Introduction: Selective Laser Sintering (SLS) is an additive manufacturing process in which a laser patterns powdered starting materials into solid 3D structures in a layer-by-layer manner. Features which are challenging to fabricate using other additive processes (e.g. overhangs, underhangs, branches, and bifurcations) are readily accessible using SLS. SLS has found great utility in the fabrication of scaffolds for bone tissue engineering[1] and patient-specific splints for human airway stabilization[2]. Despite the potential for fabrication of complex, high-resolution structures with SLS using diverse materials (including biomaterials), prohibitive costs of commercial systems have hindered the wide adoption of this technology in the scientific community. We hypothesized that a consumer laser cutter could be used in conjunction with open-source hardware and software to inexpensively perform SLS. Here, we implemented and characterized sintering with polymers and biomaterials, introduced post-processing techniques for sintered parts, and demonstrated biocompatibility of sintered polycaprolactone (PCL).

Methods: We implemented OpenSLS by installing a custom powder handling module inside a laser cutter and overriding the native electronics[3]. Sintered parts were assessed by scanning electron microscopy (SEM) and microcomputed tomography (µCT). PCL biocompatibility was evaluated by seeding human mesenchymal stem cells (hMSC) labeled with GFP and H2B-mCherry on sintered PCL surfaces and imaging with epifluorescent microscopy.

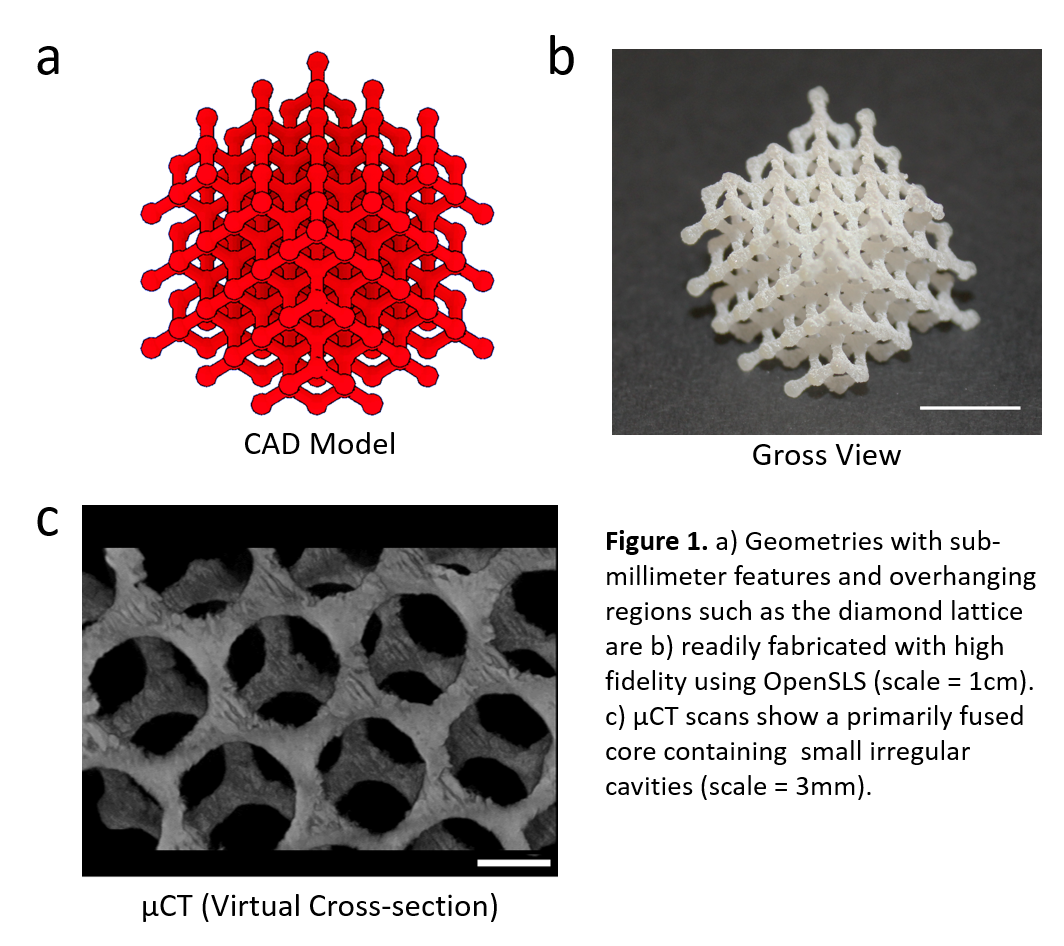

Results and Discussion: Nylon was sintered into structures with sub-millimeter features and overhanging/branching regions (Figure 1).

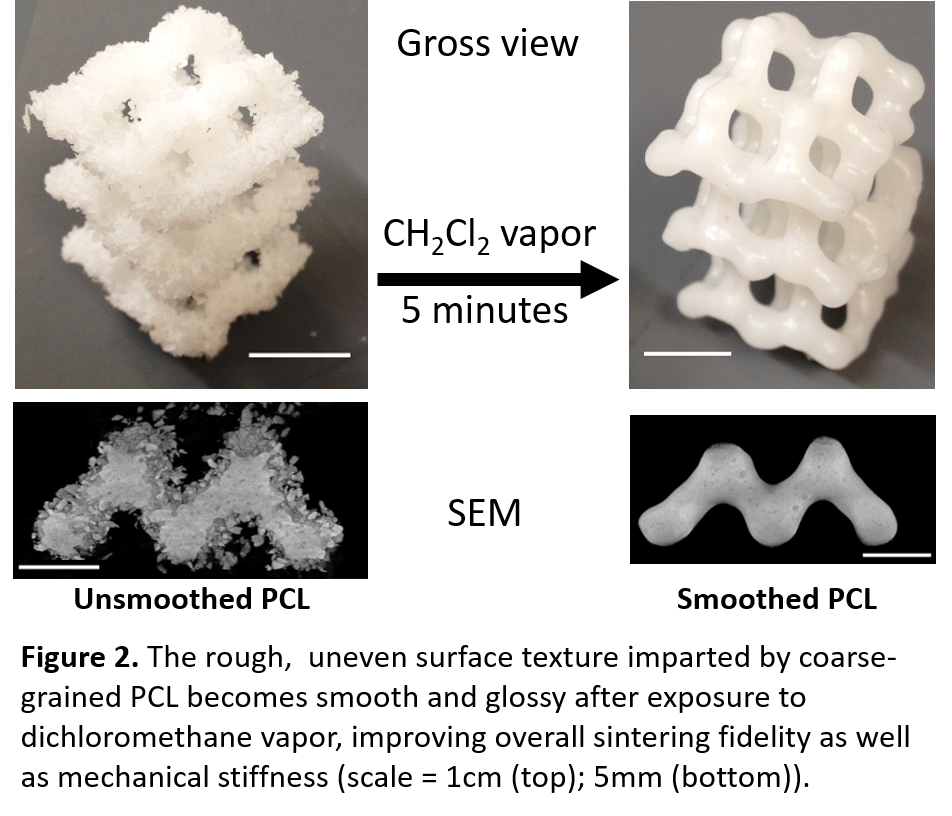

Sintered surfaces appear similar to those of nylon parts fabricated on commercial SLS systems[4]. Nylon filaments exhibit a mostly fused core but show small irregular interior cavities. PCL was also sintered into lattice structures, which could be useful as bone scaffolds. Finding that coarse PCL grains yielded rough, poorly connected lattices, we developed a vapor smoothing technique (Figure 2) which reduced the average surface roughness from 120µm to 5µm and increased the elastic modulus from 30MPa to 60MPa.

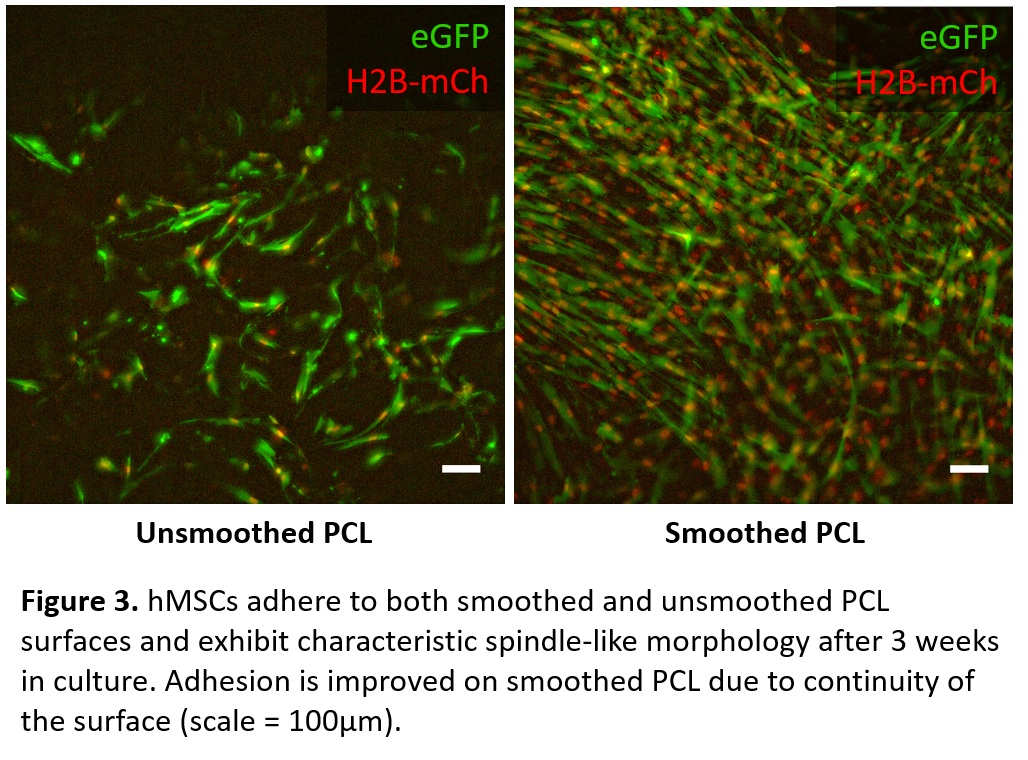

The stiffer scaffolds more closely match bone mechanics while the smoothed surfaces enhance cell adhesion. hMSCs attached, survived, and exhibited characteristic spindle-like morphology on both vapor-smoothed and unsmoothed sintered PCL (Figure 3), suggesting that sintered PCL will be useful for cell studies.

Conclusions: Architecturally complex, physiologically relevant structures can be fabricated at high resolution using a low-cost, open-source platform. The use of biomaterials in this system is straightforward and produces structures that are compatible with cell studies. OpenSLS could serve the scientific community as an accessible platform for fabricating structures composed of a wide range of materials, including non-traditional materials not supported by commercial SLS suppliers.

We gratefully acknowledge the many open-source and related projects that critically facilitated this work, including Arduino.cc, RepRap.org, Ultimachine.com, Python.org, Blender.org, NIH ImageJ, Fiji.sc, slic3r.org, netfabb.com, pronterface.com, enblend.sourceforge.net, thingiverse.com, and openscad.org.; We are grateful to SeeMeCNC for assisting with the acquisition, installation, and configuration of the laser cutter that was converted into OpenSLS.

References:

[1] Williams, J. M. et al. Bone tissue engineering using polycaprolactone scaffolds fabricated via selective laser sintering. Biomaterials 26, 4817–4827 (2005).

[2] Zopf, D. A., Hollister, S. J., Nelson, M. E., Ohye, R. G. & Green., G. E. Bioresorbable Airway Splint Created with a Three-Dimensional Printer. N. Engl. J. Med. 368, 2042–3 (2013).

[3] Design files, wiring configuration, firmware, software, and workflow overview are available at github.com/MillerLabFTW/OpenSLS

[4] Salmoria, G. V., Leite, J. L., Vieira, L. F., Pires, a. T. N. & Roesler, C. R. M. Mechanical properties of PA6/PA12 blend specimens prepared by selective laser sintering. Polym. Test. 31, 411–416 (2012).