Introduction: Matching structure to function is a challenge to synthetic biomaterials[1],[2]. The skeletal hierarchical structure from microscale to nanoscale formed by the cooperation of organic molecules and inorganic crystals, has not been fully investigated and utilized. Combination of nano-hydroxyapatite (n-HA) crystals and polyurethane (PU) block copolymer will give us a chance to establish a biomimetic hierarchical structure and realize biological function. This study has explored the effect of nano- to micro- structure on the mechanical and biological properties of the composite scaffold.

Materials and Methods: The n-HA/PU composite scaffolds with 40 wt% n-HA crystals were made by in situ polymerization and simultaneous foaming[3]. Both pristine castor oil (CO) and glyceride of castor oil (GCO) were separately used to prepare PU scaffolds (named n-HA/CO-PU, n-HA/GCO-PU). The physico-chemical properties were analyzed by FTIR, XRD, XPS, NMR, DMA, SEM, TEM, mechanical test and micro-CT analysis. The cell behavior and bone regeneration capacity were also evaluated via in vitro culture and in vivo implantation.

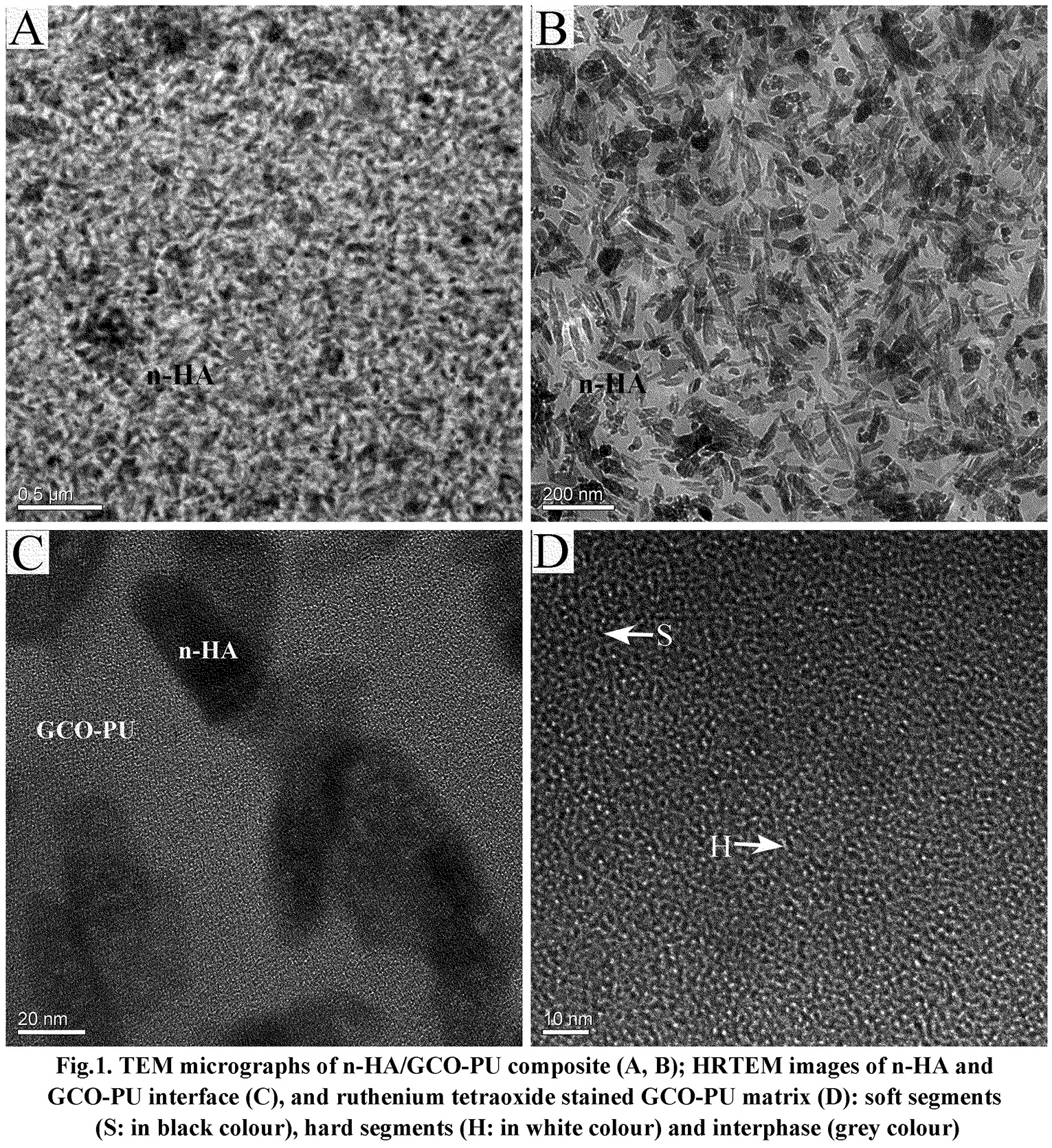

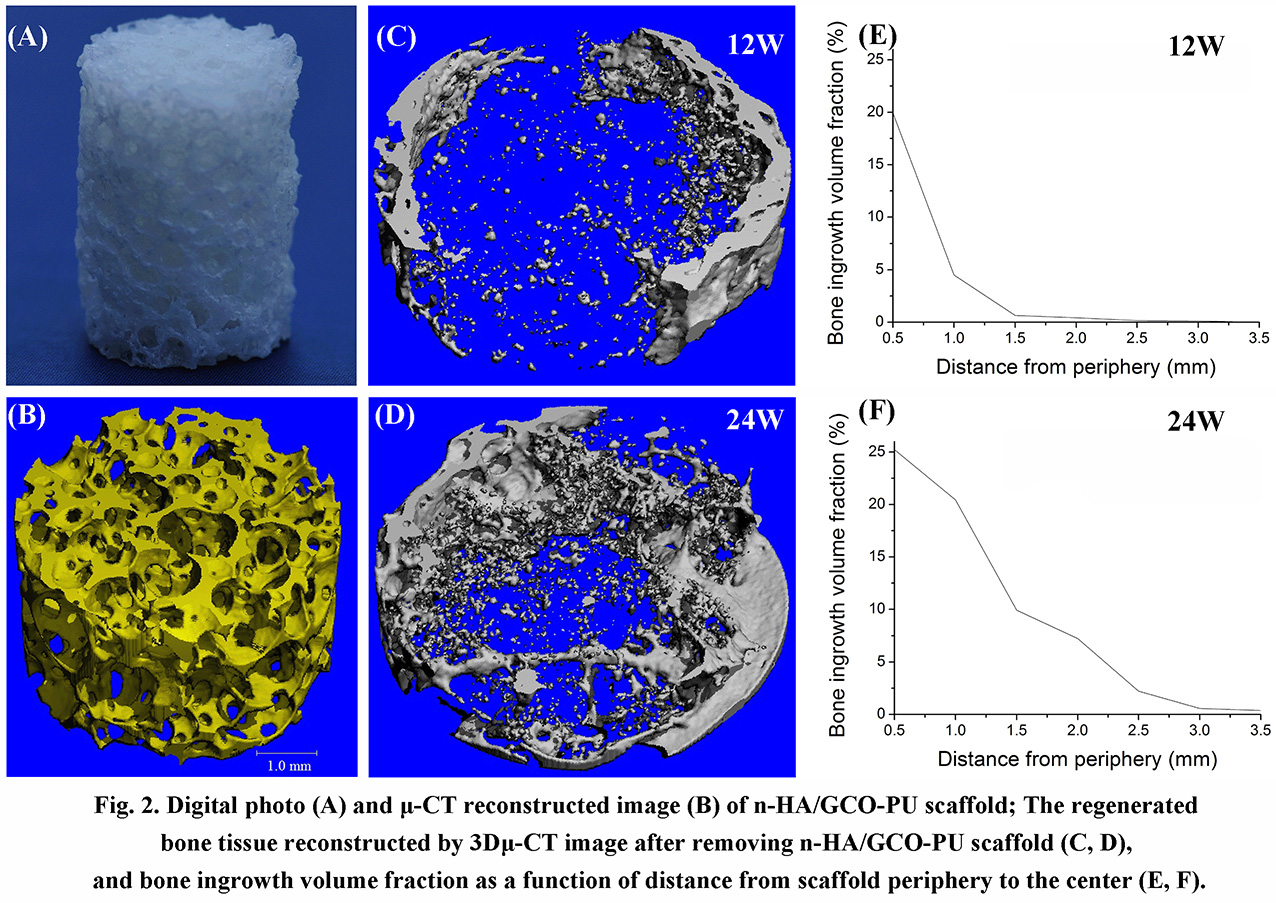

Results and Discussion: The composite scaffolds have been structured in three levels: the PU hard/soft block structure in molecular level, the n-HA crystals dispersed in PU matrix in nano-level (Fig. 1), and the porous scaffold structure in micro-level [Fig. 2]. The three level hierarchical structures may be similar to the segmented collagen, the mineral in organic matrix and the cancellous structure of natural bone, making up the material basis of high performance scaffold for bone regeneration[4].

The results showed that the modification of PU soft segment by GCO could largely increase the scaffold compressive strength by 48% and elastic modulus by 96%. The n-HA crystals with fine dispersity not only improved the interface bonding with PU matrix, but also provided good bioactivityfor bonding with bone tissue. The hierarchical structure and good mechanical quality of the n-HA/GCO-PU composite scaffold were found to be appropriate for growth of cells and regeneration of bony tissue [Fig. 2], presenting good prospect for bone repair and regeneration.

Conclusion: We found that the use of glyceride of castor oil for soft segment, and the incorporation of n-HA crystals are crucial for the mechanical improvement of PU-based composite scaffolds; the scaffold composition, porous structure and mechanical quality are favorable for cell proliferation and new boneregeneration. Combination of the two factors afford better mechanical improvement, suggesting the important role of the tightly bonding interface between n-HA crystals and PU matrix. The nano- to micro- hierarchical structure, improved mechanical properties of the nano composite scaffold can be a biomimetic approach to natural bone tissue, presenting strong vitality in bone regeneration and reconstruction.

The authors appreciate financial support from China NSFC fund (No. 31370971), Sichuan and Chengdu project (No. 2012FZ0125, 12DXYB145JH-005).

References:

[1] Masami O., Baiju J., Synthetic biopolymer nanocomposites for tissue engineering scaffolds, Prog. Polym. Sci.2013, 38: 1487-1503

[2] Reznikov, N.; Shahar, R.; Weiner, S. Bone Hierarchical structure in three dimensions. Acta Biomater. 2014,10, 3815-3826

[3] Wang, L.; Li, Y.; Zuo, Y.; Zhang, L.; Zou, Q.; Cheng, L.; Jiang, H. Porous bioactive scaffold of aliphatic polyurethane and hydroxyapatite for tissue regeneration. Biomed. Mater. 2009, 4, 0250039 (7pp)

[4] Bechtle, S.; Ang, S.F.; Schneider, G.A. On The Mechanical properties of hierarchically structured biological materials. Biomaterials. 2010, 31, 6378-6385