Introduction: In surgery for the extraction of soft tissue, blood vessels must be occluded with medical devices. For the limitation of the operating area, surgical pure Ti or Ti alloys clips are used due to both good mechanical properties and excellent biocompatibility. However, there is a difficulty in precise monitoring of the operated area by using CT since Ti possesses high X-ray absorption coefficient. To solve these problem, biodegradable metallic device with good workability for occlusion is required in medical field. Therefore, this study attempted to develop biodegradable occlusion device by using Mg-Zn-Ca alloy.

Materials and Methods: A Mg-0.2at.%Zn-0.1at.%Ca cast ingot was subjected to solution treatment followed by extrusion at an extrusion ratio of 17:1 and at 623 K. Further extrusion with an extrusion ratio of 25:1 and temperature of 573 K were conducted. The extrusion was annealed at 673 K for 2 hours to improve the ductility. After machining to the specimen with a diameter of 3 mm and a height of 6 mm, the mechanical properties were examined by compression tests at an initial strain rate of 1×10-3 s-1. The deformed microstructure was observed to investigate the deformation mechanism by electron backscattering diffraction method.

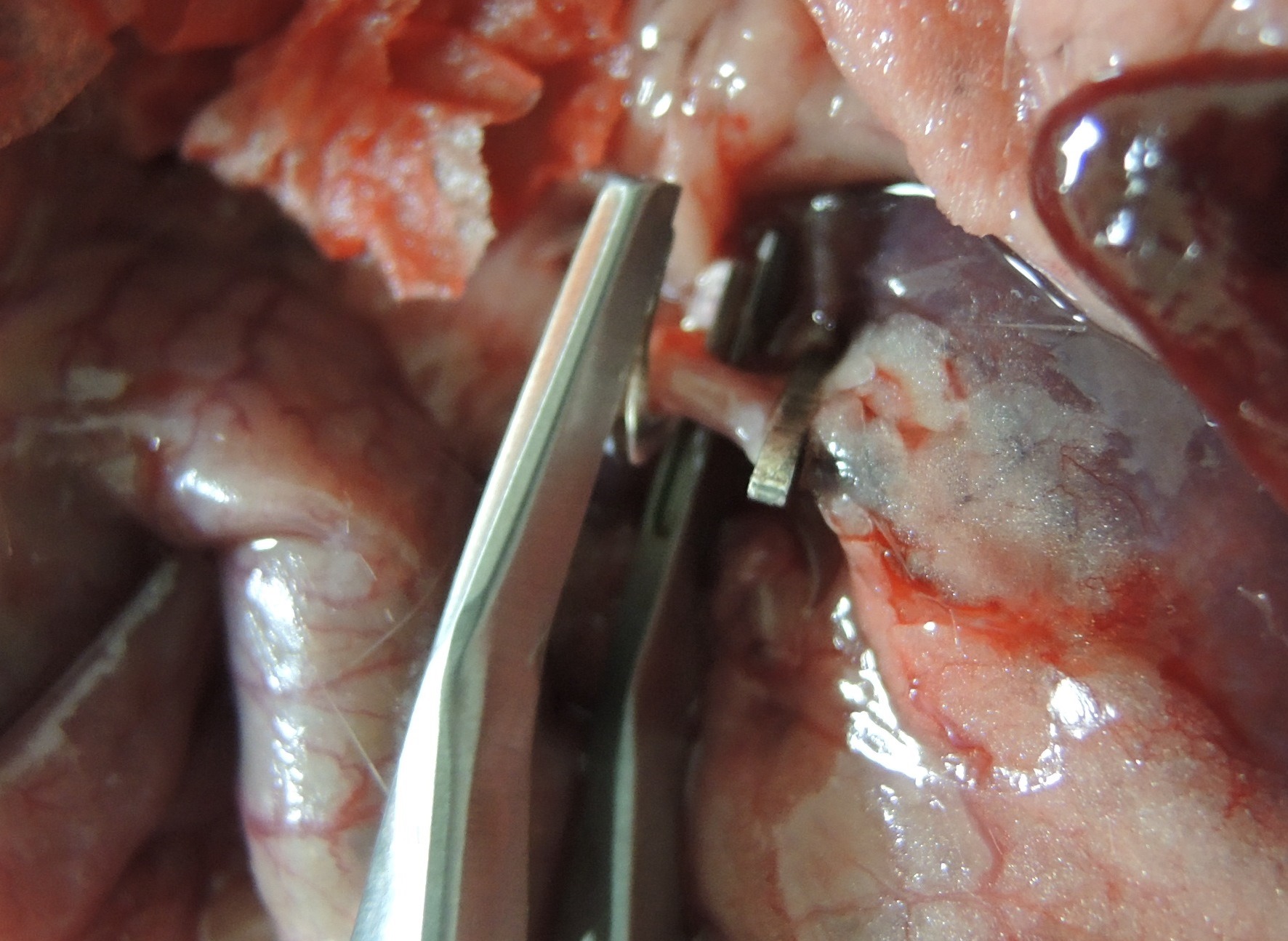

To confirm the occlusion capability, the occlusion of the clip made of the Mg-Zn-Ca alloy were conducted by using 32-week-old Wistar rats. The left renal vein was occluded and transected after anesthetization by inhaling a mixture of isoflurane gas and air. After monitor of transected cross section, the rats were sacrificed in a painless way. This study was approved by the Institutional Animal Care and Use Committee (Permission number: P141203) and was carried out according to the Kobe University Animal Experimentation Regulation.

Results and Discussion: From the true stress strain curves of the Mg-Zn-Ca alloy obtained by the compressive test, the fracture strain of the Mg-Zn-Ca alloy was over 0.40. This result implies that this alloy possess sufficient workability to apply to the occlusion devices. The crystallographic orientation distribution map indicated that the low tilt angle boundaries were formed with every a few micrometer at the later stage of the compressive deformation. Thus, it can be expected that the good workability of the Mg-Zn-Ca alloy is attributed to the dynamic recovery during the deformation.

Figure shows a renal vein during occlusion at the in vivo experiment. No crack was observed on the clip surface even after fully fastening of the clips. Since the blood did not spread from the cross section of the veins, it can be said that the occlusion of the veins was successfully conducted by using the present alloy clip.

Conclusion: A Magnesium-Zinc-Calcium alloy exhibited excellent ductility. As a result, in vivo test revealed the stability and clinical feasibility of the clip made of the Mg-Zn-Ca alloy. A biodegradable occlusion device was successfully developed by using the Mg-Zn-Ca alloy.

the Ministry of Education, Science and Culture through the Grant-in Aid for Scientific Research