Introduction: Hydrogels are a popular choice for cartilage tissue engineering (TE) scaffolds due to their hydrophilicity[1]. Closely mimicking the highly hydrated extracellular matrix of biological tissues increases the scaffold’s biocompatibility. However, use of hydrogels within TE is limited by poor mechanical properties, preventing their use as a long term solution for cartilage damage[2]. The properties of natural cartilage could be reproduced by successfully imitating the nanostructure of cartilage, creating a scaffold that models the extracellular matrix as a fibre reinforced hydrogel. The fibres mimic the nanoscale collagen fibres within cartilage, and the hydrogel mimics the proteoglycan ground substance and allows for the large water content of natural cartilage. This study utilises electrospinning to create a mesh of gelatin nanofibres that are infiltrated with a hydrogel to create a fibre reinforced composite.

Materials and Methods: A 12 wt % gelatin solution was prepared, with citric acid as a crosslinker and sodium hypophoshite as a catalyst in a 90 v/v % aqueous acetic acid solution. The solution was prepared at room temperature and then electrospun horizontally for four hours. The nanofibrous meshes were then removed from the collector and crosslinked at 150°C for four hours, creating gelatin fibres that are stable in water. These fibres were then infiltrated with a homogeneous alginate hydrogel or a double network hydrogel to create fibre reinforced composites.

Unidirectional tensile tests and mode III toughness tests were conducted on an Instron (5544 universal testing machine) to compare the mechanical properties of the fibrous meshes, the crosslinked hydrogels, and the composites. Atomic force microscopy (AFM) was used to study single fibres within the meshes, and dual beam focused ion beam (FIB) scanning electron microscopy (SEM) was used to visualise the structures in 3D.

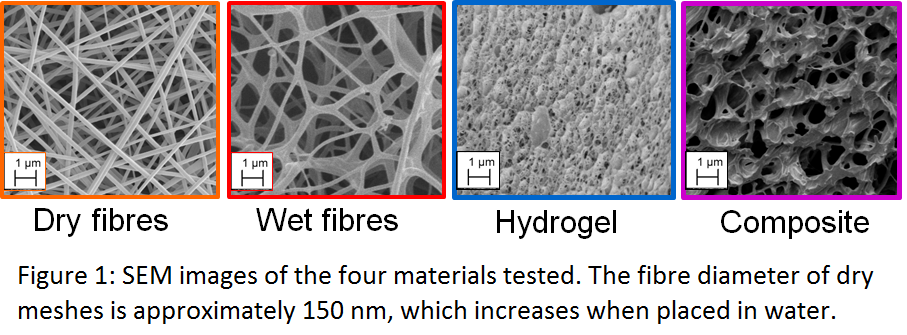

Results and Discussion: Figure 1 shows the microstructure of the four materials tested. It can be seen the fibres have swollen when placed in water, and that the hydrogel has infiltrated the fibres to create a composite.

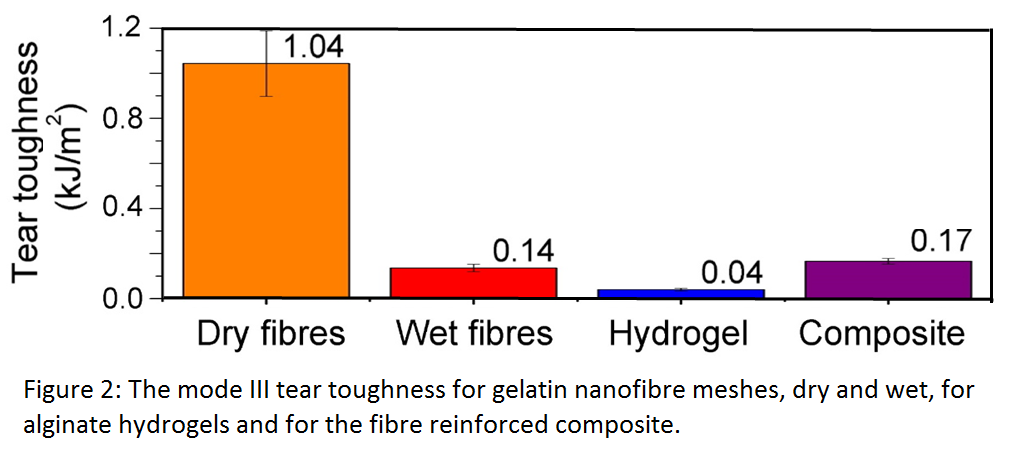

The tensile tests demonstrated the addition of randomly aligned fibres to a hydrogel can more than double the tensile strength and the elastic modulus. Toughness was calculated from mode III fracture tests as the analysis is independent of geometry. The fibres improved the toughness of the hydrogels to greater than either of the independent components of the composite. Alginate on its own has a toughness of just 0.04 kJ/m2, which is increased to 0.17 kJ/m2 when reinforced with randomly aligned nanofibres as shown in Figure 2.

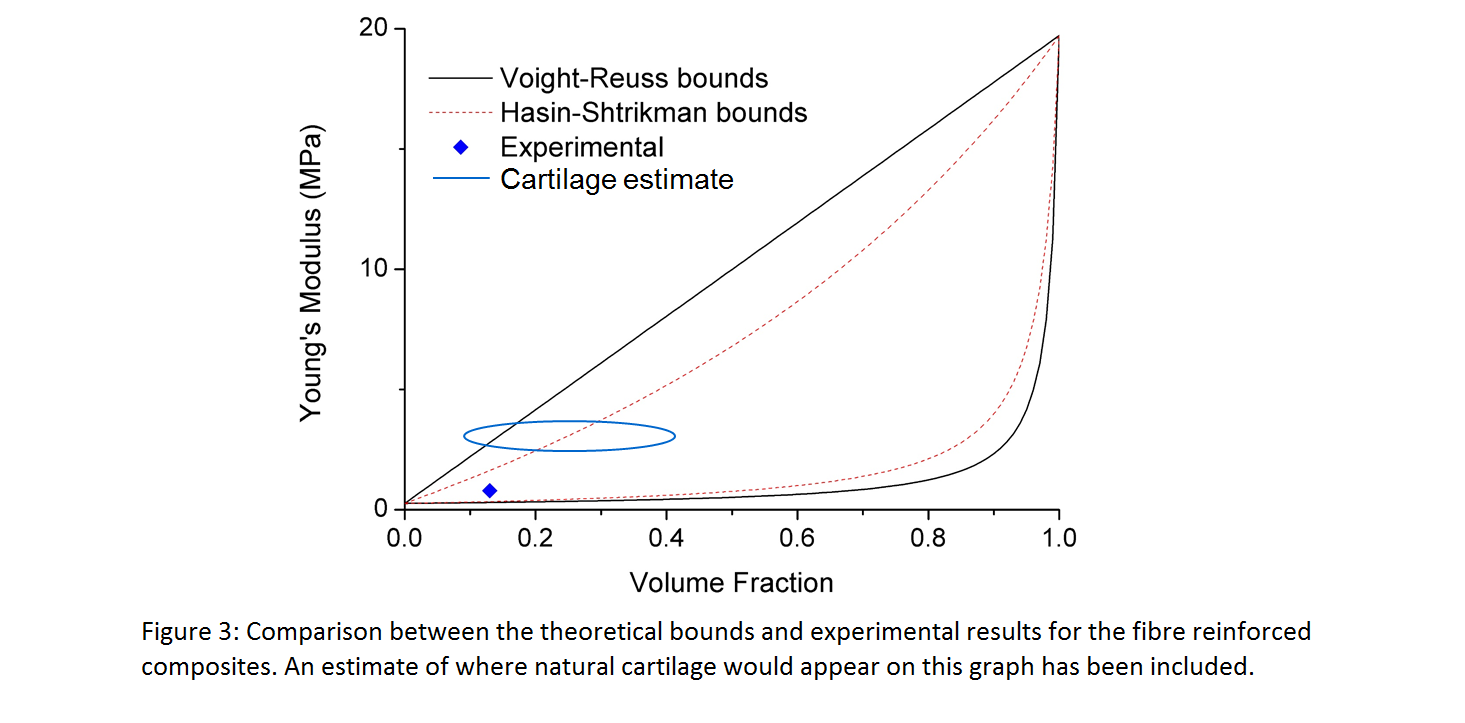

There are established models that predict the effects of fibre reinforcement within a composite. However these are difficult to apply to electrospun fibre reinforced hydrogels due to the uncertainty in parameters caused by the small length scale and variability in the method of manufacture. The mechanical properties of electrospun fibres can be determined by using an AFM for three-point bending tests, or by calculation modelling the fibrous mesh as an open celled foam. The volume fraction of the fibres within the composites can be estimated using the porosity of the fibrous mesh or by using FIB SEM images to create a 3D model. These values are used to calculate the upper and lower bounds of the composite properties and compared with the experimental results, as shown in figure 3.

Conclusions: Fibre reinforced hydrogels are made using electrospun gelatin nanofibres and composite theory is used to demonstrate the potential of these materials. The fibre reinforcement improves the tensile properties and the toughness of the hydrogels, towards that of natural healthy cartilage.

This work was funded by the Engineering and Physical Sciences Research Council (1354760)

References:

[1] Lee, K.Y. & Mooney, D. J. (2001). Hydrogels for tissue engineering. Chemical Reviews, 101(7), 1869-79

[2] Butcher, A. L., Offeddu, G. S., & Oyen, M. L. (2014). Nanofibrous hydrogel composites as mechanically robust tissue engineering scaffolds. Trends in Biotechnology, 32(11), 564–570.