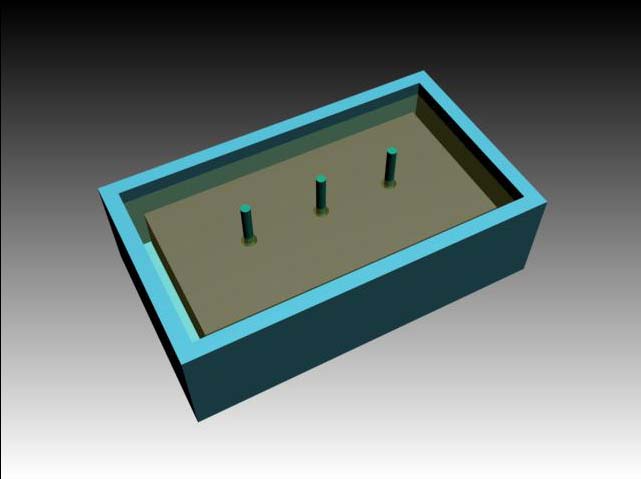

Introduction: Open-source approach may bring the benefit of giving access to scientific progress without the costs of royalties due for patented technologies. Some basic processes are in the realm of mankind knowledge and their patenting sounds inappropriate, in our opinion. The process of polymerization of monomers in a liquid phase to give a solid block of polymerized material, by simply decreasing the temperature below the melting point, can be defined an open-source low-cost technology. In case of the melting point occurring below 100°C, this process can be certainly performed with low-cost tools like a simple thermostatic bath (figure 1). However, common thermoplastic manufacturing like cast-moulding generally requires higher temperatures, to guarantee that monomers will duly fill all the volume of the cast before curing; ensuring at the same time that a minimum volume of material will be used for the artifact.

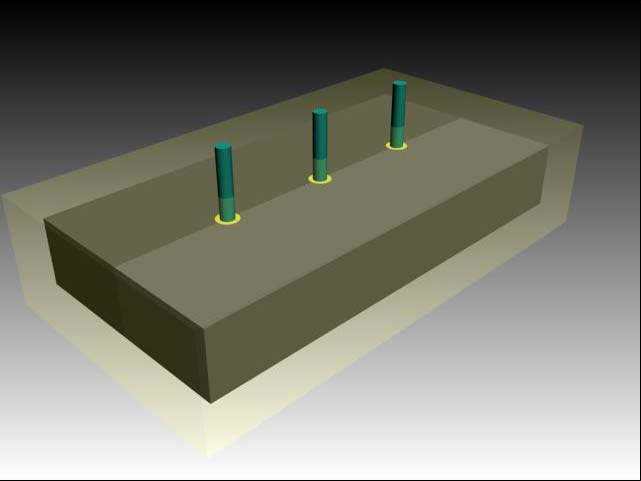

Materials and Methods: Having an excess of volume of monomers in liquid phase in respect to the volume of the solid polymerized artifact, in the figure of 1000/1 or higher, could certainly help in obtaining an homogeneous mould at temperatures just above the melting point (figure 2). However, it is likely that a similar prosess would be more expensive in terms of gross weight of polymer to be used. Furthermore, it could generate a hardly acceptable amount of waste products, which will add enviromental costs as well.

We propose to manufacture polymeric artifacts by using poly-hydroxy-alkanoates (PHA) originated from waste-feeded bacteria. In this family of polymers we can find different compounds having a variable range of melting point. The vast amount of material required by this low-temperature polymerization in excess of polymer (LTPEP) should not be considered a relevant cost as it originates from organic waste. At the same time, their “waisting” in a LTPEP should not be considered an environmental burden as they are fully bio-recyclable.

Results and Discussion: We designed a possible production process and we choose the nerve-guides used to support peripheral nerve regeneration as the clinical artifact to be produced. Artificial nerve-guides are medical devices which provide protection and guidance to severed nerve-stumps in lesions where a gap has residuated from trauma [1],[2]. Nerve-guides currently FDA/CE approved for human use are cylindrical in shape. They are provided in different lengths and diameters, however no manufacturer produces a set of guides with such a number of options able to fit all the clinical occurences. This means that, often, the lesion has to be adapted to the available guide (and not viceversa).

Producing artificial nerve-guides by LTPEP employing PHA may help the translation of this devices into clinical practice in Humans, where a vast combination of diameters and lengths would be desirable. The low-cost of their proposed manufacturing by LTPEP would also contribute in reduction of the tag price for the Health System, as these devices are at the moment quite expensive.

Conclusions: We would like to conclude that, further to our specific interest in nerve-guides, we are aware that this proposed open-source low-cost technology may also configure a kind of paradigm shift in polymeric manufacturing for many thermoplastic artifacts, by reducing the tempertaure and the complexity of cast-moulding and by reducing the concerns linked to the excess of waste products.

References:

[1] Merolli A, et Al. In-vivo regeneration of rat sciatic nerve in a double-halved stitch-less guide: a pilot study. Microsurgery 2009; 29: 310-318

[2] Merolli A, et Al. Peripheral nerve regeneration inside collagen-based artificial nerve guides in humans. J Appl Biomater Funct Mater. 2015 Mar 18;13(1):61-5