Introduction: Biodegradable conductive materials have promises to be applied for myocardium, nerve, muscle and bone tissue repair. The conductive hydrogel promoted growth and maturation of cardiac cells, and enhanced the electrical and mechanical coupling and contractile properties[1]. The conductive material also improved neurite outgrowths from the nerve cells by integrating biochemical and electrical stimulations[2]. However, biodegradable conductive elastomer was rarely reported. To address this limitation, we will utilize polyurethane chemistry to design a biodegradable polymer with elasticity and conductivity.

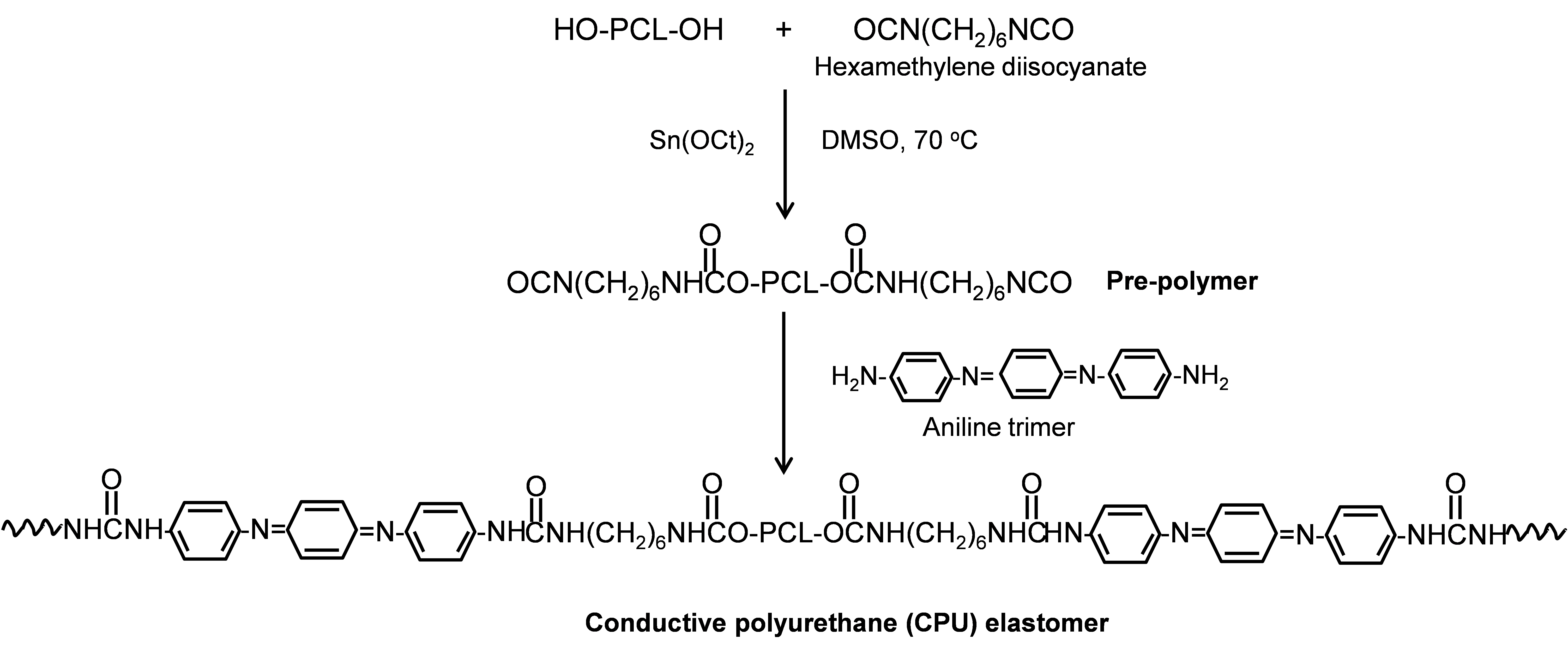

Here, we combined polycaprolactone diol (PCL) as a soft segment, 1, 6-hexamethylene diisocyante (HDI) as a hard segment and aniline trimer as a chain extender to achieve a biodegradable polyurethane with electrical and electrochemical properties. The electrical and electrochemical properties, morphologies, mechanical properties, degradation behavior, electrical stability and cytocompatibility of the conductive polyurethane were evaluated.

Materials and Methods:

The conductive polyurethane (CPU) was synthesized by a two-step process (Fig. 1) and then fabricated into films doped with (1S)-(+)-10-camphorsulfonic acid (CSA) by solvent casting. The chemical structures of oxidized aniline trimer and CPU films were confirmed by 1H NMR, 13C NMR and FTIR, respectively. The morphologies of CPU films were observed on a scanning electron microscope (SEM). The electrical conductivities of CPU films at dry and wet states were measured by four-probe technique. The electroactivities of CPU films were characterized by UV-vis and cyclic voltammogram measurements. Mechanical properties of CPU films were measured on a MTS workstation with a head crossing rate of 10 mm/min. Cyclic stretching of CPU films at a maximum strain of 30% was tested at a constant rate of 10 mm/min for 10 cycles. The electrical stability of doped CPU films was carried out in cell culture medium under a constant DC voltage of 100±2 mV for 150 h. In vitro degradation of CPU films was detected in phosphate buffer solution (PBS) and lipase/PBS solutions. The electrical conductivity changes of CPU films were measured after degradation in 100 U/mL lipase/PBS solution for 3 and 7 d at 37 oC. The cytocompatibility of CPU films was evaluated using 3T3 fibroblasts.

Results and Discussion: All CPU films showed good elasticity within 30% strain range, and their initial moduli increased with increasing CSA content. The roughness of CPU films increased with increasing CSA amount. The electrical conductivity of CPU films also enhanced with increasing CSA dopant amount, ranging from 2.7±0.9×10-10 to 4.4±0.6×10-7 S/cm at dry state and 4.2±0.5×10-8 to 7.3±1.5×10-5 S/cm at wet state. These values (wet) were in the semiconductive region. The redox peaks (0.17 V and 0.82 V) of CPU1.5 film (molar ratio of CSA:aniline trimer was 1.5:1) in cyclic voltammogram indicated its good electroactivity. The doped CPU film exhibited excellent electrical stability (91% of initial conductivity after 150 h charge) in cell culture medium. The degradation of CPU films became faster with increasing CSA dopant amount in either PBS or lipase/PBS solutions. After 7 d of enzymatic degradation, all CSA doped CPU films lost their conductivity. Their conductivities were similar to that of the undoped CPU film, which may attribute to the dopant leaching during degradation. The 3T3 fibroblasts proliferated and spread on all CPU films. There was no significantly difference on cell proliferation between CPU films and the tissue culture polystyrene, except for the CPU1.5 film. The CPU1.5 film having the highest dopant content showed less cell viability within 5 d incubation, which may be resulted from the rough surface and leached dopant.

Conclusions: A biodegradable conductive polyurethane containing aniline trimer was synthesized. They had good elasticity conductive stability and biocompatibility, which are closely relevant with dopant amount. This biodegradable conductive polyurethane would find opportunities to be applied as tissue engineered scaffolds and smart drug release carriers.

Research Enhancement Program from UT Arlington; Beginning-in-Aid award (#14BGIA20510066) from the American Heart Association

References:

[1] T. Dvir, et al, "Nanowired three dimensional cardiac patches", Nat Nanotechnol. Vol. 6, 2011.

[2] B. Zhu , et al,"Large enhancement in neurite outgrowth on a cell membrane-mimicking conducting polymer", Nat Commun. Vol. 5, 2014.