Fabrication of uniform calcium alginate gel particles with low-cost widely available ink-jet printer system

-

1

University of Birmingham, Chemical Engineering, United Kingdom

Introduction: Alginate is a natural polysaccharide, extracted from brown algae. It has wide field of application due to its biodegradability, low cost and gelation under mild conditions with crosslinking agents like Ca2+, Ba2+ or other multivalent ions [1],[2]. Alginate is used widely in biomedical applications in the form of gel particles. These particles are used for the delivery of compounds such as lipids, probiotics [3], enzymes [4], vitamins [5] and more. Many methods have been used for particle production, including dropping, jet break-up, extrusion [6], emulsification [7], microfluidic devices [8] and more. The production of uniform, mono-modal distributed particles using lab-based equipment is however challenging. Although the production of larger gel particles (100µm and more) is straight-forwards, the production of uniform particles in the range of 10 to 100µm remains problematic. Here, we demonstrate a new method to produce mono-modally distributed uniform particles using a low cost, widely available ink-jet printer system.

Materials and Methods: The gel particles were produced using a standard inkjet printer (HP Deskjet 1010). First, a cleaned cartridge (HP 301 black) was filled with 5ml of sodium alginate solution (Sigma). A document file in Microsoft Word format containing black coloured rectangle was sent (200 copy) from laptop to printer (HP 1010 printer) and the cartridge sprayed droplets into a beaker containing 30ml of 0.1 M Calcium Chloride solution (Sigma) with 150µl of Tween 80 (MP Biomedicals) under agitation. Then the particles were washed twice with distilled water (Arium Advance system).

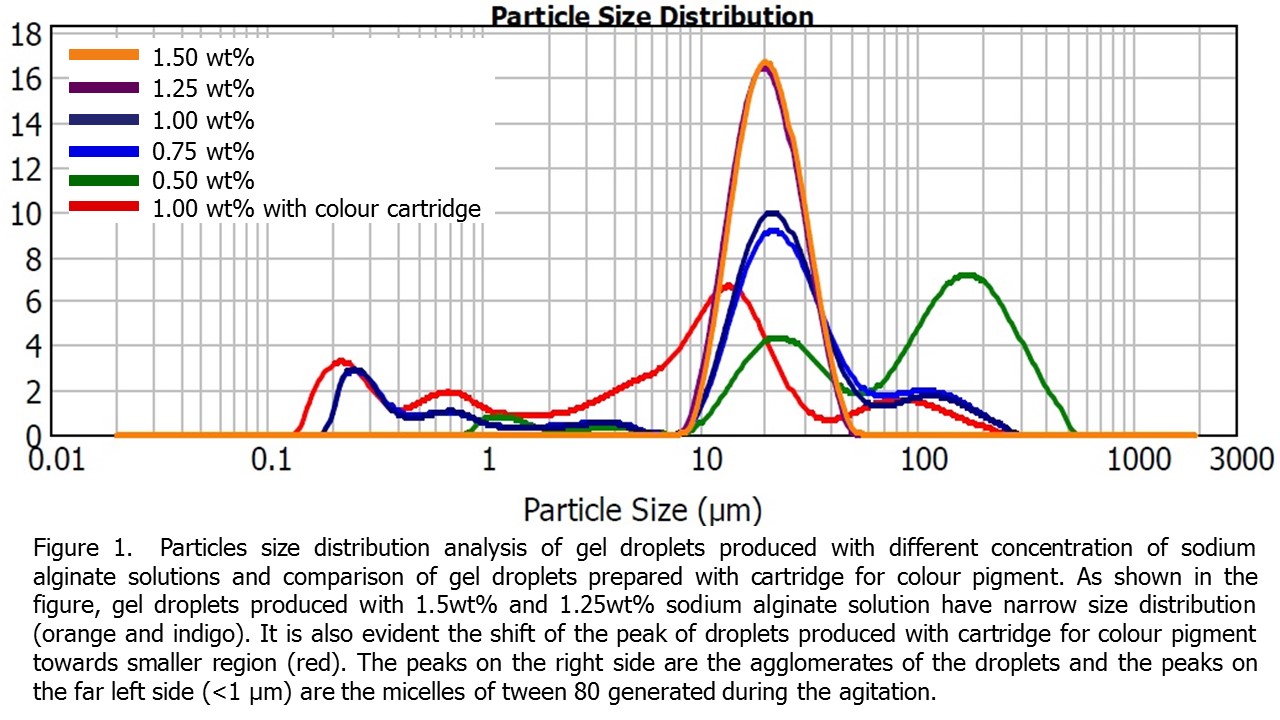

Results and Discussion: The procedure was conducted with different concentrations of alginate solution (0.5wt%, 0.75wt%, 1.0wt%, 1.25wt%, 1.5wt%). The best in terms of uniformity of generated gel particles was at 1.25wt% and 1.5wt%. The vol. weighted mean size was 21.9µm.

As shown in

the formulated gel particles were more dispersed, with lower concentrations of alginate solution (<0.5%w/w) the gel particles tent to form aggregates and in case of higher concentration (>1.5% w/w) the printhead had clogged very often because of high viscosity. We also sprayed with colour dye containing cartridge to generate gel particles. This time d(0.5) of the particles were 8.3µm.

We conclude that the method provide a process of production of gel particles that can be conducted in a cheap and easy manner for encapsulation of various materials or generation of functional particles for use in a lab. It is also possible to scale up the production with stacked cartridges comprising integrated electronic system.

Ministry of Education And Science of Republic of Kazakhstan; "Bolashak" education funding program of Republic of Kazakhstan; University of Birmingham

References:

[1] G. Orive, A. M. Carcaboso, R. M. Hernández, A. R. Gascón, and J. L. Pedraz, “Biocompatibility evaluation of different alginates and alginate-based microcapsules.,” Biomacromolecules, vol. 6, no. 2, pp. 927–31, Jan. 2005.

[2] T. Andersen, J. E. Melvik, O. Gåserød, E. Alsberg, and B. E. Christensen, “Ionically gelled alginate foams: physical properties controlled by operational and macromolecular parameters.,” Biomacromolecules, vol. 13, no. 11, pp. 3703–10, Nov. 2012.

[3] A. Sohail, M. S. Turner, A. Coombes, T. Bostrom, and B. Bhandari, “Survivability of probiotics encapsulated in alginate gel microbeads using a novel impinging aerosols method.,” Int. J. Food Microbiol., vol. 145, no. 1, pp. 162–8, Jan. 2011.

[4] D. M. Hariyadi, Y. Wang, S. C.-Y. Lin, T. Bostrom, B. Bhandari, and A. G. a. Coombes, “Novel alginate gel microspheres produced by impinging aerosols for oral delivery of proteins,” J. Microencapsul., vol. 29, no. 3, pp. 250–261, May 2012.

[5] N. Abubakr, A. Jayemanne, N. Audrey, S. X. Lin, and X. D. Chen, “Effects of encapsulation process parameters of calcium alginate beads on Vitamin B 12 drug release kinetics,” Asia-Pacific J. Chem. Eng., p. n/a–n/a, 2009.

[6] B. Bugarski, Q. Li, M. F. A. Goosen, D. Poncelet, R. J. Neufeld, and G. Vunjak, “Electrostatic droplet generation: Mechanism of polymer droplet formation,” AIChE J., vol. 40, no. 6, pp. 1026–1031, Jun. 1994.

[7] L. T. L. P. W. S. H. L. W. Chan, “Microencapsulation of oils using sodium alginate,” J. Microencapsul., Sep. 2008.

[8] D. Holmes and S. Gawad, “The application of microfluidics in biology.,” Methods Mol. Biol., vol. 583, pp. 55–80, Jan. 2010.

Keywords:

Hydrogel,

Rapid prototyping,

Biodegradable material,

targeting delivery

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

Poster

Topic:

Biomaterials in printing

Citation:

Askarov

B

(2016). Fabrication of uniform calcium alginate gel particles with low-cost widely available ink-jet printer system.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.00101

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.