Introduction: Ultra-high molecular weight polyethylene (UHMWPE) has been the most common bearing material used in total joint replacement due to its high toughness and wear resistance. In recent years, UHMWPE has been replaced by radiation crosslinked UHMWPE (XPE) which has substantially higher wear resistance compared to its uncrosslinked counterpart. However, XPE is known to exhibit a dose dependent decrease in tensile properties. It would be beneficial if the base polymer would have higher tensile properties. In this study, we blended UHMWPE with very low molecular weight polyethylenes to determine whether they would assist in better fusion of UHMWPE resin powder during consolidation and result in higher tensile properties.

Materials and Methods: GUR 1020 UHMWPE powder (Celanese, Oberhausen, Germany) was blended with 5%, 10% and 20% of two very low molecular weight polyethylenes with a number average molecular weight, Mn, of 1800 g/mol and 6300 g/mol, respectively. The blends including a 100% UHMWPE control were compression molded at 180 ˚C and 10 MPa pressure. ASTM 638 type V specimens were prepared (n=5) and subjected to tensile testing at 10mm/min crosshead speed. Tensile modulus, yield stress, maximum strain and tensile strength were measured.

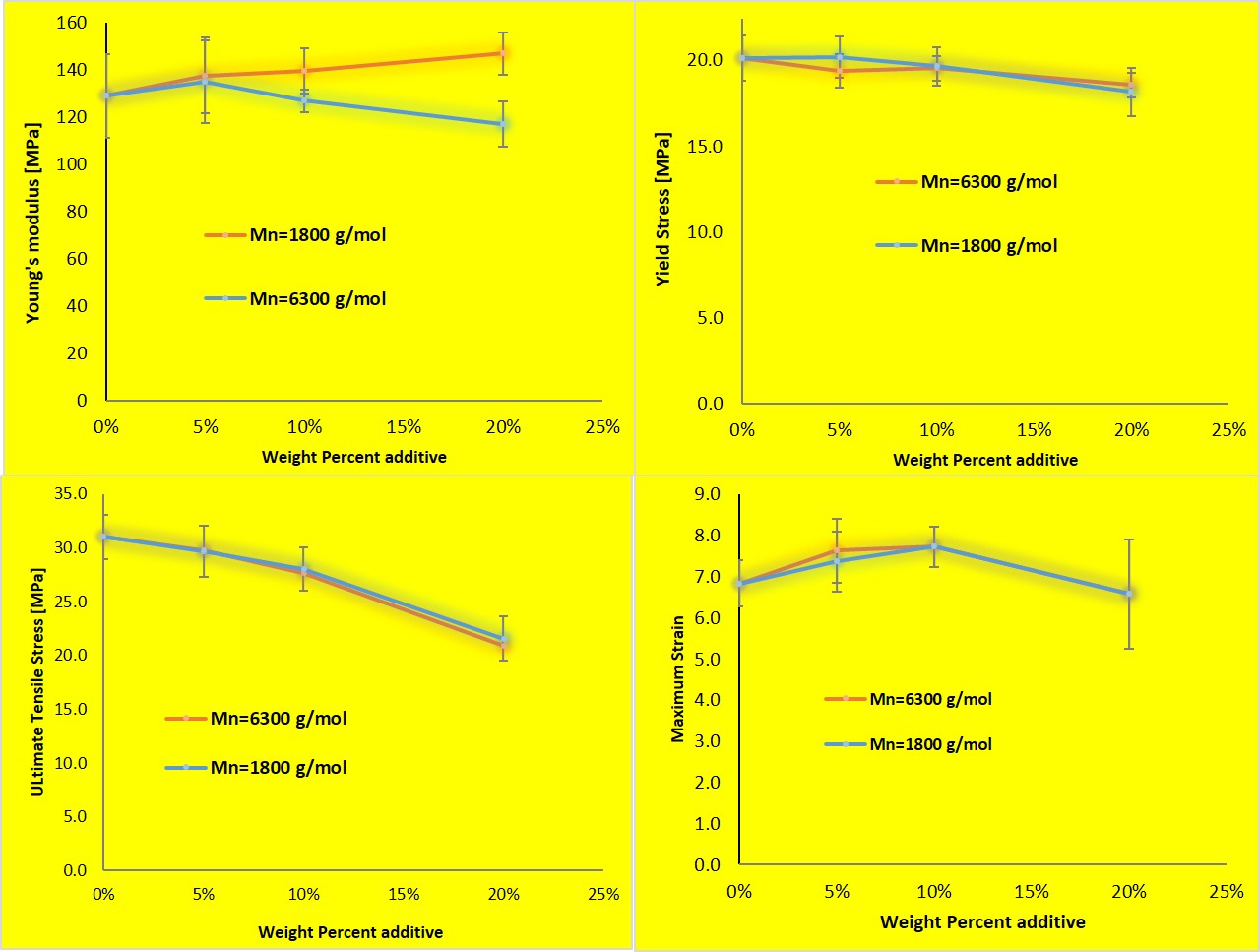

Results: The tensile tests revealed small differences in the tensile properties in the blended UHMWPEs compared to the control (see Figure 1). At 20% loading, the 1800 g/mol additive had a significantly lower modulus compared to the control (p=0.007, ANOVA) whereas all other comparisons did not exhibit any statistically significant differences (p>0.05, ANOVA). At 20%, both additives showed a small but significant decrease in yield stress (p==0.001 and p=0.006 for additives with 1800 g/mol and 6300 g/mol, respectively). There was no particular trend in the maximum strain but the ultimate tensile stress decreased monotonically with increase in additive. There was an approximately 10% decrease in ultimate tensile stress at 10% loading, regardless of additive, and a 32% decrease at 20% loading.

Discussions: This study showed that the addition of very low molecular weight polyethylenes did not substantially alter the tensile properties of UHMWPE up to 20% loading, except for a small decrease in yield stress and a large decrease in the ultimate tensile strength. This indicated that even if these small macromolecules can diffuse easily into the UHMWPE powder in the melt state, there must be almost no co-crystallization with the large UHMWPE macromolecules, otherwise, a profound increase in tensile properties would have been observed. In fact, the decrease in the ultimate tensile strength with increase in additive concentration up to 20% indicated an inhomogeneous blend in which the additive served as defects. This suggests that larger macromolecules of polyethylene additives are necessary, with a molecular weight sufficiently small to diffuse into UHMWPE powders but sufficiently large to effectively entangle and co-crystallize with UHMWPE in order to enhance tensile properties.

Conclusions: Very low molecular weight polyethylenes do not consolidate well with UHMWPE and therefore medium molecular weight polyethylenes are recommended to increase tensile properties of UHMWPE via entanglement and co-crystallization.

Figure 1. Tensile properties of control and blends of UHMWPE with very low molecular weight polyethylenes.