Introduction: Tissue engineering aims to replicate the architecture and function of human tissue for both treatment of disease and toxicity evaluation. One promising method of achieving this is 3D bioprinting, which aims to selectively print or deposit the constituent parts of structure in such as way to reproduce the main functions. 3D bioprinting has been mainly preformed using one of three major additive manufacturing techniques: inkjet, micro extrusion and laser assisted[1],[2]. Micro valve based printing offers a compromise between the fast printing of inkjet and the good handling of water based inks of micro extrusion. It could therefore potentially prove to be important for certain bioprinting applications but it has not been thoroughly tested so far.

Mimicking blood vessels architecture is a major goal in tissue engineering as they are essential to provide the cells with a supply of oxygen and nutrients, especially for complex tissue architectures. Another example are attempts to reproduce stem cell crypt morphology in the large intestine[3], due to the importance of the intestine for functions such as drug administration, nutrients transport and cell differentiation.

In this work, we use a Picodot jetting valve to ink jet two hydrogel based inks, one providing structure and the other a fugitive ink that is removed to create vascular and crypts-like structures[4],[5].

Materials and Methods: Ink formulations: 10%w/v gelatine (Type A, 300 bloom) ink solution was prepared by dissolving gelatine powder in DI water and was kept at 370C during printing process. Gelatine methacrylate (GelMA) was synthesized following a previously reported procedure[6]. GelMA ink was prepared by dissolving 15%w/v GelMA and 0.3% w/v photoinitiator (Irgacure 2959) in Phosphate Buffer Saline.

3D Printing system: Structures of intestinal crypts and vascular structures were fabricated by a jetting valve system Picodot LV (Nordson EFD). The Picodot print head jetting is synchronized with a 3-axis high performance linear stage (Aerotech). The ink was jetted through a 50 μm nozzle by an applied air pressure of 30 psi and a rod movement driven by two piezoelectric actuators. Two gelatine-based inks were used. Firstly, gelatine was used as a fugitive ink which was removed in a final step to create the vascular spaces, and secondly, photopolymerizable GelMA was used for the structural part of the scaffold.

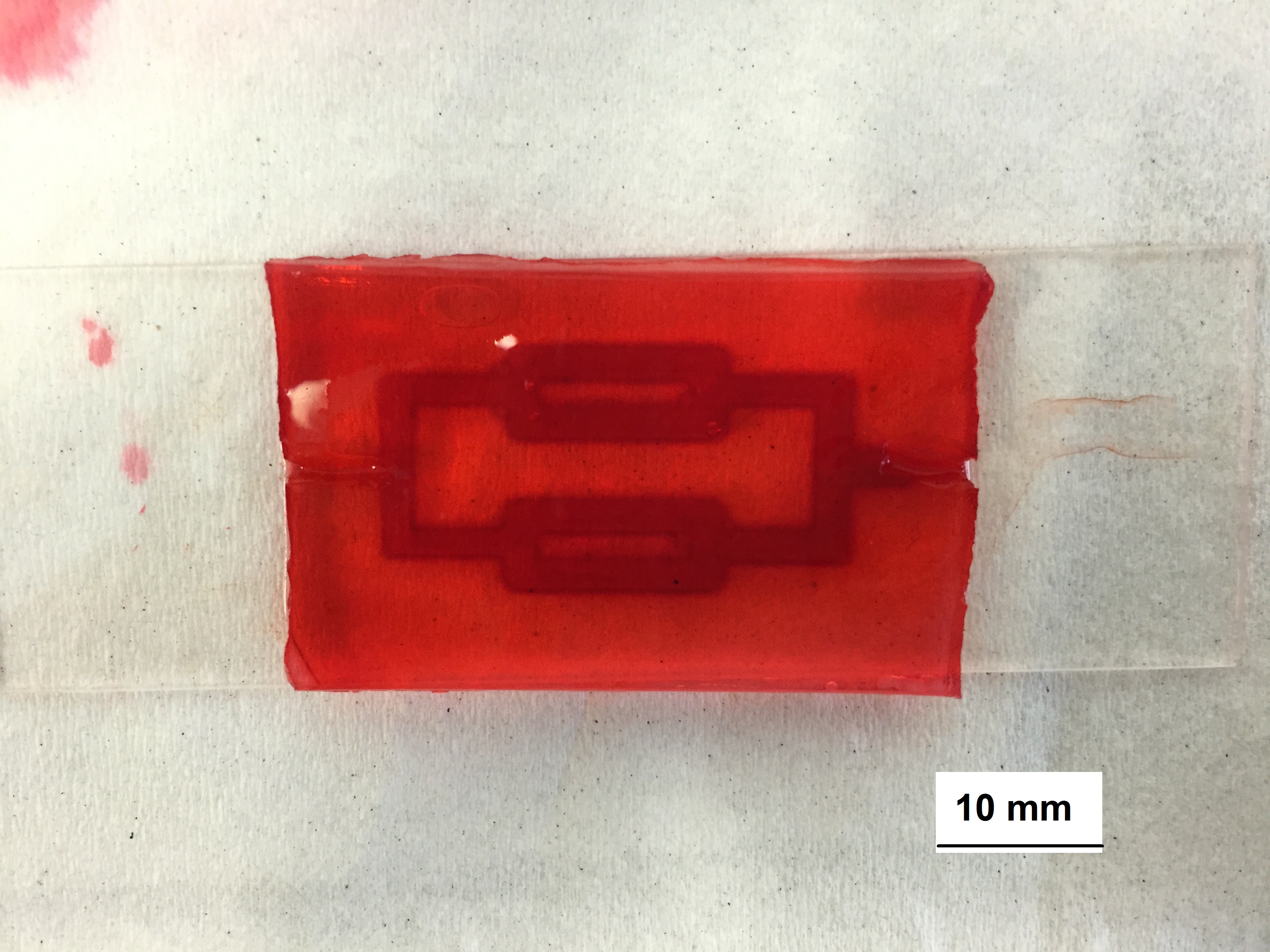

For printing intestinal crypts structures, we printed an array of pillars using gelatine as a sacrificial template. For vascular structure, we printed a branched 3D network of gelatine. In both cases, GelMA was casted onto the printed template and the gelatine was washed by DI water at 370 C. The vascular structure was perfused with red dye to prove the structure was able to support perfusion.

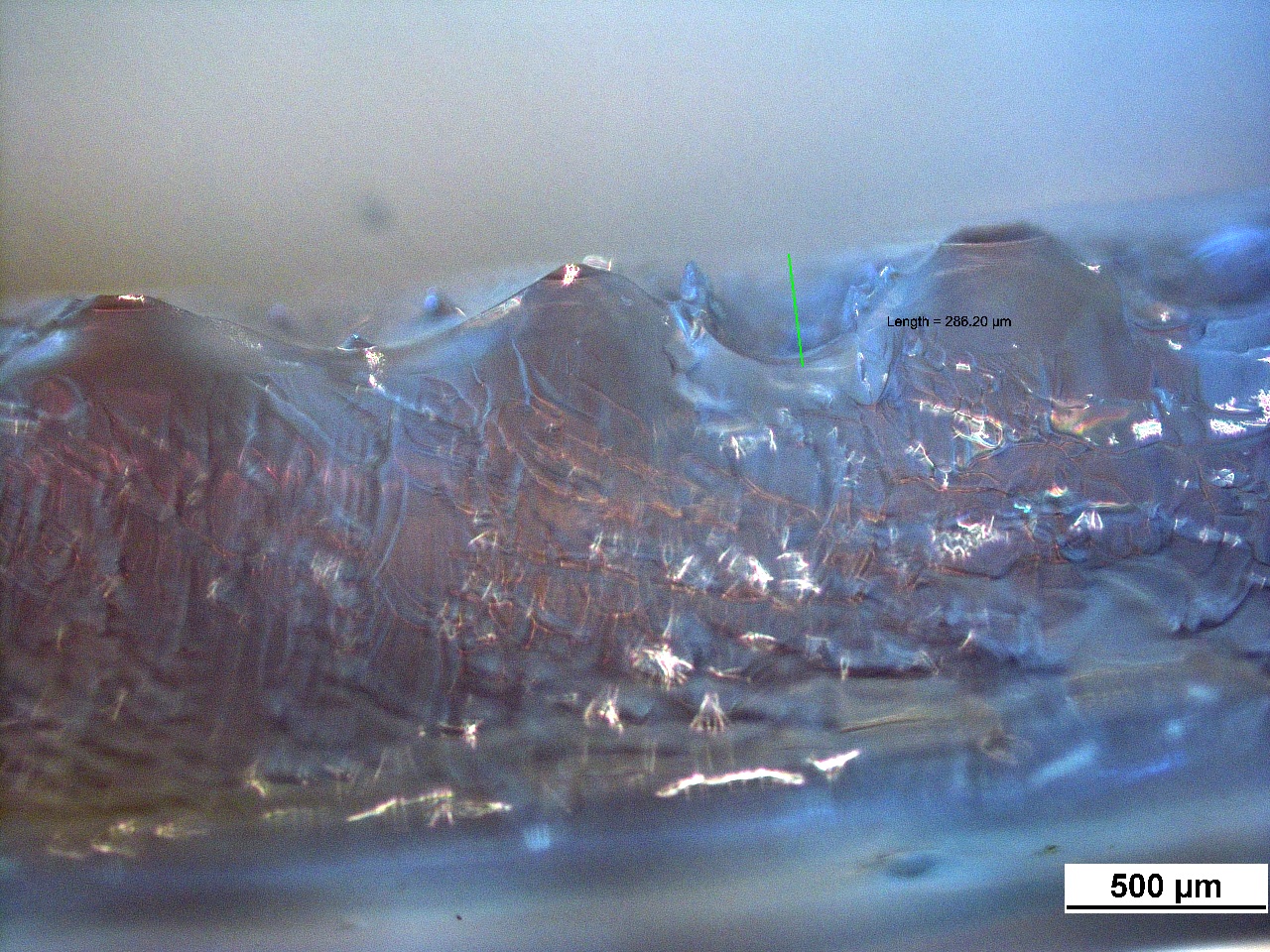

Results and Discussion: Crypts structures were obtained after eliminating the sacrificial ink.

The obtained vascular structure was perfused with red dye to test flow feasibility. In addition, red dye diffusion throughout the GelMA scaffold was observed.

Conclusion: We demonstrated the feasibility of a simple fabrication process for recreating intestinal crypts and vascular structures using Picodot LV jetting valve embedded in a linear stage using gelatine as a fugitive ink and GelMA as a scaffold.

As a next step, we plan to use cell laden GelMA for casting and monitor the viability of the cells.

References:

[1] Murphy, Sean V., and Anthony Atala. "3D bioprinting of tissues and organs."Nature biotechnology 32.8 (2014): 773-785.

[2] Dababneh, Amer B., and Ibrahim T. Ozbolat. "Bioprinting Technology: A Current State-of-the-Art Review." Journal of Manufacturing Science and Engineering 136.6 (2014): 061016.

[3] Wang, Lin, et al. "Synergic effects of crypt-like topography and ECM proteins on intestinal cell behavior in collagen based membranes." Biomaterials 31.29 (2010): 7586-7598.

[4] Kolesky, David B., et al. "3D bioprinting of vascularized, heterogeneous cell‐laden tissue constructs." Advanced Materials 26.19 (2014): 3124-3130.

[5] Miller, Jordan S., et al. "Rapid casting of patterned vascular networks for perfusable engineered three-dimensional tissues." Nature materials 11.9 (2012): 768-774.

[6] JNichol, Jason W., et al. "Cell-laden microengineered gelatin methacrylate hydrogels." Biomaterials 31.21 (2010): 5536-5544.