Introduction: Among vast array of advanced biomaterials investigated for various tissue engineering applications, bacterial cellulose (BC) has not yet been characterized and evaluated in depth[1],[2] despite a strong potential of becoming a high value product of biotechnology. The unique physical and mechanical properties of BC define a wide range of applications such as high quality audio membranes[3], fuel cells[4], and novel materials for medical applications[5]. In this work we have examined the effect of glucose concentration and culture time on thickness of the synthesized BC as a indication of its production rate and also the BC's mechanical properties and cell viability.

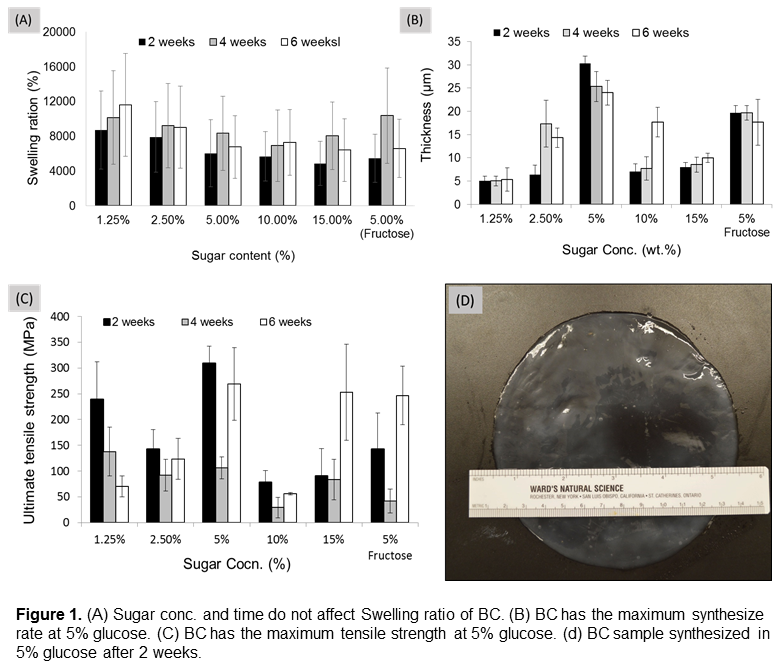

Materials and Methods: The BC pellicles arise from the strain of yeast and bacteria (symbiotic colony of Acetobacter and Saccharomyces ). BC pellicles were cultured in deionized water with the following glucose concentration of 1.25%, 2.5%, 5%, 10%, and 15%, and 5% fructose (Sigma-Aldrich St. Louis, MO, US). BCs were harvested at 2, 4, and 6 weeks. Samples were washed with water (Fig.1d).

Swelling ratio: Dry and wet weight of samples were measured and difference in weight was normalized by dry weight and reported as the swelling ratio.

Mechanical test: Sample thicknesses were measured with a non-contact conductance based custom device. Tensile test was performed on samples with gauge length of 10 mm and strain rate 10 mm/min. Ultimate tensile stress and Young’s modulus of the samples were calculated and average standard deviations were reported.

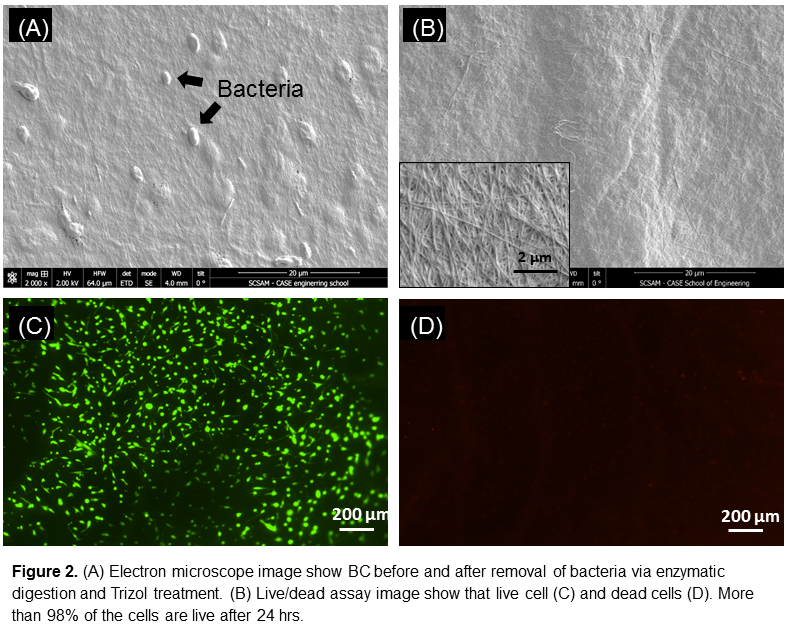

Decellularization: BC samples underwent lysozyme treatment for 2 hours followed by trizol treatment for 30 mins. Samples were analyzed with scanning electron microscope to check whether the microbial mass is removed following decellularization.

Live/dead assay: Mesenchymal stem cells (MSCs) were cultured on sterilized samples to investigate cell adhesion and cell viability. Samples were stained with live/dead assay kit (life technologies) and imaged with fluorescent microscopy.

Results and Discussion: Results show (Fig.1a) that the swelling ratio of the BCs did not change statistically significant (p>0.05) with increasing concentration of sugar in culture. The maximum cellulose production and highest tensile strength were occured at the glucose concentration of 5% (Fig.1b and Fig.1c). BC made in glucose solution has higher strength and production rate (p<0.05) compared to that of fructose solution while having comparable swelling ratio. Electron microscope images (Fig.2a&b) showed complete removal of bacteria and yeast from the cellulose samples. More than 98% of the cells cultured on BC synthesized at 5% glucose solution were alive (Fig.2c&d).

Conclusion: The optimal culturing condition for synthesizing the BC, fabrication rate, physical and mechanical properties occurs at 5% wt. glucose solution by 2 weeks. Most importantly, the mechanical properties converged and exceeded those of load bearing tissues such as bone and tendons. Therefore, the material holds promise for repair and regeneration of load- bearing tissues.

References:

[1] Bielecki et al.,Bacterial cellulose. In: Steinbuchel A, editor. Biopolymers: vol. 5. Polysaccharides I. Munster, Gremany: Wiley-VCH, Verlag GmbH; 2002. 37–90.

[2] C. Dufresne, E. Farnworth, Food Research International,2000;33:409-421.

[3] Nishi et al., J Mater Sci 1990;25: 2997-3001.

[4] Evans et al., Biosens Bioelectron,2003;18:917-23.

[5] Fontana et al., Applied Biochemistry and Biotechnology, 1990;4(25):253-64.