Statement of Purpose: Although porous metal scaffolds are widely used, there are still demands for gradient porous structure which mimics the structure of real bone. By mimicking bone structure, reduced “stress shielding effect” is expected[1]. In this study, intrinsic ductility of porous titanium scaffold by dynamic freeze casting was used to fabricate gradient porous structure. After shaping two different forms, they were assembled into a single scaffold by unidirectional compressing (z-axis) to make gradient porous structure[2]. Another advantage of porous scaffolds besides biomimicking is their ability to load and release drugs[3]. Through two body combination after drug loading, different release behavior can be achieved for each part.

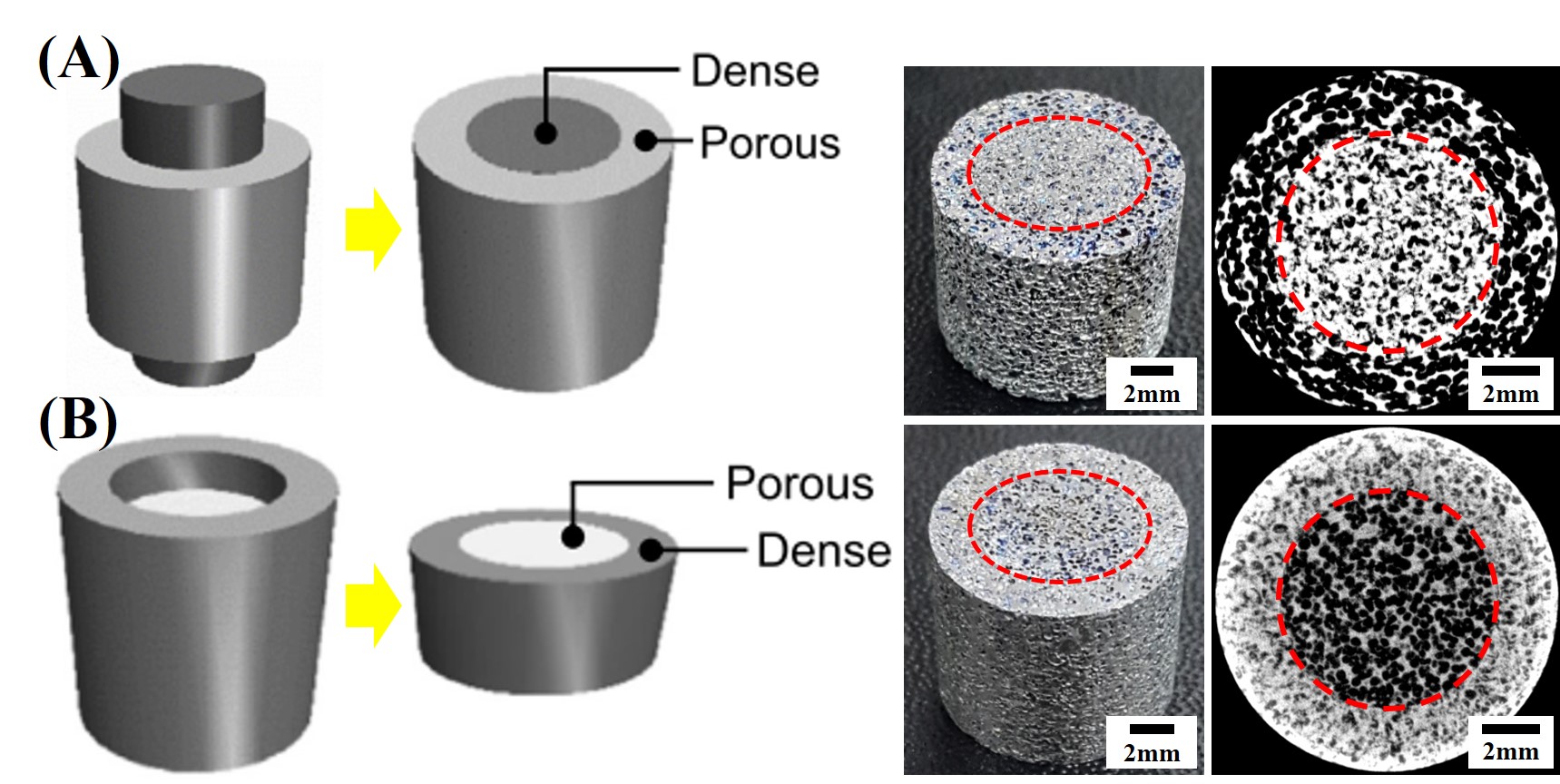

Methods: Commercial pure titanium was mixed with camphene and oligomeric polyester dispersant in an Al mold and the Al mold was rotated at a speed of 30 rpm at 44°C for 12 h. After densifying the specimen using CIP process, the resulting green body was freeze dried in vacuum chamber to remove the camphene.. Heat treatment was done in vacuum system at 1300℃ for 2 h. After sintering, it was machined into a rod and a ring shape with different heights and the different combination of rod and ring are referred to as positive and negative as shown in Fig. 1. Rod and ring with different height are compressed along the z-axis into one scaffold. The morphology of scaffolds was observed by micro CT. Green Fluorescent Protein (GFP) was loaded in the negative scaffold and the release behavior was observed by confocal laser scanning microscopy (CLSM).

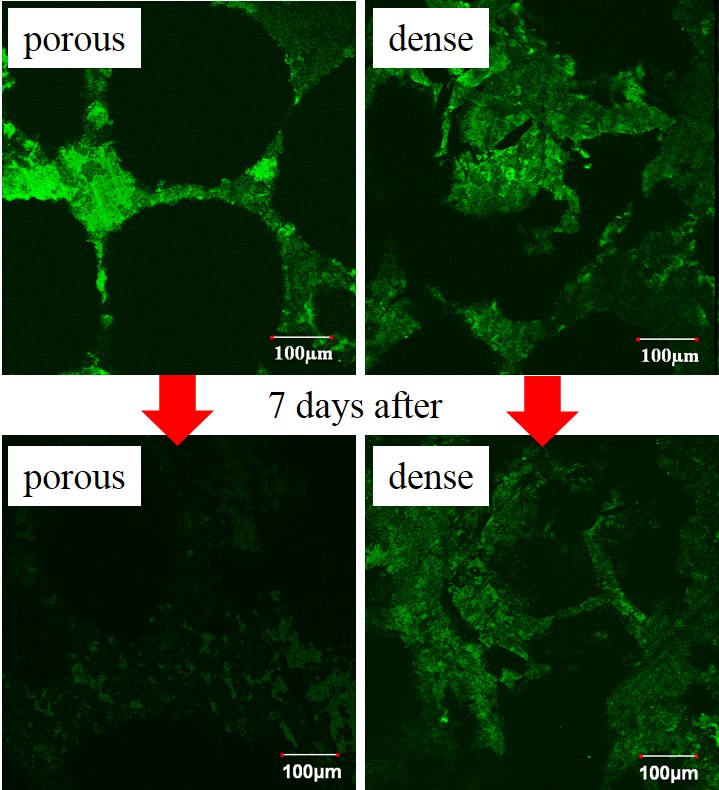

Results and Discussion: Spherical pore shape became irregular shape with decreasing porosity because of unidirectional compressing (Fig. 1). After compressing, porosity and pore size decreased dramatically. As combined specimens have decreased porosity part, mechanical properties were significantly increased, resulting from the densified part which can endure more load, while maintaining the stiffness under 15 GPa, which is in the range of elastic modulus of bone (Fig. 2). In addition, after 7 d of release in Phosphate Buffer Saline (PBS), larger amount of GFP remained in dense region in the negative scaffold as showin in Fig.3. indicating that densified porous structure prolonged release of growth factors.

Conclusions: Functionally graded porous titanium scaffold was successfully fabricated by unidirectional compressing. As combined structure has less porous part, mechanical properties were enhanced significantly. Also prolonged release of drug was achieved for densified part. Thus, drug-loaded functionally graded porous titanium scaffolds have a potential to be used for dental and orthopedic implant with its enhanced mechanical properties and prolonged drug release behavior.

Figure 1. Schematic images, optical images after unidirectional compressing, and micro CT images of positive scaffold (A), and negative scaffold (B).

Figure 2. Mechanical properties of homogeneous 70% porous Ti scaffold and combined scaffolds.

Figure 3. Surface images of GFP loaded combined scaffolds before and after 7-days release test for porous and dense parts.

Technology Innovation Program (Contract No.10037915, WPM Biomedical Materials — Implant Materials) funded by the Ministry of Knowledge Economy (MKE, Korea)

References:

[1] Y. Torres, P. Trueba, J. Pavón, I. Montealegre, and J.A. Rodríguez-Ortiz, "Designing, processing and characterisation of titanium cylinders with graded porosity: An alternative to stress-shielding solutions.", Materials and Design. Vol. 63, Nov. 2014.

[2] Hyun-Do Jung, Tae-Sik Jang, Lifeng Wang, Hyoun-Ee Kim, Young-Hag Koh, and Ju-ha Song, "Novel strategy for mechanically tunable and bioactive metal implants.", Biomaterials. Vol. 37, Jan. 2015.

[3] Xiaoqiang Sun, Yunqing Kang, Jiguang Bao, Yuanyuan Zhang, and Yunzhi Yang, "Modeling vascularized bone regeneration within a porous biodegradable CaP scaffold loaded with growth factors.", Biomaterials. Vol. 34, Jul. 2013.