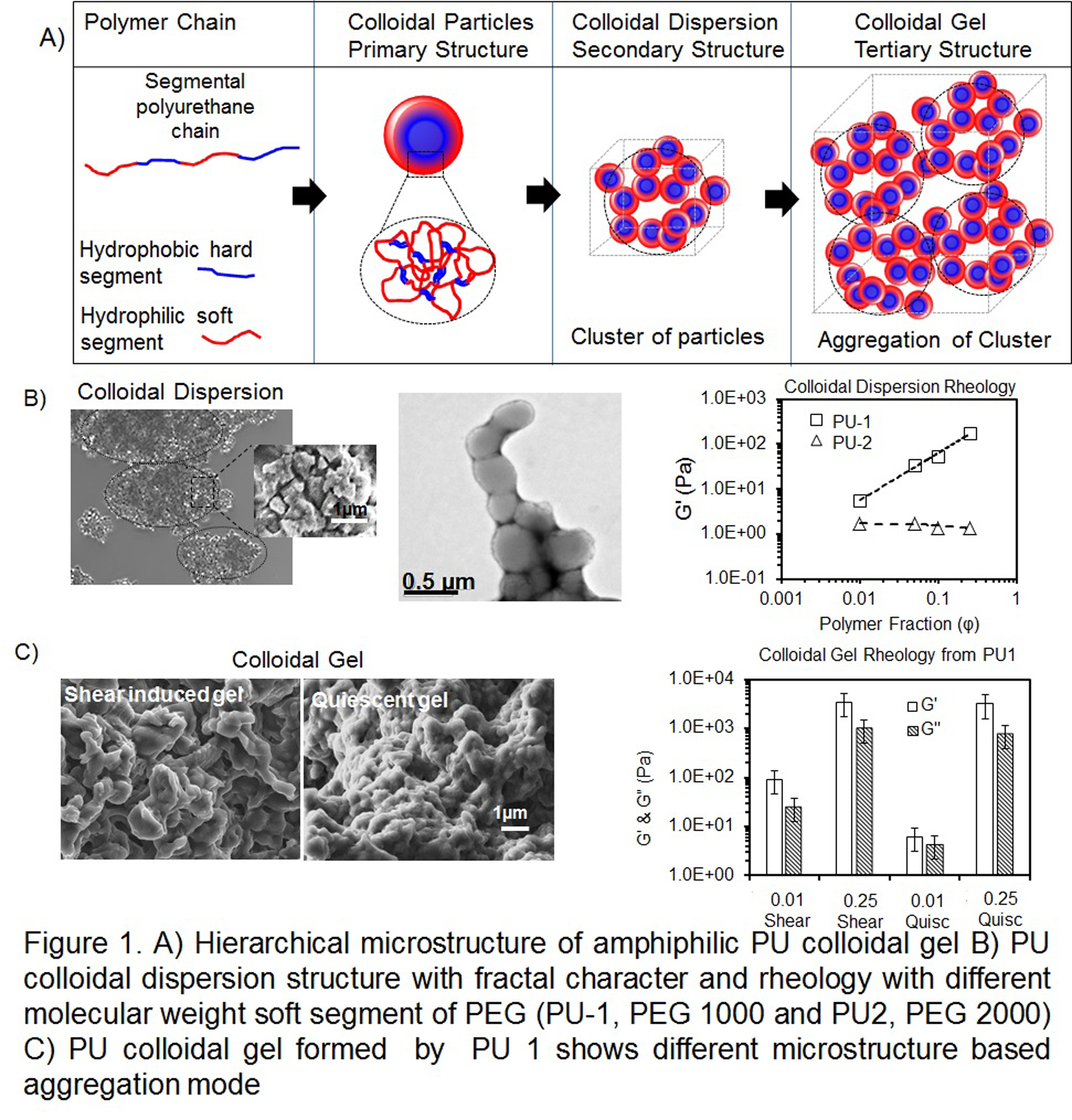

Introduction: Control of microstructure with hydrogel material is limited due to the structural constraints imposed by the molecular design of polymer which can be avoided by amphiphilic polyurethanes (PUs)[1],[2]. Amphiphilic PUs with alternating hydrophilic soft segment and hydrophobic hard segment can hierarchically assemble into colloidal microgel where sub-micron size colloidal particles are clustered into dispersion through interparticle aggregation which further associates into gel like structure (Figure 1A). We hypothesized that hierarchical microstructure of colloidal PU gel controlled at multiple length scale enables engineering of physicomechanical properties of gel which can regulate cellular organization for different applications including stem cell differentiation and endothelial network formation.

Materials and Methods: Amphiphilic PUs designed from polyethylene glycol (PEG) of different molecular weight as soft segment and aliphatic diisocyanate and L-tyrosine based chain extender as hard segment were used to form colloidal gel in aqueous medium with defined weight fraction[1]. Microstructure of the gels was examined from oscillatory rheology and electron microscopy and morphological charcterizations. Cellular organization in these gels was examined using mesenchymal stem cells (MSCs) and endothelial cells (ECs) to analyze the effect of gel microstructure on chondrogenesis of stem cells and endothelial network formation, respectively.

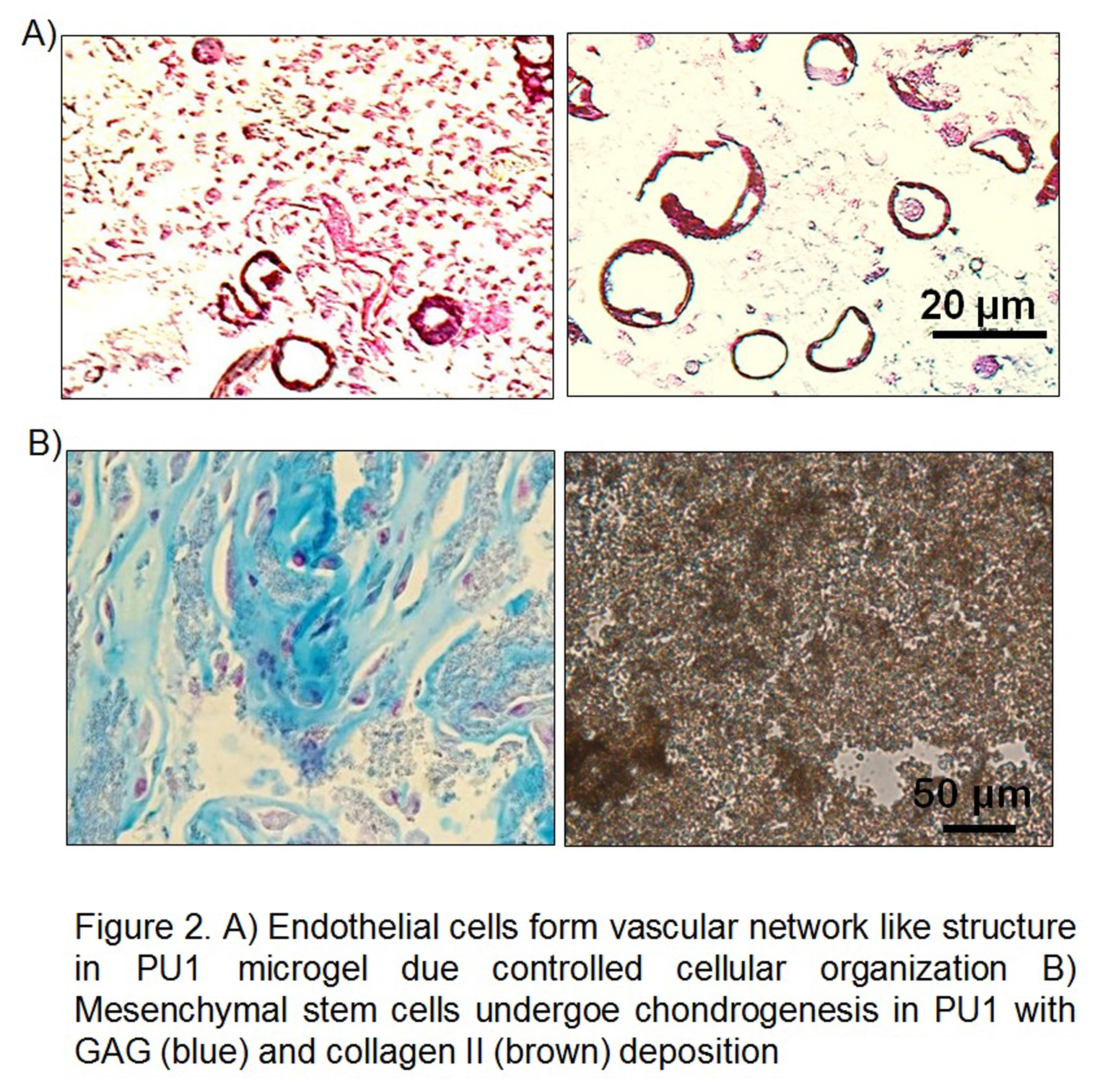

Results and Discussions: Microstructural analysis of PU dispersion (Figure 1B) and colloidal gel (Figure 1C) shows the hierarchical structure with fractal character evolving with clustering of submicron particles and aggregation of clusters into gel structure. Polymer composition, polymer fraction, and mode of aggregation regulate the structures at microscale (dispersion) through interparticle interactions and at mesoscale (gel) dimension through intercluster interactions, as shown by the microscopic images and rheological characters. Physicomechanically, colloidal dispersion from PU2 with high molecular weight PEG (2000) shows weaker interactions leading to ineffective gel compared to PU1 with low molecular weight PEG (1000). Consequently, colloidal gels were formed from PU1 was further engineered through different aggregation modes with different gel content. Gel structures are controlled by mesoscale characteristics at lower gel fraction but through microscale characteristics at higher gel fraction indicating the interplay of interactions at two scale lengths. These colloidal PU microgels influenced cellular organization of ECs and MSCs in the PU1 gels (Figure 2), which is not observed in traditional hydrogels. ECs formed lumen like structures (Figure 2A) due to controlled cellular aggregation demonstrating the effect multiscale structure on EC organization. MSCs were effectively differentiated into chondrogenic lineages (Figure 2B) as these gels promoted cellular aggregation. Both of these studies demonstrated the effect PU microgel architecture on cellular organization where both micro and mesoscale organizations were controlled to promote cell response.

Conclusion: Amphiphilic PUs can form colloidal microgel with a hierarchical structure which is controlled at multiple scale lengths, by varying polymer structure, composition and mode of gelation. This type of control at different scale lengths induces a self-similar fractal pattern to regulate cellular organization and functions, as evident from ECs and MSCs response. Unique control in gel structure and properties achieved by the versatile nature of colloidal PU microgel is not feasible through conventional hydrogels. Most significantly, these materials show easily adjustable characteristics for regulating cell response in tissue engineering and cell delivery applications.

References:

[1] Nalluri SM, Krishnan GR, Cheah C, Arzumand A, Yuan Y, Richardson CA, Yang S, Sarkar D. Hydrophilic polyurethane matrix promotes chondrogenesis of mesenchymal stem cells. Materials Science and Engineering: C. 2015;54:182-95

[2] Kim BK. Aqueous polyurethane dispersions. Colloid Polym Sci. 1996;274(7):599-611