Shape Memory Polymers are a class of materials able to change their shape in a predefined way, from a temporary shape to a permanent one when exposed to an external stimulus[1], such as a temperature change. The development of shape memory electrospun mats may lead to the realization of smart devices, miniaturized, structured on a micro/nanoscale, of great interest in the biomedical field.

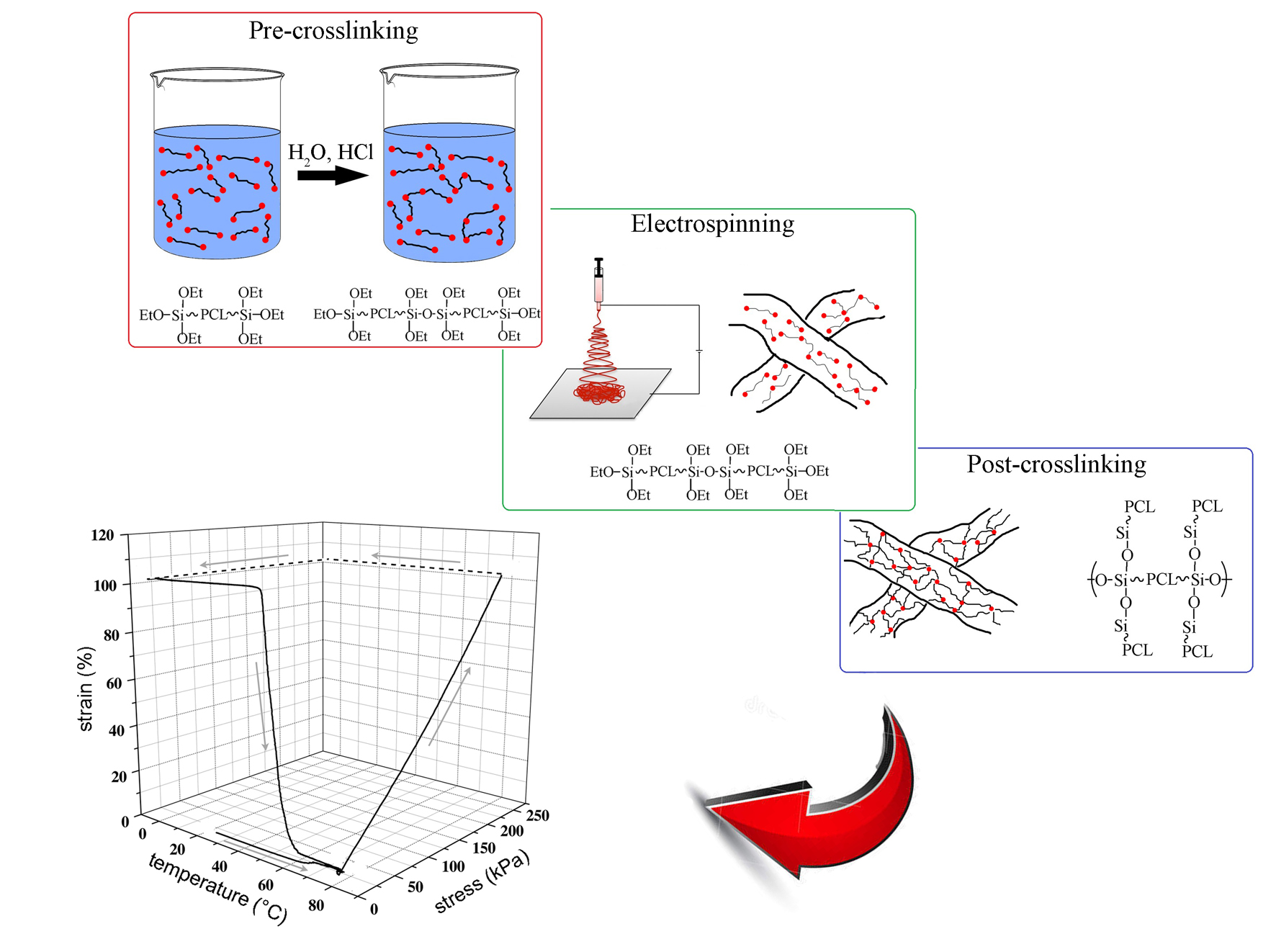

Poly(ε-caprolactone)-based non-woven fibrous mats with shape memory properties were obtained, starting from a previously synthesized triethoxysilane poly(ε-caprolactone)[2], by combining electrospinning process and sol-gel reaction. The adoption of a crosslinking approach based on the sol-gel chemistry allows overcoming the problems of free radical approaches, where the permanence of initiators in the fibers could be deleterious for biomedical applications.

In order to obtain a non-woven electrospun mat an increase of the molecular weight of the starting material was necessary previous to the electrospinning process. This was achieved through a partial crosslink reaction via sol-gel exploiting the triethoxysilane reactive terminals. After the attainment of the electrospun mat an optimized post-treatment was performed in in the presence of acid environment in order to obtain materials with different crosslinking degrees from 33% to 88%. The crosslinking degree of PCL governed the mechanical properties (storage modulus and tensile modulus) in the rubbery plateau region and, together with the micro-fibrous structure of the mat, it was correlated to the shape memory properties of the material by applying an ‘ad-hoc’ thermomechanical cycle.

The results showed that the obtained post-crosslinked electrospun mats had excellent one-way shape memory capabilities, being able to both fix the temporary deformations and to recover the permanent shape up to 100% when heated slightly above the melting temperature. Interestingly, it was demonstrated (by means of scanning electron microscopy) that mats fibrous morphology was maintained after the application of the thermomechanical cycles.

The Italian Ministry of University and Research; FP7 COST Action MP1206 “Electrospun Nanofibres for bioinspired composite materials and innovative industrial applications”; Mrs. Valentina Ferrari and Dr. Giovanna Cornacchia for the SEM analysis kindly performed

References:

[1] A. Lendlein, S. Kelch, Angew. Chem., Int. Ed., 41, 2034 (2002)

[2] K. Paderni, S. Pandini, S. Passera, F. Pilati, M. Toselli, M. Messori, J Mater Sci, 47, 4354–4362 (2012)