Introduction: Biomineralization is the process by which bones and teeth are formed through the nucleation of calcium phosphate polymorphs (CaP), principally apatite, onto the surface of collagen. To mimic the composition of mineralized tissues, synthetic grafts and bone void fillers are frequently formulated to include CaP polymorphs intended to improve biocompatibility and osteoconductivity of biomaterials. The biological performance of CaP materials is associated with fundamental parameters including chemical composition, morphology, and resorbability of the CaP polymorph[1]. However, to date, there has not been a method available that provides control over the resulting CaP polymorphs within mineralized biopolymers[2]. For tissue engineering applications, ideal CaP-composite materials would include biomimetic CaP polymorphs in place of the synthetic hydroxyapatite currently used. Here we have developed a method for in situ biomimetic mineralization of polymeric hydrogels, where the incorporated CaP phase can be selectively tuned in chemical composition and morphology to mimic bone and dental mineral.

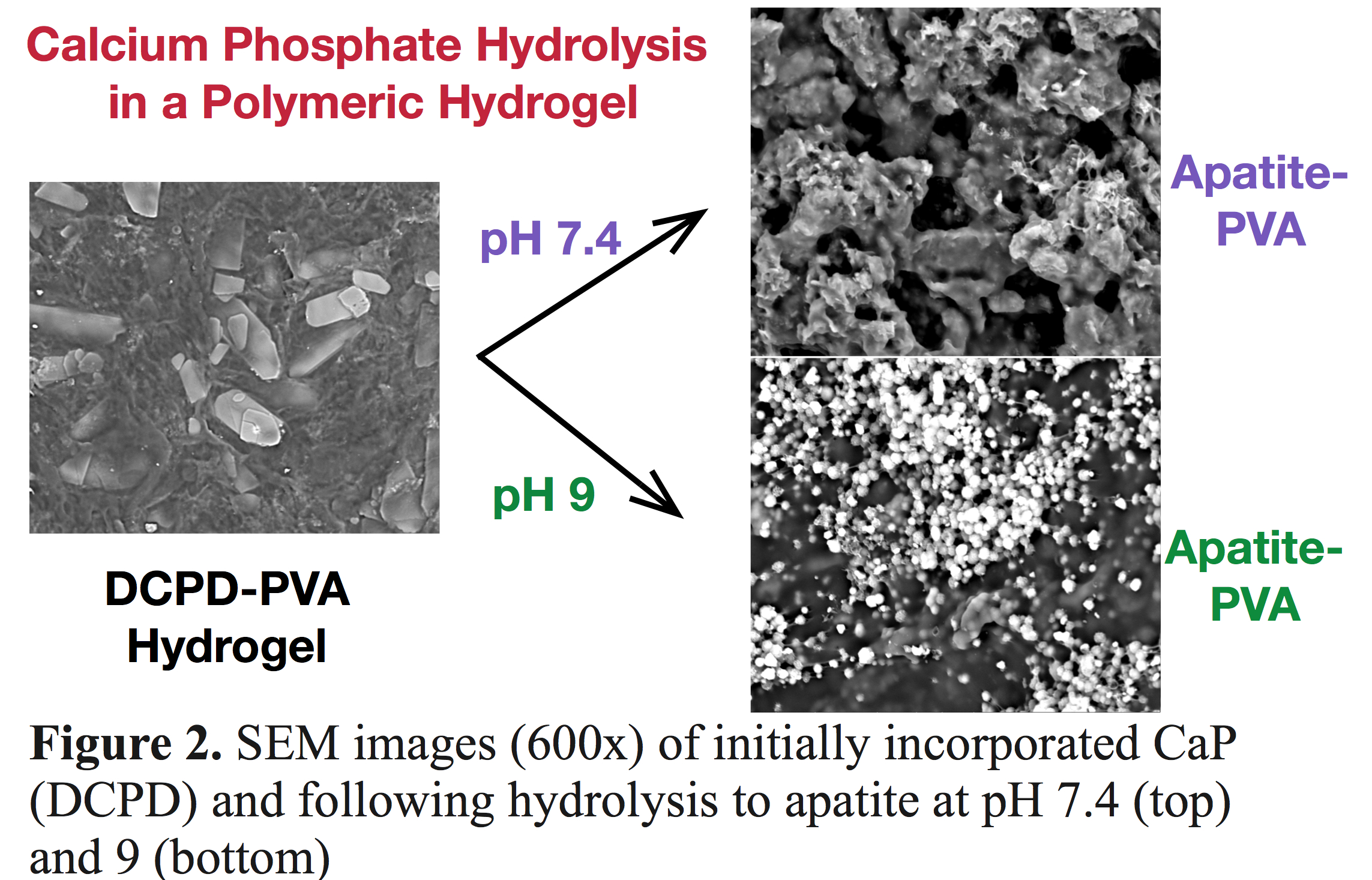

Materials and Methods: Composite apatite-poly (vinyl alcohol) (PVA) hydrogels were prepared following a newly developed stepwise synthetic method: 1) An immature CaP phase Dicalcium Phosphate Dihydrate (DCPD) is precipitated in an aqueous PVA solution by the concurrent addition of calcium and phosphate salts under acidic conditions. 2) The heterogeneous DCPD-PVA solution is then transformed into a hydrogel by physically crosslinking PVA via cyclic freezing/thawing (5x). 3) The resulting composite hydrogels are subsequently immersed in an aqueous buffered solution with predetermined pH values of 7.4 or 9 at 37 °C to facilitate hydrolysis of the incorporated DCPD to apatite. The chemical composition and morphology of the CaP particles incorporated into the hydrogel were determined by X-ray diffraction (XRD) and infrared spectroscopy (IR), and scanning electron microscopy (SEM).

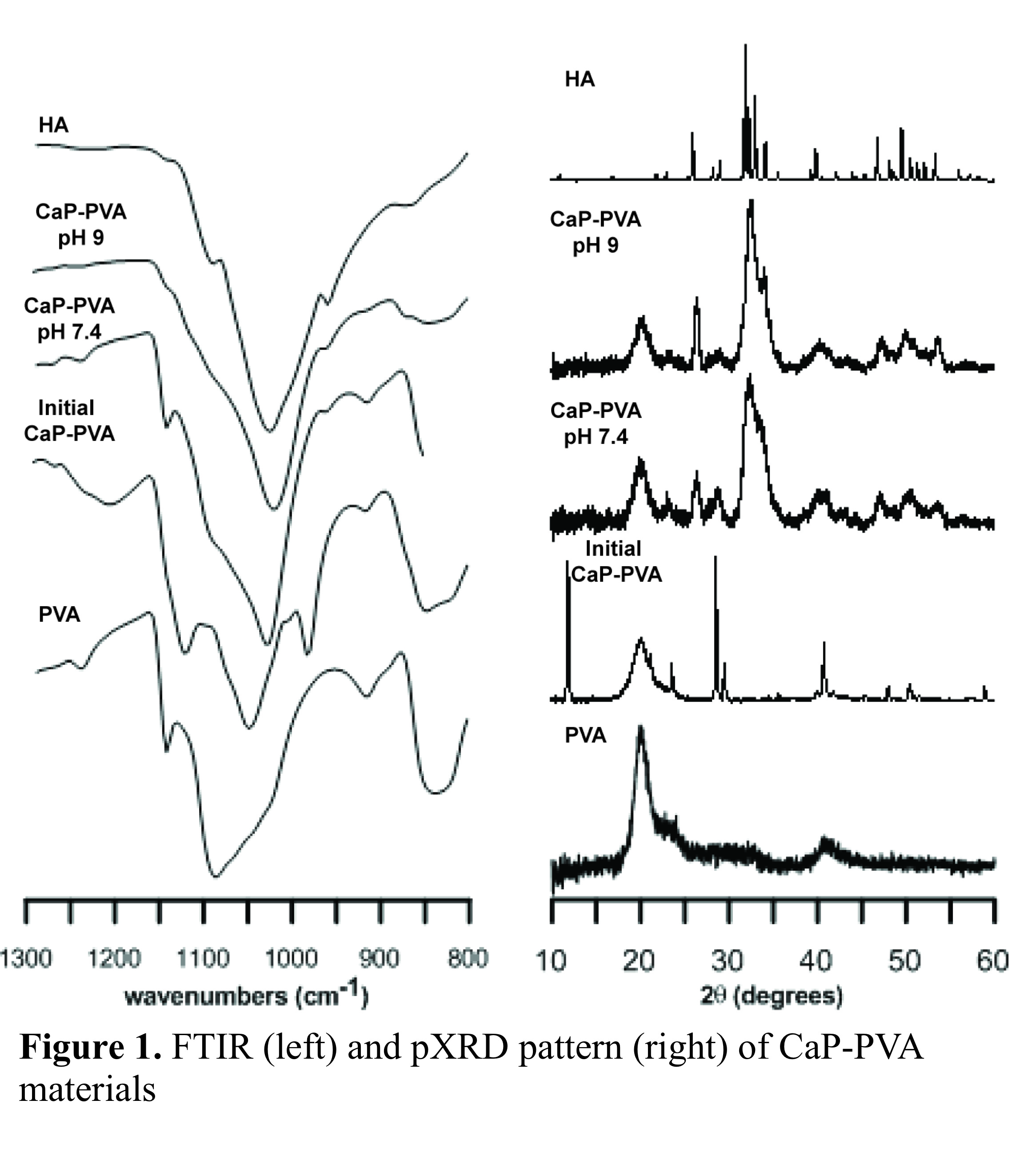

Results and Discussion: The CaP polymorphs incorporated in the polymeric hydrogel before and after hydrolysis were examined by XRD and IR (Figure 1). The initial CaP phase incorporated into the polymeric matrix is unequivocally identified as DCPD, and subsequent hydrolysis at pH 7.4 and 9 resulted in the transformation of the DCPD to apatite. Notably, the morphology of the incorporated apatite phase was found to differ based on the hydrolysis solution pH: DCPD is converted to large interconnected crystals at pH 7.4 compared to individual spherical particles at pH 9 (Figure 2). The variations in particle morphology were determined to be a result of a pH-dependent hydrolysis pathway, where at pH 7.4 the formation of Octacalcium Phosphate (OCP) as a transition state was necessary, while at pH 9 direct conversion to apatite was seen. These findings correlate with reported biomineralization mechanisms where biological apatite is formed from an unstable CaP precursor phase using OCP as an intermediate. Thus, our newly developed synthetic method facilitates the formation of biomimetic CaP composite materials that can be easily tuned for specific applications. This method further facilitates the preparation of carbonated and fluoride doped lattices intended to mimic the natural composition of bone and dental apatites, respectively.

Conclusion: This novel method for the preparation of CaP-composite materials provides a previously inaccessible synthetic handle for controlling the chemical composition and particle morphology of biomimetic apatite incorporated into polymers. Development of biomineralized materials will enable studies of the effect of biomineralization processes on cells in vitro, and has high potential to provide next-generation synthetic bone and dental graft material.

This work was supported by start up funds provided by the Colorado School of Mines

References:

[1] S. V. Dorozhkin and M. Epple, Angewandte Chemie-International Edition, 2002, 41, 3130-3146.

[2] S. Schweizer and A. Taubert, Macromolecular Bioscience, 2007, 7, 1085-1099.