Introduction: 3-D porous biomaterials have been widely studied for applications in orthopedics, tissue engineering and drug delivery[1]-[3]. Although many fabrication approaches have been invented, readily control and low-temperature fabrication of porous structure remains challenge for ceramic or ceramic composite systems. Here, a novel fabrication technique of porous ceramic composite scaffolds is reported, and its applications as drug delivery system and the cell-loaded tissue engineering scaffolds were also developed.

Materials and Methods: Firstly, 10 wt% corn starch suspension, 20~44wt.% hydroxyapatite (HA) and a surfactant of TritonX-100 were mixed and the mixture was then heated to 90oC and foamed by vigorous stirring. The foam was set for 24hr and dried by heating at 50oC or freeze-dry. For cell-load scaffolds, the corn starch, DI water and surfactant were replaced by pre-gelatinized starch, Dulbecco’s modified eagle medium and albumin, respectively. Osteoblasts were added to the slurry before foaming and the stir foaming was performed at 37oC.

Porosity of the scaffold was calculated from apparent density and pore structure was characterized by scanning electron microscopy (SEM). Drug delivery experiment used bromophenol blue (BPB) as a model drug and its concentration was measured spectrophotometically by microplate reader. Cell-load scaffold was characterized by fluorescence microscopy (FM).

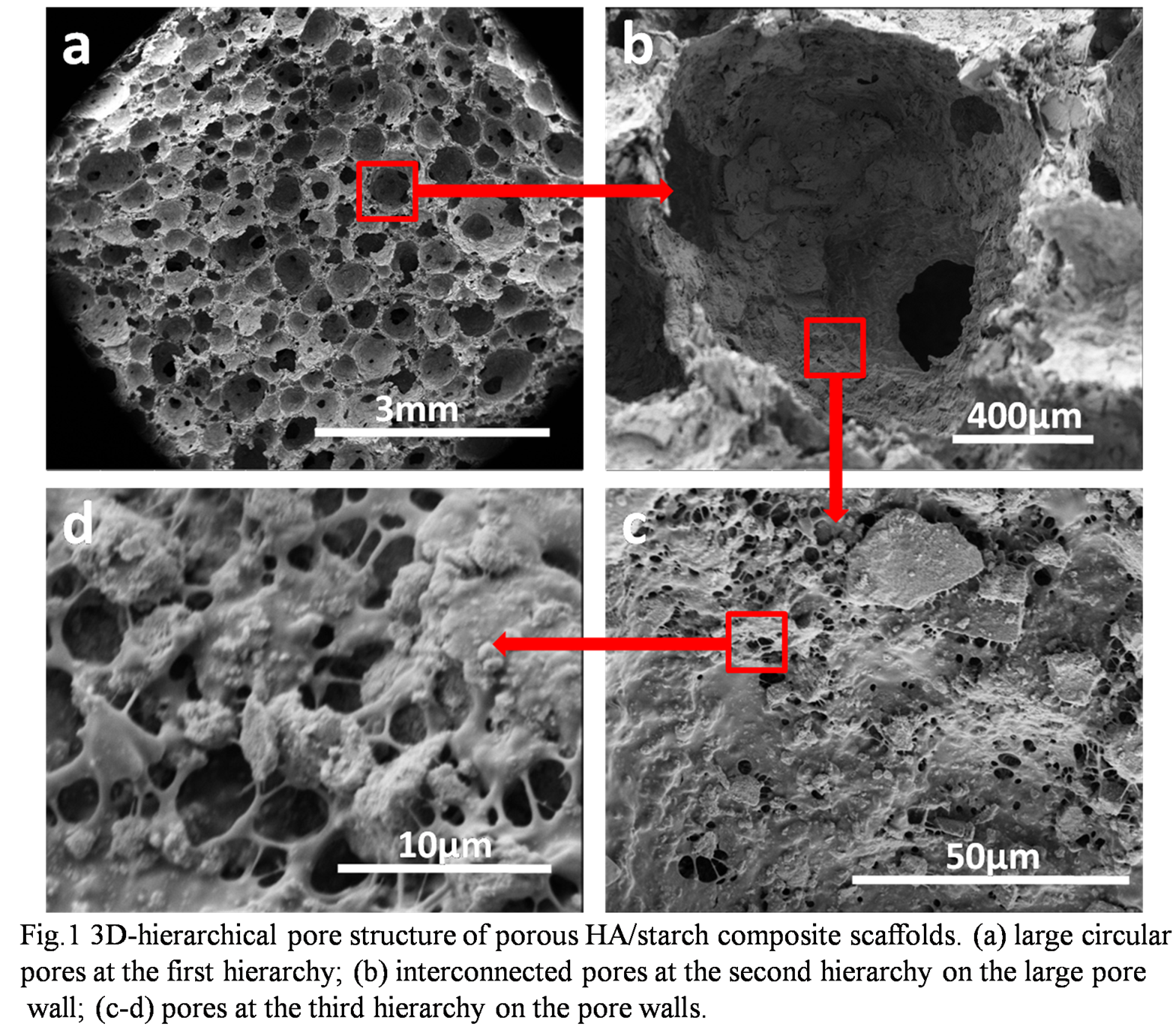

Results and Discussion: HA/starch composite scaffolds had high porosities of >85% and comprised of 3D-hierarchical pore structure with pore sizes varied from micron to millimeter range.

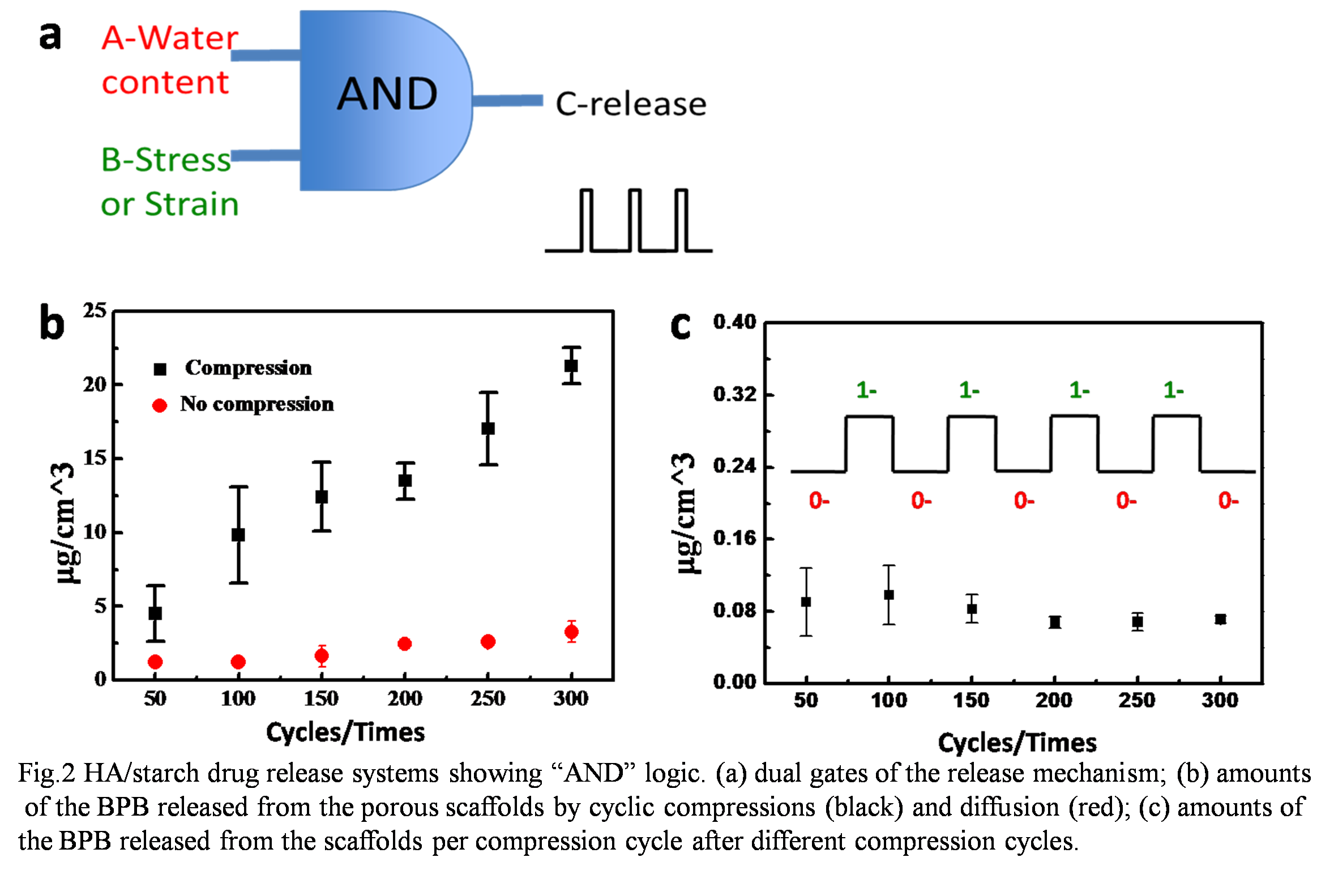

The scaffolds demonstrated high elasticity and resilience when absorbing water, and this unique property was suitable for loading drug and achieving precise on-demand release by pressure. Results of drug release test showed that BPB release exhibited AND logic with dual-control gates of water content and pressure. After 300 times cyclic compression, the amount of the BPB released from the scaffold with 66% water content was 0.021mg/cm3, much greater than that diffused from the same scaffold (0.003 mg/cm3).

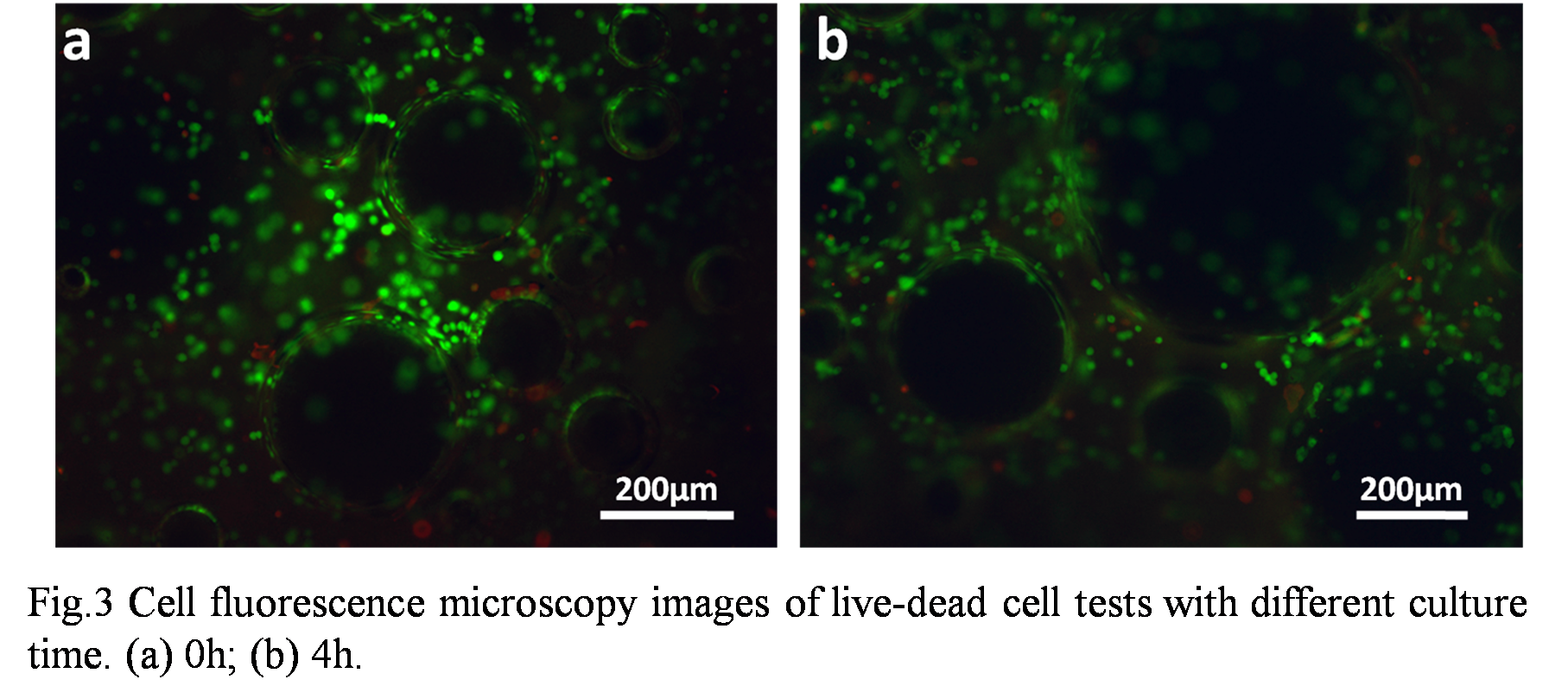

Moreover, this low-temperature technique was extended to load cells in situ into the porous scaffold. Live/dead cell tests revealed that the composite scaffold had good cytocompatibility and the osteoblasts loaded in the porous structure showed satisfactory viability up to 5 days.

Conclusion: The present study reported a low-temperature fabrication technique of porous ceramic composite scaffolds for drug delivery system, which shows AND logic release, and this fabrication technique can be extended to incorporate live cells to the scaffold at 37oC. This fabrication technique is therefore highly promising for 3D bone tissue engineering and drug delivery scaffolds.

References:

[1] Hollister S J. Porous scaffold design for tissue engineering[J]. Nature materials, 2005, 4(7): 518-524.

[2] Ma P X. Scaffolds for tissue fabrication[J]. Materials today, 2004, 7(5): 30-40.

[3] Bose S, Tarafder S. Calcium phosphate ceramic systems in growth factor and drug delivery for bone tissue engineering: a review[J]. Acta biomaterialia, 2012, 8(4): 1401-1421.