Polymeric heart valves (PHV) have been investigated since 1960 but their success has been hampered due to an overall lack of durability, leaflets calcification and thromboembolic complications. The aim of this work was to develop a prototype of a new elastomeric biocompatible valve, durable and free from calcification.

In previous studies a polymeric materials was chosen and characterized for the development of a single-body PHV: Carbosil F® (CF), a thermoplastic fluorinated silicone polycarbonate-urethane (DSM, Heerlen, Netherlands). The material was modified by adding 30% (w/w) of PDMS (CF30) to improve the stability and in vitro evaluated in term of bio/hemocompatibility, calcification, degradation and mechanical properties. The results of in vitro tests demonstrated that the material has the potential to be used for the fabrication of synthetic valve avoiding calcification and thromboembolic complications.

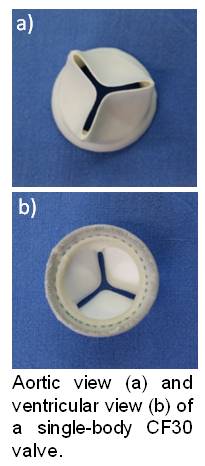

In this study a single-body PHV prototype, with an incorporated stent, was manufactured using CF30 material and by a combined technique consisting in dipping and spray material deposition. A polycarbonate valve mould reproducing the geometry of a commercially available biological aortic valve, a tubular mould and a countermould were supplied by Pro.Ra. (Florence, Italy), while a Mitroflow® valve stent was supplied by Sorin Group Italia (Vercelli, Italy).

Aortic view (a) and ventricular view (b) of a single-body CF30 valve.

Stent was placed onto the valve mould, then the mould was fit on tubular mould and dipped into a CF30 solution for 10 times. After each dip, the stent was dried under hot air flow. After that the dipped mould was mounted as a rotating mandrel in a spray-machine instrument and coated by a CF30 solution. At the end of the process, the device was bathed in H2O to allow solvent removal and the tubular mould was gently removed.

The countermould was tightened on the mould up to 300 mm of thickness and the valve was bathed at 37°C o.n. Then the excess of polymer was cut away by a heating tip and the polymeric valve was removed from the moulds. Six valve prototypes were subjected to hydrodynamic test and accelerated fatigue test at 37°C in a pulsatile flow simulator and failure monitored. DP vs cardiac output showed a linear trend and the effective orifice area (EOA) was about 2,7 cm2. All valves showed a slight pinwheel effect during leaflet closure.

In the long-term fatigue tests (1000 cycles/min, mean pressure gradient > 95 mmHg), one CF30 valve failed at 18 million cycles, with failure primarily due to the development of a break at leaflet commissures in the region of stent tip, while the other five CF30 valves exceeded 50 million cycles (equivalent to 15 months in vivo) without any sign of failure.

In conclusion, in this study we demonstrated that the combination of a dipping and a spray technique resulted suitable to manufacture, with the CF30 material, a new single-body fatigue resistant heart valve, which has the potential to be used as a synthetic cardiac valve substitute.

The Authors wish to thank Sorin Group Italia (Vercelli, Italy) for kindly providing the valve stent.