In-vitro dissolution and mineralization of silicon-doped hydroxyapatite produced by a thermal technique

-

1

McGill university, Mechanical Engineering, Canada

-

2

Materium Innovations Company, Canada

Introduction: Hydroxyapatite (HA, Ca5(PO4)3OH) is the most extensively used material for bone implant applications due to its similarity with the mineral component of bone, which results in high osteoconductivity and facilitates bone regeneration and growth. However, HA has low resorbability compared to other synthetic biomaterials, thus making it difficult to replace by the newly formed bone. Researchers have shown that substitution of silicon into HA can enhance resorbability and osteogenic properties of HA by modifying its morphology and crystal structure.[1][2][3] Various chemical techniques are suggested for synthesizing Si-doped HA.[3][4][5] However, these techniques are complex and are not useful for producing Si-doped HA in large scale. Here, we developed a simple powder metallurgy-inspired technique to make Si-doped HA scaffold. This method included the physical mixing of silica (SiO2) and HA powder, followed by pellet pressing and sintering at an elevated temperature, which enhanced atomic diffusions and led to the incorporation of Si into HA unit cells.

Method: Adequate amounts of SiO2 and HA powder with the weight ratios of SiO2:HA equal to 0:100, 2:98, and 100:0 were immersed in ethanol, and 3 wt% of binder (PEG) was added to these mixtures. The solutions were stirred for one week with rate of 500 rpm and finally dried in the oven. The dried powders were pressed into the cylindrical compacts using a pellet press. The compacts were subsequently calcined and sintered at 400 and 1100 ºC for 5 and 8 h, respectively. The compression test was done on the sintered samples to evaluate their mechanical strength. The sintered samples were also immersed in simulated body fluid (SBF) for 2 weeks to evaluate their mineralization and dissolution at physiological conditions. Inductively coupled plasma atomic emission spectroscopy (ICP-OES) was used to measure [Ca], [P], and [Si] in SBF solutions at different incubation times.

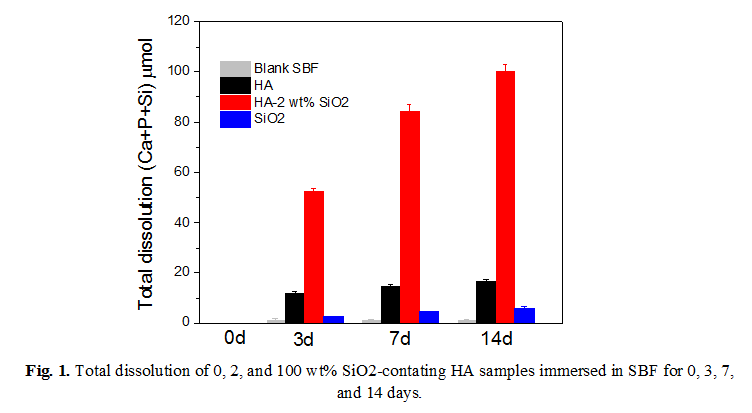

Results and Discussion: Our results showed that 2 wt% SiO2 doping significantly improved the dissolution rate of HA when immersed in SBF (Fig. 1)

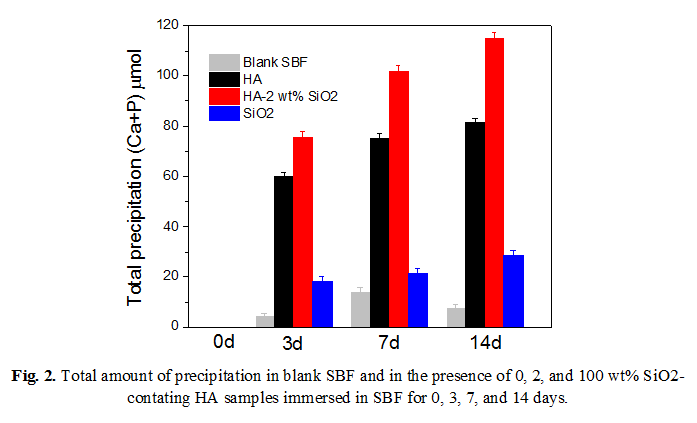

while it had negligible effect on deteriorating its sinterability and mechanical strength. The faster dissolution rate of 2 wt% SiO2-containing HA was attributed to the formation of tricalcium phosphate (TCP) with higher resorbability than HA during the sintering stage. Also, the precipitation rate of calcium phosphate from SBF was faster on 2 wt% silica-containing HA (Fig. 2)

possibly due to its higher dissolution rate, which would increase the local concentration of Ca and P close to the surface[6].

Conclusion: 2 wt% of silica incorporated into HA by a simple powder metallurgy-inspired technique, could significantly improve the in-vitro mineralization and dissolution rate of HA. This finding can provide a basis for developing bioactive implants with improved osteogenic properties.

References:

[1] A. E. Porter, C. M. Botelho, M. A. Lopes, J. D. Santos, S. M. Best, and W. Bonfield, "Ultrastructural comparison of dissolution and apatite precipitation on hydroxyapatite and silicon-substituted hydroxyapatite in vitro and in vivo," J Biomed Mater Res A, vol. 69, pp. 670-9, Jun 15 2004.

[2] E. S. Thian, J. Huang, S. M. Best, Z. H. Barber, and W. Bonfield, "Novel silicon-doped hydroxyapatite (Si-HA) for biomedical coatings: an in vitro study using acellular simulated body fluid," J Biomed Mater Res B Appl Biomater, vol. 76, pp. 326-33, Feb 2006.

[3] Y. Belmamouni, M. Bricha, J. Ferreira, and K. El Mabrouk, "Hydrothermal Synthesis of Si-doped Hydroxyapatite Nanopowders: Mechanical and Bioactivity Evaluation," International Journal of Applied Ceramic Technology, vol. 12, pp. 329-340, 2015.

[4] L. Boyer, J. Carpena, and J. L. Lacout, "Synthesis of phosphate-silicate apatites at atmospheric pressure," Solid State Ionics, vol. 95, pp. 121-129, 2/2/ 1997.

[5] T. Tian, D. Jiang, J. Zhang, and Q. Lin, "Synthesis of Si-substituted hydroxyapatite by a wet mechanochemical method," Materials Science and Engineering: C, vol. 28, pp. 57-63, 1/10/ 2008.

[6] J. Weng, Q. Liu, J. G. Wolke, X. Zhang, and K. de Groot, "Formation and characteristics of the apatite layer on plasma-sprayed hydroxyapatite coatings in simulated body fluid," Biomaterials, vol. 18, pp. 1027-35, Aug 1997.

Keywords:

Tissue Engineering,

Tissue Regeneration,

Bone repair,

Biodegradable material

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

Poster

Topic:

Regenerative medicine: biomaterials for control of tissue induction

Citation:

Tavafoghi

M,

Gamys

C,

Gosselin

M and

Zhao

F

(2016). In-vitro dissolution and mineralization of silicon-doped hydroxyapatite produced by a thermal technique.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.00837

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.