Introduction: It has been well known that poly(2-methacryloyloxyethyl phosphorylcholine), MPC polymer, exhibited the excellent biocompatibility derived from phosphorylcholine (PC) group[1]. In these years, we have succeeded in the syntheses of diamine and diol monomers containing PC group to develop novel biomaterials, which were prepared by polycondensation or polyaddition using these monomers[2],[3]. Especially, it was found that soluble polyimides and poly(amide-imide)s having PC group exhibited the good biocompatibility derived from PC group in addition to the high thermal stability derived from rigid backbone. By the way, we focused on the polymer ultrathin film with a thickness less than 100 nm, so called nanosheet, which possessed interesting features such as flexibility, adhesiveness and smoothness[4],[5]. Therefore, in this paper, we attempted to fabricate the nanosheets from these polymers, and the application to the coating agent consisted of the fragmented nanosheets was investigated.

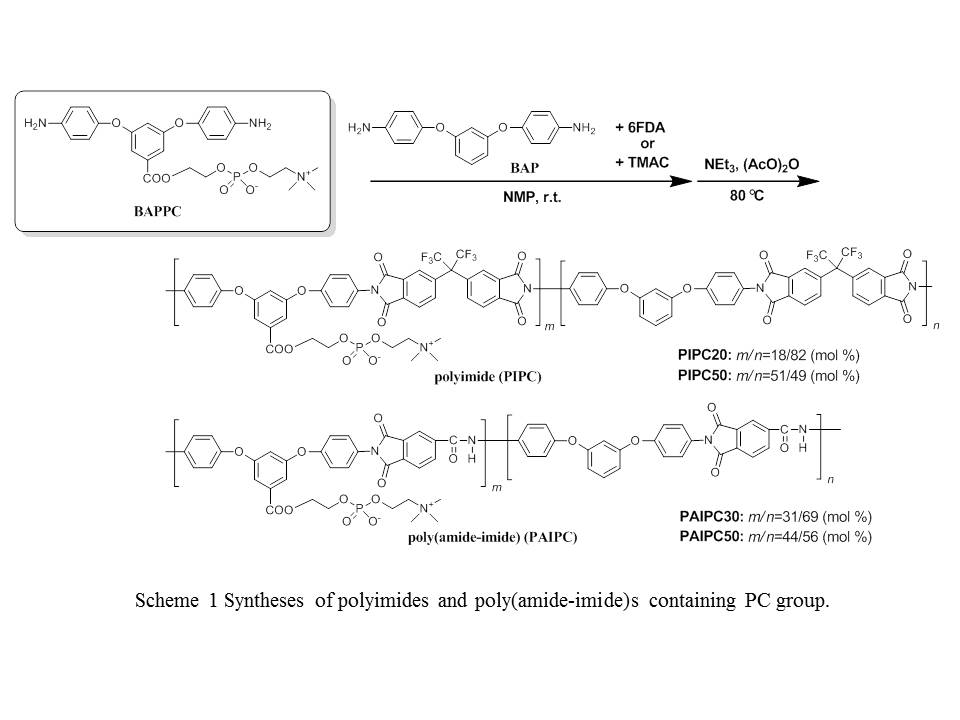

Materials and Methods: A PC-diamine monomer, 2-[3,5-bis(4-aminophenoxy)phenylcarbonyloxy]ethyl phosphorylcholine (BAPPC), was synthesized according to the literature[2]. Next, polyimide (PIPC) and poly(amide-imide) (PAIPC) containing PC group were prepared by the polycondensation of BAPPC and 3,5-bis(4-aminophenoxy)benzene (BAP) with 4,4'-(hexafluoroisopropylidene)diphthalic anhydride (6FDA) or trimellitic anhydride chloride (TMAC) followed by the chemical imidization, as shown in Scheme 1.

The nanosheets of these polymers were fabricated by spin-coating method, and they were peeled off by “sacrificial layer method” according to the literature[4]. Then, the nanosheets were homogenized in water to obtain fragmented nanosheets of submillimeter-size. Moreover, the coating ability of the dispersion of fragmented nanosheets in water was evaluated.

Results and Discussion: The polyimides (PIPC20, 50) and poly(amide-imide)s (PAIPC30, 50) were prepared by changing the molar ratio of BAPPC and BAP in the polymerizations. These polymers were soluble in aprotic polar solvents such as DMF, DMSO and NMP, in which PIPC20 was also soluble in chloroform and THF. It was found by the thermogravimetric analysis that the thermal stability of these polymers was over 200°C, which was expected to be stable for the heating sterilization.

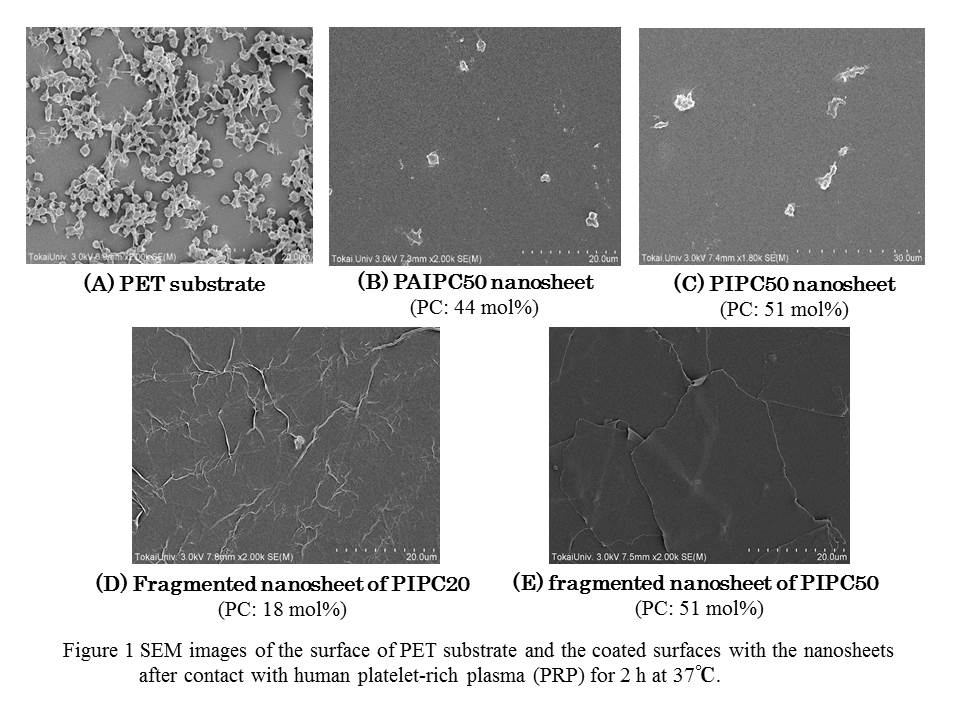

Meanwhile, the nanosheets of these PC-polymers were successfully prepared, the thickness of which could be controlled by changing the concentration of polymer solution. Then, it was confirmed from the platelet adhesion test that the obtained nanosheets exhibited the high antithrombogenic property, as shown in Figure 1(B) and (C). Furthermore, several substrates could be coated by the fragmented nanosheets, and the coated surfaces of fragmented nanosheets exhibited the improved antithrombogenicity as shown in Figure 1(D) and (E).

Conclusion: In this study, it was revealed that the obtained polyimide and poly(amide-imide) containing PC group showed good features for biomaterials, and the nanosheets of these polymers could be used as coating agents for several substrates. Therefore, it is expected that these nanosheets composed of PC polymers will be applied to coating reagents on the several surfaces of medical devices, for example, catheters, artificial vessels, and microfluide devices.

References:

[1] K. Ishihara and M. Takai, J. Royal Soc. Interface 6, S279 (2009).

[2] K. Horiguchi, N. Shimoyamada, D. Nagawa Y. Nagase, Y. Iwasaki, K. Ishihara, Trans. Mater. Res. Soc., Jpn. 33, 1261 (2008).

[3] Y. Sakagami, K. Horiguchi, Y. Narita, W. Sirithep, K. Morita, Y. Nagase, Polym. J. 45, 1159 (2013).

[4] Y. Okamura, K. Kabata, M. Kinoshita, D. Saito, S. Takeoka, Adv. Mater. 21, 4388 (2009).

[5] Y. Okamura, K. Kabata, M. Kinoshita, H. Miyazaki, A. Saito, T. Fujie, S. Ohtsubo, D. Saito, S. Takeoka, Adv. Mater. 25, 545 (2013).