Introduction: Electrospinning is a versatile fibre-based technique for scaffold production with smaller fibre diameter, and thus larger surface area to volume ratio compared to melt extrusion. Recent developments in direct writing melt-electrospinning makes use of the stable and predictable fibre deposition to fabricate scaffolds in the layer-by-layer manner[1],[2].

Synthetic materials including polymers and bioactive glass (BG) are most common for bone scaffold fabrication[3],[4]. Among the synthetic polymers, polycaprolactone (PCL), which is a FDA-approved aliphatic polyester, has been become a promising candidate for bone scaffold material due to its favourable rheological and viscoelastic properties[5]. Bioactive glass (BG) is a synthetic material known to bind seamlessly to bone and promote osteogenesis. Strontium-substituted BG derived from the original 45S5 BG by substituting 0-100% of the calcium component of the 45S5 formulation for strontium[6], and have shown superior osteogenic capacity to 45S5 BG[7]. We hypothesize that melt-electrospun PCL/SrBG composite scaffolds will provide a promising bone graft substitute, which will be osteoinductive, osteoconductive, capable of osteointegration and bioresorbable in a controlled rate. The scaffolds can be manufactured with a tailored structure according to specific defect site, and can be replaced by the body’s own newly regenerated bone over time.

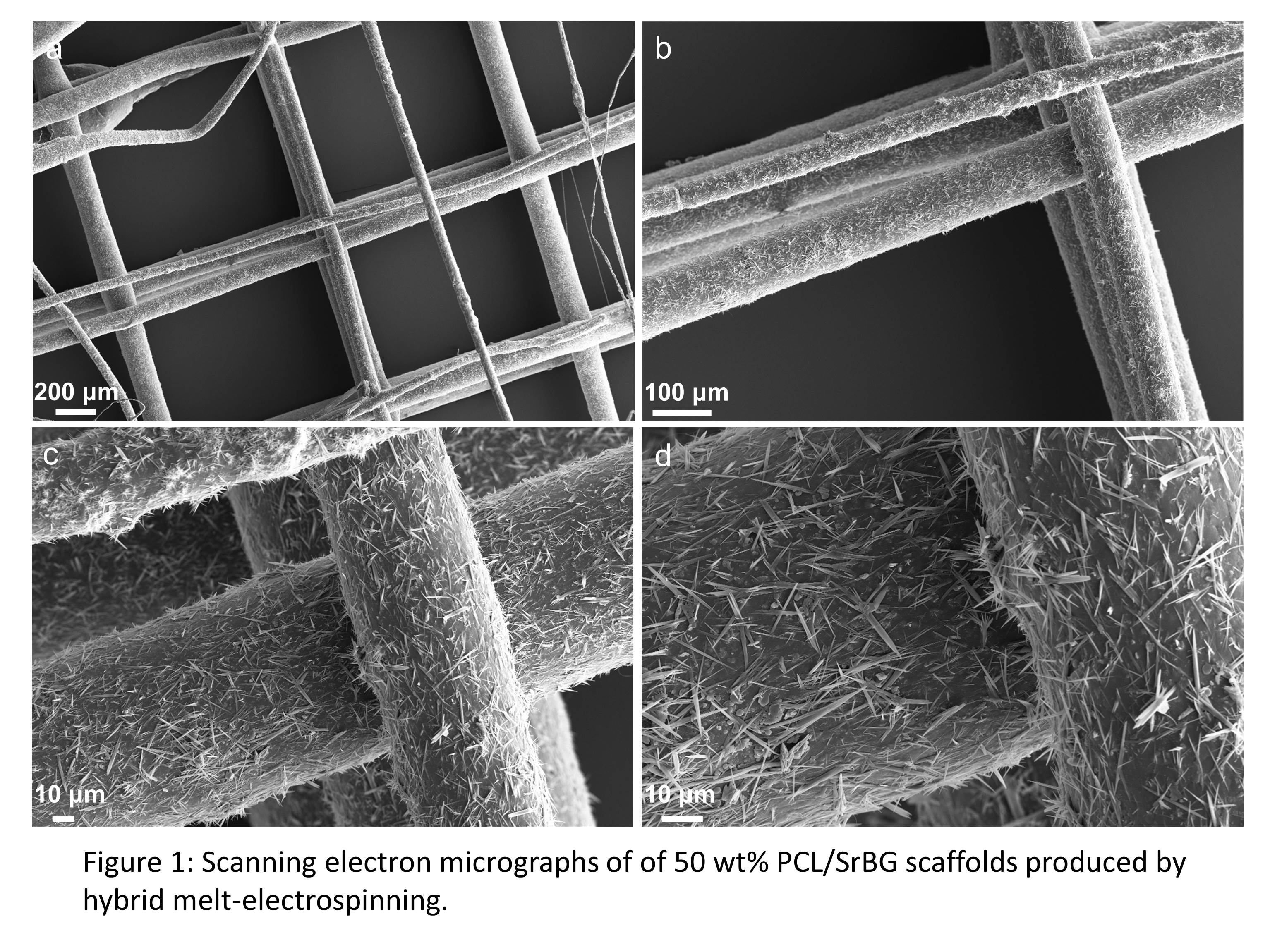

Materials and Methods: The SrBG particles were ground down to < 6 μm prior to composite preparation with a micronizing mill to reduce the risk of needle blockage. The 50 wt% PCL/SrBG composites were prepared by incorporating fine SrBG particles into the PCL bulk using solvent precipitation technique. PCL/SrBG composite scaffolds were fabricated using a novel solvent assisted hybrid melt-electrospinning technique in the direct write mode. Light microscopy and scanning electron microscopy (SEM) were used to characterize surface topography and fibre diameter. Mechanical stiffness of PCL/SrBG fibres were assessed with atomic force microscopy. Cell attachment and morphology were assessed with confocal laser scanning microscopy and SEM . Cell proliferation and osteoblastic differentiation were assessed with PicoGreen and alkaline phosphatase assays.

Results and Discussion: Our hybrid melt-electrospinning system overcame the difficulties of PCL/SrBG composite melt-electrospinning associated with viscoelastic properties of the composite material. These composite scaffolds were produced in a layer-by-layer manner with 90° cross-hatched deposition with the fibre spacing of 1 mm. Examination by scanning electron microscopy showed enhanced micro structure on the surface of PCL/SrBG fibres, while the surface of PCL only fibres were smooth. The submicron structures generated during the hybrid melt-electrospinning process largely increased the surface area of composite scaffolds and created roughness ideal for cell attachment. The in vitro results showed good cell adherence onto both the PCL/SrBG and PCL only scaffolds. However, PCL/SrBG composite scaffolds showed significantly higher osteoblast differentiation compared to PCL only scaffolds.

Conclusion: We are the first to produce the composite PCL/SrBG (50 wt%) scaffolds via a novel hybrid melt-electrospinning technique. These composite scaffolds are promising bone graft substitutes, and may also lead to patient-specific and off-the-shelf solution for clinical treatment of critical-sized bone defects.

Dr Henrietta Cathey (Electron microscope probe analysis); Dr Charlotte Allen, Dr Sunny Hu and Mr. Mitchell De Bruyn (Inductively coupled plasma analysis); Dr Marie-Luise Wille (micro-CT scanning and analysis); Dr Christina Theodoropoulos (Confocal microscopy); Dr Tong Li (Atomic force microscopy); ARC Linkage for funding

References:

[1] Brown, T. D. et al. Melt electrospinning of poly(ε-caprolactone) scaffolds: Phenomenological observations associated with collection and direct writing. Mater. Sci. Eng. C (2014). doi:10.1016/j.msec.2014.07.034

[2] Muerza-Cascante, M. L., Haylock, D., Hutmacher, D. W. & Dalton, P. D. Melt Electrospinning and Its Technologization in Tissue Engineering. Tissue Eng. Part B. Rev. 00, 1–16 (2014).

[3] Rezwan, K., Chen, Q. Z., Blaker, J. J. & Boccaccini, A. R. Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering. Biomaterials 27, 3413–3431 (2006).

[4] Boccaccini, A. R. et al. Polymer/bioactive glass nanocomposites for biomedical applications: A review. Compos. Sci. Technol. 70, 1764–1776 (2010).

[5] Woodruff, M. A. & Hutmacher, D. W. The return of a forgotten polymer—Polycaprolactone in the 21st century. Prog. Polym. Sci. 35, 1217–1256 (2010).

[6] O’Donnell, M. D. et al. Materials characterisation and cytotoxic assessment of strontium-substituted bioactive glasses for bone regeneration. J. Mater. Chem. 20, 8934 (2010).

[7] Gentleman, E. et al. The effects of strontium-substituted bioactive glasses on osteoblasts and osteoclasts in vitro. Biomaterials 31, 3949–3956 (2010).