Introduction: Hyaluronic acid (HA) is a naturally derived polysaccharide that can be found throughout synovial fluid acting as a lubricant. The hydrophilic and lubricious properties of HA have been used for medical devices to improve biocompatibility and to reduce biofouling. Crosslinked HA has been applied to various prosthetic devices, such as intraocular lenses [1]. HA could inhibit cell attachment, reduce platelet adhesion, prevent fibrin deposition, and improve hemocompatibility [2],[3]. Polyethylene terephthalate (PET) is commonly used for biomedical applications such as arterial bypass, vascular prostheses, and surgical meshes [4]. PET has a low bending stiffness, among other favorable material properties that have been characterized for textile heart valve development [5]. Previous study has shown that silylated HA-cetyltrimethylammonium (silyl HA-CTA) can be used to enhance PET with HA and reduce thrombogenicity [6]. The purpose of this study was to improve upon the success of prior work with a novel method using HA-CTA to effectively create HA-PET composite containing more HA.

Methods: PET multifilament fabrics were soaked in different concentrations of HA-CTA ethanol solution for 1 hour at 50˚C. The fabrics were dried in a vacuum oven for 2 hours, then crosslinked in in a 2.5 % (v/v) poly (hexamethylene diisocyanate) HMDI/acetone solution for 1 hour, and dried at 50°C in a vacuum oven for 1 hour. Samples were hydrolyzed to remove the CTA complex and revert the HA back to its native state. The treatment process was repeated a second time to incorporate more into the PET fabrics. Goniometry and thermogravimetric analysis (TGA) were used to analyze the wettability and HA weight content of the samples, respectively. Fourier transform infrared spectroscopy (FTIR) verified whether the changes in surface chemistry and weight were due to HA enhancement.

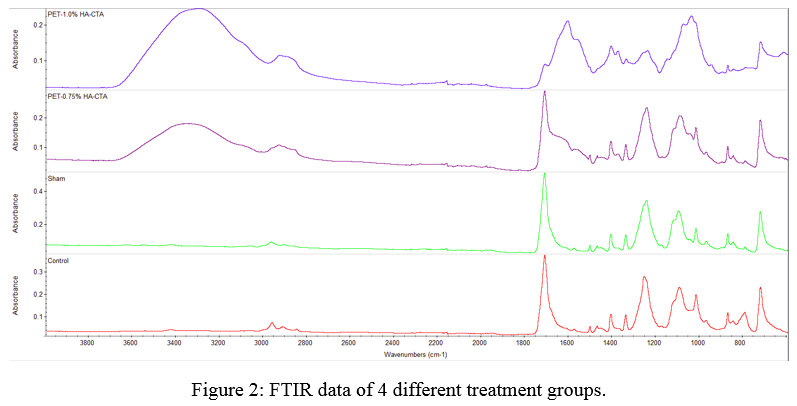

Results: Figure 1 shows PET samples treated with HA have significantly lower water contact angles than the control group (plain PET). Shams (went through the treatment process but were not exposed to HA) remain hydrophobic and do not exhibit a decrease in contact angle. TGA revealed that PET treated with 0.75% and 1.0% HA-CTA contain approximately 1.51% and 4.47% HA, respectively. Figure 2 confirms that wettability and changes in weight content of PET were due to the HA enhancement. Wavenumber 3400 and 1600 cm-1 represent the hydroxyl and carboxyl groups of HA, and 1719 cm-1 reflects the carbonyl stretching band of PET. In addition, preliminary studies verified decreased blood clotting of HA enhanced PET relative to PET and good durability of the HA enhancement.

Conclusion: Our novel treatment process successfully enhanced PET with HA and changed the surface behavior of the fabrics, making them more hydrophilic. Future studies will further investigate the durability of the enhancement and biological interactions with the material appropriate for the target applications of the HA-PET composite.

Center for Cardiovascular Research at Colorado State University; The Biomaterials Research and Engineering Laboratory at Colorado State University; The NIH R01 Grant; Undergraduates: Cassidy Wright and Charlotte Mitchell

References:

[1] Beavers E. M. U.S. Patent No. 4,663,233; 1987.

[2] Necas et al. Veterinarni Medicina; 2008.

[3] DeFife el al. Journal of Biomedical Materials Research; 1999.

[4] Al Meslmani et al. Materials Science and Engineering: C; 2014.

[5] Heim et al. Textile Research Journal; 2008.

[6] James et al. Society for Biomaterials; 2014