Introduction: Because of their exceptional biological properties, reconstituted collagen gels are widely used as scaffolds even though their low elastic modulus (~ 500 Pa) limits their applications[1],[2]. The mechanical properties of collagen are governed by viscoelasticity. Unfortunately, few reports deal the mechanical properties of hydrogels that need to be addressed to understand the behavior of suchhydrogels when submitted to either creep-like or relaxation-like mechanical testing.

Materials and Methods: Type I collagen was extracted from rat-tail tendons and solubilized in acetic acid solution (0.02N) at 4 g/L as previously reported[3]. Unconfined compression tests were made on disk shaped samples with a 25 mm compression plate attached to a 150 gf load cell mounted on a Biomomentum Mach 1 (Laval, Canada) testing apparatus. Compression tests were performed at room temperature in Phosphate-Buffered Saline (PBS) solution. Viscoelastic models[4] based on two time constants Maxwell and standard linear solid were used. In addition, to reconcile experimental results and theory nonlinear stress-strain relationship based on Neo-Hookean and Mooney-Rivlin models were used.

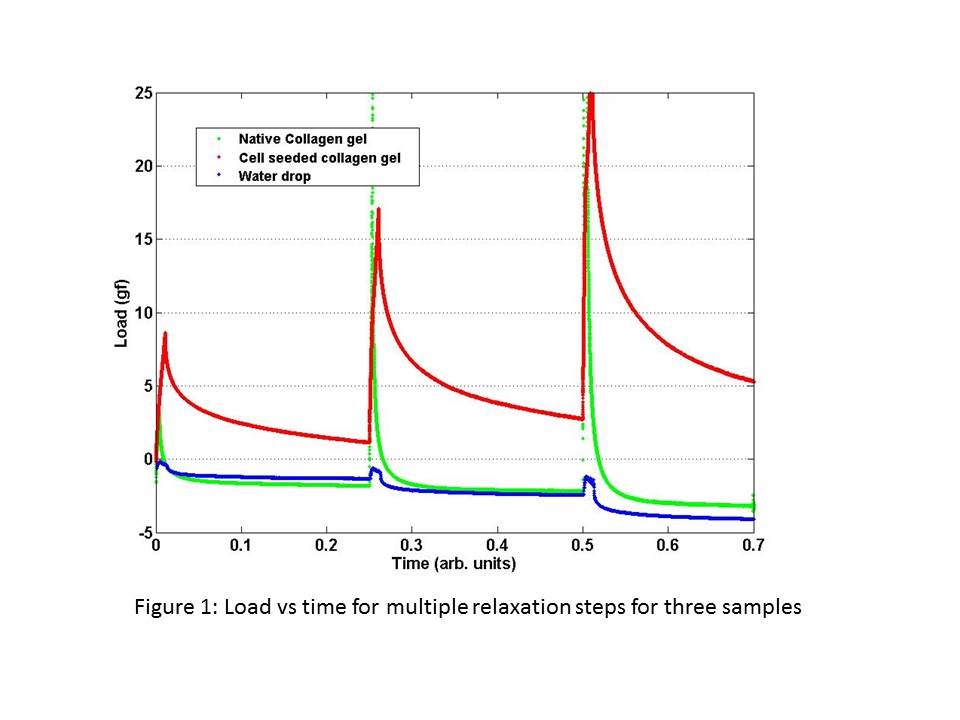

Results: Figure 1 shows a typical multiple relaxation test obtained with three samples: a water drop, a native collagen hydrogel and a collagen gel that has been colonized with smooth muscle cells for one week. The load of the water drop is increasingly oriented toward the tension side (negative) of the load curve due to increased surface tension force. The load curve of the native collagen gel is almost neutral and slightly toward the negative part. This indicates that the collagen native hydrogel exhibits no real residual stress when compressed for many steps. The viscoelastic model of such a material necessitates the use of Maxwell bodies. The other curve shows a residual stress that increases with the depth of the compression. In this case, the standard linear solid viscoelastic model is used.

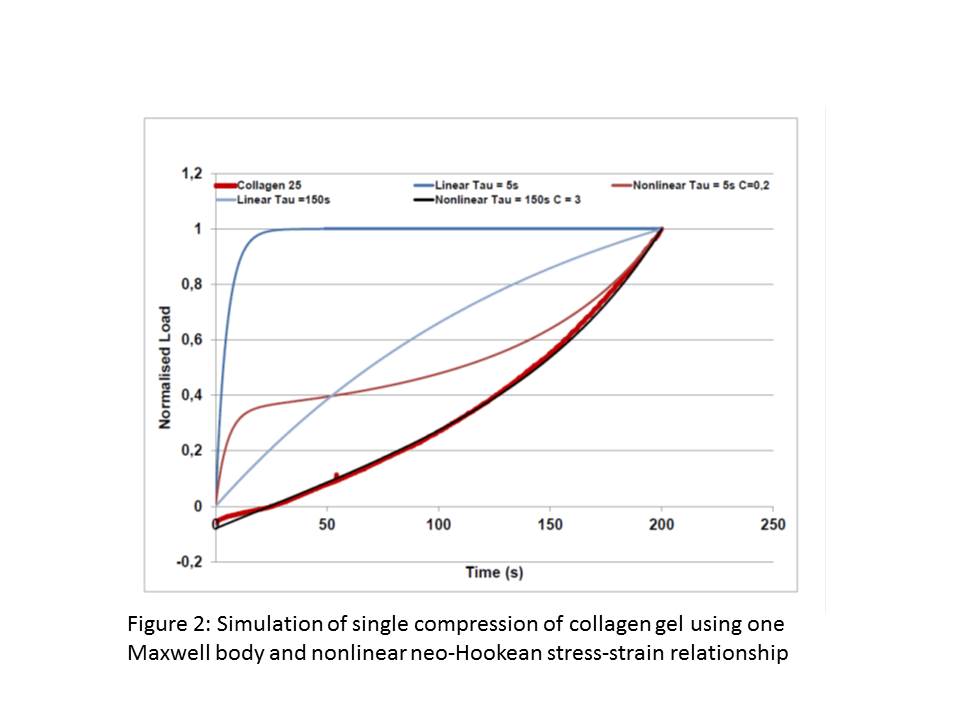

In figure 2, only the compression phase is illustrated. The simulation curves to reproduce the experimental result are indicated. Using a single Maxwell body, one can reproduce the experimental load if two conditions are met. The first condition requires a long time constant (~ 150s).

As illustrated, a fast time constant is not adequate to reproduce the results. The second condition requires that a nonlinear relationship between Load and strain be used. In this case, a neo-hookean approach is used. Only in this combination of parameters, can one hope to reproduce experimental tests with simulation using standard viscoelastic models.

Conclusion: This paper will present the results of many tests performed on collagen gels and present the conclusions regarding the viscoelastic models that should be retained when dealing with collagen gels mechanical properties.

NSERC CREATE; NSERC-Canada; FRQ-S; FRQ-NT

References:

[1] Sander et al., Collagen: Structure and Mechanics, P. Fratzl (ed.), ch 17, Springer, 2008

[2] Seifu et al., Nature Reviews Cardiology, 2013, 10, 7, 410

[3] Rajan, N; Habermehl, J; Coté, M.-F; Doillon, C.J; Mantovani, D., Nature Protocols, 2006,1,2753-8.

[4] Fung, Biomechanics: Mechanical properties of living tissues, 2nd ed. 1993