Introduction: Bone tissue defects such as fractures, traumas, diseases and congenital problems are a devastating and costly problem in health care. One of the challenges is the development of new therapies or medical devices for improve the quality of life.

Tissue Engineering[1] involves the use of biomaterials as scaffolds to provide structural support to cells, signaling molecules and cells to improve or restore tissue or organs that were damaged.

The objective of this study is produces scaffolds from a blend of synthetic polymer polycaprolactone (PCL) and bovine bone filling (natural hydroxyapatite) using a rapid prototyping technology, 3-D Bioplotter® System and study their biocompatibility and mechanical properties to be use in bone tissue regeneration.

Materials: PCL from Capa™ 6400, bovine bone filling Nukbone® (NKB) and synthetic hydroxyapatite (Sigma-Aldrich) were used. The blend was prepared by mixing PCL/NKB at different ratios.

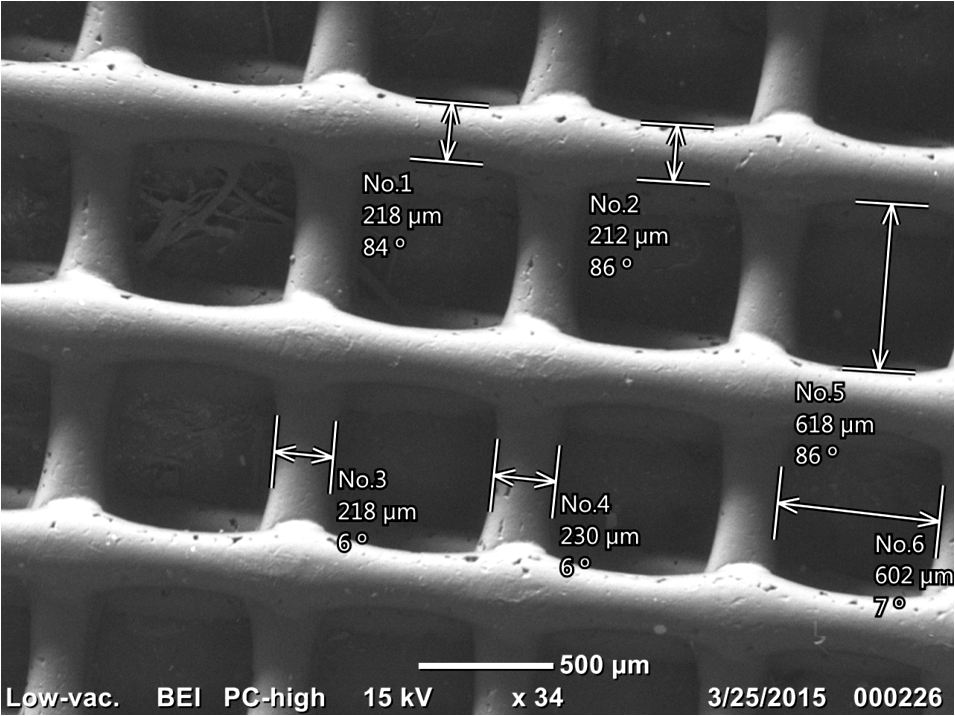

Method: All the scaffolds were built using a plotting system that consists in an extrusion process by the deposition of layer-by-layer until a 3D object was obtained. The blend was molten at 90°C in a high temperature stainless steel cartridge and plot by air pressure into a metal needle with a nozzle size of 300 µm.

The compressive modulus was calculated from the stress-deformation curve. The chemical and physical characterization was development by FT-IR analysis, X-ray diffractometer and scanning electron microscopy.

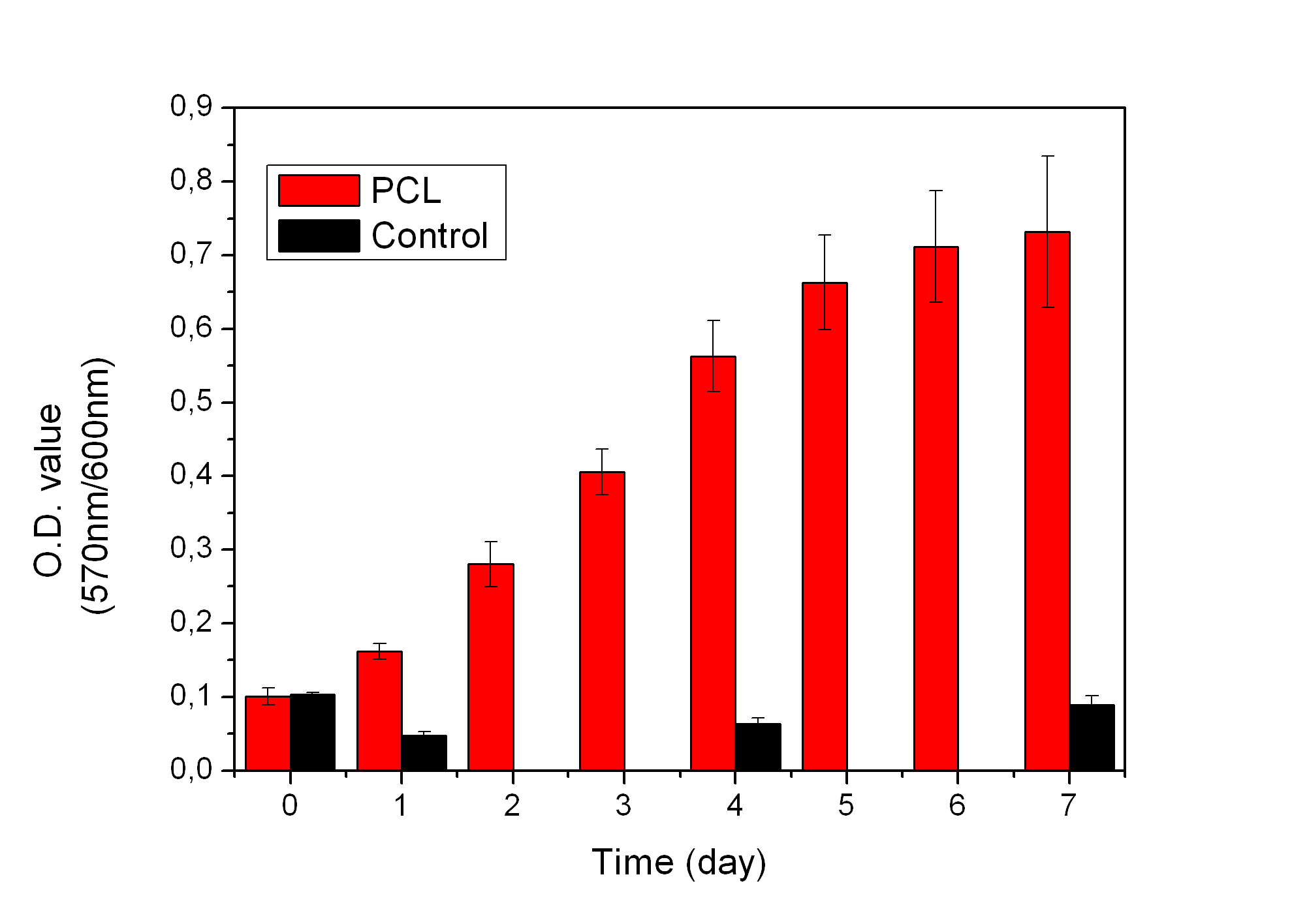

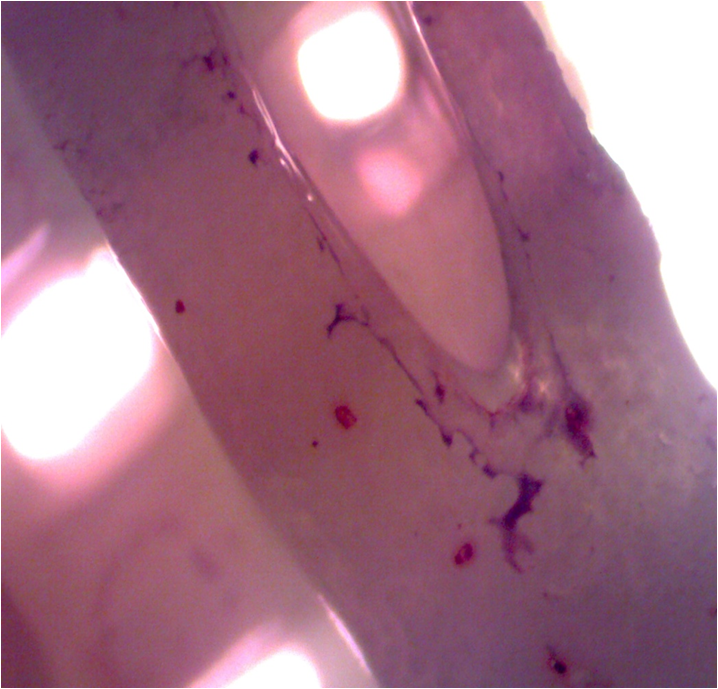

The biocompatibility of the scaffolds were tested with alamar blue reagent at 10% w/v and by seeding human mesenchymal stem cells from amniotic membrane (AM-hMSC) that were isolated according to methodology by Rodriguez-Fuentes et al[2]. and then differentiated into osteoblast-like cells. The visible absorbance was measured at 570nm. Finally the scaffolds were stained with Alizarin red staining 3 and Cristal violet dye.

Results: The scaffolds showed biocompatibility, they encourage the function of cells demonstrated by the deposition of calcium salts over the 3-dimensional structure.

The micrograph in SEM showed a porous structure with pores sizes about 620 µm an optimum value to allow cell attachment. There were slightly differences in compressive moduli between PCL and the blends of PCL/NKB samples. The XRD pattern exhibit low intensities in the peaks of the blend sample compared with the pure components and the FTIR spectra of the blend showed the chemical bands of each component of the mixture without chemical reaction.

Discussion: The addition of hydroxyapatite into the blend increased the hydrophilicity of the PCL and as a consequence the biocompatibility. On the other hand, the use of an additive manufacture ensures the porosity of the 3D structure.

Conclusion: The PCL/NKB scaffolds have been great potential to be used in tissue engineering due to mineralization of calcium salts. The porosity obtained and their interconnectivity played an important role in the biocompatibility with the cells.

Dra. Nayeli Rodríguez Fuentes for her support in biological test; Prof. Brian Amsden and Dr. Leone Ploeg from Human Mobility Research Centre (HMRC) in Kingston, Ontario, Canada for the technical support provided.; PAPIIT for their financial support through IG100114 project, CONACyT through project 214128, to “The Association of Universities and Colleges of Canada (AUCC) by the support received by the scholarship Canada-Latin America and the Caribbean Research Exchanges Grants (LACREG)”; BECAS MIXTAS 2015 - MZO2016 Mobility abroad by the support received by the scholarship

References:

[1] Langer R, Vacanti J.P. Tissue Engineering. Science 260, 920,-926, 1993.

[2] Rodríguez –Fuentes, N. et al. Nukbone® promotes proliferation and osteoblastic differentiation of mesenchymal stem cells from human amniotic membrane. Biochemical and Byophysical Research Communications. 434, 676-860, 2013.