Introduction: The surgical application of permanent implants, e.g. osteosynthesis plates to stabilize fractured bones during healing, may be accompanied by disadvantages on the long-term, in particular when being placed in children or adolescent where impaired growth can result. Furthermore, implant dislocations, implant-associated infections or injuries of nerves and vessels can appear as side effects. Secondary surgeries to remove the implant after successful bone healing and to clinically eradicate this artificial foreign body often are expensive and complex. Resorbable implants, however, degenerate in-vivo, the foreign material is absorbed and no secondary surgery is necessary. Still, the mechanical strength of existing bioresorbable ceramic[1] or polymeric[2] biomaterials is too low for load-bearing applications. On the contrary, magnesium could be used as a biomaterial for the production of metallic, resorbable implants with sufficient mechanical properties[3].

In this study, we show preliminary results of 3D-magnesium-structures produced by the additive manufacturing technology selective laser melting (SLM). Due to the production flexibility this technology is already used to manufacture permanent, patient-specific, metallic implants made of cpTi[4]. However, only a couple of SLM-Mg studies have been published so far[5],[6]. Patient-specific, temporary solutions could be offered to the surgeon for the benefit of the patient.

Methods: Before handling Mg powder (AZ91, SFM, Switzerland), a detailed risk assessment was performed taking into account the management, storage, SLM-processing and post-treatment of reactive Mg-powder[7]. After all safety provisions and standard operating procedures have been established, 2D and 3D samples out of Mg were produced by SLM using a modified Realizer 100 SLM machine operated under a protective gas atmosphere and equipped with a 100 W continuous wave Ytterbium-fibre laser with a wavelength between 1068 and 1095 nm. 30-50 µm thick layers of Mg powder were spread on a Mg substrate. The particle size, shape and chemical composition were studied by SEM/EDX (TM-3030Plus, Hitachi, Japan) and the size distribution measured by laser scattering (Helos, Sympatec GmbH, Germany).

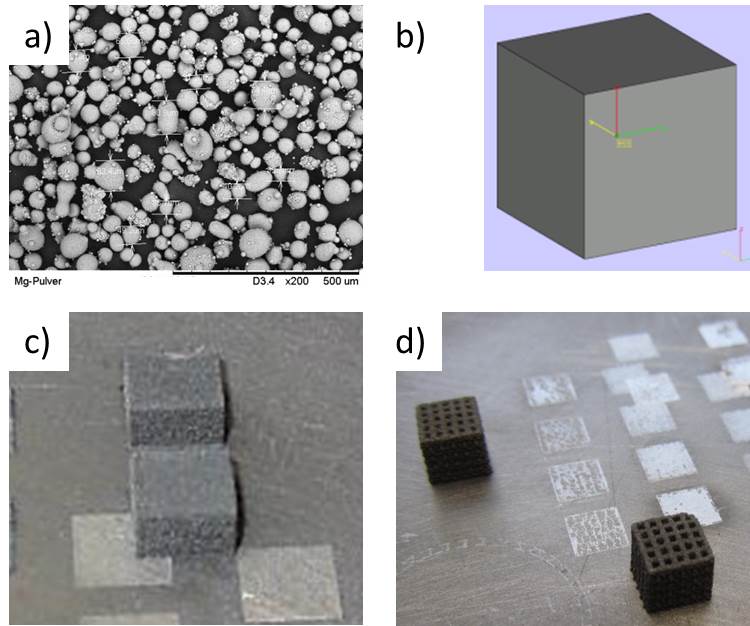

Results: The Mg particles have spherical shape with a diameter between 20 – 150 µm (Fig. 1a). First 3D samples of simple cubic geometry (see fig. 1b and c) and more complex, open-porous 3D samples (see fig. 1d) were produced out of Mg by SLM.

Fig. 1: a) SEM image of AZ91 powder, b) simple 3D CAD-model, c) rectangular object with dimension 5.5 x 5.5 x 2.5 mm3 and d) 3D SLM-cube with 5.5 mm edge length and 500 µm thick orthogonal channels in all three spatial directions.

Discussion and Conclusions: We showed the feasibility to produce simple and dense but also complex-shaped, open-porous 3D structures out of Mg by SLM. Further studies are necessary for the structural, mechanical, corrosional and biological characterization of this novel biomaterial.

This work was supported by the stiftungfhnw.

References:

[1] M. de Wild et al., Investigation of structural resorption behavior of biphasic bioceramics with help of gravimetry, μCT, SEM, and XRD, J Biomed Mater Res B Appl Biomater 1-8 (2015).

[2] B. Grassiot et al., Our experience about the use of resorbable plates in the treatment of craniostenosis, Rev Stomatol Chir Maxillofac Chir Orale, 2213-6533; 15 (2015).

[3] F. Witte, The history of biodegradable magnesium implants: a review, Acta Biomater. 6; 5, 1680-92 (2010).

[4] H. Rotaru et al., Maxillofac Plast Reconstr Surg, Selective laser melted titanium implants: a new technique for the reconstruction of extensive zygomatic complex defects, 37:1;1 (2015).

[5] L. Jauer et al., (2013), Selective laser melting of biodegradable metals, European Cells and Materials 26:Suppl. 5, 21.

[6] M. Gieseke, Selective Laser Melting of Magnesium and Magnesium Alloys, Magnesium Technology 2013, 65-68 (2013).

[7] S. Böhringer et al., Safety recipient for controlled selective laser melting of magnesium, European Cells and Materials, in print (2015).