Introduction: Implant designs calls for functional performance at various sections of the implant. For instance during insertion process, initially quick advance is desired, while stability takes centre stage in subsequent turns. Similarly trabecular bone require deeper threads for stability, while cortical bone requires shallow threads to sustain lesser stress at the cortico-cancellous interface. These requirements calls for a contradictory design for a single implant. The article numerically analyses dental implant with variable pitch and variable depth of thread in order to meet out both the contradicting ends of a dental implant. For the purpose both experimental studies as well as FE simulations are being conducted to validate the computational model.

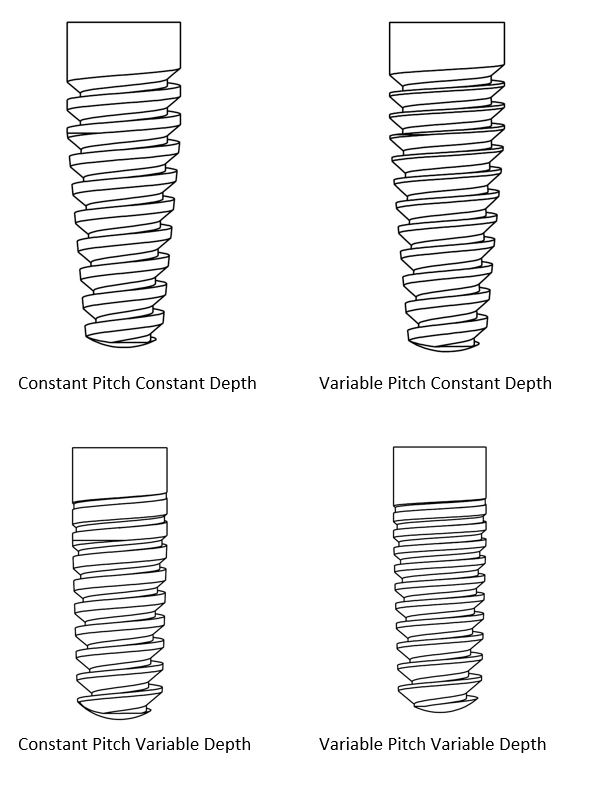

Materials and Methods: A three dimensional model is constructed in SolidWorks and finite element simulation is carried out in Ansys Workbench. For the same configuration of overall design, two types of pitch are considered for the study: implant with constant pitch and implant with variable pitch. Similarly for the threads, implants with constant depth of thread and with variable depth are considered. This yields total permutation of four combinations of pitch type and thread depth type. Implants are machined on sliding stock – ten axis – Swiss CNC machine Tornos DECO 13e. Experiments are carried out on various densities of Sawbone blocks.

Results: Maximum stress occur at the crestal region, less thread depth and less pitch is able to withstand the induced stresses. While the functional aspects required at the apical region are met with deeper thread depth and higher pitch. With the decrease in thread pitch there is decrease in stress. Thread design affect the stress more in cancellous bone as compared to cortical bone.

Discussion: The variable pitch enhances the cutting ability in the apical region whereas enhances insertion torque in the cortical region thereby indicating higher initial stability. The variable depth of the thread indicates higher osseointegration in the cancellous bone which may lead to higher pull out loads. This may lead to better implant design than with normal depth and pitch as is seen in today’s commercial implants

Conclusion: The FE analysis and experimental studies of the implants reflect that implant with variable pitch and variable depth of thread provides better functional performance as compared to that of constant pitch and constant depth of cut. Although the manufacturing such an implant has proved to be a machining challenge.

Council of Scientific & Industrial Research (CSIR)