Chitosan:PEGDA hybrid-gel scaffolds printed by stereolithography

-

1

Case Western Reserve University, Department of Mechanical and Aerospace Engineering, United States

Introduction: 3D biofabrication strategies enable the development of tissue engineering scaffolds with complex heterogeneous architectures[1]. The hybridization of natural and synthetic polymer offers the advantages of enabling cell adhesion and adjustment of mechanical properties[2]. In the present work we have developed a hybrid resin of natural polymer chitosan and synthetic polymer polytheylene glycol diacrylate (PEGDA) with Irgacure 819 as photoinitiator for photo-printing by stereolithography. Due to rigid crystalline structure of chitosan polymer, its solubility is restricted in dilute acids and it becomes an obstacle to formulate chitosan with other photocurable synthetic polymers, as the protonated amines will quench the newly formed free radicals by the photoinitiators[3]. We have developed a novel and simplified approach to address this issue by dialyzing chitosan in salt solution.

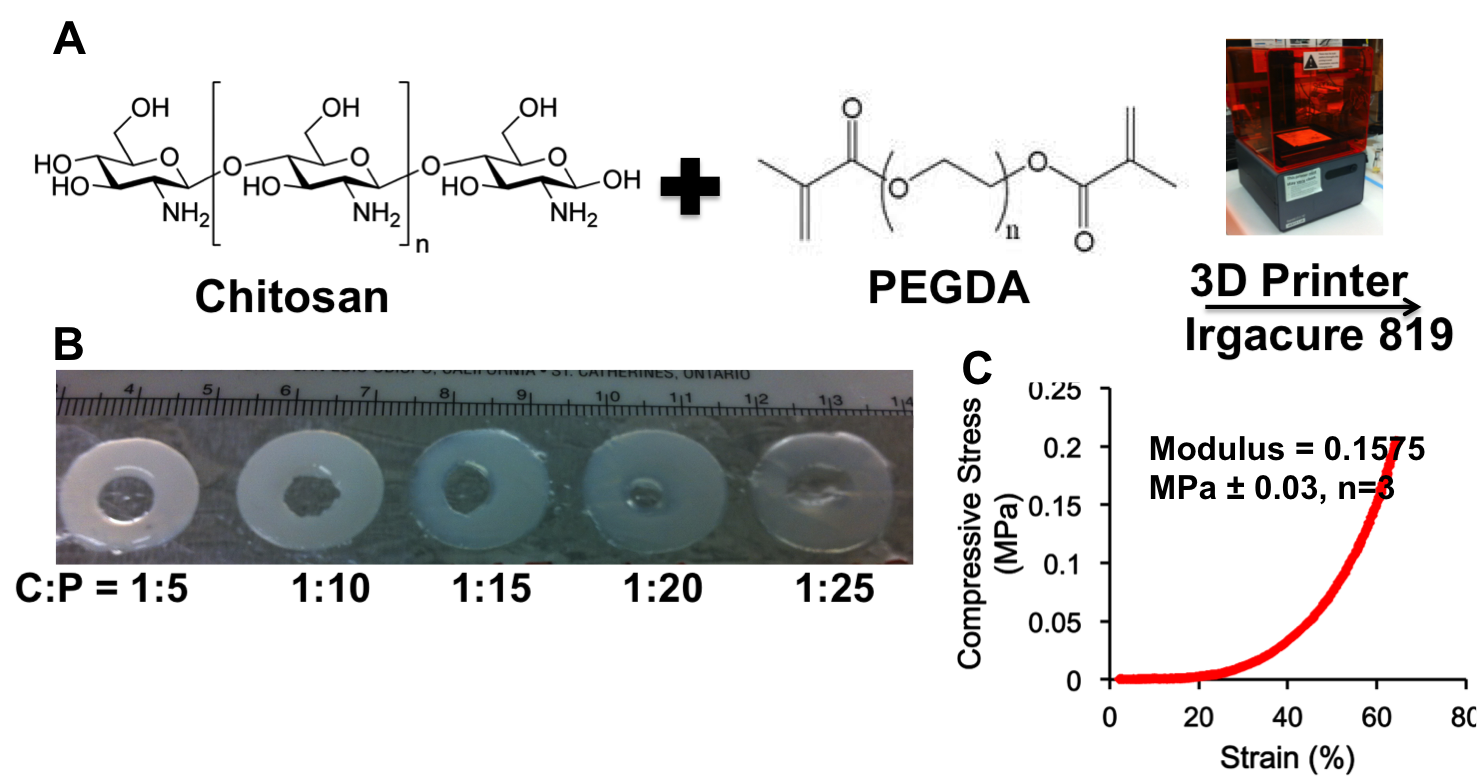

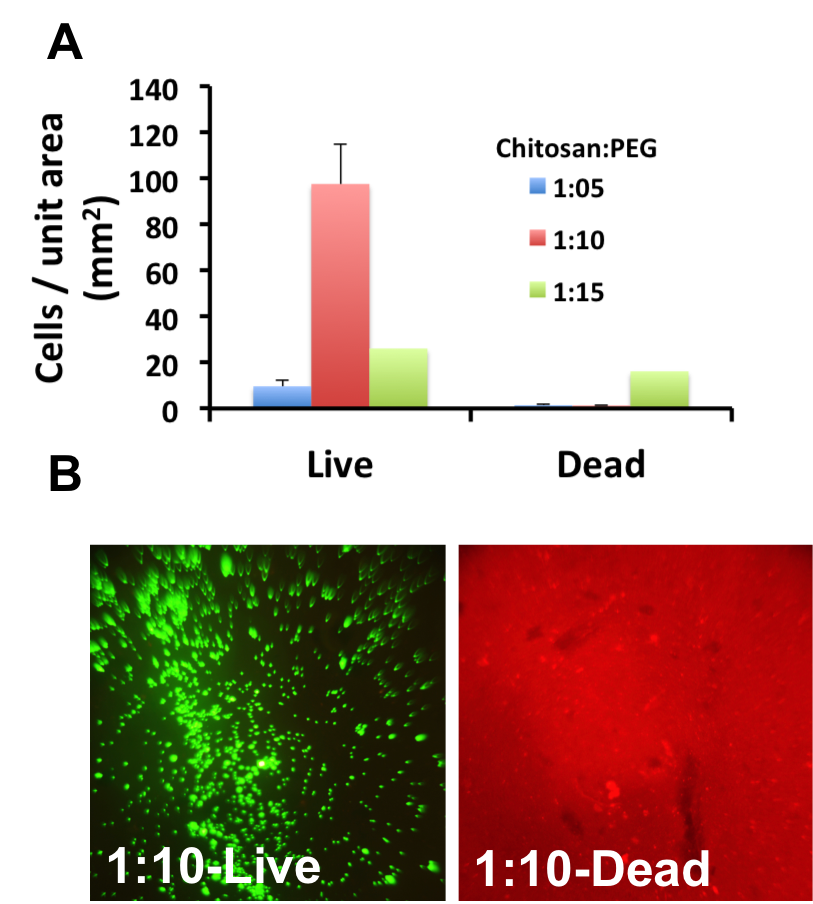

Materials and Method: High molecular weight (η=800-2000 cP) chitosan solution (18mg/ml) was prepared in 1% acetic acid and dialyzed in 0.1N CH3COONa for 24h. Photocurable resins were prepared by mixing varying feed ratios of Chitosan to PEGDA (MW=575 Da) such as 1:5, 1:10, 1:20 and 1:25 with Irgacure 819 in N-vinyl-2-pyrolidinone (100 mg/ml) as photoinitiator. Scaffolds were designed in SolidWorks. 3D printing was performed by Form 1+ High Resolution printer (Formlab) and layer by layer using 405 nm laser via galvanometric mirrors. Young’s modulus of scaffolds was calculated from the slope of stress-strain curves in the range of 20-40% strain using a compression test device. Cell viability was measured at day 1 using calcein AM/ethidium homodimer 1 LIVE/DEAD assay.

Results and Discussion: To deprotonate the primary amines we have dialyzed chitosan in 0.1N sodium acetate solution that enabled photocuring of Chitosan:PEGDA hybrid gels. Chitosan increased the viscosity of resin and decreased the minimum required concentration of PEGDA from 20% to 12.5%[4]. The required concentration of photoinitiator was reduced from 0.0325 to 0.02 % as the feed ratio of Chitosan to PEG increased from 1:5 to 1:25, likely due to the higher concentration of diacrylate functional group. However, higher concentration diacrylate group was responsible for excessing crosslinking at higher ratios and resulted in less precise shapes (Fig 1B). So we have chosen feed ratios of 1:5 to 1:15 for further studies. Hybrid of PEG with chitosan (1:10) has enhanced the modulus (157.5 kPa ± 0.03, n=3) 40 fold higher compared to uncrosslinked chitosan[5] (Fig 1C). The same feed ratio (1:10) was found to be result in higher number of live cells after 24h of incubation as evidenced by Live Dead assay. The lower live cell cell counts of hybrid with 1:5 (~ 10 fold) and 1:15 (~4 fold) compared to 1:10 was assumed to be due to higher concentration of photoinitiator and higher concentration of PEGDA which is less conducive to cell adhesion, respectively (Fig 2A&B).

Conclusion: Chitosan:PEGDA hybrid resins were formulated for 3D bioprinting of complex structured scaffold for tissue engineering. Presently we have used only high molecular weight chitosans. However for fabricating more precise 3D structures we plan to use low and medium molecular weight chitosan in our future experiments.

References:

[1] Bajaj P.et.al. Ann Biomed Eng. 2014;16: 247-76

[2] Zhu J. Biomaterials 2010; 31: 4639–4656

[3] Jung S et.al. Langmuir 2012; 28: 17061−17070

[4] Mazzoccoli et al J Biomed Mater Res A. 2010; 93: 558–566

[5] Subramanian A. J Biomed Mater Res 2005; 75A: 742–753

Keywords:

Biocompatibility,

3D scaffold,

Biodegradable material,

Polymeric material

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

Poster

Topic:

Biomaterials in constructing tissue substitutes

Citation:

N

S,

Morris

VB,

Younesi

M and

Akkus

O

(2016). Chitosan:PEGDA hybrid-gel scaffolds printed by stereolithography.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.00514

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.