.2016.07.064

Kao, C.-Y., Chen, T.-Y., Chang, Y.-B., Chiu, T.-W., Lin, H.-Y., Chen, C.-D., et al. (2014). Utilization of carbon dioxide in industrial flue gases for the cultivation of microalga Chlorella sp. Bioresour. Technol. 166, 485–493. doi: 10.1016/j.biortech.2014.05.094

Kesaano, M., and Sims, R. (2014). Algal biofilm based technology for wastewater treatment. Algal Res. 5, 231–240. doi: 10.1016/j.algal.2014.02.003

Khan, S. A., Rashmi, Hussain, M. Z., Prasad, S., and Banerjee, U. C. (2009). Prospects of biodiesel production from microalgae in India. Renew. Sust. Energy Rev. 13, 2361–2372. doi: 10.1016/j.rser.2009.04.005

Kita, J., and Ohsumi, T. (2004). Perspectives on biological research for CO2 ocean sequestration. J. Oceanogr. 60, 695–703. doi: 10.1007/s10872-004-5762-1

Kittel, J., Idem, R., Gelowitz, D., Tontiwachwuthikul, P., Parrain, G., and Bonneau, A. (2009). Corrosion in MEA units for CO2 capture: pilot plant studies. Energy Procedia 1, 791–797. doi: 10.1016/j.egypro.2009.01.105

Koller, M., Muhr, A., and Braunegg, G. (2014). Microalgae as versatile cellular factories for valued products. Algal Res. 6, 52–63. doi: 10.1016/j.algal.2014.09.002

Koutra, E., Economou, C. N., Tsafrakidou, P., and Kornaros, M. (2018). Bio-based products from microalgae cultivated in digestates. Trends Biotechnol. 36, 819–833. doi: 10.1016/j.tibtech.2018.02.015

Kovscek, A. R., and Cakici, M. D. (2005). Geologic storage of carbon dioxide and enhanced oil recovery. II. Cooptimization of storage and recovery. Energy Convers. Manage. 46, 1941–1956. doi: 10.1016/j.enconman.2004.09.009

Kuo, C. M., Lin, T. H., Yang, Y. C., Zhang, W. X., Lai, J. T., Wu, H. T., et al. (2017). Ability of an alkali-tolerant mutant strain of the microalga Chlorella sp. AT1 to capture carbon dioxide for increasing carbon dioxide utilization efficiency. Bioresour. Technol. 244, 243–251. doi: 10.1016/j.biortech.2017.07.096

Lackner, K. S. (2003). A guide to CO2 sequestration. Science 300, 1677–1678. doi: 10.1126/science.1079033

Lam, M. K., Lee, K. T., and Mohamed, A. R. (2012). Current status and challenges on microalgae-based carbon capture. Int. J. Greenhouse Gas Control 10, 456–469. doi: 10.1016/j.ijggc.2012.07.010

Li, G., Xiao, P., Webley, P., Zhang, J., Singh, R., and Marshall, M. (2008). Capture of CO2 from high humidity flue gas by vacuum swing adsorption with zeolite 13X. Adsorption 14, 415–422. doi: 10.1007/s10450-007-9100-y

Li, Y., Horsman, M., Wu, N., Lan, C. Q., and Dubois-Calero, N. (2008). Biofuels from microalgae. Biotechnol. Prog. 24, 815–820. doi: 10.1021/bp070371k

Lin, Y., Kong, C., Zhang, Q., and Chen, L. (2016). Metal organic frameworks for carbon dioxide capture and methane storage. Adv. Energy Mater. 7:1601296. doi: 10.1002/aenm.201601296

Markou, G., and Nerantzis, E. (2013). Microalgae for high-value compounds and biofuels production: a review with focus on cultivation under stress conditions. Biotechnol. Adv. 31, 1532–1542. doi: 10.1016/j.biotechadv.2013.07.011

Mata, T. M., Martins, A. A., and Caetano, N. S. (2010). Microalgae for biodiesel production and other applications: a review. Renew. Sustain. Energy Rev. 14, 217–232. doi: 10.1016/j.rser.2009.07.020

McCoy, S. T., and Rubin, E. S. (2008). An engineering-economic model of pipeline transport of CO2 with application to carbon capture and storage. Int. J. Greenhouse Gas Control 2, 219–229. doi: 10.1016/S1750-5836(07)00119-3

Meinshausen, M., Meinshausen, N., Hare, W., Raper, S. C. B., Frieler, K., Knutti, R., et al. (2009). Greenhouse-gas emission targets for limiting global warming to 2 degrees C. Nature 458, 1158–1196. doi: 10.1038/nature08017

Nandasiri, M. I., Jambovane, S. R., McGrail, B. P., Schaef, H. T., and Nune, S. K. (2016). Adsorption, separation, and catalytic properties of densified metal-organic frameworks. Coord. Chem. Rev. 311, 38–52. doi: 10.1016/j.ccr.2015.12.004

Ng, I. S., Tan, S. I., Kao, P. H., Chang, Y. K., and Chang, J. S. (2017). Recent developments on genetic engineering of microalgae for biofuels and bio-based chemicals. Biotechnol. J. 12:1600644. doi: 10.1002/biot.201600644

Nouha, K., John, R. P., Yan, S., Tyagi, R., Surampalli, R. Y., and Zhang, T. C. (2015). “Carbon capture and sequestration: biological technologies,” in Carbon Capture and Storage: Physical, Chemical, and Biological Methods, ed. R. Y. Surampalli (Reston: American Society of Civil Engineers), 65–111. doi: 10.1061/9780784413678.ch04

Odjadjare, E. C., Mutanda, T., and Olaniran, A. O. (2015). Potential biotechnological application of microalgae: a critical review. Crit. Rev. Biotechnol. 37, 37–52. doi: 10.3109/07388551.2015.1108956

Orr, V. C., and Rehmann, L. (2016). Ionic liquids for the fractionation of microalgae biomass. Curr. Opin. Green Sustain. Chem. 2, 22–27. doi: 10.1016/j.cogsc.2016.09.006

Pérez, A. T. E., Camargo, M., Rincón, P. C. N., and Marchant, M. A. (2017). Key challenges and requirements for sustainable and industrialized biorefinery supply chain design and management: a bibliographic analysis. Renew. Sustain. Energy Rev. 69, 350–359. doi: 10.1016/j.rser.2016.11.084

Pires, J., Martins, F., Alvim-Ferraz, M., and Simões, M. (2011). Recent developments oncarbon capture and storage: an overview. Chem. Eng. Res. Des. 89, 1446–1460. doi: 10.1016/j.cherd.2011.01.028

Pires, J. C. (2017). COP21: the algae opportunity? Renew. Sustain. Energy Rev. 79, 867–877. doi: 10.1016/j.rser.2017.05.197

Pires, J. C. M., Alvim-Ferraz, M. C. M., Martins, F. G., and Simoes, M. (2012). Carbon dioxide capture from flue gases using microalgae: engineering aspects and biorefinery concept. Renew. Sustain. Energy Rev. 16, 3043–3053. doi: 10.1016/j.rser.2012.02.055

Rignot, E., and Kanagaratnam, P. (2006). Changes in the velocity structure of the Greenland ice sheet. Science 311, 986–990. doi: 10.1126/science.1121381

Rockstrom, J., Steffen, W., Noone, K., Persson, A., Chapin, F. S., Lambin, E. F., et al. (2009). A safe operating space for humanity. Nature 461, 472–475. doi: 10.1038/461472a

Ryan, C. (2009). Cultivating Clean Energy. The Promise of Algae Biofuels. Washington, DC: NRDC Publications.

Scholes, C. A., Kentish, S. E., and Stevens, G. W. (2009). The effect of condensable minor components on the gas separation performance of polymeric membranes for carbon dioxide capture. Energy Procedia 1, 311–317. doi: 10.1016/j.egypro.2009.01.043

Schüler, L. M., Schulze, P. S., Pereira, H., Barreira, L., León, R., and Varela, J. (2017). Trends and strategies to enhance triacylglycerols and high-value compounds in microalgae. Algal Res. 25, 263–273. doi: 10.1016/j.algal.2017.05.025

Searchinger, T., Heimlich, R., Houghton, R. A., Dong, F., Elobeid, A., Fabiosa, J., et al. (2008). Use of US croplands for biofuels increases greenhouse gases through emissions from land use change. Science 319, 1238–1240. doi: 10.1126/science.1151861

Singh, J., and Thakur, I. S. (2015). Evaluation of cyanobacterial endolith Leptolyngbya sp. ISTCY101, for integrated wastewater treatment and biodiesel production: a toxicological perspective. Algal Res. 11, 294–303. doi: 10.1016/j.algal.2015.07.010

Singh, J., Tripathi, R., and Thakur, I. S. (2014). Characterization of endolithic cyanobacterial strain, Leptolyngbya sp. ISTCY101, for prospective recycling of CO2 and biodiesel production. Bioresour. Technol. 166, 345–352. doi: 10.1016/j.biortech.2014.05.055

Solomon, S., Plattner, G. K., Knutti, R., and Friedlingstein, P. (2009). Irreversible climate change due to carbon dioxide emissions. Proc. Natl. Acad. Sci. U.S.A. 106, 1704–1709. doi: 10.1073/pnas.0812721106

Svensson, R., Odenberger, M., Johnsson, F., and Stromberg, L. (2004). Transportation systemsfor CO2 – application to carbon capture and storage. Energy Convers. Manage. 45, 2343–2353. doi: 10.1016/j.biortech.2010.02.088

Sydney, E. B., Sturm, W., de Carvalho, J. C., Thomaz-Soccol, V., Larroche, C., Pandey, A., et al. (2010). Potential carbon dioxide fixation by industrially important microalgae. Bioresour. Technol. 101, 5892–5896. doi: 10.1016/j.biortech.2010.02.088

’t Lam, G. P., Vermuë, M. H., Eppink, M. H. M., Wijffels, R. H., and van den Berg, C. (2017). Multi-product microalgae biorefineries: from concept towards reality. Trends biotechnol. 36, 216–227. doi: 10.1016/j.tibtech.2017.10.011

Tang, D., Han, W., Li, P., Miao, X., and Zhong, J. (2011). CO2 biofixation and fatty acid composition of Scenedesmus obliquus and Chlorella pyrenoidosa in response to different CO2 levels. Bioresour. Technol. 102, 3071–3076. doi: 10.1016/j.biortech.2010.10.047

Thomas, D. M., Mechery, J., and Paulose, S. V. (2016). Carbon dioxide capture strategies from flue gas using microalgae: a review. Environ. Sci. Pollut. R. 23, 16926–16940. doi: 10.1007/s11356-016-7158-3

Trickett, C. A., Helal, A., Al-Maythalony, B. A., Yamani, Z. H., Cordova, K. E., and Yaghi, O. M. (2017). The chemistry of metal–organic frameworks for CO2 capture, regeneration and conversion. Nat. Rev. Mater. 2:17045. doi: 10.1038/natrevmats.2017.45

Tuinier, M. J., van Sint Annaland, M., Kramer, G. J., and Kuipers, J. A. M. (2010). Cryogenic CO2 capture using dynamically operated packed beds. Chem. Eng. Sci. 65, 114–119. doi: 10.1016/j.ces.2009.01.055

Vanthoor-Koopmans, M., Wijffels, R. H., Barbosa, M. J., and Eppink, M. H. M. (2013). Biorefinery of microalgae for food and fuel. Bioresour. Technol. 135, 142–149. doi: 10.1016/j.biortech.2012.10.135

Varshney, P., Mikulic, P., Vonshak, A., Beardall, J., and Wangikar, P. P. (2014). Extremophilic micro-algae and their potential contribution in biotechnology. Bioresour. Technol. 184, 363–372. doi: 10.1016/j.biortech.2014.11.040

Vuppaladadiyam, A. K., Yao, J. G., Florin, N., George, A., Wang, X., Labeeuw, L., et al. (2018). Impact of flue gas compounds on microalgae and mechanisms for carbon assimilation and utilization. ChemSusChem 11, 334–355. doi: 10.1002/cssc.201701611

Wang, B., Li, Y., Wu, N., and Lan, C. Q. (2008). CO2 bio-mitigation using microalgae. Appl. Microbiol. Biotechnol. 79, 707–718. doi: 10.1007/s00253-008-1518-y

Wang, J., Liu, W., and Liu, T. (2017). Biofilm based attached cultivation technology for microalgal biorefineries—a review. Bioresour. Technol. 244, 1245–1253. doi: 10.1016/j.biortech.2017.05.136

Wang, Q., Luo, J., Zhong, Z., and Borgna, A. (2011). CO2 capture by solid adsorbents and theirapplications: current status and new trends. Energy Environ. Sci. 4, 42–55. doi: 10.1039/C0EE00064G

Wang, Y., Guo, W., Cheng, C. L., Ho, S. H., Chang, J. S., and Ren, N. (2016). Enhancing bio-butanol production from biomass of Chlorella vulgaris JSC-6 with sequential alkali pretreatment and acid hydrolysis. Bioresour. Technol. 200, 557–564. doi: 10.1016/j.biortech.2015.10.056

White, D. A., Pagarette, A., Rooks, P., and Ali, S. T. (2013). The effect of sodium bicarbonate supplementation on growth and biochemical composition of marine microalgae cultures. J. Appl. Phycol. 25, 153–165. doi: 10.1007/s10811-012-9849-6

Whitton, B. A. (2012). Ecology of Cyanobacteria II: Their Diversity in Space and Time. Dordrecht: Springer. doi: 10.1007/978-94-007-3855-3

Williams, P. J. l. B, and Laurens, L. M. L. (2010). Microalgae as bio-diesel and biomass feedstocks: review and analysis of the biochemistry, energetics and economics. Energy Environ. Sci. 3, 554–590. doi: 10.1039/b924978h

Williamson, P., Wallace, D. W., Law, C. S., Boyd, P. W., Collos, Y., Croot, P., et al. (2012). Ocean fertilization for Geoengineering: a review of effectiveness, environmental impacts and emerging governance. Process Saf. Environ. Prot. 1, 475–488. doi: 10.1016/j.psep.2012.10.007

Yadav, G., and Sen, R. (2017). Microalgal green refinery concept for biosequestration of carbon-dioxide vis-à-vis wastewater remediation and bioenergy production: recent technological advances in climate research. J. CO2 Util. 17, 188–206. doi: 10.1016/j.jcou.2016.12.006

Yang, B., Liu, J., Ma, X., Guo, B., Liu, B., Wu, T., et al. (2017). Genetic engineering of the Calvin cycle toward enhanced photosynthetic CO2 fixation in microalgae. Biotechnol. Biofuels 10:229. doi: 10.1186/s13068-017-0916-8

Yeong, T. K., Jiao, K., Zeng, X., Lin, L., Pan, S., and Danquah, M. K. (2018). Microalgae for biobutanol production–Technology evaluation and value proposition. Algal Res. 31, 367–376. doi: 10.1016/j.algal.2018.02.029

Yoo, C., Jun, S. Y., Lee, J. Y., Ahn, C. Y., and Oh, H. M. (2010). Selection of microalgae for lipid production under high levels carbon dioxide. Bioresour. Technol. 101, S71–S74. doi: 10.1016/j.biortech.2009.03.030

Zhou, W., Li, Y., Min, M., Hu, B., Zhang, H., Ma, X., et al. (2012). Growing wastewater-born microalga Auxenochlorella protothecoides UMN280 on concentrated municipal wastewater for simultaneous nutrient removal and energy feedstock production. Appl. Energy 98, 433–440. doi: 10.1016/j.apenergy.2012.04.005

Zhou, W., Wang, J., Chen, P., Ji, C., Kang, Q., Lu, B., et al. (2017). Bio-mitigation of carbon dioxide using microalgal systems: advances and perspectives. Renew. Sustain. Energy Rev. 76, 1163–1175. doi: 10.1016/j.rser.2017.03.065

Keywords: microalgae, biorefinery, carbon capture, bio-sequestration, CO2 mitigation, biofuel

Citation: Singh J and Dhar DW (2019) Overview of Carbon Capture Technology: Microalgal Biorefinery Concept and State-of-the-Art. Front. Mar. Sci. 6:29. doi: 10.3389/fmars.2019.00029

Received: 01 August 2018; Accepted: 21 January 2019;

Published: 05 February 2019.

Edited by:

Pannaga Pavan Jutur, International Centre for Genetic Engineering and Biotechnology, IndiaReviewed by:

Jafar Razeghi, University of Tabriz, IranEdwin Zondervan, University of Bremen, Germany

Copyright © 2019 Singh and Dhar. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Dolly Wattal Dhar, ZG9sbHl3YXR0YWxkaGFyQHlhaG9vLmNvbQ==

Jyoti Singh

Jyoti Singh Dolly Wattal Dhar

Dolly Wattal Dhar