Titanium alloys include a series of advantageous properties for biomedical applications, such as density, high mechanical strength, wear and corrosion resistance, hardness and modulus of elasticity[1]. In addition, studies have shown that titanium favors the integration with bone tissues (osseointegration)[2]. Many alloys used in the aerospace industry were used as biomaterials, for example, the Ti-6Al-4V alloy (Ti-64), who possesses excellent mechanical properties. However the evidence of allergenic reactions and neurological problems related to the aluminum and vanadium ions, made necessary the development of alloys specifically for biomedical use[3]. The alloys with predominance of body centered cubic structure (β phase) have been reason to search for biomedical applications because in general have lower elastic modulus than other structures as the hexagonal compact (α phase), preventing stress shielding effect[4]. The addition of substitutional elements in titanium alloys can significantly change its structure/microstructure and its mechanical properties[5].

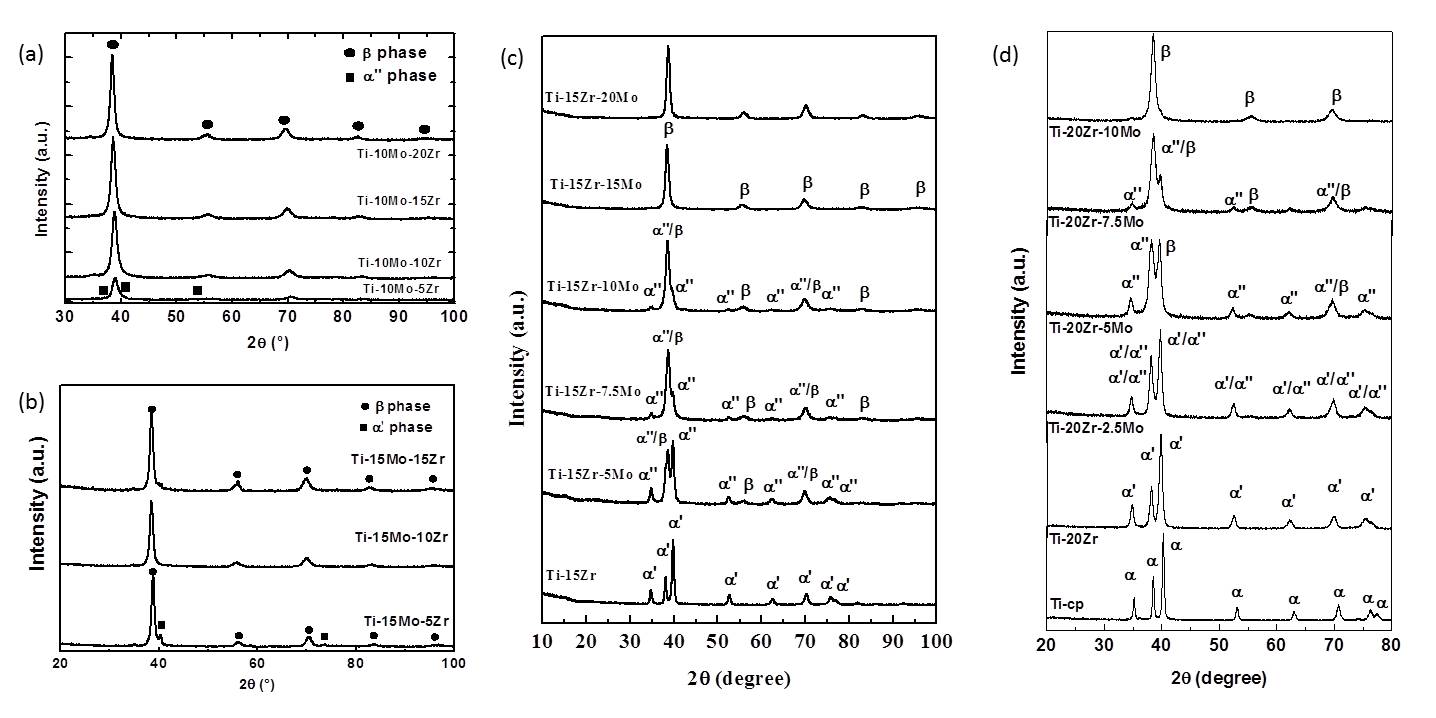

In this study Ti-Mo-Zr alloys were prepared by arc-melting, heat treated for homogenization by 24 hours at 1000° C, hot rolled and heat treated for stress relief by 6 hours at 1000° C. The structure and microstructure of alloys were evaluated by x-ray diffraction (XRD), optical (OM) and scanning electron microscopy (SEM), whose results indicated the presence of α’, α’’ and β phase, depending of substitutional element quantity (Fig. 1).

Fig. 1 – X-ray diffractograms for Ti-10Mo-Zr (a), Ti-15Mo-Zr (b), Ti-15Zr-Mo (d) and Ti-20Zr-Mo (d) alloys, after homogenization heat treatment.

It can be observed the action β-stabilizer of zirconium in titanium alloys that have another β stabilizer element[6],[7]. The SEM results corroborated XRD measurements, showing the β-stabilizer effect of zirconium in the presence of another β-stabilizer element, in this case, molybdenum.

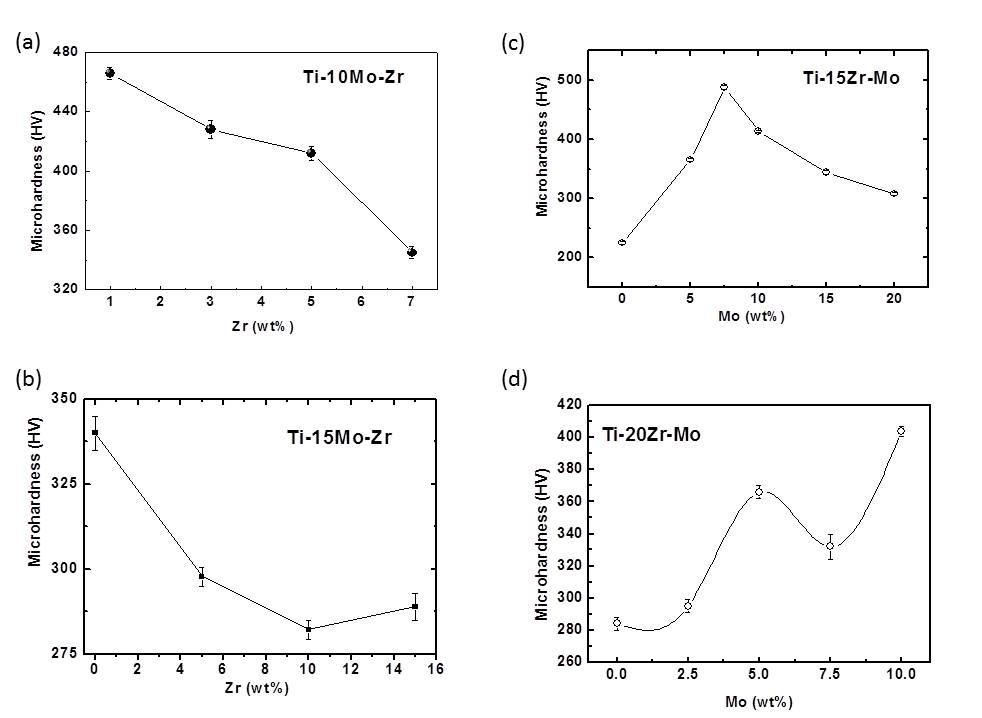

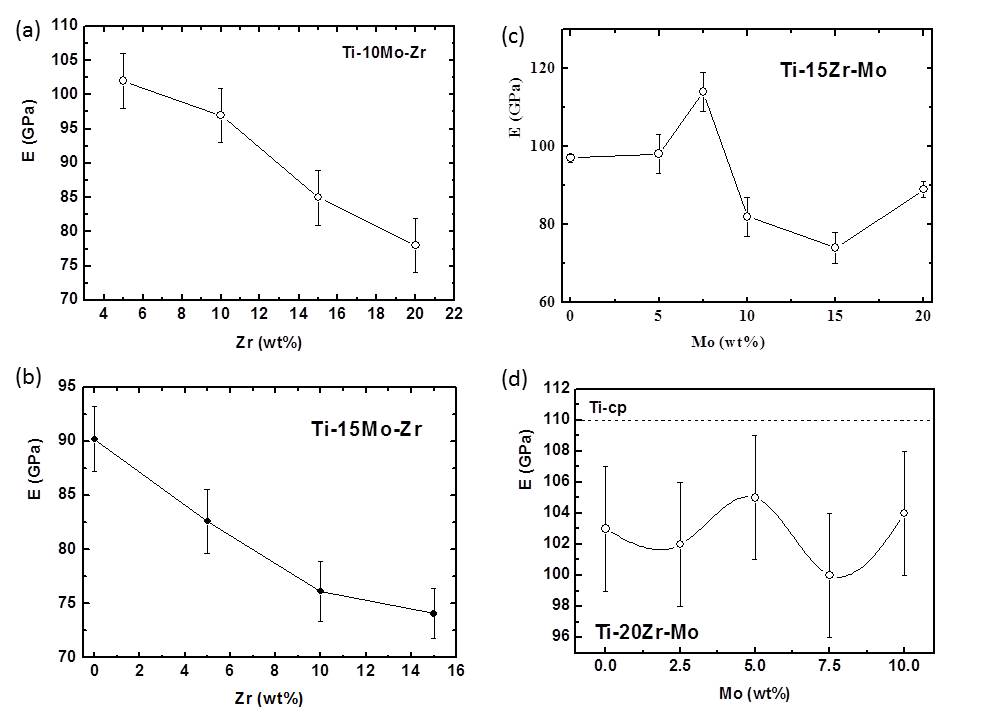

The mechanical characterization of the produced alloys was made by microhardness and dynamical elastic modulus measurements. The results of Vickers microhardness (Fig. 2) and elastic modulus (Fig. 3) suffered strong influence regarding the processing and the substitutional element content[6].

Fig. 2 – Microhardness for Ti-10Mo-Zr (a), Ti-15Mo-Zr (b), Ti-15Zr-Mo (d) and Ti-20Zr-Mo (d) alloys, after homogenization heat treatment.

Fig. 3 – Dynamic elastic modulus for Ti-10Mo-Zr (a), Ti-15Mo-Zr (b), Ti-15Zr-Mo (d) and Ti-20Zr-Mo (d) alloys, after homogenization heat treatment.

The reduction of α’ phase in the alloys increases dislocations mobility, decreasing the hardness. The increase in the hardness for the alloys of the Ti-15Zr-Mo and Ti-20Zr-Mo systems was attributed to solid state hardening or precipitation of ω phase[8].

The addition of zirconium decreases the elastic modulus of the Ti-10Mo-Zr and Ti-15Mo-Zr alloys, due, mainly the increase of β phase. The addition of molybdenum in Ti-15Zr-Mo and Ti-20Mo-Zr alloys, increases the elastic modulus of the alloy, due the precipitation of ω phase[8].

Ti-Mo-Zr alloys were produced by arc-melting with good homogeneity and stoichiometry, with predominance of β phase. The microhardness have higher values than that of pure titanium The addition of zirconium decreases the elastic modulus of the alloys, showing that although neutral, in the presence of another β stabilizer element, this element has β stabilizing effect. No cytotoxic effects were observed in all studied alloys, showing that these alloys have potential to be used in orthopedic applications.

The authors would like the brazilian agencies Capes, CNPq and FAPESP for the financial support.

References:

[1] Li Y, Yang C, Zhao H, Qu S, Li X, Li Y. New Developments of Ti-Based Alloys for Biomedical Applications. Materials 2014;7:1709-800

[2] Rack HJ, Qazi JI. Titanium alloys for biomedical applications. Materials Science and Engineering: C 2006;26:1269-77.

[3] Geetha M, Singh AK, Asokamani R, Gogia AK. Ti based biomaterials, the ultimate choice for orthopaedic implants - A review. Progress in Materials Science 2009;54:397-425.

[4] Nie L, Zhan Y, Liu H, Tang C. Novel β-type Zr–Mo–Ti alloys for biological hard tissue replacements. Materials & Design 2014;53:8-12.

[5] Niinomi M, Nakai M. Titanium-Based Biomaterials for Preventing Stress Shielding between Implant Devices and Bone. International Journal of Biomaterials 2011;2011:836587, 10 pages.

[6] Correa DRN, Vicente FB, Araújo RO, Lourenço ML, Kuroda PAB, Buzalaf MAR, et al. Effect of the substitutional elements on the microstructure of the Ti-15Mo-Zr and Ti-15Zr-Mo systems alloys. Journal of Materials Research and Technology 2015;4:180-5.

[7] Correa DRN, Kuroda PAB, Grandini CR. Structure, Microstructure, and Selected Mechanical Properties of Ti-Zr-Mo Alloys for Biomedical Applications. Advanced Materials Research 2014;922:75-80.

[8] Banerjee D, Williams JC. Perspectives on Titanium Science and Technology. Acta Materialia 2013;61:844-79.