Introduction: There is a constant effort in order to develop surface modification techniques to enhance implants fixation and biocompatibility[1]. However a large number of these techniques have been reported as detrimental to fatigue performance of titanium and its alloys[2],[3]. The goal of the present study was to obtain self-organized TiO2 nanotubes on Ti-6Al-4V surface and investigate their fatigue and fracture behavior.

Materials and Methods: TiO2 nanotubes were obtained on Ti-6Al-4V polished specimens by anodic oxidation in an aqueous electrolyte 1.0 M(NH4)2SO4 + NH4F(0,5 wt.%), applying 20V for 1h. Axial fatigue tests were performed according to the staircase method[4] in a physiological solution (9 g/L NaCl) at 37°C, a frequency of 10 Hz, a stress ratio of R = 0.1 and a run-out of 5x106 cycles. The fatigue limit for polished and modified conditions was calculated through the Dixon and Mood approach[5]. The nanotubes layer and the fracture surfaces were evaluated by Scanning Electron Microscopy (SEM).

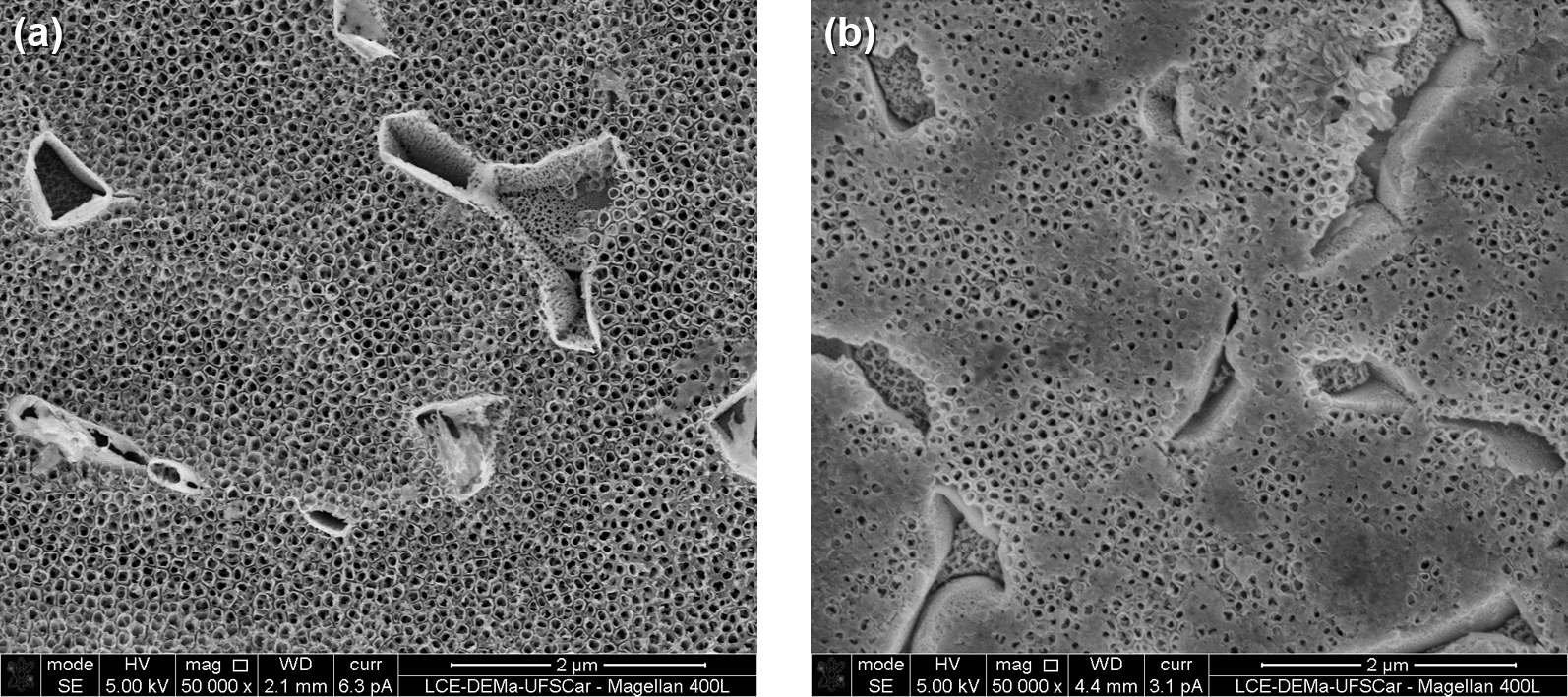

Results and Discussion: The anodized layer mainly consists of a highly ordered array of nanotubes, with an average internal diameter of 90 nm and length of 600 nm. The micrograph illustrated in Figure 1(a) shows the ordered distribution, except for some areas where the alloy microstructure comprehends beta phase. Nonetheless, a fine compact layer at the interface with the substrate is generated during anodization independently of the crystal structure. This characteristic, along with the nano scale thickness of the modified layer, are the main reasons for the similar fatigue performance of polished and modified conditions. The fatigue limit for both was calculated to be 845 MPa. Figure 1(b) illustrates the integrity of the coating of a specimen that survived the run-out.

Figure 1 - SEM micrographs of nanotubes layer: (a) as formed and (b) after fatigue test of a survival specimen.

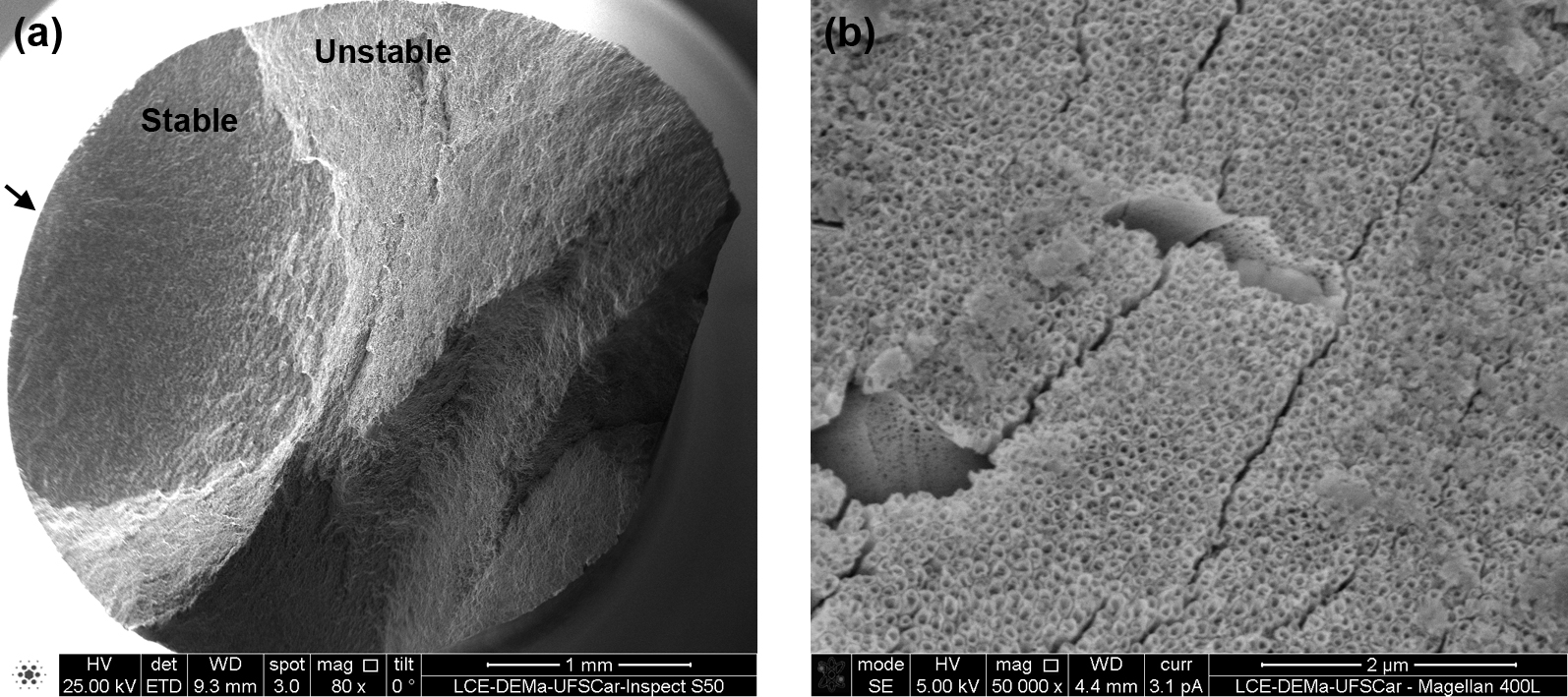

Figure 2(a) presents a micrograph of a typical fracture surface. It basically consists of surface crack nucleation (see arrow), stable propagation with the presence of striations and unstable propagation with dimples. No difference in the fractographic aspect was observed between the polished and modified surfaces, justifying again the similar fatigue behavior. The modified surface of a fractured specimen is shown in Figure 2(b), where small cracks can be noted. Since the fatigue performance was not affected by the modification, these cracks may be considered irrelevant. Moreover, the cracks were only observed in regions close to the fracture surface, indicating that they probably occurred with the rupture of the tested specimen.

Figure 2 - SEM micrographs of (a) fatigue fracture surface and (b) nanotubes layer of a fractured specimen.

Conclusion: The fatigue behavior of Ti-6Al-4V was not affected by nanotubes formation mainly because of the nano scale thickness of the layer and the presence of a compact oxide layer at the interface with the substrate.

FAPESP (proc.2012/11350-0,2012/01652-9); CNPq (proc.155348/2014-0)

References:

[1] Kurella A, Dahotre NB. Review paper: Surface Modification for Bioimplants: The Role of Laser Surface Engineering. Journal of Biomaterials Applications 2005;20:5-50.

[2] Apachitei I, Lonyuk B, Fratila-Apachitei LE, Zhou J, Duszczyk J. Fatigue response of porous coated titanium biomedical alloys. Scr Mater 2009;61:113-6.

[3] Leinenbach C, Eifler D. Fatigue and cyclic deformation behaviour of surface-modified titanium alloys in simulated physiological media. Biomaterials 2006;27:1200-8.

[4] ISO 12107, ISO, Geneva, 2012.

[5] Dixon WJ, Mood AM. A Method for Obtaining and Analyzing Sensitivity Data. J Am Stat Assoc 1948;43:109-26.